The Role of Battery Acid in Concentrated Solar Power Systems

AUG 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CSP Battery Acid Background and Objectives

Concentrated Solar Power (CSP) systems have emerged as a promising renewable energy technology, harnessing the sun's thermal energy to generate electricity. The integration of battery acid in these systems represents a significant advancement in energy storage and efficiency. This technological evolution stems from the need to address the intermittent nature of solar energy and enhance the overall performance of CSP plants.

The primary objective of incorporating battery acid in CSP systems is to improve energy storage capabilities, thereby enabling continuous power generation even during periods of low solar irradiance or at night. This integration aims to overcome one of the main challenges faced by solar energy: its dependence on daylight hours. By effectively storing excess thermal energy produced during peak sunlight hours, CSP plants can maintain a stable power output, meeting grid demands more reliably.

Historically, CSP technology has undergone several iterations since its inception in the 1980s. Early systems focused primarily on direct power generation without significant storage capabilities. The introduction of molten salt as a heat transfer fluid marked a significant milestone, allowing for better heat retention. However, the quest for more efficient and cost-effective storage solutions led to the exploration of battery acid as a potential medium.

The development of battery acid applications in CSP systems is driven by several key factors. Firstly, the chemical properties of battery acid, particularly its high specific heat capacity and thermal conductivity, make it an excellent candidate for thermal energy storage. Secondly, the relatively low cost and widespread availability of battery acid components offer economic advantages over some alternative storage mediums.

Research objectives in this field are multifaceted. Scientists and engineers are working to optimize the composition of battery acid mixtures to maximize heat storage capacity while minimizing corrosion and degradation of system components. Another crucial goal is to develop advanced heat exchanger designs that can efficiently transfer thermal energy between the solar collectors, the battery acid storage system, and the power generation units.

Furthermore, there is a strong focus on enhancing the safety and environmental sustainability of battery acid usage in CSP systems. This includes developing containment strategies to prevent leaks, implementing recycling protocols, and exploring less hazardous acid formulations that maintain high performance characteristics.

As the technology progresses, researchers aim to achieve higher operating temperatures, which could significantly increase the overall efficiency of CSP plants. The ultimate goal is to create a robust, scalable, and cost-effective energy storage solution that can be widely adopted, potentially revolutionizing the solar energy sector and contributing to the global transition towards renewable energy sources.

The primary objective of incorporating battery acid in CSP systems is to improve energy storage capabilities, thereby enabling continuous power generation even during periods of low solar irradiance or at night. This integration aims to overcome one of the main challenges faced by solar energy: its dependence on daylight hours. By effectively storing excess thermal energy produced during peak sunlight hours, CSP plants can maintain a stable power output, meeting grid demands more reliably.

Historically, CSP technology has undergone several iterations since its inception in the 1980s. Early systems focused primarily on direct power generation without significant storage capabilities. The introduction of molten salt as a heat transfer fluid marked a significant milestone, allowing for better heat retention. However, the quest for more efficient and cost-effective storage solutions led to the exploration of battery acid as a potential medium.

The development of battery acid applications in CSP systems is driven by several key factors. Firstly, the chemical properties of battery acid, particularly its high specific heat capacity and thermal conductivity, make it an excellent candidate for thermal energy storage. Secondly, the relatively low cost and widespread availability of battery acid components offer economic advantages over some alternative storage mediums.

Research objectives in this field are multifaceted. Scientists and engineers are working to optimize the composition of battery acid mixtures to maximize heat storage capacity while minimizing corrosion and degradation of system components. Another crucial goal is to develop advanced heat exchanger designs that can efficiently transfer thermal energy between the solar collectors, the battery acid storage system, and the power generation units.

Furthermore, there is a strong focus on enhancing the safety and environmental sustainability of battery acid usage in CSP systems. This includes developing containment strategies to prevent leaks, implementing recycling protocols, and exploring less hazardous acid formulations that maintain high performance characteristics.

As the technology progresses, researchers aim to achieve higher operating temperatures, which could significantly increase the overall efficiency of CSP plants. The ultimate goal is to create a robust, scalable, and cost-effective energy storage solution that can be widely adopted, potentially revolutionizing the solar energy sector and contributing to the global transition towards renewable energy sources.

Market Analysis for CSP Battery Acid Solutions

The market for battery acid solutions in Concentrated Solar Power (CSP) systems is experiencing significant growth, driven by the increasing adoption of CSP technology worldwide. As renewable energy sources gain prominence, CSP systems have emerged as a viable alternative to traditional power generation methods. The role of battery acid in these systems is crucial for energy storage and efficiency, making it a key component in the CSP market.

The global CSP market is projected to expand at a compound annual growth rate (CAGR) of 10.3% from 2021 to 2026, reaching a market value of $7.6 billion by the end of the forecast period. This growth is primarily attributed to the rising demand for clean energy solutions and the increasing investments in solar power infrastructure. Within this broader market, the demand for battery acid solutions is expected to grow proportionally, as energy storage becomes increasingly important for the stability and reliability of CSP systems.

Several factors are driving the market demand for CSP battery acid solutions. Firstly, the intermittent nature of solar energy necessitates efficient storage solutions to ensure a consistent power supply. Battery acid plays a crucial role in this aspect by enabling the storage of excess energy generated during peak sunlight hours for use during periods of low solar radiation or at night. This capability enhances the overall efficiency and reliability of CSP systems, making them more attractive to utilities and power producers.

Secondly, the push for grid stability and load balancing is creating opportunities for battery acid solutions in CSP systems. As power grids integrate more renewable energy sources, the need for energy storage to manage fluctuations in supply and demand becomes critical. CSP systems equipped with battery acid storage can provide grid operators with greater flexibility in managing power distribution, thereby increasing the market potential for these solutions.

Geographically, the market for CSP battery acid solutions is most robust in regions with high solar irradiance and supportive government policies. Countries such as Spain, the United States, China, and those in the Middle East and North Africa (MENA) region are leading the adoption of CSP technology and, consequently, driving the demand for battery acid solutions. These regions are expected to continue dominating the market in the coming years, with emerging economies in Asia and Africa presenting significant growth opportunities.

The market landscape for CSP battery acid solutions is characterized by a mix of established players and new entrants. Major battery manufacturers and chemical companies are expanding their product portfolios to cater to the specific needs of CSP systems. Additionally, collaborations between CSP technology providers and battery solution companies are becoming more common, fostering innovation and market growth.

The global CSP market is projected to expand at a compound annual growth rate (CAGR) of 10.3% from 2021 to 2026, reaching a market value of $7.6 billion by the end of the forecast period. This growth is primarily attributed to the rising demand for clean energy solutions and the increasing investments in solar power infrastructure. Within this broader market, the demand for battery acid solutions is expected to grow proportionally, as energy storage becomes increasingly important for the stability and reliability of CSP systems.

Several factors are driving the market demand for CSP battery acid solutions. Firstly, the intermittent nature of solar energy necessitates efficient storage solutions to ensure a consistent power supply. Battery acid plays a crucial role in this aspect by enabling the storage of excess energy generated during peak sunlight hours for use during periods of low solar radiation or at night. This capability enhances the overall efficiency and reliability of CSP systems, making them more attractive to utilities and power producers.

Secondly, the push for grid stability and load balancing is creating opportunities for battery acid solutions in CSP systems. As power grids integrate more renewable energy sources, the need for energy storage to manage fluctuations in supply and demand becomes critical. CSP systems equipped with battery acid storage can provide grid operators with greater flexibility in managing power distribution, thereby increasing the market potential for these solutions.

Geographically, the market for CSP battery acid solutions is most robust in regions with high solar irradiance and supportive government policies. Countries such as Spain, the United States, China, and those in the Middle East and North Africa (MENA) region are leading the adoption of CSP technology and, consequently, driving the demand for battery acid solutions. These regions are expected to continue dominating the market in the coming years, with emerging economies in Asia and Africa presenting significant growth opportunities.

The market landscape for CSP battery acid solutions is characterized by a mix of established players and new entrants. Major battery manufacturers and chemical companies are expanding their product portfolios to cater to the specific needs of CSP systems. Additionally, collaborations between CSP technology providers and battery solution companies are becoming more common, fostering innovation and market growth.

Technical Challenges in CSP Battery Acid Integration

The integration of battery acid in Concentrated Solar Power (CSP) systems presents several significant technical challenges that must be addressed for successful implementation. One of the primary issues is the corrosive nature of battery acid, which can lead to accelerated degradation of system components. This necessitates the development and use of highly resistant materials for storage tanks, piping, and other critical infrastructure elements.

Another major challenge lies in maintaining the stability and performance of the battery acid under the extreme temperature conditions typical in CSP systems. The acid must remain effective and stable across a wide temperature range, from ambient conditions to the high temperatures generated during solar energy concentration. This requires careful formulation and potentially the development of new acid compositions tailored specifically for CSP applications.

Safety considerations also pose significant technical hurdles. The large-scale storage and handling of battery acid in CSP facilities demand robust containment systems and stringent safety protocols. Engineers must design fail-safe mechanisms to prevent leaks and spills, as well as implement advanced monitoring systems to detect any potential issues before they escalate.

The integration of battery acid storage with the existing CSP infrastructure presents its own set of challenges. Designers must optimize the layout and connections between the acid storage units and the power generation components to maximize efficiency while minimizing potential risks. This may require innovative approaches to heat exchange and energy transfer systems.

Furthermore, the long-term performance and durability of battery acid in CSP systems remain largely unknown. Extensive research and testing are needed to understand how the acid behaves over extended periods under operational conditions. This includes studying potential chemical changes, efficiency losses, and maintenance requirements over the lifespan of the CSP plant.

Environmental concerns also add complexity to the integration process. The use of large quantities of battery acid raises questions about potential ecological impacts in case of accidents or during decommissioning. Developing environmentally friendly disposal or recycling methods for used acid becomes crucial for sustainable implementation.

Lastly, the scalability of battery acid integration in CSP systems presents a significant technical challenge. As CSP plants grow in size and capacity, the volume of acid required increases proportionally. This scaling up process demands innovative solutions in acid production, transportation, and on-site management to ensure economic viability and operational feasibility at industrial scales.

Another major challenge lies in maintaining the stability and performance of the battery acid under the extreme temperature conditions typical in CSP systems. The acid must remain effective and stable across a wide temperature range, from ambient conditions to the high temperatures generated during solar energy concentration. This requires careful formulation and potentially the development of new acid compositions tailored specifically for CSP applications.

Safety considerations also pose significant technical hurdles. The large-scale storage and handling of battery acid in CSP facilities demand robust containment systems and stringent safety protocols. Engineers must design fail-safe mechanisms to prevent leaks and spills, as well as implement advanced monitoring systems to detect any potential issues before they escalate.

The integration of battery acid storage with the existing CSP infrastructure presents its own set of challenges. Designers must optimize the layout and connections between the acid storage units and the power generation components to maximize efficiency while minimizing potential risks. This may require innovative approaches to heat exchange and energy transfer systems.

Furthermore, the long-term performance and durability of battery acid in CSP systems remain largely unknown. Extensive research and testing are needed to understand how the acid behaves over extended periods under operational conditions. This includes studying potential chemical changes, efficiency losses, and maintenance requirements over the lifespan of the CSP plant.

Environmental concerns also add complexity to the integration process. The use of large quantities of battery acid raises questions about potential ecological impacts in case of accidents or during decommissioning. Developing environmentally friendly disposal or recycling methods for used acid becomes crucial for sustainable implementation.

Lastly, the scalability of battery acid integration in CSP systems presents a significant technical challenge. As CSP plants grow in size and capacity, the volume of acid required increases proportionally. This scaling up process demands innovative solutions in acid production, transportation, and on-site management to ensure economic viability and operational feasibility at industrial scales.

Current Battery Acid Solutions for CSP Systems

01 Battery acid composition and management

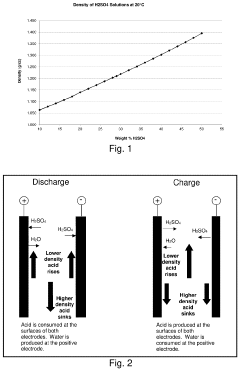

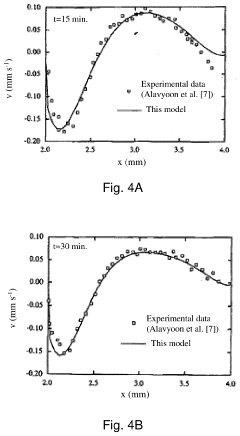

Battery acid, typically sulfuric acid, is a crucial component in lead-acid batteries. Its composition, concentration, and management are essential for optimal battery performance and longevity. Innovations in this area focus on improving acid formulations, monitoring acid levels, and developing systems for acid circulation and maintenance.- Battery acid composition and management: Battery acid, typically sulfuric acid, is a crucial component in lead-acid batteries. Its composition and management are essential for battery performance and longevity. This includes controlling acid concentration, monitoring acid levels, and managing acid circulation within the battery cells.

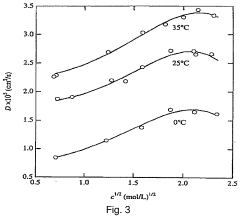

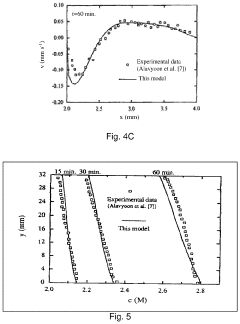

- Battery charging and discharging processes: The charging and discharging processes of batteries involve complex interactions with the battery acid. Proper management of these processes can significantly impact battery life and efficiency. This includes optimizing charge rates, preventing overcharging, and managing acid stratification during cycling.

- Battery acid monitoring and maintenance: Continuous monitoring and maintenance of battery acid are crucial for ensuring optimal battery performance and safety. This involves regular checks of acid specific gravity, topping up electrolyte levels, and implementing measures to prevent acid leakage or spillage.

- Innovations in battery acid formulations: Advancements in battery acid formulations aim to improve battery performance, longevity, and safety. This includes developing gel electrolytes, incorporating additives to reduce corrosion, and creating acid mixtures that enhance charge acceptance and reduce water loss.

- Safety measures and environmental considerations: Implementing safety measures and addressing environmental concerns related to battery acid are critical aspects of battery design and usage. This includes developing spill-proof designs, improving acid containment systems, and exploring more environmentally friendly alternatives to traditional sulfuric acid electrolytes.

02 Battery charging and discharging control

Advanced control systems for battery charging and discharging processes are developed to optimize battery performance and lifespan. These systems monitor various parameters such as voltage, current, and temperature to regulate the charging and discharging cycles, preventing overcharging and deep discharging which can damage the battery and affect the acid balance.Expand Specific Solutions03 Battery acid level monitoring and maintenance

Innovations in battery acid level monitoring and maintenance systems are crucial for ensuring proper battery function. These systems include sensors for detecting acid levels, automated refilling mechanisms, and alert systems to notify users of low acid conditions, helping to prevent battery damage and extend battery life.Expand Specific Solutions04 Battery acid recycling and environmental considerations

Advancements in battery acid recycling technologies and processes are being developed to address environmental concerns. These innovations focus on efficient acid recovery methods, neutralization techniques, and the development of more environmentally friendly battery acid formulations to reduce the environmental impact of battery disposal and recycling.Expand Specific Solutions05 Battery acid alternatives and novel electrolyte systems

Research is ongoing to develop alternatives to traditional sulfuric acid electrolytes in batteries. This includes the exploration of novel electrolyte systems, such as gel electrolytes, solid-state electrolytes, and other innovative formulations that aim to improve battery performance, safety, and environmental compatibility while potentially reducing the reliance on conventional battery acid.Expand Specific Solutions

Key Players in CSP Battery Acid Industry

The role of battery acid in Concentrated Solar Power (CSP) systems represents an emerging field within the solar energy sector. The market is in its early growth stage, with increasing interest due to the potential for improved energy storage solutions. While the global CSP market is projected to reach $30 billion by 2026, the specific battery acid application is still developing. Companies like Sharp Corp., SolarReserve, and Fraunhofer-Gesellschaft are at the forefront of research and development in this area, leveraging their expertise in solar technologies and energy storage. However, the technology is not yet fully mature, with ongoing efforts to optimize efficiency, cost-effectiveness, and scalability for widespread commercial adoption.

Commissariat à l´énergie atomique et aux énergies Alternatives

Technical Solution: The French Alternative Energies and Atomic Energy Commission (CEA) has been researching innovative approaches to concentrated solar power, including the potential use of battery technologies for energy storage. While not directly using battery acid in CSP systems, they have explored hybrid systems that combine CSP with electrochemical storage. One concept involves using excess solar thermal energy to charge high-temperature batteries, such as sodium-sulfur (NaS) or sodium-nickel chloride (ZEBRA) batteries [3]. These batteries can operate at temperatures around 300-350°C, which aligns well with CSP operating temperatures. The stored electrical energy can then be used to supplement power generation during periods of low solar irradiance or at night. Additionally, CEA has investigated the use of molten salt mixtures containing lithium, which could potentially interface with certain types of high-temperature batteries [4].

Strengths: Integration of thermal and electrical storage can increase system flexibility; potential for round-the-clock power generation; leverages existing battery technologies. Weaknesses: Complexity of managing both thermal and electrical storage systems; high-temperature batteries may have limited lifespan; potential safety concerns with high-temperature battery operation.

Solartec AG

Technical Solution: Solartec AG, a German solar technology company, has been working on advanced CSP systems that incorporate novel energy storage solutions. While specific details of their proprietary technologies are not publicly available, they have been exploring the use of phase change materials (PCMs) for thermal energy storage in CSP plants. These PCMs, which could potentially include certain salt hydrates or organic compounds, undergo phase transitions at specific temperatures, allowing them to store and release large amounts of latent heat [5]. In the context of battery acid integration, Solartec has been investigating the potential of using acid-base reactions for thermochemical energy storage. This approach could involve the controlled reaction between sulfuric acid (a common battery acid) and bases like ammonia or metal oxides to store and release heat [6]. The reversible nature of these reactions could provide a high-density energy storage mechanism for CSP systems.

Strengths: High energy density storage potential; possibility of long-term storage without significant losses; utilization of relatively inexpensive and abundant materials. Weaknesses: Corrosive nature of acids may pose material challenges; complexity of managing chemical reactions in a large-scale energy system; potential safety and environmental concerns with handling large quantities of reactive chemicals.

Innovative Battery Acid Technologies for CSP

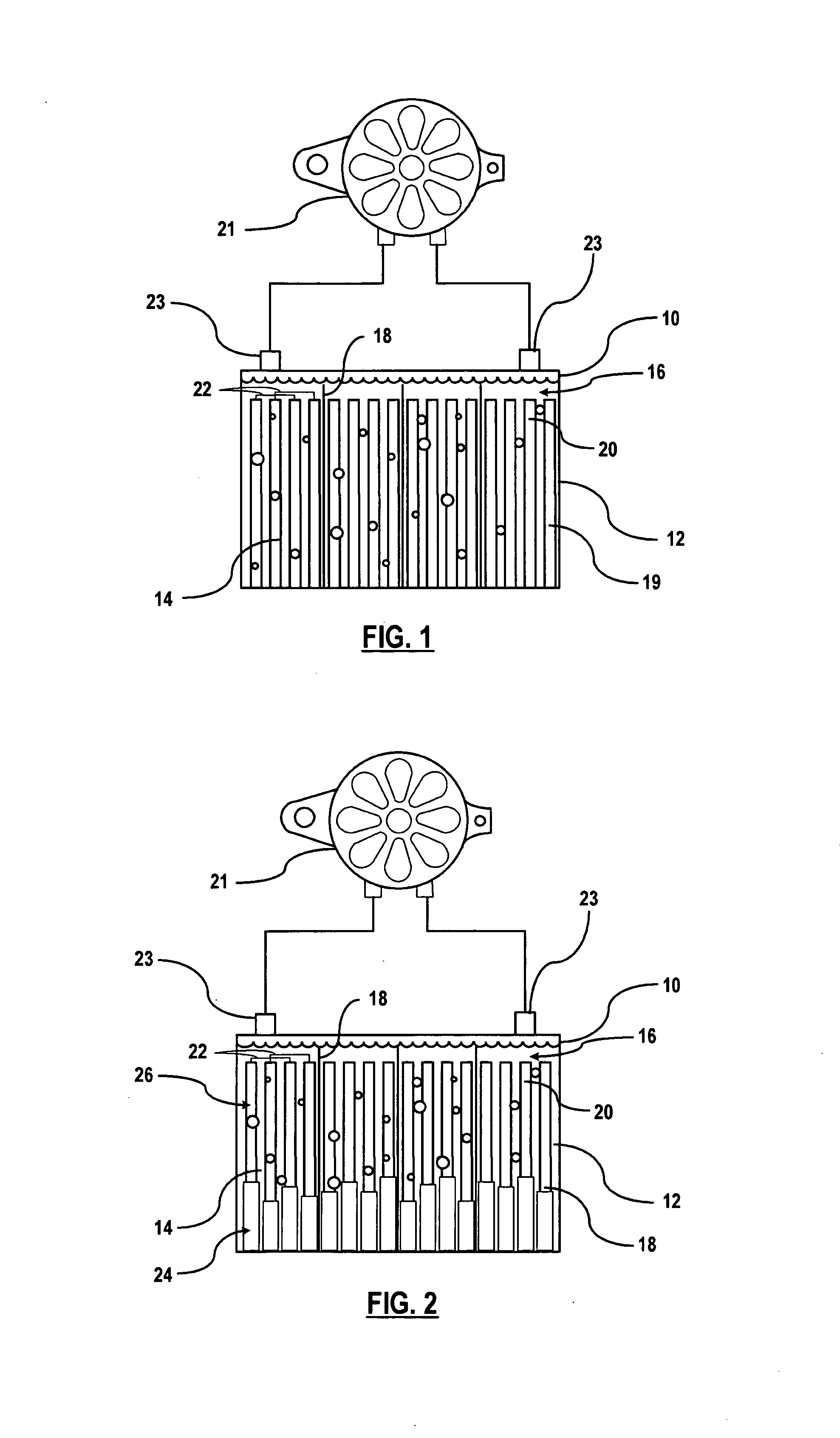

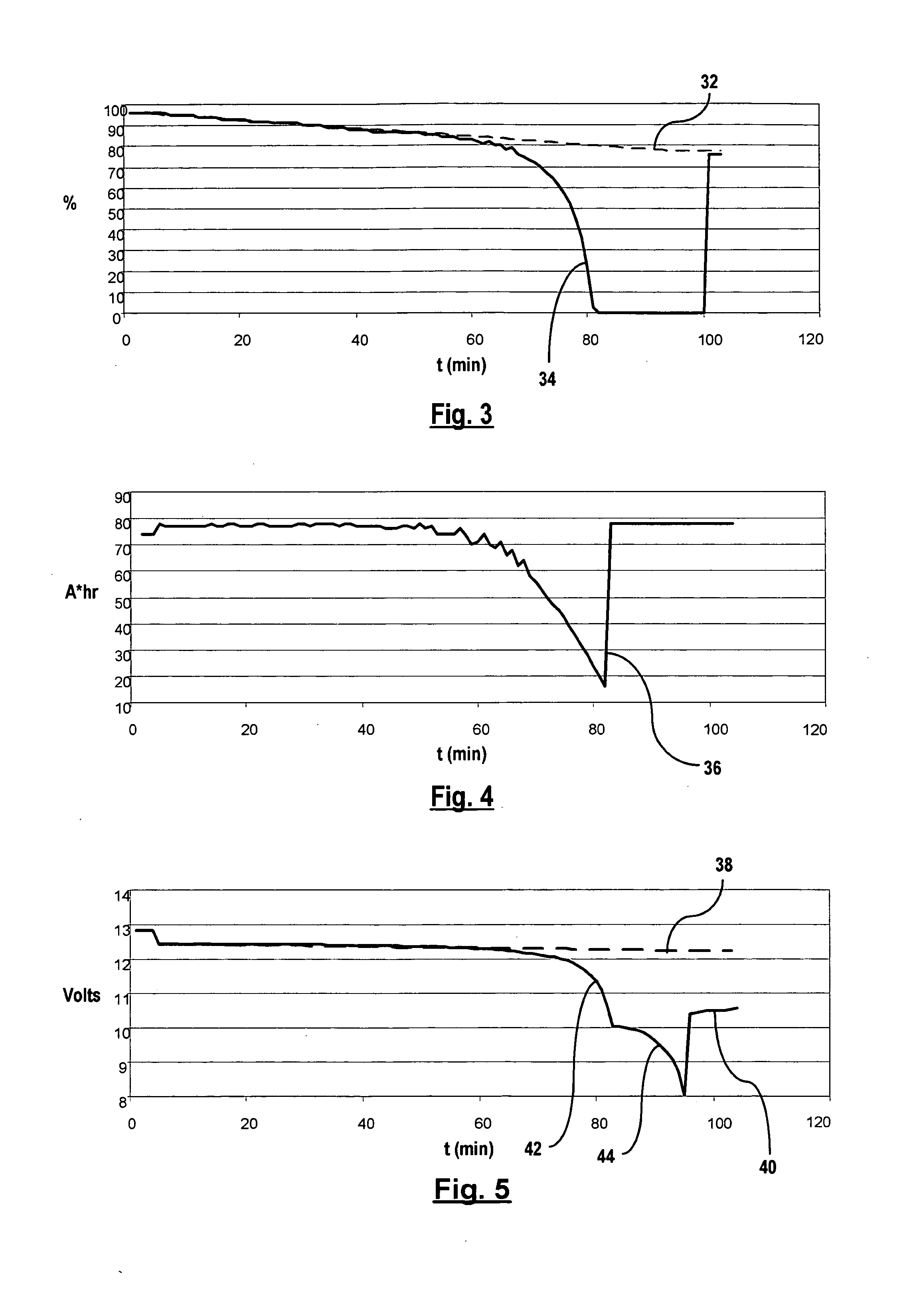

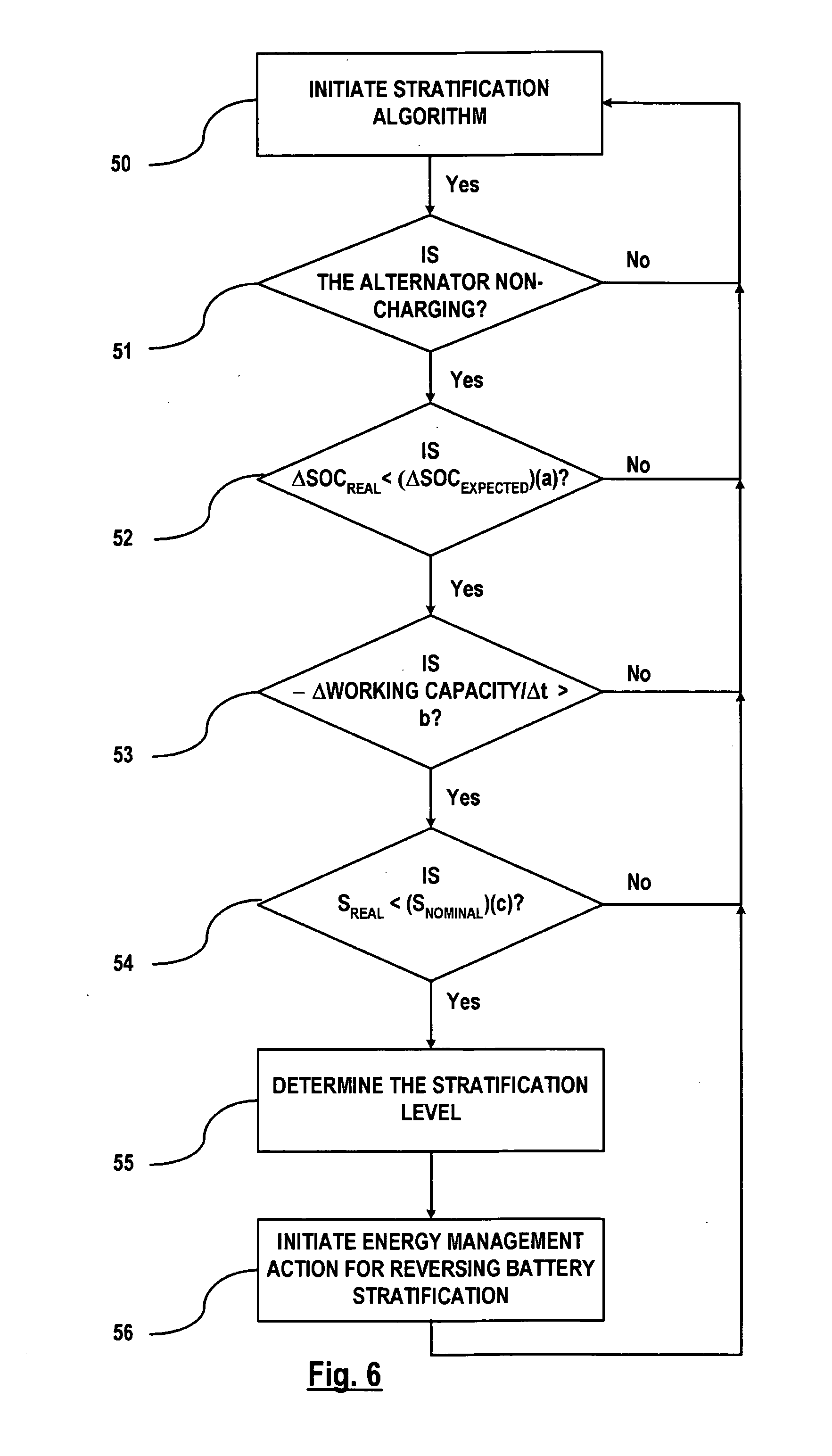

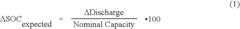

Method for detecting battery stratification

PatentInactiveUS20080007225A1

Innovation

- An energy management algorithm that detects stratification by monitoring state of charge, working capacity, and voltage differential thresholds, and corrects it by increasing the battery charge voltage to remix the acid concentration.

Acid stratification mitigation, electrolytes, devices, and methods related thereto

PatentActiveUS20240222702A1

Innovation

- Introducing an acid-soluble and acid-stable polymer with high molecular weight into the electrolyte to increase viscosity, which resists convective flows and reduces acid stratification by partially immobilizing the acid, thereby enhancing battery performance.

Environmental Impact of Battery Acid in CSP

The environmental impact of battery acid in Concentrated Solar Power (CSP) systems is a critical consideration that requires careful analysis and management. Battery acid, typically sulfuric acid, is used in some CSP systems for energy storage purposes. While it plays a crucial role in enhancing the efficiency and reliability of these systems, its potential environmental effects cannot be overlooked.

One of the primary concerns is the risk of acid leakage or spills. If not properly contained, battery acid can contaminate soil and water sources, leading to severe ecological damage. The high acidity can alter soil pH, affecting plant growth and microbial activity in the surrounding ecosystem. Furthermore, if the acid reaches water bodies, it can cause significant harm to aquatic life and disrupt the balance of aquatic ecosystems.

Air pollution is another potential issue associated with battery acid in CSP systems. During charging and discharging cycles, batteries may release hydrogen gas, which, if not properly vented, can pose explosion risks. Additionally, the production and transportation of battery acid contribute to carbon emissions, partially offsetting the environmental benefits of renewable energy generation.

The disposal of spent battery acid presents another environmental challenge. Improper disposal can lead to long-term environmental contamination and pose risks to human health. Recycling and neutralization processes must be implemented to mitigate these risks, but these processes themselves can have environmental impacts if not managed correctly.

However, it's important to note that the environmental impact of battery acid in CSP systems is not entirely negative. By enabling more efficient energy storage, these systems can significantly increase the overall efficiency of solar power generation, potentially reducing reliance on fossil fuels and decreasing greenhouse gas emissions on a larger scale.

To minimize the environmental impact, stringent safety measures and containment protocols must be implemented in CSP facilities using battery acid. This includes regular inspections, proper sealing and containment of battery systems, and comprehensive emergency response plans. Additionally, research into alternative energy storage technologies, such as flow batteries or molten salt storage, may provide more environmentally friendly options for future CSP systems.

In conclusion, while battery acid plays a vital role in enhancing the performance of CSP systems, its environmental impact must be carefully managed through proper handling, containment, and disposal practices. Balancing the benefits of improved energy storage with potential environmental risks is crucial for the sustainable development of CSP technology.

One of the primary concerns is the risk of acid leakage or spills. If not properly contained, battery acid can contaminate soil and water sources, leading to severe ecological damage. The high acidity can alter soil pH, affecting plant growth and microbial activity in the surrounding ecosystem. Furthermore, if the acid reaches water bodies, it can cause significant harm to aquatic life and disrupt the balance of aquatic ecosystems.

Air pollution is another potential issue associated with battery acid in CSP systems. During charging and discharging cycles, batteries may release hydrogen gas, which, if not properly vented, can pose explosion risks. Additionally, the production and transportation of battery acid contribute to carbon emissions, partially offsetting the environmental benefits of renewable energy generation.

The disposal of spent battery acid presents another environmental challenge. Improper disposal can lead to long-term environmental contamination and pose risks to human health. Recycling and neutralization processes must be implemented to mitigate these risks, but these processes themselves can have environmental impacts if not managed correctly.

However, it's important to note that the environmental impact of battery acid in CSP systems is not entirely negative. By enabling more efficient energy storage, these systems can significantly increase the overall efficiency of solar power generation, potentially reducing reliance on fossil fuels and decreasing greenhouse gas emissions on a larger scale.

To minimize the environmental impact, stringent safety measures and containment protocols must be implemented in CSP facilities using battery acid. This includes regular inspections, proper sealing and containment of battery systems, and comprehensive emergency response plans. Additionally, research into alternative energy storage technologies, such as flow batteries or molten salt storage, may provide more environmentally friendly options for future CSP systems.

In conclusion, while battery acid plays a vital role in enhancing the performance of CSP systems, its environmental impact must be carefully managed through proper handling, containment, and disposal practices. Balancing the benefits of improved energy storage with potential environmental risks is crucial for the sustainable development of CSP technology.

Safety Regulations for Battery Acid in CSP

Safety regulations for battery acid in Concentrated Solar Power (CSP) systems are crucial to ensure the protection of workers, the environment, and the integrity of the system itself. These regulations typically encompass several key areas, including storage, handling, transportation, and disposal of battery acid.

Storage regulations often mandate that battery acid must be kept in sealed, corrosion-resistant containers in well-ventilated areas. These storage facilities should be equipped with appropriate safety features such as spill containment systems, eye wash stations, and emergency showers. Temperature control is also essential, as extreme temperatures can affect the stability of the acid.

Handling procedures are strictly regulated to minimize the risk of exposure. Personal protective equipment (PPE) requirements are typically stringent, including acid-resistant gloves, face shields, and protective clothing. Training programs for personnel working with battery acid are mandatory, covering topics such as proper handling techniques, emergency response procedures, and first aid measures.

Transportation of battery acid for CSP systems is subject to hazardous materials regulations. This includes proper labeling of containers, use of approved transport vehicles, and adherence to specific routing requirements. Documentation, such as material safety data sheets (MSDS), must accompany all shipments.

Disposal regulations are designed to prevent environmental contamination. Neutralization of the acid before disposal is often required, and the resulting waste must be handled by licensed hazardous waste disposal facilities. Recycling of battery acid, when possible, is encouraged to minimize environmental impact.

Emergency response plans are a critical component of safety regulations. These plans must outline procedures for dealing with spills, leaks, or other accidents involving battery acid. Regular drills and training sessions are typically mandated to ensure all personnel are prepared for potential emergencies.

Monitoring and reporting requirements are also part of safety regulations. Regular inspections of storage areas, handling equipment, and safety systems are usually required. Any incidents or near-misses must be reported to relevant authorities, and corrective actions must be implemented to prevent future occurrences.

Compliance with these regulations is often overseen by multiple agencies, including environmental protection agencies, occupational safety and health administrations, and local fire departments. Regular audits and inspections are conducted to ensure ongoing compliance with all applicable regulations.

As technology and understanding of risks evolve, safety regulations for battery acid in CSP systems are periodically reviewed and updated. This ensures that they remain effective in protecting workers, the public, and the environment while allowing for the efficient operation of CSP systems.

Storage regulations often mandate that battery acid must be kept in sealed, corrosion-resistant containers in well-ventilated areas. These storage facilities should be equipped with appropriate safety features such as spill containment systems, eye wash stations, and emergency showers. Temperature control is also essential, as extreme temperatures can affect the stability of the acid.

Handling procedures are strictly regulated to minimize the risk of exposure. Personal protective equipment (PPE) requirements are typically stringent, including acid-resistant gloves, face shields, and protective clothing. Training programs for personnel working with battery acid are mandatory, covering topics such as proper handling techniques, emergency response procedures, and first aid measures.

Transportation of battery acid for CSP systems is subject to hazardous materials regulations. This includes proper labeling of containers, use of approved transport vehicles, and adherence to specific routing requirements. Documentation, such as material safety data sheets (MSDS), must accompany all shipments.

Disposal regulations are designed to prevent environmental contamination. Neutralization of the acid before disposal is often required, and the resulting waste must be handled by licensed hazardous waste disposal facilities. Recycling of battery acid, when possible, is encouraged to minimize environmental impact.

Emergency response plans are a critical component of safety regulations. These plans must outline procedures for dealing with spills, leaks, or other accidents involving battery acid. Regular drills and training sessions are typically mandated to ensure all personnel are prepared for potential emergencies.

Monitoring and reporting requirements are also part of safety regulations. Regular inspections of storage areas, handling equipment, and safety systems are usually required. Any incidents or near-misses must be reported to relevant authorities, and corrective actions must be implemented to prevent future occurrences.

Compliance with these regulations is often overseen by multiple agencies, including environmental protection agencies, occupational safety and health administrations, and local fire departments. Regular audits and inspections are conducted to ensure ongoing compliance with all applicable regulations.

As technology and understanding of risks evolve, safety regulations for battery acid in CSP systems are periodically reviewed and updated. This ensures that they remain effective in protecting workers, the public, and the environment while allowing for the efficient operation of CSP systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!