The Role of Battery Acid in Hybrid Power Systems

AUG 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Acid Evolution

Battery acid, primarily composed of sulfuric acid and water, has played a crucial role in the evolution of hybrid power systems. The journey of battery acid in these systems can be traced back to the early 20th century when lead-acid batteries were first introduced. Initially, these batteries were used in automotive applications, but their potential for energy storage in hybrid systems was quickly recognized.

In the 1970s and 1980s, as concerns about energy efficiency and environmental impact grew, research into hybrid power systems intensified. During this period, the role of battery acid became more prominent. Engineers and scientists began to explore ways to optimize the acid composition and concentration to improve battery performance and longevity in hybrid applications.

The 1990s saw significant advancements in battery acid technology. Researchers developed new additives and electrolyte formulations that enhanced the acid's ability to withstand the frequent charge-discharge cycles typical in hybrid systems. These improvements led to increased battery life and efficiency, making hybrid power systems more viable for a wider range of applications.

As hybrid vehicles gained popularity in the early 2000s, battery acid evolution accelerated. Manufacturers focused on developing maintenance-free batteries with improved acid circulation and reduced water loss. This period also saw the introduction of gel electrolytes and absorbed glass mat (AGM) technologies, which offered better performance and safety compared to traditional flooded lead-acid batteries.

In recent years, the focus has shifted towards sustainability and environmental concerns. Battery acid formulations have been refined to reduce toxicity and improve recyclability. Researchers have also explored alternatives to traditional sulfuric acid, such as organic electrolytes and ionic liquids, which show promise for future hybrid power applications.

The evolution of battery acid has not been limited to chemical composition alone. Advancements in battery management systems have allowed for more precise control of acid levels and charge states, further optimizing battery performance in hybrid systems. These intelligent systems can monitor and adjust acid concentration in real-time, extending battery life and improving overall system efficiency.

Looking ahead, the role of battery acid in hybrid power systems continues to evolve. While lithium-ion batteries have gained prominence in many applications, advanced lead-acid batteries with improved acid formulations still play a significant role, particularly in large-scale energy storage and certain automotive applications. Ongoing research focuses on developing more environmentally friendly acid compositions, improving energy density, and enhancing the ability of battery acid to function effectively in extreme temperatures and conditions.

In the 1970s and 1980s, as concerns about energy efficiency and environmental impact grew, research into hybrid power systems intensified. During this period, the role of battery acid became more prominent. Engineers and scientists began to explore ways to optimize the acid composition and concentration to improve battery performance and longevity in hybrid applications.

The 1990s saw significant advancements in battery acid technology. Researchers developed new additives and electrolyte formulations that enhanced the acid's ability to withstand the frequent charge-discharge cycles typical in hybrid systems. These improvements led to increased battery life and efficiency, making hybrid power systems more viable for a wider range of applications.

As hybrid vehicles gained popularity in the early 2000s, battery acid evolution accelerated. Manufacturers focused on developing maintenance-free batteries with improved acid circulation and reduced water loss. This period also saw the introduction of gel electrolytes and absorbed glass mat (AGM) technologies, which offered better performance and safety compared to traditional flooded lead-acid batteries.

In recent years, the focus has shifted towards sustainability and environmental concerns. Battery acid formulations have been refined to reduce toxicity and improve recyclability. Researchers have also explored alternatives to traditional sulfuric acid, such as organic electrolytes and ionic liquids, which show promise for future hybrid power applications.

The evolution of battery acid has not been limited to chemical composition alone. Advancements in battery management systems have allowed for more precise control of acid levels and charge states, further optimizing battery performance in hybrid systems. These intelligent systems can monitor and adjust acid concentration in real-time, extending battery life and improving overall system efficiency.

Looking ahead, the role of battery acid in hybrid power systems continues to evolve. While lithium-ion batteries have gained prominence in many applications, advanced lead-acid batteries with improved acid formulations still play a significant role, particularly in large-scale energy storage and certain automotive applications. Ongoing research focuses on developing more environmentally friendly acid compositions, improving energy density, and enhancing the ability of battery acid to function effectively in extreme temperatures and conditions.

Hybrid Power Demand

The demand for hybrid power systems has been steadily increasing in recent years, driven by the growing need for reliable, efficient, and environmentally friendly energy solutions. These systems, which typically combine conventional power sources with renewable energy technologies, are becoming increasingly popular across various sectors, including residential, commercial, and industrial applications.

In the residential sector, homeowners are increasingly turning to hybrid power systems to reduce their reliance on the grid and lower their energy costs. The integration of solar panels with battery storage and traditional grid connections allows for greater energy independence and resilience during power outages. This trend is particularly evident in areas prone to natural disasters or with unreliable grid infrastructure.

Commercial and industrial sectors are also embracing hybrid power systems to meet their energy needs while reducing their carbon footprint. Large-scale facilities, such as manufacturing plants and data centers, are implementing hybrid solutions to ensure uninterrupted power supply and optimize energy consumption. These systems often incorporate a mix of renewable sources, such as solar and wind, alongside conventional generators and grid connections.

The transportation sector is another significant driver of hybrid power demand. Electric and hybrid vehicles are gaining market share, leading to increased demand for charging infrastructure and energy storage solutions. This trend is expected to accelerate as governments worldwide implement stricter emissions regulations and incentivize the adoption of cleaner transportation technologies.

Remote and off-grid applications represent a growing market for hybrid power systems. In areas where grid connection is not feasible or cost-effective, hybrid solutions provide a reliable and sustainable power source. This includes remote communities, telecommunications infrastructure, and temporary installations for construction or events.

The global market for hybrid power systems is projected to experience substantial growth in the coming years. Factors contributing to this growth include increasing energy demand, rising awareness of environmental issues, and advancements in renewable energy technologies. Additionally, the declining costs of solar panels and battery storage systems are making hybrid power solutions more accessible and economically viable for a wider range of applications.

As the demand for hybrid power systems continues to grow, the role of battery acid becomes increasingly important. Battery acid, typically sulfuric acid in lead-acid batteries, plays a crucial role in the energy storage component of these systems. The efficiency, longevity, and performance of batteries directly impact the overall effectiveness of hybrid power solutions, making advancements in battery technology and acid formulations a key area of focus for researchers and manufacturers in the industry.

In the residential sector, homeowners are increasingly turning to hybrid power systems to reduce their reliance on the grid and lower their energy costs. The integration of solar panels with battery storage and traditional grid connections allows for greater energy independence and resilience during power outages. This trend is particularly evident in areas prone to natural disasters or with unreliable grid infrastructure.

Commercial and industrial sectors are also embracing hybrid power systems to meet their energy needs while reducing their carbon footprint. Large-scale facilities, such as manufacturing plants and data centers, are implementing hybrid solutions to ensure uninterrupted power supply and optimize energy consumption. These systems often incorporate a mix of renewable sources, such as solar and wind, alongside conventional generators and grid connections.

The transportation sector is another significant driver of hybrid power demand. Electric and hybrid vehicles are gaining market share, leading to increased demand for charging infrastructure and energy storage solutions. This trend is expected to accelerate as governments worldwide implement stricter emissions regulations and incentivize the adoption of cleaner transportation technologies.

Remote and off-grid applications represent a growing market for hybrid power systems. In areas where grid connection is not feasible or cost-effective, hybrid solutions provide a reliable and sustainable power source. This includes remote communities, telecommunications infrastructure, and temporary installations for construction or events.

The global market for hybrid power systems is projected to experience substantial growth in the coming years. Factors contributing to this growth include increasing energy demand, rising awareness of environmental issues, and advancements in renewable energy technologies. Additionally, the declining costs of solar panels and battery storage systems are making hybrid power solutions more accessible and economically viable for a wider range of applications.

As the demand for hybrid power systems continues to grow, the role of battery acid becomes increasingly important. Battery acid, typically sulfuric acid in lead-acid batteries, plays a crucial role in the energy storage component of these systems. The efficiency, longevity, and performance of batteries directly impact the overall effectiveness of hybrid power solutions, making advancements in battery technology and acid formulations a key area of focus for researchers and manufacturers in the industry.

Acid Challenges

Battery acid, primarily composed of sulfuric acid, plays a crucial role in hybrid power systems but also presents significant challenges. One of the primary issues is corrosion, which can severely impact the longevity and performance of battery components. The highly corrosive nature of sulfuric acid can lead to the degradation of battery terminals, connectors, and other metal parts, potentially causing system failures and reduced efficiency.

Another major challenge is the risk of acid leakage. Improper handling, manufacturing defects, or physical damage to batteries can result in acid spills, posing serious safety hazards to both personnel and equipment. This risk is particularly concerning in hybrid power systems where batteries are often integrated with other components, increasing the potential for widespread damage in case of a leak.

The maintenance of proper acid concentration levels presents an ongoing challenge in hybrid power systems. Over time, the acid concentration can change due to factors such as overcharging, undercharging, or water loss through electrolysis. Maintaining the optimal acid concentration is critical for battery performance and longevity, requiring regular monitoring and adjustment.

Temperature management is another significant concern when dealing with battery acid. Extreme temperatures can affect the chemical reactions within the battery, potentially leading to reduced capacity, shortened lifespan, or even thermal runaway in severe cases. Hybrid power systems must incorporate effective cooling mechanisms to mitigate these risks, especially in high-temperature environments or during rapid charge-discharge cycles.

The environmental impact of battery acid is a growing concern in the context of hybrid power systems. Improper disposal of batteries or acid can lead to soil and water contamination, posing serious ecological risks. As the adoption of hybrid power systems increases, the need for sustainable acid management and recycling processes becomes more pressing.

Lastly, the transportation and storage of battery acid present logistical challenges. Strict regulations govern the handling of hazardous materials, requiring specialized equipment, training, and safety protocols. This can increase the complexity and cost of implementing and maintaining hybrid power systems, particularly in remote or challenging environments.

Addressing these acid-related challenges is crucial for the continued development and widespread adoption of hybrid power systems. Innovations in battery technology, such as the development of safer electrolytes or advanced containment systems, will be key to overcoming these obstacles and enhancing the reliability and safety of hybrid power solutions.

Another major challenge is the risk of acid leakage. Improper handling, manufacturing defects, or physical damage to batteries can result in acid spills, posing serious safety hazards to both personnel and equipment. This risk is particularly concerning in hybrid power systems where batteries are often integrated with other components, increasing the potential for widespread damage in case of a leak.

The maintenance of proper acid concentration levels presents an ongoing challenge in hybrid power systems. Over time, the acid concentration can change due to factors such as overcharging, undercharging, or water loss through electrolysis. Maintaining the optimal acid concentration is critical for battery performance and longevity, requiring regular monitoring and adjustment.

Temperature management is another significant concern when dealing with battery acid. Extreme temperatures can affect the chemical reactions within the battery, potentially leading to reduced capacity, shortened lifespan, or even thermal runaway in severe cases. Hybrid power systems must incorporate effective cooling mechanisms to mitigate these risks, especially in high-temperature environments or during rapid charge-discharge cycles.

The environmental impact of battery acid is a growing concern in the context of hybrid power systems. Improper disposal of batteries or acid can lead to soil and water contamination, posing serious ecological risks. As the adoption of hybrid power systems increases, the need for sustainable acid management and recycling processes becomes more pressing.

Lastly, the transportation and storage of battery acid present logistical challenges. Strict regulations govern the handling of hazardous materials, requiring specialized equipment, training, and safety protocols. This can increase the complexity and cost of implementing and maintaining hybrid power systems, particularly in remote or challenging environments.

Addressing these acid-related challenges is crucial for the continued development and widespread adoption of hybrid power systems. Innovations in battery technology, such as the development of safer electrolytes or advanced containment systems, will be key to overcoming these obstacles and enhancing the reliability and safety of hybrid power solutions.

Current Acid Solutions

01 Battery acid composition and management

This category focuses on the composition and management of battery acid, including innovations in electrolyte formulations, acid level monitoring, and maintenance techniques. These advancements aim to improve battery performance, longevity, and safety by optimizing the acid composition and ensuring proper acid levels within the battery.- Battery acid composition and management: Battery acid, typically sulfuric acid, is a crucial component in lead-acid batteries. Its composition, concentration, and management are essential for optimal battery performance and longevity. Innovations in this area focus on improving acid formulations, monitoring acid levels, and developing systems for acid circulation and maintenance.

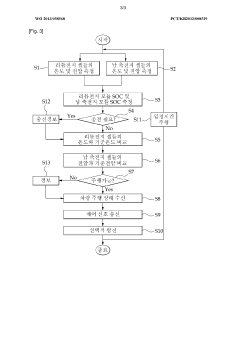

- Battery charging and discharging control: Advanced charging and discharging control systems are developed to optimize battery performance and prevent acid-related issues. These systems monitor acid concentration, temperature, and other parameters to adjust charging rates and prevent overcharging or deep discharging, which can affect acid balance and battery life.

- Acid level monitoring and maintenance: Innovations in acid level monitoring and maintenance systems help ensure proper acid levels in batteries. These include automated systems for adding water or electrolyte, sensors for detecting low acid levels, and methods for equalizing acid concentration across cells.

- Battery acid recycling and environmental considerations: Advancements in battery acid recycling and handling focus on environmental protection and resource conservation. This includes methods for neutralizing and treating spent battery acid, recovering valuable materials, and developing more eco-friendly acid formulations or alternatives.

- Battery acid alternatives and gel electrolytes: Research into alternatives to traditional liquid battery acid, such as gel electrolytes or solid-state electrolytes, aims to improve safety, reduce maintenance, and enhance battery performance. These alternatives can potentially mitigate issues associated with conventional battery acid while maintaining or improving energy storage capabilities.

02 Battery charging and discharging control

This area covers methods and systems for controlling the charging and discharging processes of batteries, with a focus on managing acid-related issues. It includes techniques for optimizing charge cycles, preventing overcharging, and mitigating acid stratification during battery operation to enhance overall battery efficiency and lifespan.Expand Specific Solutions03 Battery acid recycling and disposal

Innovations in this category address the environmental concerns associated with battery acid. It encompasses methods for recycling spent battery acid, neutralizing hazardous components, and developing eco-friendly disposal techniques. These advancements aim to reduce the environmental impact of battery acid and promote sustainable battery management practices.Expand Specific Solutions04 Battery acid leak detection and prevention

This point focuses on technologies for detecting and preventing battery acid leaks. It includes the development of sensors, monitoring systems, and protective coatings to identify potential leaks early and prevent acid-related damage to battery components and surrounding equipment, thereby enhancing battery safety and reliability.Expand Specific Solutions05 Battery acid-resistant materials and designs

This category covers the development of materials and designs that are resistant to battery acid corrosion. It includes innovations in electrode materials, separator technologies, and battery casing designs that can withstand prolonged exposure to acidic environments, leading to improved battery durability and performance in harsh conditions.Expand Specific Solutions

Battery Manufacturers

The battery acid technology in hybrid power systems is in a mature stage, with a diverse competitive landscape. The market size is substantial, driven by the growing demand for hybrid vehicles and energy storage solutions. Established players like Robert Bosch GmbH, LG Energy Solution, and Johnson Controls dominate the market, leveraging their extensive R&D capabilities and global presence. Emerging companies such as Gridtential Energy and ArcActive are introducing innovative lead-carbon technologies, challenging traditional lead-acid batteries. The industry is characterized by ongoing research and development efforts, focusing on improving energy density, cycle life, and environmental sustainability. Collaborations between automotive manufacturers and battery suppliers are increasingly common, as seen with partnerships involving companies like Hyundai Motor Co. and Chery Automobile.

Robert Bosch GmbH

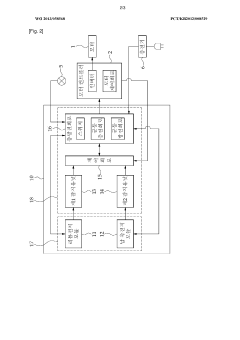

Technical Solution: Bosch has developed innovative solutions for hybrid power systems that optimize the use of battery acid. Their 48V hybrid system incorporates advanced lead-acid batteries with improved acid circulation technology, enhancing performance and lifespan[1]. Bosch's intelligent battery sensor (IBS) precisely monitors the state of charge and health of the battery, ensuring optimal acid utilization[2]. The company's start-stop technology, integrated with their hybrid systems, reduces acid stratification by minimizing prolonged periods of inactivity[3]. Bosch has also introduced a dual-battery system for hybrid vehicles, combining a conventional lead-acid battery with a lithium-ion battery, optimizing the use of battery acid while providing high power output[4].

Strengths: Comprehensive system integration, advanced monitoring technologies, and wide range of hybrid solutions. Weaknesses: Complexity of dual-battery systems may increase maintenance requirements and costs.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed lithium-ion battery technologies for hybrid power systems that minimize the use of traditional battery acid. Their advanced battery management system (BMS) optimizes cell performance and longevity[1]. The company's lithium-ion polymer batteries utilize a gel electrolyte instead of liquid acid, enhancing safety and energy density[2]. LG's hybrid battery packs incorporate both high-power and high-energy cells, balancing performance and efficiency for various hybrid applications[3]. They have also introduced silicon-based anodes that significantly increase energy density, potentially reducing the overall battery size in hybrid systems[4]. LG's thermal management solutions ensure optimal operating conditions, crucial for maintaining electrolyte stability and preventing degradation[5].

Strengths: High energy density, improved safety features, and advanced thermal management. Weaknesses: Higher initial cost compared to lead-acid batteries and potential challenges in recycling at end-of-life.

Key Acid Innovations

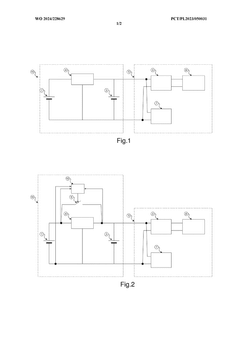

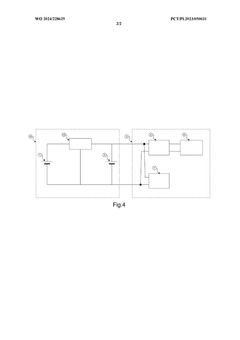

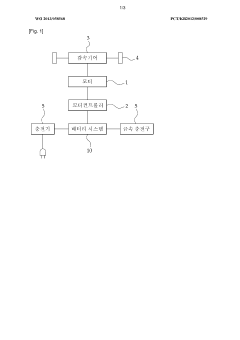

Hybrid battery system and photovoltaic installation comprising the same

PatentWO2024228629A1

Innovation

- A hybrid battery system where lithium-ion and lead-acid batteries have short-circuited poles connected to a charging current and voltage regulating circuit, utilizing power electronic converters for bidirectional charge flow and regulation, eliminating compensating currents and optimizing energy distribution.

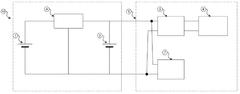

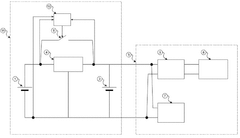

Hybrid battery system for an electric vehicle

PatentWO2013058568A1

Innovation

- A hybrid battery system that selectively uses lithium and lead-acid battery modules based on power requirements, employing temperature and voltage sensing units, a control circuit, and a charging/discharging circuit to manage energy distribution and prevent output voltage drops and temperature-related deterioration, utilizing inexpensive lead-acid batteries to reduce manufacturing costs and simplify the system.

Environmental Impact

The environmental impact of battery acid in hybrid power systems is a critical consideration for sustainable energy solutions. Battery acid, primarily composed of sulfuric acid, plays a crucial role in the performance and longevity of lead-acid batteries, which are commonly used in hybrid power systems. However, its production, use, and disposal can have significant environmental implications.

The manufacturing process of battery acid involves the extraction and processing of raw materials, which can lead to habitat destruction, air and water pollution, and greenhouse gas emissions. The energy-intensive nature of acid production contributes to the overall carbon footprint of hybrid power systems, potentially offsetting some of the environmental benefits these systems aim to achieve.

During the operational phase of hybrid power systems, battery acid poses risks of soil and water contamination if not properly contained. Leaks or spills can occur due to improper handling, accidents, or equipment failure, leading to localized environmental damage. The acidic nature of the electrolyte can alter soil pH, harm vegetation, and adversely affect aquatic ecosystems if it enters water bodies.

The disposal of spent batteries and their acid components presents another environmental challenge. Improper disposal can result in the release of toxic substances into the environment, including lead and other heavy metals. This can contaminate soil and groundwater, posing long-term risks to human health and ecosystems. Recycling of lead-acid batteries, while beneficial, also requires careful management to prevent environmental contamination during the recycling process.

To mitigate these environmental impacts, several strategies can be employed. Implementing strict safety protocols and containment measures can minimize the risk of acid spills and leaks during operation. Developing more efficient recycling technologies and establishing comprehensive battery collection and recycling programs can reduce the environmental burden of battery disposal. Additionally, research into alternative battery technologies with less harmful electrolytes or the development of safer, more environmentally friendly acid formulations could significantly reduce the ecological footprint of hybrid power systems.

The transition towards more sustainable energy storage solutions, such as lithium-ion or flow batteries, may offer reduced environmental impacts compared to traditional lead-acid batteries. However, these alternatives come with their own set of environmental considerations, including the sourcing of raw materials and end-of-life management.

In conclusion, while battery acid plays a vital role in hybrid power systems, its environmental impact necessitates careful management throughout the lifecycle of these systems. Balancing the benefits of hybrid power with environmental protection requires ongoing research, innovation, and the implementation of best practices in production, use, and disposal of battery components.

The manufacturing process of battery acid involves the extraction and processing of raw materials, which can lead to habitat destruction, air and water pollution, and greenhouse gas emissions. The energy-intensive nature of acid production contributes to the overall carbon footprint of hybrid power systems, potentially offsetting some of the environmental benefits these systems aim to achieve.

During the operational phase of hybrid power systems, battery acid poses risks of soil and water contamination if not properly contained. Leaks or spills can occur due to improper handling, accidents, or equipment failure, leading to localized environmental damage. The acidic nature of the electrolyte can alter soil pH, harm vegetation, and adversely affect aquatic ecosystems if it enters water bodies.

The disposal of spent batteries and their acid components presents another environmental challenge. Improper disposal can result in the release of toxic substances into the environment, including lead and other heavy metals. This can contaminate soil and groundwater, posing long-term risks to human health and ecosystems. Recycling of lead-acid batteries, while beneficial, also requires careful management to prevent environmental contamination during the recycling process.

To mitigate these environmental impacts, several strategies can be employed. Implementing strict safety protocols and containment measures can minimize the risk of acid spills and leaks during operation. Developing more efficient recycling technologies and establishing comprehensive battery collection and recycling programs can reduce the environmental burden of battery disposal. Additionally, research into alternative battery technologies with less harmful electrolytes or the development of safer, more environmentally friendly acid formulations could significantly reduce the ecological footprint of hybrid power systems.

The transition towards more sustainable energy storage solutions, such as lithium-ion or flow batteries, may offer reduced environmental impacts compared to traditional lead-acid batteries. However, these alternatives come with their own set of environmental considerations, including the sourcing of raw materials and end-of-life management.

In conclusion, while battery acid plays a vital role in hybrid power systems, its environmental impact necessitates careful management throughout the lifecycle of these systems. Balancing the benefits of hybrid power with environmental protection requires ongoing research, innovation, and the implementation of best practices in production, use, and disposal of battery components.

Safety Regulations

Safety regulations play a crucial role in the implementation and operation of hybrid power systems that utilize battery acid. These regulations are designed to protect workers, the environment, and the general public from potential hazards associated with the use of battery acid in energy storage applications.

One of the primary concerns addressed by safety regulations is the proper handling and storage of battery acid. Strict guidelines are in place for the transportation, storage, and disposal of this corrosive substance. Facilities using hybrid power systems must adhere to specific containment requirements, including the use of acid-resistant materials for storage tanks and secondary containment systems to prevent leaks and spills.

Personal protective equipment (PPE) requirements are another key aspect of safety regulations. Workers handling battery acid must wear appropriate protective gear, including acid-resistant gloves, face shields, and protective clothing. Regular training on proper handling procedures and emergency response protocols is mandated to ensure worker safety.

Environmental protection is a significant focus of safety regulations in this field. Stringent measures are in place to prevent the release of battery acid into the environment. This includes proper disposal procedures for spent batteries and acid, as well as requirements for neutralization and treatment of any acid waste before disposal.

Emergency response planning is a critical component of safety regulations for hybrid power systems using battery acid. Facilities must have detailed plans in place for responding to spills, leaks, or other accidents involving battery acid. This includes the availability of appropriate spill containment and neutralization materials, as well as procedures for evacuating affected areas and notifying relevant authorities.

Ventilation requirements are also addressed in safety regulations, as battery charging can produce potentially explosive hydrogen gas. Proper ventilation systems must be in place to prevent the accumulation of dangerous gases and maintain safe working conditions.

Regular inspections and maintenance of battery systems are mandated to ensure ongoing compliance with safety regulations. This includes routine checks of battery integrity, acid levels, and the condition of containment systems. Documentation of these inspections and any maintenance activities is typically required for regulatory compliance.

Safety regulations also extend to the design and construction of hybrid power systems. Specific standards must be met for electrical safety, including proper insulation, grounding, and protection against short circuits. The integration of battery systems with other components of the hybrid power system must be done in a manner that minimizes risks and ensures overall system safety.

In conclusion, safety regulations for battery acid in hybrid power systems encompass a wide range of measures designed to protect human health and the environment. Compliance with these regulations is essential for the safe and responsible implementation of this technology in various applications.

One of the primary concerns addressed by safety regulations is the proper handling and storage of battery acid. Strict guidelines are in place for the transportation, storage, and disposal of this corrosive substance. Facilities using hybrid power systems must adhere to specific containment requirements, including the use of acid-resistant materials for storage tanks and secondary containment systems to prevent leaks and spills.

Personal protective equipment (PPE) requirements are another key aspect of safety regulations. Workers handling battery acid must wear appropriate protective gear, including acid-resistant gloves, face shields, and protective clothing. Regular training on proper handling procedures and emergency response protocols is mandated to ensure worker safety.

Environmental protection is a significant focus of safety regulations in this field. Stringent measures are in place to prevent the release of battery acid into the environment. This includes proper disposal procedures for spent batteries and acid, as well as requirements for neutralization and treatment of any acid waste before disposal.

Emergency response planning is a critical component of safety regulations for hybrid power systems using battery acid. Facilities must have detailed plans in place for responding to spills, leaks, or other accidents involving battery acid. This includes the availability of appropriate spill containment and neutralization materials, as well as procedures for evacuating affected areas and notifying relevant authorities.

Ventilation requirements are also addressed in safety regulations, as battery charging can produce potentially explosive hydrogen gas. Proper ventilation systems must be in place to prevent the accumulation of dangerous gases and maintain safe working conditions.

Regular inspections and maintenance of battery systems are mandated to ensure ongoing compliance with safety regulations. This includes routine checks of battery integrity, acid levels, and the condition of containment systems. Documentation of these inspections and any maintenance activities is typically required for regulatory compliance.

Safety regulations also extend to the design and construction of hybrid power systems. Specific standards must be met for electrical safety, including proper insulation, grounding, and protection against short circuits. The integration of battery systems with other components of the hybrid power system must be done in a manner that minimizes risks and ensures overall system safety.

In conclusion, safety regulations for battery acid in hybrid power systems encompass a wide range of measures designed to protect human health and the environment. Compliance with these regulations is essential for the safe and responsible implementation of this technology in various applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!