Strategies to Facilitate Battery Acid Recovery in Remote Areas

AUG 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Acid Recovery Background and Objectives

Battery acid recovery has become an increasingly critical issue in remote areas, where access to proper disposal and recycling facilities is often limited. The background of this challenge stems from the widespread use of lead-acid batteries in various applications, including automotive, renewable energy storage, and backup power systems. As these batteries reach the end of their lifecycle, the need for efficient and environmentally responsible acid recovery methods has grown exponentially.

The evolution of battery acid recovery techniques has been driven by both environmental concerns and economic incentives. Historically, improper disposal of battery acid has led to soil and water contamination, posing significant risks to ecosystems and human health. This has prompted the development of more sustainable recovery strategies, particularly in areas where traditional recycling infrastructure is lacking.

The primary objective of facilitating battery acid recovery in remote areas is to minimize environmental impact while maximizing resource utilization. This involves developing innovative solutions that can be implemented with limited resources and infrastructure. Key goals include reducing the volume of hazardous waste, recovering valuable materials, and creating sustainable practices that can be easily adopted in remote communities.

Another crucial aspect of battery acid recovery is the potential for economic benefits. By implementing effective recovery strategies, remote areas can transform a waste management challenge into an opportunity for local economic development. This includes the creation of jobs in the recycling sector and the potential for generating revenue from recovered materials.

Technological advancements have played a significant role in shaping the current landscape of battery acid recovery. Recent innovations have focused on developing portable and scalable solutions that can be deployed in remote locations. These technologies aim to overcome the logistical challenges associated with transporting hazardous materials over long distances.

The global push towards renewable energy sources has further emphasized the importance of efficient battery acid recovery. As remote areas increasingly adopt solar and wind power systems, which often rely on lead-acid batteries for energy storage, the demand for localized recovery solutions has grown. This trend is expected to continue, driving further innovation in the field of battery acid recovery.

In addressing the challenges of battery acid recovery in remote areas, a multifaceted approach is necessary. This includes not only technological solutions but also the development of educational programs to raise awareness about proper battery disposal and the benefits of recycling. Additionally, policy initiatives and regulatory frameworks play a crucial role in creating an environment that supports sustainable recovery practices.

The evolution of battery acid recovery techniques has been driven by both environmental concerns and economic incentives. Historically, improper disposal of battery acid has led to soil and water contamination, posing significant risks to ecosystems and human health. This has prompted the development of more sustainable recovery strategies, particularly in areas where traditional recycling infrastructure is lacking.

The primary objective of facilitating battery acid recovery in remote areas is to minimize environmental impact while maximizing resource utilization. This involves developing innovative solutions that can be implemented with limited resources and infrastructure. Key goals include reducing the volume of hazardous waste, recovering valuable materials, and creating sustainable practices that can be easily adopted in remote communities.

Another crucial aspect of battery acid recovery is the potential for economic benefits. By implementing effective recovery strategies, remote areas can transform a waste management challenge into an opportunity for local economic development. This includes the creation of jobs in the recycling sector and the potential for generating revenue from recovered materials.

Technological advancements have played a significant role in shaping the current landscape of battery acid recovery. Recent innovations have focused on developing portable and scalable solutions that can be deployed in remote locations. These technologies aim to overcome the logistical challenges associated with transporting hazardous materials over long distances.

The global push towards renewable energy sources has further emphasized the importance of efficient battery acid recovery. As remote areas increasingly adopt solar and wind power systems, which often rely on lead-acid batteries for energy storage, the demand for localized recovery solutions has grown. This trend is expected to continue, driving further innovation in the field of battery acid recovery.

In addressing the challenges of battery acid recovery in remote areas, a multifaceted approach is necessary. This includes not only technological solutions but also the development of educational programs to raise awareness about proper battery disposal and the benefits of recycling. Additionally, policy initiatives and regulatory frameworks play a crucial role in creating an environment that supports sustainable recovery practices.

Market Analysis for Remote Battery Recycling

The market for remote battery recycling is experiencing significant growth, driven by the increasing adoption of renewable energy systems and off-grid power solutions in remote areas. As these regions embrace sustainable energy practices, the demand for efficient battery recycling solutions has surged. The market is characterized by a diverse range of stakeholders, including battery manufacturers, recycling companies, renewable energy providers, and local communities.

Remote areas face unique challenges in battery recycling, primarily due to limited infrastructure and transportation difficulties. This has created a niche market for innovative recycling solutions that can operate effectively in isolated environments. The potential market size for remote battery recycling is substantial, with estimates suggesting a compound annual growth rate (CAGR) of over 8% in the coming years.

The market is segmented based on battery types, with lead-acid batteries dominating the recycling landscape in remote areas due to their widespread use in off-grid solar systems. However, the growing adoption of lithium-ion batteries in renewable energy applications is expected to shift market dynamics in the near future.

Geographically, developing regions such as Sub-Saharan Africa, parts of Asia, and remote islands in the Pacific are emerging as key markets for remote battery recycling. These areas are witnessing rapid deployment of off-grid solar systems, creating a parallel demand for effective battery disposal and recycling solutions.

The market is also influenced by regulatory factors, with many countries implementing stricter environmental regulations regarding battery disposal. This has created opportunities for companies offering compliant recycling solutions tailored for remote locations.

A notable trend in the market is the integration of mobile recycling units that can be deployed to remote areas, addressing the logistical challenges of transporting used batteries to centralized recycling facilities. This approach not only reduces transportation costs but also minimizes the environmental impact associated with long-distance battery transportation.

The economic viability of remote battery recycling is further enhanced by the recovery of valuable materials such as lead, plastic, and electrolytes. As raw material prices fluctuate, the recycling of these components becomes increasingly attractive, driving market growth.

Challenges in the market include the need for specialized equipment capable of operating in harsh environments, the high initial investment required for setting up recycling facilities in remote areas, and the need for skilled personnel to operate these facilities. Despite these challenges, the market presents significant opportunities for companies that can develop cost-effective, scalable solutions for battery recycling in remote locations.

Remote areas face unique challenges in battery recycling, primarily due to limited infrastructure and transportation difficulties. This has created a niche market for innovative recycling solutions that can operate effectively in isolated environments. The potential market size for remote battery recycling is substantial, with estimates suggesting a compound annual growth rate (CAGR) of over 8% in the coming years.

The market is segmented based on battery types, with lead-acid batteries dominating the recycling landscape in remote areas due to their widespread use in off-grid solar systems. However, the growing adoption of lithium-ion batteries in renewable energy applications is expected to shift market dynamics in the near future.

Geographically, developing regions such as Sub-Saharan Africa, parts of Asia, and remote islands in the Pacific are emerging as key markets for remote battery recycling. These areas are witnessing rapid deployment of off-grid solar systems, creating a parallel demand for effective battery disposal and recycling solutions.

The market is also influenced by regulatory factors, with many countries implementing stricter environmental regulations regarding battery disposal. This has created opportunities for companies offering compliant recycling solutions tailored for remote locations.

A notable trend in the market is the integration of mobile recycling units that can be deployed to remote areas, addressing the logistical challenges of transporting used batteries to centralized recycling facilities. This approach not only reduces transportation costs but also minimizes the environmental impact associated with long-distance battery transportation.

The economic viability of remote battery recycling is further enhanced by the recovery of valuable materials such as lead, plastic, and electrolytes. As raw material prices fluctuate, the recycling of these components becomes increasingly attractive, driving market growth.

Challenges in the market include the need for specialized equipment capable of operating in harsh environments, the high initial investment required for setting up recycling facilities in remote areas, and the need for skilled personnel to operate these facilities. Despite these challenges, the market presents significant opportunities for companies that can develop cost-effective, scalable solutions for battery recycling in remote locations.

Technical Challenges in Remote Acid Recovery

Recovering battery acid in remote areas presents several significant technical challenges that must be addressed to ensure efficient and safe operations. The primary obstacle is the lack of established infrastructure in these locations, which complicates the transportation, storage, and processing of hazardous materials like battery acid. This absence of proper facilities and equipment can lead to increased risks of environmental contamination and pose health hazards to local communities.

Another major challenge is the limited access to specialized personnel and expertise in remote areas. Battery acid recovery requires skilled technicians who are trained in handling corrosive substances and operating specialized equipment. The scarcity of such professionals in remote locations can hinder the implementation of effective recovery strategies and increase the likelihood of accidents or improper handling.

The harsh environmental conditions often found in remote areas further complicate the recovery process. Extreme temperatures, high humidity, or arid conditions can affect the stability of battery acid and the performance of recovery equipment. These factors necessitate the development of robust and adaptable technologies that can withstand diverse climatic conditions while maintaining operational efficiency.

Energy supply is another critical issue in remote acid recovery. Many remote areas lack reliable power sources, which are essential for operating recovery equipment and maintaining proper storage conditions. This challenge requires innovative solutions such as the integration of renewable energy systems or the development of energy-efficient recovery technologies that can function with limited power resources.

The management of waste generated during the recovery process poses additional technical difficulties. Remote areas often lack proper waste disposal facilities, making it challenging to handle and neutralize the byproducts of acid recovery safely. This necessitates the development of closed-loop systems or on-site treatment methods that minimize waste generation and environmental impact.

Logistical challenges also play a significant role in remote acid recovery. The transportation of recovered acid or neutralized materials from remote locations to processing facilities can be complex and costly. This requires careful planning and the development of efficient transportation methods that comply with safety regulations for hazardous materials.

Lastly, the scale of operations in remote areas often differs from those in urban settings. Smaller volumes of battery acid may need to be processed, which can affect the economic viability of recovery operations. This challenge calls for the development of scalable and modular recovery systems that can be efficiently deployed and operated in remote locations, regardless of the volume of acid to be processed.

Another major challenge is the limited access to specialized personnel and expertise in remote areas. Battery acid recovery requires skilled technicians who are trained in handling corrosive substances and operating specialized equipment. The scarcity of such professionals in remote locations can hinder the implementation of effective recovery strategies and increase the likelihood of accidents or improper handling.

The harsh environmental conditions often found in remote areas further complicate the recovery process. Extreme temperatures, high humidity, or arid conditions can affect the stability of battery acid and the performance of recovery equipment. These factors necessitate the development of robust and adaptable technologies that can withstand diverse climatic conditions while maintaining operational efficiency.

Energy supply is another critical issue in remote acid recovery. Many remote areas lack reliable power sources, which are essential for operating recovery equipment and maintaining proper storage conditions. This challenge requires innovative solutions such as the integration of renewable energy systems or the development of energy-efficient recovery technologies that can function with limited power resources.

The management of waste generated during the recovery process poses additional technical difficulties. Remote areas often lack proper waste disposal facilities, making it challenging to handle and neutralize the byproducts of acid recovery safely. This necessitates the development of closed-loop systems or on-site treatment methods that minimize waste generation and environmental impact.

Logistical challenges also play a significant role in remote acid recovery. The transportation of recovered acid or neutralized materials from remote locations to processing facilities can be complex and costly. This requires careful planning and the development of efficient transportation methods that comply with safety regulations for hazardous materials.

Lastly, the scale of operations in remote areas often differs from those in urban settings. Smaller volumes of battery acid may need to be processed, which can affect the economic viability of recovery operations. This challenge calls for the development of scalable and modular recovery systems that can be efficiently deployed and operated in remote locations, regardless of the volume of acid to be processed.

Current Remote Acid Recovery Methods

01 Electrolyte recovery and recycling

Methods for recovering and recycling electrolyte from used batteries. This involves processes to extract, purify, and reuse the acid solution, reducing waste and environmental impact while conserving resources.- Electrolyte recovery and recycling: Methods for recovering and recycling electrolyte from used batteries. This involves processes to extract, purify, and reuse the sulfuric acid electrolyte, reducing waste and environmental impact while conserving resources. Techniques may include filtration, neutralization, and concentration steps to prepare the recovered acid for reuse in new batteries or other industrial applications.

- Battery acid neutralization and treatment: Techniques for neutralizing and treating battery acid to make it safe for disposal or further processing. This may involve using alkaline substances to neutralize the acid, followed by additional treatment steps to remove contaminants. The treated acid can then be safely disposed of or potentially used in other industrial processes.

- Acid recovery systems in battery manufacturing: Innovative systems and equipment designed for recovering acid during the battery manufacturing process. These systems aim to capture and recycle acid that would otherwise be lost during production, improving efficiency and reducing waste. They may include specialized collection mechanisms, purification units, and reintegration processes to feed the recovered acid back into the manufacturing line.

- Battery acid concentration and purification: Methods for concentrating and purifying recovered battery acid to meet the quality standards required for reuse. This may involve evaporation techniques, membrane filtration, or chemical treatments to remove impurities and adjust the acid concentration. The goal is to produce high-quality acid that can be used in new batteries or other industrial applications, reducing the need for fresh acid production.

- Integrated battery recycling and acid recovery: Comprehensive approaches that combine battery recycling with acid recovery as part of a holistic process. These methods aim to maximize the recovery of all valuable components from used batteries, including the acid electrolyte, metals, and plastics. The integrated approach can improve the overall efficiency and economic viability of battery recycling operations while minimizing environmental impact.

02 Battery acid neutralization techniques

Processes for neutralizing battery acid to make it safe for disposal or further processing. This may include chemical treatments, pH adjustment, and conversion of acidic components into less harmful substances.Expand Specific Solutions03 Acid recovery systems for battery manufacturing

Innovative systems designed to recover and reuse acid during the battery manufacturing process. These systems aim to minimize acid waste, improve efficiency, and reduce production costs in battery factories.Expand Specific Solutions04 Lead-acid battery recycling processes

Comprehensive recycling processes for lead-acid batteries, including acid recovery as a key component. These methods focus on separating and recovering various materials from spent batteries, with specific attention to acid management and reuse.Expand Specific Solutions05 Advanced acid purification technologies

Cutting-edge technologies for purifying recovered battery acid, removing contaminants, and restoring it to a usable state. These may include membrane filtration, ion exchange, or other advanced separation techniques to produce high-quality recovered acid.Expand Specific Solutions

Key Players in Remote Recycling Solutions

The battery acid recovery market in remote areas is in an early development stage, with growing interest due to environmental concerns and resource scarcity. The market size is relatively small but expanding, driven by increasing adoption of renewable energy systems and electric vehicles in remote locations. Technologically, the field is evolving, with companies like Toyota Motor Corp. and FUJIFILM Corp. leading research efforts. Emerging players such as Asaka Riken Co., Ltd. and Guangdong Bangpu Recycling Technology Co., Ltd. are developing specialized solutions for remote applications. The competitive landscape is diverse, with both established conglomerates and innovative startups vying for market share in this niche but promising sector.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed an innovative battery acid recovery system specifically designed for remote areas. The system utilizes a modular approach, allowing for easy transportation and setup in challenging environments. It employs a combination of electrodialysis and membrane technology to efficiently separate and recover sulfuric acid from spent battery electrolytes[1]. The process is optimized for low energy consumption, making it suitable for off-grid operations powered by renewable energy sources. CATL's system also incorporates a smart monitoring platform that enables remote diagnostics and operation, reducing the need for on-site expertise[2].

Strengths: Modular design for easy deployment, energy-efficient process, remote monitoring capabilities. Weaknesses: May require significant initial investment, potential challenges in scaling up for large-scale operations in very remote locations.

Guangdong Bangpu Recycling Technology Co., Ltd.

Technical Solution: Guangdong Bangpu has developed a comprehensive battery recycling solution tailored for remote areas. Their approach combines mobile recycling units with a centralized processing facility. The mobile units are equipped with a proprietary acid neutralization technology that converts battery acid into a stable, transportable form[3]. This intermediate product is then shipped to the central facility for further processing and recovery. The company has also implemented a blockchain-based tracking system to ensure transparency and traceability throughout the recycling process, addressing concerns about environmental compliance in remote areas[4].

Strengths: Mobile solution for initial processing, blockchain-based traceability, adaptable to various remote conditions. Weaknesses: Reliance on transportation infrastructure for final processing, potential high operational costs in extremely isolated areas.

Innovative Approaches to Acid Reclamation

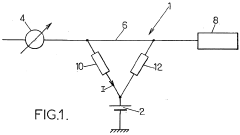

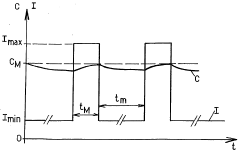

Method for maintaining the charge of a lead storage battery

PatentWO2006064125A1

Innovation

- Implementing a method that alternates between low and high electricity levels during conservation and charging phases, respectively, to maintain the state of charge, with controlled current intensity to minimize self-discharge and corrosion, thereby reducing thermal risks and water loss.

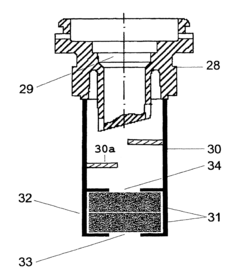

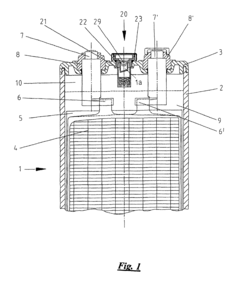

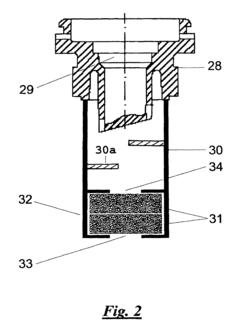

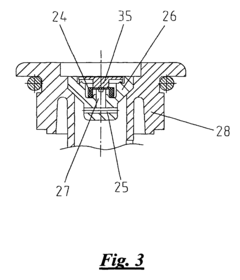

Vent valve for acid batteries

PatentActiveUS7951475B2

Innovation

- A vent valve design featuring a cylindrical plug with a passage opening, a turbulence chamber, and a gas-permeable filter unit that separates solids and liquids from the gas flow, reducing the risk of acid escape and valve clogging, and incorporating a dual- or single-chamber system with a filter unit that ensures effective pressure relief.

Environmental Impact Assessment

The environmental impact assessment of battery acid recovery strategies in remote areas is a critical component of implementing sustainable solutions. The process of recovering battery acid can have significant implications for local ecosystems, water resources, and human health if not managed properly. In remote areas, where environmental monitoring and regulatory oversight may be limited, the potential for negative impacts is heightened.

One of the primary environmental concerns is the risk of soil and water contamination. Battery acid, primarily composed of sulfuric acid, can severely alter soil pH levels if leaked or improperly handled during the recovery process. This acidification can lead to the degradation of soil quality, affecting local flora and potentially entering the food chain. Furthermore, if the acid reaches water bodies, it can cause devastating effects on aquatic ecosystems, disrupting the delicate balance of pH-sensitive organisms and potentially leading to mass die-offs of fish and other aquatic life.

Air quality is another important consideration in the environmental impact assessment. Some recovery methods may involve heating or chemical processes that release harmful fumes or particulate matter. In remote areas with limited air quality monitoring, these emissions could go unchecked, potentially affecting both human populations and wildlife in the vicinity of recovery operations.

The disposal of byproducts and waste materials from the recovery process also poses environmental challenges. Without proper waste management infrastructure, which is often lacking in remote areas, there is a risk of improper disposal leading to long-term environmental degradation. This could include the contamination of groundwater resources, which are often crucial for remote communities and ecosystems.

Energy consumption and carbon footprint are additional factors to consider. Recovery processes may require significant energy inputs, which in remote areas often rely on diesel generators or other fossil fuel-based power sources. This not only contributes to greenhouse gas emissions but also raises questions about the overall sustainability of the recovery operation.

To mitigate these potential impacts, strategies for battery acid recovery in remote areas must incorporate robust environmental safeguards. This may include the use of containment systems to prevent spills, treatment of wastewater before release, and the implementation of air filtration systems for any processes that generate emissions. Additionally, the development of closed-loop systems that minimize waste generation and maximize resource recovery can significantly reduce the environmental footprint of these operations.

Monitoring and assessment protocols are essential components of any environmental impact mitigation strategy. Regular soil and water testing, as well as air quality monitoring, should be implemented to detect any potential contamination early and allow for rapid response. Furthermore, the establishment of environmental baseline data prior to the commencement of recovery operations is crucial for accurately assessing long-term impacts and the effectiveness of mitigation measures.

One of the primary environmental concerns is the risk of soil and water contamination. Battery acid, primarily composed of sulfuric acid, can severely alter soil pH levels if leaked or improperly handled during the recovery process. This acidification can lead to the degradation of soil quality, affecting local flora and potentially entering the food chain. Furthermore, if the acid reaches water bodies, it can cause devastating effects on aquatic ecosystems, disrupting the delicate balance of pH-sensitive organisms and potentially leading to mass die-offs of fish and other aquatic life.

Air quality is another important consideration in the environmental impact assessment. Some recovery methods may involve heating or chemical processes that release harmful fumes or particulate matter. In remote areas with limited air quality monitoring, these emissions could go unchecked, potentially affecting both human populations and wildlife in the vicinity of recovery operations.

The disposal of byproducts and waste materials from the recovery process also poses environmental challenges. Without proper waste management infrastructure, which is often lacking in remote areas, there is a risk of improper disposal leading to long-term environmental degradation. This could include the contamination of groundwater resources, which are often crucial for remote communities and ecosystems.

Energy consumption and carbon footprint are additional factors to consider. Recovery processes may require significant energy inputs, which in remote areas often rely on diesel generators or other fossil fuel-based power sources. This not only contributes to greenhouse gas emissions but also raises questions about the overall sustainability of the recovery operation.

To mitigate these potential impacts, strategies for battery acid recovery in remote areas must incorporate robust environmental safeguards. This may include the use of containment systems to prevent spills, treatment of wastewater before release, and the implementation of air filtration systems for any processes that generate emissions. Additionally, the development of closed-loop systems that minimize waste generation and maximize resource recovery can significantly reduce the environmental footprint of these operations.

Monitoring and assessment protocols are essential components of any environmental impact mitigation strategy. Regular soil and water testing, as well as air quality monitoring, should be implemented to detect any potential contamination early and allow for rapid response. Furthermore, the establishment of environmental baseline data prior to the commencement of recovery operations is crucial for accurately assessing long-term impacts and the effectiveness of mitigation measures.

Regulatory Framework for Hazardous Waste Handling

The regulatory framework for hazardous waste handling in remote areas, particularly concerning battery acid recovery, is a complex and critical aspect of environmental protection and public safety. In many countries, the management of hazardous waste is governed by stringent regulations that aim to minimize environmental impact and protect human health. These regulations typically encompass the entire lifecycle of hazardous materials, from generation to disposal, including transportation, storage, and treatment.

For battery acid recovery in remote areas, the regulatory landscape often presents unique challenges. Remote locations may lack the infrastructure and resources necessary to fully comply with standard hazardous waste regulations. As a result, many jurisdictions have developed specific provisions or exemptions for remote areas, balancing the need for environmental protection with the practical limitations of these locations.

Key components of the regulatory framework for battery acid recovery in remote areas often include specific guidelines for temporary storage, transportation requirements, and treatment protocols. These regulations may mandate the use of specialized containment systems, such as acid-resistant containers, and require regular inspections to ensure compliance. Additionally, there are often strict documentation and reporting requirements to track the movement and disposal of hazardous materials.

Training and certification requirements for personnel handling battery acid and other hazardous materials are typically a crucial part of the regulatory framework. This ensures that individuals involved in the recovery process are adequately prepared to handle these materials safely and in compliance with relevant regulations. In remote areas, these requirements may be adapted to account for limited access to training facilities, potentially incorporating online or distance learning components.

The regulatory framework also often addresses emergency response procedures specific to battery acid spills or accidents in remote locations. This may include requirements for on-site spill response equipment, communication protocols with relevant authorities, and procedures for environmental remediation in case of accidents.

International agreements and conventions, such as the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal, play a significant role in shaping national regulations, especially for countries that may lack comprehensive hazardous waste management systems. These agreements provide a framework for the responsible management of hazardous wastes across borders, which is particularly relevant for remote areas that may need to transport recovered battery acid to centralized treatment facilities.

Enforcement of these regulations in remote areas presents unique challenges. Regulatory bodies often employ a combination of self-reporting, periodic inspections, and remote monitoring technologies to ensure compliance. Penalties for non-compliance can be severe, including fines, revocation of operating permits, and potential criminal charges for egregious violations.

For battery acid recovery in remote areas, the regulatory landscape often presents unique challenges. Remote locations may lack the infrastructure and resources necessary to fully comply with standard hazardous waste regulations. As a result, many jurisdictions have developed specific provisions or exemptions for remote areas, balancing the need for environmental protection with the practical limitations of these locations.

Key components of the regulatory framework for battery acid recovery in remote areas often include specific guidelines for temporary storage, transportation requirements, and treatment protocols. These regulations may mandate the use of specialized containment systems, such as acid-resistant containers, and require regular inspections to ensure compliance. Additionally, there are often strict documentation and reporting requirements to track the movement and disposal of hazardous materials.

Training and certification requirements for personnel handling battery acid and other hazardous materials are typically a crucial part of the regulatory framework. This ensures that individuals involved in the recovery process are adequately prepared to handle these materials safely and in compliance with relevant regulations. In remote areas, these requirements may be adapted to account for limited access to training facilities, potentially incorporating online or distance learning components.

The regulatory framework also often addresses emergency response procedures specific to battery acid spills or accidents in remote locations. This may include requirements for on-site spill response equipment, communication protocols with relevant authorities, and procedures for environmental remediation in case of accidents.

International agreements and conventions, such as the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal, play a significant role in shaping national regulations, especially for countries that may lack comprehensive hazardous waste management systems. These agreements provide a framework for the responsible management of hazardous wastes across borders, which is particularly relevant for remote areas that may need to transport recovered battery acid to centralized treatment facilities.

Enforcement of these regulations in remote areas presents unique challenges. Regulatory bodies often employ a combination of self-reporting, periodic inspections, and remote monitoring technologies to ensure compliance. Penalties for non-compliance can be severe, including fines, revocation of operating permits, and potential criminal charges for egregious violations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!