The Role of Battery Acid in Hydrogen Storage Materials

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Acid in H2 Storage: Background and Objectives

The exploration of battery acid's role in hydrogen storage materials represents a significant intersection of electrochemistry and energy storage technologies. This research area has gained prominence due to the increasing global focus on sustainable energy solutions and the need for efficient hydrogen storage systems. The evolution of this field can be traced back to the early studies on lead-acid batteries, which provided foundational knowledge about the behavior of sulfuric acid in electrochemical systems.

As the demand for clean energy alternatives grew, researchers began investigating the potential of hydrogen as a versatile energy carrier. However, the challenge of storing hydrogen efficiently and safely has been a persistent obstacle. This led to the exploration of various materials and methods for hydrogen storage, including the potential use of battery acid components.

The primary objective of this research is to understand and harness the properties of battery acid, particularly sulfuric acid, in enhancing hydrogen storage capabilities. Researchers aim to develop novel materials or modify existing ones that can effectively absorb, store, and release hydrogen using principles derived from battery acid chemistry. This includes investigating how the acidic environment affects hydrogen uptake and release in different materials, and how it can be optimized for maximum storage efficiency.

Another crucial goal is to explore the potential of battery acid-based systems in improving the energy density and cycle life of hydrogen storage materials. By leveraging the unique properties of battery acids, scientists hope to overcome some of the limitations associated with conventional hydrogen storage methods, such as low gravimetric and volumetric capacities.

The research in this field also aims to address safety concerns associated with hydrogen storage, particularly in mobile applications. Battery acid-inspired systems could potentially offer more stable and controllable hydrogen storage solutions, reducing the risks associated with high-pressure storage tanks.

Furthermore, this research seeks to bridge the gap between laboratory discoveries and practical applications. The ultimate objective is to develop commercially viable hydrogen storage solutions that can be integrated into various sectors, including transportation, stationary power generation, and portable electronics.

As the field progresses, researchers are also focusing on the environmental impact and sustainability of these new storage materials. This includes investigating the recyclability of battery acid-based hydrogen storage systems and their overall life cycle assessment.

As the demand for clean energy alternatives grew, researchers began investigating the potential of hydrogen as a versatile energy carrier. However, the challenge of storing hydrogen efficiently and safely has been a persistent obstacle. This led to the exploration of various materials and methods for hydrogen storage, including the potential use of battery acid components.

The primary objective of this research is to understand and harness the properties of battery acid, particularly sulfuric acid, in enhancing hydrogen storage capabilities. Researchers aim to develop novel materials or modify existing ones that can effectively absorb, store, and release hydrogen using principles derived from battery acid chemistry. This includes investigating how the acidic environment affects hydrogen uptake and release in different materials, and how it can be optimized for maximum storage efficiency.

Another crucial goal is to explore the potential of battery acid-based systems in improving the energy density and cycle life of hydrogen storage materials. By leveraging the unique properties of battery acids, scientists hope to overcome some of the limitations associated with conventional hydrogen storage methods, such as low gravimetric and volumetric capacities.

The research in this field also aims to address safety concerns associated with hydrogen storage, particularly in mobile applications. Battery acid-inspired systems could potentially offer more stable and controllable hydrogen storage solutions, reducing the risks associated with high-pressure storage tanks.

Furthermore, this research seeks to bridge the gap between laboratory discoveries and practical applications. The ultimate objective is to develop commercially viable hydrogen storage solutions that can be integrated into various sectors, including transportation, stationary power generation, and portable electronics.

As the field progresses, researchers are also focusing on the environmental impact and sustainability of these new storage materials. This includes investigating the recyclability of battery acid-based hydrogen storage systems and their overall life cycle assessment.

Market Analysis for H2 Storage Solutions

The hydrogen storage market is experiencing significant growth, driven by the increasing demand for clean energy solutions and the global push towards decarbonization. As governments and industries worldwide seek to reduce their carbon footprint, hydrogen has emerged as a promising alternative fuel source, particularly in sectors such as transportation, power generation, and industrial processes.

The market for hydrogen storage solutions is expected to expand rapidly in the coming years, with projections indicating a compound annual growth rate (CAGR) of over 5% between 2021 and 2026. This growth is fueled by several factors, including advancements in hydrogen production technologies, increasing investments in hydrogen infrastructure, and supportive government policies promoting the adoption of hydrogen-based technologies.

One of the key drivers of market growth is the automotive sector, where hydrogen fuel cell vehicles are gaining traction as a viable alternative to traditional internal combustion engines and battery electric vehicles. Major automakers are investing heavily in hydrogen technology, with several models already available in select markets and more expected to be launched in the near future.

The industrial sector is another significant contributor to the hydrogen storage market, with applications in chemical manufacturing, steel production, and other energy-intensive processes. As industries seek to reduce their carbon emissions, hydrogen is increasingly being viewed as a potential solution for high-temperature processes that are difficult to electrify.

Geographically, Asia-Pacific is expected to be the fastest-growing market for hydrogen storage solutions, driven by ambitious hydrogen strategies in countries like Japan, South Korea, and China. Europe is also a key market, with several countries implementing national hydrogen strategies and investing in large-scale hydrogen projects.

The market landscape is characterized by a mix of established players and innovative startups. Major companies in the hydrogen storage market include Air Liquide, Linde plc, Worthington Industries, and Hexagon Composites. These companies are investing in research and development to improve storage technologies and reduce costs.

Despite the promising outlook, the hydrogen storage market faces several challenges. The high cost of hydrogen production, storage, and distribution remains a significant barrier to widespread adoption. Additionally, the lack of a comprehensive hydrogen infrastructure and concerns about safety and regulatory frameworks are factors that need to be addressed to facilitate market growth.

In conclusion, the market analysis for hydrogen storage solutions indicates a growing and dynamic sector with significant potential. As technology advances and costs decrease, the market is expected to expand further, playing a crucial role in the global transition to a low-carbon economy.

The market for hydrogen storage solutions is expected to expand rapidly in the coming years, with projections indicating a compound annual growth rate (CAGR) of over 5% between 2021 and 2026. This growth is fueled by several factors, including advancements in hydrogen production technologies, increasing investments in hydrogen infrastructure, and supportive government policies promoting the adoption of hydrogen-based technologies.

One of the key drivers of market growth is the automotive sector, where hydrogen fuel cell vehicles are gaining traction as a viable alternative to traditional internal combustion engines and battery electric vehicles. Major automakers are investing heavily in hydrogen technology, with several models already available in select markets and more expected to be launched in the near future.

The industrial sector is another significant contributor to the hydrogen storage market, with applications in chemical manufacturing, steel production, and other energy-intensive processes. As industries seek to reduce their carbon emissions, hydrogen is increasingly being viewed as a potential solution for high-temperature processes that are difficult to electrify.

Geographically, Asia-Pacific is expected to be the fastest-growing market for hydrogen storage solutions, driven by ambitious hydrogen strategies in countries like Japan, South Korea, and China. Europe is also a key market, with several countries implementing national hydrogen strategies and investing in large-scale hydrogen projects.

The market landscape is characterized by a mix of established players and innovative startups. Major companies in the hydrogen storage market include Air Liquide, Linde plc, Worthington Industries, and Hexagon Composites. These companies are investing in research and development to improve storage technologies and reduce costs.

Despite the promising outlook, the hydrogen storage market faces several challenges. The high cost of hydrogen production, storage, and distribution remains a significant barrier to widespread adoption. Additionally, the lack of a comprehensive hydrogen infrastructure and concerns about safety and regulatory frameworks are factors that need to be addressed to facilitate market growth.

In conclusion, the market analysis for hydrogen storage solutions indicates a growing and dynamic sector with significant potential. As technology advances and costs decrease, the market is expected to expand further, playing a crucial role in the global transition to a low-carbon economy.

Current Challenges in H2 Storage Technologies

Hydrogen storage technologies face several significant challenges that hinder their widespread adoption and commercialization. One of the primary obstacles is achieving high volumetric and gravimetric storage capacities while maintaining practical operating conditions. Current storage systems struggle to meet the U.S. Department of Energy's targets for onboard hydrogen storage in light-duty vehicles, which include a gravimetric capacity of 6.5 wt% and a volumetric capacity of 50 g/L.

Material stability and durability present another major challenge. Many promising hydrogen storage materials suffer from degradation over multiple charge-discharge cycles, leading to reduced storage capacity and overall system performance. This issue is particularly pronounced in complex hydrides and chemical hydrogen storage materials, where the reversibility of hydrogen uptake and release reactions is crucial for long-term viability.

Cost-effectiveness remains a significant barrier to the widespread implementation of hydrogen storage technologies. The production of advanced materials and the manufacturing of storage systems often involve expensive processes and rare elements, making them economically unfeasible for large-scale applications. Reducing costs while maintaining or improving performance is a key focus area for researchers and industry stakeholders.

Safety concerns also pose challenges in hydrogen storage technologies. The high pressures required for compressed hydrogen storage and the potential for uncontrolled hydrogen release in some storage materials raise safety issues that must be addressed. Developing robust safety protocols and engineering solutions to mitigate risks associated with hydrogen storage and handling is crucial for public acceptance and regulatory compliance.

Energy efficiency in the storage and release processes is another area of concern. Many storage materials require high temperatures or complex catalysts to facilitate hydrogen uptake and release, leading to significant energy losses and reduced overall system efficiency. Improving the kinetics of hydrogen absorption and desorption reactions while minimizing energy input is a critical challenge for researchers.

Lastly, the integration of hydrogen storage systems with fuel cell technologies and existing infrastructure presents logistical and technical challenges. Developing storage solutions that are compatible with current refueling systems, meet transportation regulations, and can be easily integrated into various applications requires careful consideration of system design and engineering constraints.

Addressing these challenges requires a multidisciplinary approach, combining advances in materials science, chemical engineering, and system integration. Ongoing research efforts focus on developing novel materials, optimizing storage conditions, and improving overall system performance to overcome these hurdles and realize the full potential of hydrogen as a clean energy carrier.

Material stability and durability present another major challenge. Many promising hydrogen storage materials suffer from degradation over multiple charge-discharge cycles, leading to reduced storage capacity and overall system performance. This issue is particularly pronounced in complex hydrides and chemical hydrogen storage materials, where the reversibility of hydrogen uptake and release reactions is crucial for long-term viability.

Cost-effectiveness remains a significant barrier to the widespread implementation of hydrogen storage technologies. The production of advanced materials and the manufacturing of storage systems often involve expensive processes and rare elements, making them economically unfeasible for large-scale applications. Reducing costs while maintaining or improving performance is a key focus area for researchers and industry stakeholders.

Safety concerns also pose challenges in hydrogen storage technologies. The high pressures required for compressed hydrogen storage and the potential for uncontrolled hydrogen release in some storage materials raise safety issues that must be addressed. Developing robust safety protocols and engineering solutions to mitigate risks associated with hydrogen storage and handling is crucial for public acceptance and regulatory compliance.

Energy efficiency in the storage and release processes is another area of concern. Many storage materials require high temperatures or complex catalysts to facilitate hydrogen uptake and release, leading to significant energy losses and reduced overall system efficiency. Improving the kinetics of hydrogen absorption and desorption reactions while minimizing energy input is a critical challenge for researchers.

Lastly, the integration of hydrogen storage systems with fuel cell technologies and existing infrastructure presents logistical and technical challenges. Developing storage solutions that are compatible with current refueling systems, meet transportation regulations, and can be easily integrated into various applications requires careful consideration of system design and engineering constraints.

Addressing these challenges requires a multidisciplinary approach, combining advances in materials science, chemical engineering, and system integration. Ongoing research efforts focus on developing novel materials, optimizing storage conditions, and improving overall system performance to overcome these hurdles and realize the full potential of hydrogen as a clean energy carrier.

Existing Battery Acid-Based H2 Storage Solutions

01 Electrolyte composition for lead-acid batteries

Improved electrolyte compositions for lead-acid batteries that enhance hydrogen storage capabilities and battery performance. These compositions may include additives or modified sulfuric acid formulations that optimize the balance between acid concentration and hydrogen absorption.- Electrolyte composition for hydrogen storage: Specialized electrolyte compositions are developed for use in batteries with hydrogen storage capabilities. These electrolytes are designed to enhance the efficiency of hydrogen storage and release, while also improving the overall performance and lifespan of the battery.

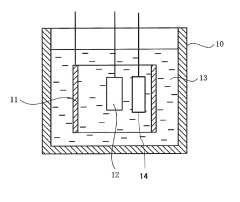

- Battery design for hydrogen storage: Innovative battery designs are created to accommodate hydrogen storage within the battery structure. These designs may include specialized compartments or materials that can safely store and release hydrogen as needed, improving the energy density and performance of the battery.

- Acid management in hydrogen storage batteries: Techniques are developed to manage and control the acid content in batteries designed for hydrogen storage. This includes methods to prevent acid degradation, maintain optimal pH levels, and ensure the longevity of the battery components while facilitating efficient hydrogen storage and release.

- Charging and discharging methods for hydrogen storage batteries: Specialized charging and discharging methods are developed for batteries with hydrogen storage capabilities. These methods are designed to optimize the storage and release of hydrogen while maintaining battery efficiency and preventing degradation of battery components.

- Safety mechanisms for hydrogen storage in batteries: Safety features and mechanisms are incorporated into battery designs to ensure the safe storage and handling of hydrogen. These may include pressure relief valves, temperature control systems, and containment structures to prevent leaks or explosions.

02 Hydrogen storage alloys in battery systems

Integration of hydrogen storage alloys into battery systems, particularly in nickel-metal hydride batteries. These alloys can absorb and release hydrogen, improving energy density and cycle life of the batteries while also providing a means for hydrogen storage.Expand Specific Solutions03 Battery management systems for hydrogen storage

Advanced battery management systems designed to optimize hydrogen storage in battery acid. These systems monitor and control various parameters such as temperature, pressure, and charge state to maximize hydrogen absorption and release efficiency.Expand Specific Solutions04 Electrode materials for enhanced hydrogen storage

Development of novel electrode materials that improve hydrogen storage capacity in battery acid environments. These materials may include modified carbon structures, metal alloys, or composite materials designed to increase hydrogen absorption while maintaining electrochemical stability.Expand Specific Solutions05 Hybrid battery-hydrogen storage systems

Innovative designs that combine traditional battery technology with dedicated hydrogen storage components. These hybrid systems aim to leverage the benefits of both technologies, providing high energy density and rapid charging capabilities while utilizing battery acid as a medium for hydrogen storage.Expand Specific Solutions

Key Players in H2 Storage Industry

The hydrogen storage materials market is in a growth phase, driven by increasing focus on clean energy solutions. The market size is expanding, with projections indicating significant growth potential in the coming years. Technologically, the field is advancing rapidly, with various companies at different stages of development. Key players like Toyota Motor Corp. and BASF SE are investing heavily in research and development, while specialized firms such as QuantumSphere, Inc. and GS Yuasa Corp. are focusing on innovative solutions. Academic institutions like Case Western Reserve University and Delft University of Technology are contributing to fundamental research, pushing the boundaries of material science in this domain. The involvement of diverse players across the value chain indicates a maturing industry with promising prospects for future advancements in hydrogen storage technology.

Toyota Motor Corp.

Technical Solution: Toyota has developed a novel approach to hydrogen storage using battery acid as a catalyst. Their method involves using sulfuric acid, a common battery acid, to enhance the hydrogen absorption and desorption processes in metal hydrides. This technique has shown to improve the kinetics of hydrogen storage materials, allowing for faster charging and discharging cycles[1]. Toyota's research has focused on optimizing the concentration of sulfuric acid to achieve the best balance between storage capacity and reaction speed. They have also explored the use of other acids and electrolytes to further improve the performance of their hydrogen storage systems[2]. Additionally, Toyota has integrated this technology into their fuel cell vehicles, demonstrating its practical application in the automotive industry[3].

Strengths: Improved hydrogen storage kinetics, faster charging/discharging cycles, practical application in fuel cell vehicles. Weaknesses: Potential corrosion issues due to acid use, may require specialized handling and safety measures.

BASF SE

Technical Solution: BASF has developed an innovative approach to hydrogen storage materials utilizing battery acid as a key component. Their research focuses on creating advanced metal-organic frameworks (MOFs) that incorporate acidic functional groups, similar to those found in battery acids, to enhance hydrogen adsorption[4]. These MOFs are designed with high surface areas and tailored pore sizes to maximize hydrogen uptake. BASF's technology also explores the use of sulfonic acid groups, commonly found in battery acids, to create hydrophilic channels within the MOF structure, facilitating hydrogen transport and storage[5]. The company has further investigated the synergistic effects of combining these acid-functionalized MOFs with traditional metal hydrides, resulting in hybrid systems with improved storage capacities and kinetics[6].

Strengths: High hydrogen storage capacity, tunable material properties, potential for room temperature storage. Weaknesses: Complex synthesis process, potential degradation of MOFs over time, higher production costs compared to traditional storage methods.

Innovations in Battery Acid for H2 Storage

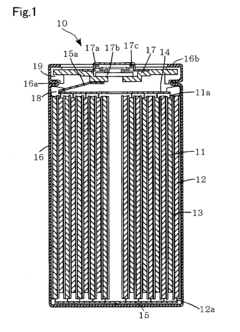

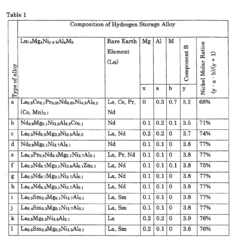

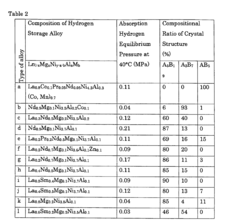

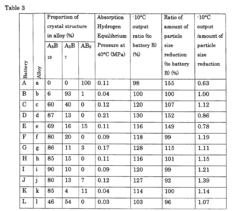

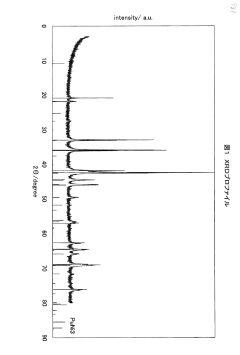

Hydrogen storage alloy and alkaline storage battery employing hydrogen storage alloy as negative electrode active material

PatentActiveEP2096691A1

Innovation

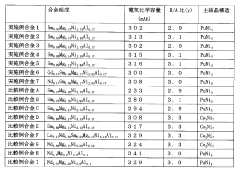

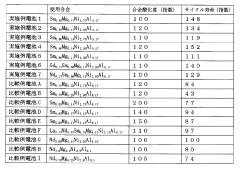

- A hydrogen storage alloy with a primary A5B19 structure, composed of a rare earth element like lanthanum and magnesium, and elements such as nickel and aluminum, is developed, where the stoichiometric ratios and composition are optimized to achieve a nickel molar ratio of 74% or more, and the rare earth element is limited to maximally two elements to suppress particle size reduction and enhance hydrogen absorption and desorption characteristics.

Hydrogen storage alloy and alkaline storage battery with the alloy

PatentActiveJP2010225577A

Innovation

- A hydrogen storage alloy with a composition of Ln1-xMgxNiy-a-bAlaMb, where Ln is mainly Sm, and a B/A ratio of 2.5 to 3.3, stabilizes the PuNi3 or CeNi3 crystal structure, enhancing corrosion resistance and enabling stable charge-discharge reactions.

Environmental Impact of Acid-Based H2 Storage

The environmental impact of acid-based hydrogen storage materials is a critical consideration in the development and implementation of sustainable energy solutions. These materials, which utilize battery acid or similar acidic compounds, offer promising potential for efficient hydrogen storage but also pose significant environmental challenges.

One of the primary environmental concerns is the potential for acid leakage or spills during storage, transportation, or usage of these materials. Such incidents could lead to soil and water contamination, causing harm to local ecosystems and potentially affecting human health. The acidic nature of these materials can alter soil pH levels, disrupt plant growth, and negatively impact aquatic life in affected water bodies.

Furthermore, the production and disposal of acid-based hydrogen storage materials contribute to environmental issues. The manufacturing process often involves energy-intensive steps and the use of potentially harmful chemicals, leading to increased carbon emissions and resource depletion. End-of-life management of these materials is equally challenging, as improper disposal can result in long-term environmental contamination.

Air quality is another area of concern. While hydrogen itself is a clean fuel, the acid components in these storage materials can potentially release harmful vapors or particulates, especially in case of material degradation or accidents. This could contribute to air pollution and pose respiratory risks to both humans and wildlife in the vicinity of storage or usage sites.

However, it's important to note that the environmental impact of acid-based hydrogen storage materials should be weighed against their potential benefits in advancing clean energy technologies. By enabling more efficient hydrogen storage, these materials could play a crucial role in reducing reliance on fossil fuels and mitigating climate change. The net environmental impact, therefore, depends on the balance between these potential benefits and the associated risks.

To address these environmental concerns, ongoing research focuses on developing safer, more stable acid-based storage materials with improved containment systems. Efforts are also being made to enhance the recyclability and biodegradability of these materials, aiming to minimize their environmental footprint throughout their lifecycle. Additionally, stringent safety protocols and regulatory frameworks are being established to govern the handling, transportation, and disposal of these materials, further mitigating potential environmental risks.

One of the primary environmental concerns is the potential for acid leakage or spills during storage, transportation, or usage of these materials. Such incidents could lead to soil and water contamination, causing harm to local ecosystems and potentially affecting human health. The acidic nature of these materials can alter soil pH levels, disrupt plant growth, and negatively impact aquatic life in affected water bodies.

Furthermore, the production and disposal of acid-based hydrogen storage materials contribute to environmental issues. The manufacturing process often involves energy-intensive steps and the use of potentially harmful chemicals, leading to increased carbon emissions and resource depletion. End-of-life management of these materials is equally challenging, as improper disposal can result in long-term environmental contamination.

Air quality is another area of concern. While hydrogen itself is a clean fuel, the acid components in these storage materials can potentially release harmful vapors or particulates, especially in case of material degradation or accidents. This could contribute to air pollution and pose respiratory risks to both humans and wildlife in the vicinity of storage or usage sites.

However, it's important to note that the environmental impact of acid-based hydrogen storage materials should be weighed against their potential benefits in advancing clean energy technologies. By enabling more efficient hydrogen storage, these materials could play a crucial role in reducing reliance on fossil fuels and mitigating climate change. The net environmental impact, therefore, depends on the balance between these potential benefits and the associated risks.

To address these environmental concerns, ongoing research focuses on developing safer, more stable acid-based storage materials with improved containment systems. Efforts are also being made to enhance the recyclability and biodegradability of these materials, aiming to minimize their environmental footprint throughout their lifecycle. Additionally, stringent safety protocols and regulatory frameworks are being established to govern the handling, transportation, and disposal of these materials, further mitigating potential environmental risks.

Safety Considerations for Acid-H2 Storage Systems

The integration of battery acid in hydrogen storage materials presents significant safety challenges that must be carefully addressed. The corrosive nature of acids combined with the highly flammable properties of hydrogen necessitates robust safety protocols and engineering controls.

Firstly, containment is paramount. Storage systems must be designed with materials resistant to acid corrosion, such as specialized plastics or coated metals. Double-walled containers with leak detection systems can provide an additional layer of protection. Proper sealing and regular integrity checks are essential to prevent acid leakage or hydrogen escape.

Ventilation is critical in mitigating the risks associated with potential hydrogen leaks. Well-designed ventilation systems should be implemented to prevent the accumulation of hydrogen gas, which could lead to explosive conditions. Hydrogen sensors should be installed to detect leaks promptly and trigger automatic safety responses.

Temperature control is another crucial aspect. The reaction between acid and hydrogen storage materials can be exothermic, potentially leading to dangerous temperature increases. Cooling systems and temperature monitoring devices should be incorporated to maintain safe operating conditions and prevent thermal runaway scenarios.

Personal protective equipment (PPE) is essential for personnel working with these systems. This includes acid-resistant clothing, gloves, and face shields. Emergency eyewash stations and safety showers should be readily accessible in case of accidental exposure.

Training and standard operating procedures (SOPs) are vital components of a comprehensive safety strategy. All personnel involved in handling or maintaining acid-H2 storage systems must receive thorough training on potential hazards, proper handling techniques, and emergency response protocols.

Emergency response planning is crucial. This includes developing detailed procedures for various scenarios such as acid spills, hydrogen leaks, or fire outbreaks. Regular drills should be conducted to ensure all personnel are familiar with these procedures and can execute them effectively.

Proper waste management and disposal procedures must be established for spent acid and contaminated materials. This may involve neutralization processes and compliance with hazardous waste regulations.

Regular maintenance and inspection schedules are necessary to ensure the ongoing integrity and safety of the storage systems. This includes checks for corrosion, leak testing, and verification of safety system functionality.

By implementing these comprehensive safety measures, the risks associated with acid-H2 storage systems can be effectively managed, allowing for the safe exploration and development of this promising hydrogen storage technology.

Firstly, containment is paramount. Storage systems must be designed with materials resistant to acid corrosion, such as specialized plastics or coated metals. Double-walled containers with leak detection systems can provide an additional layer of protection. Proper sealing and regular integrity checks are essential to prevent acid leakage or hydrogen escape.

Ventilation is critical in mitigating the risks associated with potential hydrogen leaks. Well-designed ventilation systems should be implemented to prevent the accumulation of hydrogen gas, which could lead to explosive conditions. Hydrogen sensors should be installed to detect leaks promptly and trigger automatic safety responses.

Temperature control is another crucial aspect. The reaction between acid and hydrogen storage materials can be exothermic, potentially leading to dangerous temperature increases. Cooling systems and temperature monitoring devices should be incorporated to maintain safe operating conditions and prevent thermal runaway scenarios.

Personal protective equipment (PPE) is essential for personnel working with these systems. This includes acid-resistant clothing, gloves, and face shields. Emergency eyewash stations and safety showers should be readily accessible in case of accidental exposure.

Training and standard operating procedures (SOPs) are vital components of a comprehensive safety strategy. All personnel involved in handling or maintaining acid-H2 storage systems must receive thorough training on potential hazards, proper handling techniques, and emergency response protocols.

Emergency response planning is crucial. This includes developing detailed procedures for various scenarios such as acid spills, hydrogen leaks, or fire outbreaks. Regular drills should be conducted to ensure all personnel are familiar with these procedures and can execute them effectively.

Proper waste management and disposal procedures must be established for spent acid and contaminated materials. This may involve neutralization processes and compliance with hazardous waste regulations.

Regular maintenance and inspection schedules are necessary to ensure the ongoing integrity and safety of the storage systems. This includes checks for corrosion, leak testing, and verification of safety system functionality.

By implementing these comprehensive safety measures, the risks associated with acid-H2 storage systems can be effectively managed, allowing for the safe exploration and development of this promising hydrogen storage technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!