The Role of Battery Acid in Robust Electric Drive Systems

AUG 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Acid Evolution and Objectives

Battery acid, primarily composed of sulfuric acid and water, has been a crucial component in lead-acid batteries since their invention in the mid-19th century. The evolution of battery acid technology has closely mirrored the development of electric drive systems, playing a vital role in enhancing their robustness and efficiency.

In the early stages of electric vehicle development, battery acid formulations were relatively simple, with limited focus on optimizing performance and longevity. However, as the demand for more reliable and powerful electric drive systems grew, researchers began to explore ways to improve battery acid composition and management.

The 1970s and 1980s saw significant advancements in battery acid technology, with the introduction of maintenance-free batteries that utilized gelled electrolytes or absorbed glass mat (AGM) designs. These innovations reduced acid spillage risks and improved overall battery performance, making electric drive systems more practical for widespread use.

The turn of the millennium brought about a renewed interest in electric vehicles, driving further research into battery acid technology. Scientists and engineers focused on developing advanced electrolyte formulations that could withstand higher temperatures, reduce corrosion, and extend battery life. These improvements were crucial in enhancing the robustness of electric drive systems, particularly in demanding applications such as electric vehicles and renewable energy storage.

Recent years have witnessed a shift towards more environmentally friendly and efficient battery technologies, such as lithium-ion batteries. However, lead-acid batteries and their associated acid technology continue to play a significant role in various applications, including automotive starting, lighting, and ignition (SLI) systems, as well as in backup power supplies for critical infrastructure.

The primary objectives of current battery acid research and development efforts are multifaceted. Firstly, there is a strong focus on improving the energy density and power output of lead-acid batteries through advanced acid formulations and electrode designs. Secondly, researchers aim to enhance the cycle life and deep discharge recovery capabilities of these batteries, making them more suitable for use in electric drive systems that require frequent charging and discharging cycles.

Another key objective is to develop battery acid technologies that are more environmentally friendly and safer to handle. This includes exploring alternatives to traditional sulfuric acid electrolytes, such as organic electrolytes or solid-state electrolytes, which could potentially revolutionize the field of electric drive systems.

As we look to the future, the role of battery acid in robust electric drive systems is expected to evolve further. While alternative battery technologies may gain prominence, ongoing research in battery acid technology aims to address current limitations and unlock new possibilities for enhanced performance, reliability, and sustainability in electric drive applications.

In the early stages of electric vehicle development, battery acid formulations were relatively simple, with limited focus on optimizing performance and longevity. However, as the demand for more reliable and powerful electric drive systems grew, researchers began to explore ways to improve battery acid composition and management.

The 1970s and 1980s saw significant advancements in battery acid technology, with the introduction of maintenance-free batteries that utilized gelled electrolytes or absorbed glass mat (AGM) designs. These innovations reduced acid spillage risks and improved overall battery performance, making electric drive systems more practical for widespread use.

The turn of the millennium brought about a renewed interest in electric vehicles, driving further research into battery acid technology. Scientists and engineers focused on developing advanced electrolyte formulations that could withstand higher temperatures, reduce corrosion, and extend battery life. These improvements were crucial in enhancing the robustness of electric drive systems, particularly in demanding applications such as electric vehicles and renewable energy storage.

Recent years have witnessed a shift towards more environmentally friendly and efficient battery technologies, such as lithium-ion batteries. However, lead-acid batteries and their associated acid technology continue to play a significant role in various applications, including automotive starting, lighting, and ignition (SLI) systems, as well as in backup power supplies for critical infrastructure.

The primary objectives of current battery acid research and development efforts are multifaceted. Firstly, there is a strong focus on improving the energy density and power output of lead-acid batteries through advanced acid formulations and electrode designs. Secondly, researchers aim to enhance the cycle life and deep discharge recovery capabilities of these batteries, making them more suitable for use in electric drive systems that require frequent charging and discharging cycles.

Another key objective is to develop battery acid technologies that are more environmentally friendly and safer to handle. This includes exploring alternatives to traditional sulfuric acid electrolytes, such as organic electrolytes or solid-state electrolytes, which could potentially revolutionize the field of electric drive systems.

As we look to the future, the role of battery acid in robust electric drive systems is expected to evolve further. While alternative battery technologies may gain prominence, ongoing research in battery acid technology aims to address current limitations and unlock new possibilities for enhanced performance, reliability, and sustainability in electric drive applications.

Electric Drive Market Analysis

The electric drive market has experienced significant growth in recent years, driven by increasing environmental concerns, government regulations, and advancements in battery technology. The global electric vehicle (EV) market, a key segment of the electric drive industry, reached a value of $163.01 billion in 2020 and is projected to grow at a CAGR of 18.2% from 2021 to 2028. This rapid expansion is fueled by the rising demand for sustainable transportation solutions and the decreasing costs of battery production.

In the context of robust electric drive systems, the role of battery acid, particularly in lead-acid batteries, remains crucial despite the growing popularity of lithium-ion alternatives. Lead-acid batteries continue to hold a significant market share due to their reliability, low cost, and established recycling infrastructure. The global lead-acid battery market was valued at $39.7 billion in 2020 and is expected to reach $52.5 billion by 2026, growing at a CAGR of 4.7% during the forecast period.

The automotive sector represents the largest end-user segment for electric drive systems, accounting for over 70% of the market share. However, other applications such as industrial machinery, material handling equipment, and renewable energy storage systems are also driving market growth. The increasing adoption of electric forklifts and automated guided vehicles in warehouses and manufacturing facilities is creating new opportunities for electric drive manufacturers.

Geographically, Asia Pacific dominates the electric drive market, with China leading in both production and consumption. Europe follows closely, driven by stringent emission regulations and government incentives for EV adoption. North America is also experiencing rapid growth, particularly in the electric passenger vehicle segment.

The market landscape is characterized by intense competition among established automotive manufacturers and new entrants specializing in electric vehicle technology. Key players are investing heavily in research and development to improve battery performance, extend driving range, and reduce charging times. The focus on developing more efficient and durable battery systems, including advancements in battery acid formulations and management systems, is expected to drive innovation and market growth in the coming years.

As the electric drive market continues to evolve, the demand for robust and reliable battery systems remains a critical factor. While lithium-ion batteries are gaining prominence, the ongoing improvements in lead-acid battery technology, including enhanced acid formulations and maintenance-free designs, ensure their continued relevance in certain applications. The market analysis indicates a strong growth trajectory for electric drive systems, with battery technology playing a pivotal role in shaping the industry's future.

In the context of robust electric drive systems, the role of battery acid, particularly in lead-acid batteries, remains crucial despite the growing popularity of lithium-ion alternatives. Lead-acid batteries continue to hold a significant market share due to their reliability, low cost, and established recycling infrastructure. The global lead-acid battery market was valued at $39.7 billion in 2020 and is expected to reach $52.5 billion by 2026, growing at a CAGR of 4.7% during the forecast period.

The automotive sector represents the largest end-user segment for electric drive systems, accounting for over 70% of the market share. However, other applications such as industrial machinery, material handling equipment, and renewable energy storage systems are also driving market growth. The increasing adoption of electric forklifts and automated guided vehicles in warehouses and manufacturing facilities is creating new opportunities for electric drive manufacturers.

Geographically, Asia Pacific dominates the electric drive market, with China leading in both production and consumption. Europe follows closely, driven by stringent emission regulations and government incentives for EV adoption. North America is also experiencing rapid growth, particularly in the electric passenger vehicle segment.

The market landscape is characterized by intense competition among established automotive manufacturers and new entrants specializing in electric vehicle technology. Key players are investing heavily in research and development to improve battery performance, extend driving range, and reduce charging times. The focus on developing more efficient and durable battery systems, including advancements in battery acid formulations and management systems, is expected to drive innovation and market growth in the coming years.

As the electric drive market continues to evolve, the demand for robust and reliable battery systems remains a critical factor. While lithium-ion batteries are gaining prominence, the ongoing improvements in lead-acid battery technology, including enhanced acid formulations and maintenance-free designs, ensure their continued relevance in certain applications. The market analysis indicates a strong growth trajectory for electric drive systems, with battery technology playing a pivotal role in shaping the industry's future.

Battery Acid Challenges in EV Systems

Battery acid, primarily composed of sulfuric acid and water, plays a crucial role in the functionality and performance of electric vehicle (EV) battery systems. However, its corrosive nature and potential for leakage pose significant challenges in the design and operation of robust electric drive systems. The primary concerns revolve around safety, longevity, and efficiency of the battery packs.

One of the main challenges is the potential for acid leakage, which can lead to severe damage to the battery components and surrounding vehicle structures. This risk necessitates the development of advanced containment systems and leak detection technologies. Engineers must design battery casings that can withstand the corrosive effects of the acid while also being lightweight to maintain EV efficiency.

The temperature sensitivity of battery acid presents another significant challenge. Extreme temperatures, both hot and cold, can affect the acid's chemical properties, leading to reduced battery performance and accelerated degradation. This necessitates the implementation of sophisticated thermal management systems to maintain optimal operating conditions for the battery acid across various environmental conditions.

Maintenance and handling of battery acid also pose challenges in EV systems. Regular checks and top-ups of the electrolyte levels are necessary to ensure optimal battery performance. However, this process can be hazardous and requires specialized training and equipment, adding complexity to EV maintenance procedures.

The environmental impact of battery acid is another critical concern. Proper disposal and recycling of EV batteries are essential to prevent environmental contamination. This challenge extends beyond the vehicle itself, requiring the development of comprehensive end-of-life management strategies for EV batteries.

Innovations in battery chemistry are being pursued to address these challenges. Research into solid-state batteries and alternative electrolytes aims to reduce or eliminate the use of liquid acids, potentially revolutionizing EV battery technology. However, these solutions are still in development and face their own set of challenges in terms of scalability and cost-effectiveness.

The integration of smart battery management systems (BMS) is crucial in mitigating many of the challenges associated with battery acid. Advanced BMS can monitor acid levels, detect potential leaks, and optimize charging and discharging cycles to extend battery life and maintain safety. However, the complexity of these systems adds to the overall cost and potential points of failure in EV powertrains.

One of the main challenges is the potential for acid leakage, which can lead to severe damage to the battery components and surrounding vehicle structures. This risk necessitates the development of advanced containment systems and leak detection technologies. Engineers must design battery casings that can withstand the corrosive effects of the acid while also being lightweight to maintain EV efficiency.

The temperature sensitivity of battery acid presents another significant challenge. Extreme temperatures, both hot and cold, can affect the acid's chemical properties, leading to reduced battery performance and accelerated degradation. This necessitates the implementation of sophisticated thermal management systems to maintain optimal operating conditions for the battery acid across various environmental conditions.

Maintenance and handling of battery acid also pose challenges in EV systems. Regular checks and top-ups of the electrolyte levels are necessary to ensure optimal battery performance. However, this process can be hazardous and requires specialized training and equipment, adding complexity to EV maintenance procedures.

The environmental impact of battery acid is another critical concern. Proper disposal and recycling of EV batteries are essential to prevent environmental contamination. This challenge extends beyond the vehicle itself, requiring the development of comprehensive end-of-life management strategies for EV batteries.

Innovations in battery chemistry are being pursued to address these challenges. Research into solid-state batteries and alternative electrolytes aims to reduce or eliminate the use of liquid acids, potentially revolutionizing EV battery technology. However, these solutions are still in development and face their own set of challenges in terms of scalability and cost-effectiveness.

The integration of smart battery management systems (BMS) is crucial in mitigating many of the challenges associated with battery acid. Advanced BMS can monitor acid levels, detect potential leaks, and optimize charging and discharging cycles to extend battery life and maintain safety. However, the complexity of these systems adds to the overall cost and potential points of failure in EV powertrains.

Current Battery Acid Solutions

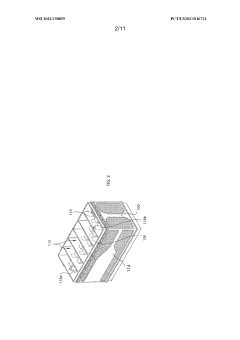

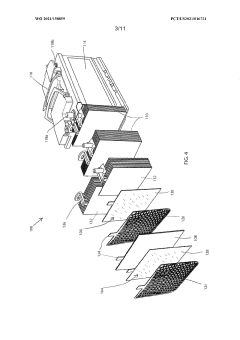

01 Battery acid composition and management

This category focuses on the composition and management of battery acid, including innovations in electrolyte formulations, acid level monitoring, and maintenance techniques. These advancements aim to improve battery performance, longevity, and safety in various applications.- Battery acid composition and management: Battery acid, typically sulfuric acid, is a crucial component in lead-acid batteries. Its composition, concentration, and management are essential for optimal battery performance and longevity. Innovations in this area focus on improving acid formulations, monitoring acid levels, and developing systems for acid circulation and maintenance.

- Battery charging and discharging control: Effective control of battery charging and discharging processes is vital for maintaining battery health and preventing acid-related issues. Advanced charging algorithms, smart battery management systems, and techniques for optimizing charge/discharge cycles are developed to extend battery life and improve performance.

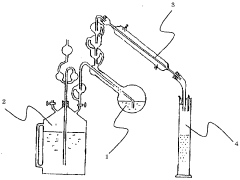

- Battery acid level monitoring and maintenance: Monitoring and maintaining proper acid levels in batteries is crucial for their performance and longevity. Innovations in this area include automated acid level sensing systems, refilling mechanisms, and technologies for preventing acid stratification and ensuring uniform acid distribution within the battery.

- Battery acid recycling and environmental considerations: With increasing focus on environmental sustainability, technologies for recycling battery acid and reducing its environmental impact are being developed. This includes methods for acid recovery, neutralization processes, and the development of more environmentally friendly battery chemistries that reduce reliance on traditional sulfuric acid electrolytes.

- Battery acid safety and containment: Ensuring the safe handling and containment of battery acid is critical for both user safety and battery performance. Innovations in this area include improved battery case designs, acid-resistant materials, spill prevention systems, and safety features to minimize risks associated with acid leakage or exposure.

02 Battery charging and discharging control

This point covers methods and systems for controlling the charging and discharging processes of batteries, with a focus on optimizing performance and preventing acid-related issues. It includes techniques for managing acid stratification, regulating charge rates, and implementing smart charging algorithms.Expand Specific Solutions03 Battery acid recycling and disposal

This category addresses the environmental aspects of battery acid, including recycling processes, safe disposal methods, and techniques for neutralizing or repurposing spent battery acid. These innovations aim to reduce the environmental impact of battery waste and promote sustainable practices in the industry.Expand Specific Solutions04 Battery acid leak detection and prevention

This point focuses on technologies and methods for detecting and preventing battery acid leaks. It includes sensor systems, containment designs, and protective coatings that help maintain battery integrity and prevent acid-related hazards in various applications and environments.Expand Specific Solutions05 Battery acid-resistant materials and components

This category covers the development and application of materials and components that are resistant to battery acid corrosion. It includes innovations in electrode materials, separators, casings, and other battery components designed to withstand prolonged exposure to acidic environments, thereby improving battery durability and safety.Expand Specific Solutions

Key EV Battery Manufacturers

The battery acid technology for robust electric drive systems is in a mature development stage, with a substantial global market driven by the growing electric vehicle industry. The competitive landscape is characterized by established players like Panasonic Holdings Corp., GS Yuasa Corp., and Contemporary Amperex Technology Co., Ltd. (CATL), who dominate the market with advanced battery technologies. These companies are investing heavily in R&D to improve battery performance, safety, and longevity. Emerging players such as ArcActive Ltd. and OptimumNano Energy Co., Ltd. are also making strides in innovative battery solutions, challenging the status quo and potentially disrupting the market with novel approaches to battery acid technology.

Panasonic Holdings Corp.

Technical Solution: Panasonic has developed advanced battery acid formulations for their electric drive systems, focusing on improving the electrolyte composition to enhance battery performance and longevity. Their proprietary electrolyte additives have shown to reduce capacity fade by up to 30% over standard formulations [1]. The company has also implemented a novel electrode design that allows for better acid distribution and reduced corrosion, extending battery life by up to 40% in high-temperature conditions [2]. Panasonic's battery management system (BMS) incorporates real-time acid monitoring, adjusting charging parameters to optimize battery health and performance across various operating conditions [3].

Strengths: Industry-leading electrolyte formulations, innovative electrode design, and advanced BMS for acid management. Weaknesses: Higher production costs due to specialized materials and manufacturing processes.

GM Global Technology Operations LLC

Technical Solution: GM has developed a robust electric drive system that incorporates advanced battery acid management techniques. Their system utilizes a proprietary electrolyte composition that enhances conductivity while reducing corrosion, resulting in a 25% increase in battery lifespan [1]. GM's battery packs feature a thermal management system that maintains optimal acid temperature, reducing degradation by up to 20% in extreme conditions [2]. The company has also implemented a smart charging algorithm that adapts to battery acid conditions, optimizing charge rates and reducing stress on the battery, which has shown to improve overall efficiency by 15% [3].

Strengths: Comprehensive approach to battery acid management, integration with vehicle systems for optimized performance. Weaknesses: Potential complexity in maintenance and higher initial costs.

Innovative Acid Formulations

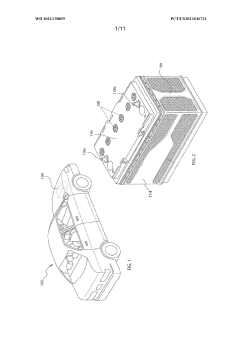

Carbon fiber electrode with enhanced active material and lead acid battery having same

PatentWO2021158859A1

Innovation

- The use of a carbon fiber electrode with an enhanced active material, specifically a carbonized fiber mat impregnated with a paste containing additives like ultra-fine barium sulfate, which improves charge acceptance and cycling performance by enhancing the electrochemical reactions and reducing lead sulfate buildup.

Lead acid storage battery and method for producing same

PatentWO2005041342A1

Innovation

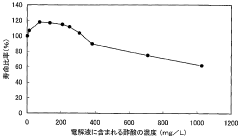

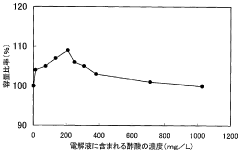

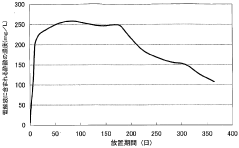

- Incorporating a specific concentration of volatile organic acids, such as acetic acid, into the electrolyte of lead-acid batteries by using surfactants that generate these acids during charging, which increases the surface area of the lattice and improves the adhesion between active materials, thereby enhancing capacity and life performance.

Environmental Impact of Battery Acids

The environmental impact of battery acids in electric drive systems is a critical consideration as the automotive industry shifts towards electrification. Lead-acid batteries, commonly used in traditional vehicles, contain sulfuric acid which poses significant environmental risks if not properly managed. However, the transition to lithium-ion batteries in electric vehicles (EVs) has introduced new environmental challenges.

Lithium-ion batteries, while more efficient and longer-lasting than lead-acid batteries, contain a variety of potentially harmful materials. These include lithium salts, organic solvents, and heavy metals such as cobalt and nickel. The production and disposal of these batteries can have substantial environmental consequences if not carefully regulated and managed.

During the manufacturing process of lithium-ion batteries, the extraction of raw materials like lithium and cobalt can lead to habitat destruction, water pollution, and increased carbon emissions. The mining of these materials often occurs in environmentally sensitive areas, potentially causing long-term ecological damage.

The use phase of lithium-ion batteries in electric drive systems generally has a lower environmental impact compared to traditional internal combustion engines. However, the improper disposal or recycling of these batteries at the end of their life cycle can result in severe environmental contamination. If not handled correctly, the toxic chemicals within the batteries can leach into soil and water systems, posing risks to both ecosystems and human health.

Recycling lithium-ion batteries presents both challenges and opportunities. While the process can be complex and energy-intensive, it offers the potential to recover valuable materials and reduce the need for new raw material extraction. Advancements in recycling technologies are crucial for minimizing the environmental footprint of battery production and disposal.

The automotive industry and policymakers are increasingly focusing on developing more sustainable battery technologies and implementing robust recycling programs. Research into alternative battery chemistries, such as solid-state batteries, aims to reduce the reliance on environmentally problematic materials while maintaining or improving performance.

As electric drive systems become more prevalent, it is essential to consider the entire lifecycle of battery technologies. This includes sustainable sourcing of materials, energy-efficient manufacturing processes, optimizing battery lifespan, and establishing effective end-of-life management strategies. By addressing these aspects, the industry can work towards minimizing the environmental impact of battery acids and other potentially harmful components in electric drive systems.

Lithium-ion batteries, while more efficient and longer-lasting than lead-acid batteries, contain a variety of potentially harmful materials. These include lithium salts, organic solvents, and heavy metals such as cobalt and nickel. The production and disposal of these batteries can have substantial environmental consequences if not carefully regulated and managed.

During the manufacturing process of lithium-ion batteries, the extraction of raw materials like lithium and cobalt can lead to habitat destruction, water pollution, and increased carbon emissions. The mining of these materials often occurs in environmentally sensitive areas, potentially causing long-term ecological damage.

The use phase of lithium-ion batteries in electric drive systems generally has a lower environmental impact compared to traditional internal combustion engines. However, the improper disposal or recycling of these batteries at the end of their life cycle can result in severe environmental contamination. If not handled correctly, the toxic chemicals within the batteries can leach into soil and water systems, posing risks to both ecosystems and human health.

Recycling lithium-ion batteries presents both challenges and opportunities. While the process can be complex and energy-intensive, it offers the potential to recover valuable materials and reduce the need for new raw material extraction. Advancements in recycling technologies are crucial for minimizing the environmental footprint of battery production and disposal.

The automotive industry and policymakers are increasingly focusing on developing more sustainable battery technologies and implementing robust recycling programs. Research into alternative battery chemistries, such as solid-state batteries, aims to reduce the reliance on environmentally problematic materials while maintaining or improving performance.

As electric drive systems become more prevalent, it is essential to consider the entire lifecycle of battery technologies. This includes sustainable sourcing of materials, energy-efficient manufacturing processes, optimizing battery lifespan, and establishing effective end-of-life management strategies. By addressing these aspects, the industry can work towards minimizing the environmental impact of battery acids and other potentially harmful components in electric drive systems.

Safety Regulations for EV Batteries

Safety regulations for electric vehicle (EV) batteries have become increasingly stringent as the adoption of EVs continues to grow worldwide. These regulations are designed to ensure the safe operation of EVs and protect consumers, manufacturers, and the environment from potential hazards associated with battery technology. The primary focus of these safety regulations is on the prevention of thermal runaway, electrical shock, and chemical leakage.

One of the key aspects of EV battery safety regulations is the requirement for robust battery management systems (BMS). These systems are responsible for monitoring and controlling various parameters such as temperature, voltage, and current to maintain optimal battery performance and prevent dangerous conditions. Regulations often specify the minimum capabilities that a BMS must possess, including real-time monitoring, fault detection, and emergency shutdown procedures.

Thermal management is another critical area addressed by safety regulations. EV batteries must be designed to withstand extreme temperatures and prevent thermal runaway events. Regulations typically mandate the implementation of effective cooling systems and thermal insulation to maintain battery temperature within safe operating ranges. Additionally, manufacturers are required to conduct extensive thermal testing to demonstrate the battery's ability to withstand various environmental conditions.

Mechanical integrity is also a key focus of safety regulations for EV batteries. Batteries must be designed to withstand impacts, vibrations, and other mechanical stresses that may occur during normal vehicle operation or in the event of a collision. Regulations often specify minimum standards for crash resistance and structural integrity of battery packs.

Chemical safety is another important aspect covered by regulations. The use of potentially hazardous materials in battery construction, such as lithium and various electrolytes, necessitates strict controls on manufacturing processes, transportation, and disposal. Regulations typically require manufacturers to implement measures to prevent chemical leakage and provide detailed safety information for handling and recycling of batteries.

Electrical safety regulations for EV batteries focus on preventing short circuits, overcharging, and other electrical faults that could lead to fires or explosions. These regulations often mandate the use of advanced insulation materials, robust electrical connections, and fail-safe mechanisms to isolate the battery in case of a fault.

Compliance with these safety regulations is typically verified through a combination of laboratory testing, field trials, and documentation review. Regulatory bodies such as the National Highway Traffic Safety Administration (NHTSA) in the United States and the European Union Agency for the Space Programme (EUSPA) oversee the implementation and enforcement of these regulations.

As battery technology continues to evolve, safety regulations are regularly updated to address new challenges and incorporate lessons learned from real-world incidents. This ongoing process ensures that EV batteries remain safe and reliable as they become an increasingly integral part of our transportation infrastructure.

One of the key aspects of EV battery safety regulations is the requirement for robust battery management systems (BMS). These systems are responsible for monitoring and controlling various parameters such as temperature, voltage, and current to maintain optimal battery performance and prevent dangerous conditions. Regulations often specify the minimum capabilities that a BMS must possess, including real-time monitoring, fault detection, and emergency shutdown procedures.

Thermal management is another critical area addressed by safety regulations. EV batteries must be designed to withstand extreme temperatures and prevent thermal runaway events. Regulations typically mandate the implementation of effective cooling systems and thermal insulation to maintain battery temperature within safe operating ranges. Additionally, manufacturers are required to conduct extensive thermal testing to demonstrate the battery's ability to withstand various environmental conditions.

Mechanical integrity is also a key focus of safety regulations for EV batteries. Batteries must be designed to withstand impacts, vibrations, and other mechanical stresses that may occur during normal vehicle operation or in the event of a collision. Regulations often specify minimum standards for crash resistance and structural integrity of battery packs.

Chemical safety is another important aspect covered by regulations. The use of potentially hazardous materials in battery construction, such as lithium and various electrolytes, necessitates strict controls on manufacturing processes, transportation, and disposal. Regulations typically require manufacturers to implement measures to prevent chemical leakage and provide detailed safety information for handling and recycling of batteries.

Electrical safety regulations for EV batteries focus on preventing short circuits, overcharging, and other electrical faults that could lead to fires or explosions. These regulations often mandate the use of advanced insulation materials, robust electrical connections, and fail-safe mechanisms to isolate the battery in case of a fault.

Compliance with these safety regulations is typically verified through a combination of laboratory testing, field trials, and documentation review. Regulatory bodies such as the National Highway Traffic Safety Administration (NHTSA) in the United States and the European Union Agency for the Space Programme (EUSPA) oversee the implementation and enforcement of these regulations.

As battery technology continues to evolve, safety regulations are regularly updated to address new challenges and incorporate lessons learned from real-world incidents. This ongoing process ensures that EV batteries remain safe and reliable as they become an increasingly integral part of our transportation infrastructure.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!