Comparative evaluation of Composite coatings coating materials and surface engineering

SEP 24, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Composite Coating Technology Background and Objectives

Composite coating technology has evolved significantly over the past several decades, transforming from simple protective layers to sophisticated engineered surfaces with multifunctional properties. The development trajectory began in the 1960s with basic composite electroplating techniques and has since expanded to include various deposition methods such as thermal spraying, physical vapor deposition (PVD), chemical vapor deposition (CVD), and sol-gel processes. This technological evolution has been driven by increasing demands across industries for materials that can withstand extreme conditions while providing enhanced performance characteristics.

The fundamental principle behind composite coatings involves combining two or more distinct materials to create a surface layer with superior properties compared to its individual components. These coatings typically consist of a matrix material (metallic, ceramic, or polymeric) reinforced with secondary phase particles, fibers, or nanostructures. This combination enables the engineering of surfaces with tailored properties such as improved wear resistance, corrosion protection, thermal stability, and reduced friction coefficients.

Recent advancements in nanotechnology have revolutionized the field, allowing for precise control over coating microstructure at the nanoscale. This has led to the development of nanocomposite coatings with exceptional properties, including ultra-hardness, self-healing capabilities, and smart functionalities that respond to environmental stimuli. The integration of computational modeling and simulation tools has further accelerated innovation by enabling the prediction of coating performance and optimization of deposition parameters.

The primary objective of current composite coating research is to develop sustainable, cost-effective solutions that can extend component lifespans while reducing maintenance requirements across critical industries. Specific technical goals include enhancing coating adhesion to substrates, improving homogeneity of particle distribution within matrices, reducing internal stresses, and developing coatings with multiple simultaneous functions such as wear resistance combined with self-lubrication or corrosion protection with thermal barrier properties.

Environmental considerations have also become increasingly important, driving research toward more eco-friendly coating processes that minimize the use of toxic materials and reduce energy consumption. This includes the development of water-based systems, solvent-free processes, and coatings derived from renewable resources. Additionally, there is growing interest in coatings that can contribute to energy efficiency through properties such as reduced friction, improved thermal management, or enhanced electrical conductivity.

The convergence of materials science, surface engineering, and advanced manufacturing technologies presents unprecedented opportunities for innovation in composite coatings, potentially enabling transformative applications in aerospace, automotive, biomedical, energy, and electronics sectors. The ultimate aim is to develop next-generation coating systems that can be precisely tailored to specific operational environments while meeting increasingly stringent performance, economic, and environmental requirements.

The fundamental principle behind composite coatings involves combining two or more distinct materials to create a surface layer with superior properties compared to its individual components. These coatings typically consist of a matrix material (metallic, ceramic, or polymeric) reinforced with secondary phase particles, fibers, or nanostructures. This combination enables the engineering of surfaces with tailored properties such as improved wear resistance, corrosion protection, thermal stability, and reduced friction coefficients.

Recent advancements in nanotechnology have revolutionized the field, allowing for precise control over coating microstructure at the nanoscale. This has led to the development of nanocomposite coatings with exceptional properties, including ultra-hardness, self-healing capabilities, and smart functionalities that respond to environmental stimuli. The integration of computational modeling and simulation tools has further accelerated innovation by enabling the prediction of coating performance and optimization of deposition parameters.

The primary objective of current composite coating research is to develop sustainable, cost-effective solutions that can extend component lifespans while reducing maintenance requirements across critical industries. Specific technical goals include enhancing coating adhesion to substrates, improving homogeneity of particle distribution within matrices, reducing internal stresses, and developing coatings with multiple simultaneous functions such as wear resistance combined with self-lubrication or corrosion protection with thermal barrier properties.

Environmental considerations have also become increasingly important, driving research toward more eco-friendly coating processes that minimize the use of toxic materials and reduce energy consumption. This includes the development of water-based systems, solvent-free processes, and coatings derived from renewable resources. Additionally, there is growing interest in coatings that can contribute to energy efficiency through properties such as reduced friction, improved thermal management, or enhanced electrical conductivity.

The convergence of materials science, surface engineering, and advanced manufacturing technologies presents unprecedented opportunities for innovation in composite coatings, potentially enabling transformative applications in aerospace, automotive, biomedical, energy, and electronics sectors. The ultimate aim is to develop next-generation coating systems that can be precisely tailored to specific operational environments while meeting increasingly stringent performance, economic, and environmental requirements.

Market Analysis of Composite Coating Applications

The global composite coatings market has demonstrated robust growth, valued at approximately $1.2 billion in 2022 and projected to reach $1.8 billion by 2027, representing a compound annual growth rate (CAGR) of 7.8%. This growth is primarily driven by increasing demand across multiple industrial sectors, particularly aerospace, automotive, oil and gas, and medical devices, where enhanced material performance is critical.

In the aerospace sector, composite coatings have gained significant traction due to their ability to provide thermal barrier protection, wear resistance, and corrosion prevention for engine components and structural elements. The sector accounts for roughly 28% of the total composite coatings market, with particular emphasis on ceramic matrix composites that can withstand extreme operating temperatures.

The automotive industry represents another substantial market segment, constituting approximately 25% of global demand. Here, composite coatings are increasingly utilized for both functional and aesthetic purposes, including wear-resistant engine components, corrosion-resistant underbody parts, and decorative exterior finishes. The industry's shift toward lightweight materials and electric vehicles has further accelerated the adoption of advanced composite coating solutions.

Industrial applications, including oil and gas, power generation, and general manufacturing, collectively account for 30% of the market share. In these sectors, composite coatings provide critical protection against harsh operating environments, chemical exposure, and mechanical wear, significantly extending equipment service life and reducing maintenance costs.

Regional analysis reveals that North America and Europe currently dominate the market with combined shares of approximately 60%, attributed to their advanced manufacturing capabilities and stringent performance requirements across industries. However, the Asia-Pacific region is emerging as the fastest-growing market with a CAGR of 9.2%, driven by rapid industrialization in China, India, and Southeast Asian countries.

Consumer preferences are increasingly shifting toward environmentally friendly coating solutions, creating significant opportunities for water-based and powder composite coatings. This trend is reinforced by stringent environmental regulations limiting volatile organic compound (VOC) emissions, particularly in Europe and North America, pushing manufacturers to develop more sustainable formulations without compromising performance characteristics.

Market challenges include high initial costs associated with advanced composite coating technologies and the technical complexity of application processes, which require specialized equipment and expertise. These factors have somewhat limited adoption among small and medium-sized enterprises, though this barrier is gradually diminishing as technologies mature and become more accessible.

In the aerospace sector, composite coatings have gained significant traction due to their ability to provide thermal barrier protection, wear resistance, and corrosion prevention for engine components and structural elements. The sector accounts for roughly 28% of the total composite coatings market, with particular emphasis on ceramic matrix composites that can withstand extreme operating temperatures.

The automotive industry represents another substantial market segment, constituting approximately 25% of global demand. Here, composite coatings are increasingly utilized for both functional and aesthetic purposes, including wear-resistant engine components, corrosion-resistant underbody parts, and decorative exterior finishes. The industry's shift toward lightweight materials and electric vehicles has further accelerated the adoption of advanced composite coating solutions.

Industrial applications, including oil and gas, power generation, and general manufacturing, collectively account for 30% of the market share. In these sectors, composite coatings provide critical protection against harsh operating environments, chemical exposure, and mechanical wear, significantly extending equipment service life and reducing maintenance costs.

Regional analysis reveals that North America and Europe currently dominate the market with combined shares of approximately 60%, attributed to their advanced manufacturing capabilities and stringent performance requirements across industries. However, the Asia-Pacific region is emerging as the fastest-growing market with a CAGR of 9.2%, driven by rapid industrialization in China, India, and Southeast Asian countries.

Consumer preferences are increasingly shifting toward environmentally friendly coating solutions, creating significant opportunities for water-based and powder composite coatings. This trend is reinforced by stringent environmental regulations limiting volatile organic compound (VOC) emissions, particularly in Europe and North America, pushing manufacturers to develop more sustainable formulations without compromising performance characteristics.

Market challenges include high initial costs associated with advanced composite coating technologies and the technical complexity of application processes, which require specialized equipment and expertise. These factors have somewhat limited adoption among small and medium-sized enterprises, though this barrier is gradually diminishing as technologies mature and become more accessible.

Current Challenges in Surface Engineering Technologies

Despite significant advancements in surface engineering technologies, several critical challenges continue to impede the widespread adoption and optimization of composite coating materials. Material compatibility issues remain at the forefront, particularly when developing multi-layer composite coatings where thermal expansion coefficient mismatches can lead to delamination and premature failure under thermal cycling conditions. This challenge becomes especially pronounced when integrating ceramic and metallic components within the same coating system.

Adhesion strength between the substrate and coating layers presents another persistent challenge. Current bonding mechanisms often fail to provide sufficient interfacial strength for applications subjected to extreme mechanical stresses or thermal shock. The development of robust intermediate layers or novel surface preparation techniques is necessary to overcome these limitations.

Uniformity and thickness control during deposition processes continue to challenge manufacturers, particularly for components with complex geometries. Conventional methods like physical vapor deposition (PVD) and chemical vapor deposition (CVD) struggle to achieve consistent coating properties on intricate surfaces, leading to performance variations across the coated component.

Porosity management represents another significant hurdle in composite coating development. While some applications benefit from controlled porosity, many high-performance environments require near-zero porosity to prevent corrosion pathways and mechanical weak points. Current technologies often fail to simultaneously optimize both porosity levels and other critical properties like hardness and wear resistance.

The environmental impact of coating processes has emerged as a growing concern. Traditional electroplating and thermal spray techniques often involve hazardous materials and generate significant waste. Developing environmentally sustainable alternatives while maintaining performance characteristics presents a complex engineering challenge that requires interdisciplinary approaches.

Cost-effectiveness remains a barrier to widespread industrial adoption. Many advanced composite coating technologies demand specialized equipment and expertise, limiting their application to high-value components. Scaling these technologies for mass production without compromising quality standards requires innovative process engineering solutions.

Quality control and non-destructive testing methodologies for composite coatings are still inadequate. Current inspection techniques often fail to detect subsurface defects or accurately characterize coating properties without damaging the component. This limitation creates uncertainty in performance predictions and complicates quality assurance protocols.

Finally, the lack of standardized testing protocols and performance metrics specifically designed for composite coatings hinders comparative evaluation across different technologies. Establishing industry-wide standards that accurately reflect in-service conditions would significantly advance the field and facilitate more informed material selection decisions.

Adhesion strength between the substrate and coating layers presents another persistent challenge. Current bonding mechanisms often fail to provide sufficient interfacial strength for applications subjected to extreme mechanical stresses or thermal shock. The development of robust intermediate layers or novel surface preparation techniques is necessary to overcome these limitations.

Uniformity and thickness control during deposition processes continue to challenge manufacturers, particularly for components with complex geometries. Conventional methods like physical vapor deposition (PVD) and chemical vapor deposition (CVD) struggle to achieve consistent coating properties on intricate surfaces, leading to performance variations across the coated component.

Porosity management represents another significant hurdle in composite coating development. While some applications benefit from controlled porosity, many high-performance environments require near-zero porosity to prevent corrosion pathways and mechanical weak points. Current technologies often fail to simultaneously optimize both porosity levels and other critical properties like hardness and wear resistance.

The environmental impact of coating processes has emerged as a growing concern. Traditional electroplating and thermal spray techniques often involve hazardous materials and generate significant waste. Developing environmentally sustainable alternatives while maintaining performance characteristics presents a complex engineering challenge that requires interdisciplinary approaches.

Cost-effectiveness remains a barrier to widespread industrial adoption. Many advanced composite coating technologies demand specialized equipment and expertise, limiting their application to high-value components. Scaling these technologies for mass production without compromising quality standards requires innovative process engineering solutions.

Quality control and non-destructive testing methodologies for composite coatings are still inadequate. Current inspection techniques often fail to detect subsurface defects or accurately characterize coating properties without damaging the component. This limitation creates uncertainty in performance predictions and complicates quality assurance protocols.

Finally, the lack of standardized testing protocols and performance metrics specifically designed for composite coatings hinders comparative evaluation across different technologies. Establishing industry-wide standards that accurately reflect in-service conditions would significantly advance the field and facilitate more informed material selection decisions.

State-of-the-Art Composite Coating Solutions

01 Metal-based composite coatings

Metal-based composite coatings involve the application of metallic materials combined with other substances to create protective layers with enhanced properties. These coatings typically incorporate metals like aluminum, zinc, or nickel with various additives to improve corrosion resistance, wear resistance, and durability. The metal components provide structural integrity while the additives contribute specific functional properties, resulting in coatings suitable for industrial applications requiring high performance under harsh conditions.- Metal-based composite coatings: Metal-based composite coatings combine metallic materials with other components to enhance properties such as corrosion resistance, wear resistance, and durability. These coatings often incorporate particles or fibers within a metal matrix to achieve superior performance characteristics. The metal matrix provides structural integrity while the embedded materials contribute specific functional properties, making these coatings suitable for industrial applications requiring protection against harsh environments.

- Polymer-based composite coatings: Polymer-based composite coatings utilize polymeric materials as the primary matrix with various additives to enhance specific properties. These coatings offer advantages such as flexibility, chemical resistance, and ease of application. By incorporating functional fillers, nanoparticles, or reinforcing agents into the polymer matrix, these coatings can be tailored for applications ranging from protective barriers to decorative finishes, providing improved adhesion and environmental protection.

- Ceramic and inorganic composite coatings: Ceramic and inorganic composite coatings combine ceramic materials with other components to create high-performance surface treatments. These coatings typically offer exceptional thermal stability, hardness, and resistance to extreme conditions. By incorporating various inorganic materials, these composites can provide enhanced properties such as thermal barrier effects, electrical insulation, or specialized optical characteristics, making them suitable for applications in aerospace, energy, and high-temperature industrial environments.

- Multi-layer composite coating systems: Multi-layer composite coating systems consist of strategically designed layers of different materials to achieve synergistic protective and functional properties. Each layer serves a specific purpose, such as adhesion promotion, barrier protection, or functional performance. This approach allows for the combination of materials that might otherwise be incompatible in a single layer, enabling customized solutions for complex protection requirements and extending the service life of the coated substrates.

- Environmentally friendly composite coatings: Environmentally friendly composite coatings focus on sustainable materials and processes that reduce environmental impact while maintaining performance requirements. These coatings typically eliminate or minimize hazardous components such as volatile organic compounds (VOCs), heavy metals, and other toxic substances. By utilizing bio-based materials, water-based formulations, or renewable resources, these composite coatings address growing regulatory requirements and market demand for sustainable protection solutions across various industries.

02 Polymer-based composite coatings

Polymer-based composite coatings combine organic polymers with various fillers, additives, or reinforcing materials to create versatile protective layers. These coatings offer benefits such as flexibility, chemical resistance, and ease of application. By incorporating different additives into the polymer matrix, properties like UV resistance, water repellency, and adhesion can be enhanced. These coatings are widely used in applications requiring environmental protection, decorative finishes, or specialized functional properties.Expand Specific Solutions03 Ceramic and inorganic composite coatings

Ceramic and inorganic composite coatings utilize non-metallic inorganic materials to create highly durable protective layers. These coatings typically incorporate ceramic particles, oxides, or other inorganic compounds to provide exceptional thermal stability, hardness, and wear resistance. The composite structure allows for customization of properties such as thermal conductivity, electrical insulation, and chemical inertness. These coatings are particularly valuable in high-temperature applications, abrasive environments, or situations requiring electrical isolation.Expand Specific Solutions04 Nanocomposite coatings

Nanocomposite coatings incorporate nanoscale particles or structures within a coating matrix to achieve enhanced performance characteristics. By dispersing nanoparticles throughout the coating, properties such as hardness, scratch resistance, and barrier protection can be significantly improved while maintaining other desirable coating attributes. The nanoscale components create unique interactions at the molecular level, resulting in synergistic effects that cannot be achieved with conventional materials. These advanced coatings find applications in electronics, automotive, aerospace, and other high-tech industries.Expand Specific Solutions05 Functional composite coatings with special properties

Functional composite coatings are designed with specific performance characteristics to address particular application requirements. These specialized coatings may offer properties such as self-healing capabilities, antimicrobial activity, thermal management, or sensing functions. By carefully selecting and combining coating components, manufacturers can create tailored solutions for unique challenges. The composite nature allows for the integration of multiple functionalities within a single coating system, providing efficient solutions for complex protection or performance needs.Expand Specific Solutions

Leading Companies and Research Institutions in Surface Engineering

The composite coatings market is currently in a growth phase, characterized by increasing adoption across aerospace, automotive, and industrial sectors. The global market size is estimated to exceed $1.5 billion, with projected annual growth of 5-7% driven by demand for enhanced surface properties and material performance. Technologically, the field shows varying maturity levels, with companies like Boeing and Airbus leading aerospace applications, while PPG Industries and Nippon Paint dominate industrial coatings. BASF and Kennametal are advancing material science innovations, particularly in wear-resistant and thermal barrier coatings. Academic institutions including Washington University and ETH Zurich are contributing fundamental research, creating a competitive landscape where industry-academic partnerships increasingly drive innovation in specialized applications and sustainable coating technologies.

Airbus Group Ltd.

Technical Solution: Airbus Group has developed sophisticated composite coating technologies specifically engineered for aerospace applications. Their advanced surface engineering approach includes multi-functional coatings that simultaneously provide corrosion protection, ice repellency, and drag reduction. Airbus's proprietary ACARE (Advanced Coating for Aerodynamic Resistance Enhancement) system utilizes nano-structured ceramic particles dispersed in a polymer matrix to create self-cleaning surfaces that maintain optimal aerodynamic performance in diverse environmental conditions[1]. Their lightning strike protection coatings incorporate conductive carbon nanotube networks within composite structures, providing electromagnetic shielding while minimizing weight penalties. Airbus has also pioneered environmentally compliant chromium-free conversion coatings that meet stringent aerospace performance requirements while reducing environmental impact[2]. Recent innovations include smart coating systems with embedded sensors that can detect and report structural stresses or environmental damage before visible signs appear[3].

Strengths: Exceptional durability in extreme aerospace environments; comprehensive testing protocols ensuring reliability; integration with structural health monitoring systems; compliance with strict aviation safety standards. Weaknesses: High implementation costs; complex application processes requiring specialized equipment; longer development cycles for certification; weight considerations for certain applications.

Kennametal, Inc.

Technical Solution: Kennametal has developed proprietary PVD (Physical Vapor Deposition) and CVD (Chemical Vapor Deposition) coating technologies specifically engineered for extreme wear applications in industrial settings. Their KCSM™ (Kennametal Composite Surface Modification) technology creates multi-layered composite coatings with alternating hard and tough layers to optimize both wear resistance and impact strength[1]. The company's KENGold™ coating system utilizes titanium aluminum nitride (TiAlN) with proprietary nanocomposite structures that significantly extend tool life in high-temperature machining operations[2]. Kennametal's surface engineering approach includes precise control of coating microstructure, with grain sizes optimized down to 10-25 nm to enhance hardness without sacrificing toughness. Their coatings incorporate gradient interfaces between substrate and coating layers to minimize stress concentration and improve adhesion under thermal cycling conditions[3].

Strengths: Exceptional wear resistance in extreme environments; precise thickness control (±0.5μm); excellent thermal stability up to 1100°C; proven performance in metal cutting applications. Weaknesses: Higher initial cost compared to uncoated tools; limited flexibility for complex geometries; requires specialized equipment for application.

Key Innovations in Coating Material Science

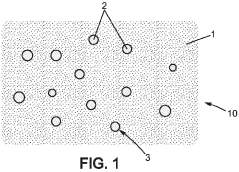

SURFACE COVERING COMPOSITE material

PatentActiveFR3019087A1

Innovation

- A composite surface coating material comprising two distinct materials, one hardening at a first threshold temperature and the other at a higher second threshold temperature, with the second material encapsulated in the first, providing thermal resistance and self-healing properties.

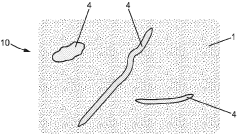

Composite material having improved aesthetics and color after secondary operations

PatentInactiveUS20210252833A1

Innovation

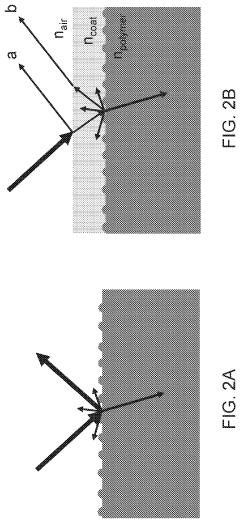

- Applying a transparent polymer surface coating with a refractive index between 1 and 2 to the thermoplastic polymer layer after secondary processes, which reduces surface roughness and diffuse reflectance, improving the material's appearance and chemical resistance.

Environmental Impact and Sustainability Considerations

The environmental impact of composite coating technologies has become increasingly significant as industries strive for sustainable manufacturing practices. Traditional coating processes often involve hazardous chemicals, high energy consumption, and substantial waste generation. Composite coatings, while offering superior performance characteristics, must be evaluated through a comprehensive sustainability lens that considers their entire lifecycle environmental footprint.

Recent life cycle assessments of various composite coating materials reveal significant variations in environmental impact. For instance, ceramic-based composite coatings typically require high-temperature processing, resulting in considerable energy consumption and associated carbon emissions. Conversely, polymer-based composites often utilize solvents that contribute to volatile organic compound (VOC) emissions, affecting air quality and posing health risks to workers and surrounding communities.

Water consumption represents another critical environmental consideration. Wet deposition methods for composite coatings can require substantial water resources, while subsequent treatment of contaminated wastewater adds further environmental and economic burdens. Advanced dry deposition techniques have emerged as promising alternatives, reducing water usage by up to 80% compared to conventional methods.

Waste management challenges persist throughout the composite coating lifecycle. The heterogeneous nature of composite materials often complicates recycling efforts, with many coated components ultimately destined for landfills. Innovative approaches to coating design now incorporate end-of-life considerations, including the development of biodegradable polymer matrices and easily separable composite structures that facilitate material recovery.

Regulatory frameworks worldwide are increasingly addressing the environmental aspects of surface engineering technologies. The European Union's REACH regulations have significantly restricted the use of hexavalent chromium and other hazardous substances commonly used in traditional coating processes, driving innovation toward greener alternatives. Similarly, the United States EPA has established stricter emissions standards for coating operations, catalyzing industry adoption of low-VOC and water-based composite coating systems.

Industry leaders are responding with sustainable coating innovations that maintain performance while reducing environmental impact. Bio-based composite coatings derived from renewable resources such as lignin, cellulose, and vegetable oils demonstrate promising corrosion resistance and mechanical properties while significantly reducing carbon footprint. Additionally, energy-efficient application technologies like UV-curable composite coatings minimize energy consumption by eliminating high-temperature curing requirements.

The transition toward circular economy principles is reshaping composite coating development strategies. Design for disassembly, material recovery, and remanufacturing are increasingly incorporated into coating selection criteria alongside traditional performance metrics. This holistic approach ensures that environmental considerations are integrated throughout the coating lifecycle rather than addressed as afterthoughts.

Recent life cycle assessments of various composite coating materials reveal significant variations in environmental impact. For instance, ceramic-based composite coatings typically require high-temperature processing, resulting in considerable energy consumption and associated carbon emissions. Conversely, polymer-based composites often utilize solvents that contribute to volatile organic compound (VOC) emissions, affecting air quality and posing health risks to workers and surrounding communities.

Water consumption represents another critical environmental consideration. Wet deposition methods for composite coatings can require substantial water resources, while subsequent treatment of contaminated wastewater adds further environmental and economic burdens. Advanced dry deposition techniques have emerged as promising alternatives, reducing water usage by up to 80% compared to conventional methods.

Waste management challenges persist throughout the composite coating lifecycle. The heterogeneous nature of composite materials often complicates recycling efforts, with many coated components ultimately destined for landfills. Innovative approaches to coating design now incorporate end-of-life considerations, including the development of biodegradable polymer matrices and easily separable composite structures that facilitate material recovery.

Regulatory frameworks worldwide are increasingly addressing the environmental aspects of surface engineering technologies. The European Union's REACH regulations have significantly restricted the use of hexavalent chromium and other hazardous substances commonly used in traditional coating processes, driving innovation toward greener alternatives. Similarly, the United States EPA has established stricter emissions standards for coating operations, catalyzing industry adoption of low-VOC and water-based composite coating systems.

Industry leaders are responding with sustainable coating innovations that maintain performance while reducing environmental impact. Bio-based composite coatings derived from renewable resources such as lignin, cellulose, and vegetable oils demonstrate promising corrosion resistance and mechanical properties while significantly reducing carbon footprint. Additionally, energy-efficient application technologies like UV-curable composite coatings minimize energy consumption by eliminating high-temperature curing requirements.

The transition toward circular economy principles is reshaping composite coating development strategies. Design for disassembly, material recovery, and remanufacturing are increasingly incorporated into coating selection criteria alongside traditional performance metrics. This holistic approach ensures that environmental considerations are integrated throughout the coating lifecycle rather than addressed as afterthoughts.

Performance Testing and Quality Standards

Performance testing and quality standards for composite coatings represent critical aspects in evaluating their industrial applicability and long-term reliability. Standardized testing protocols established by organizations such as ASTM, ISO, and NACE provide consistent frameworks for assessing coating performance across different applications and environments.

Adhesion testing stands as a fundamental quality parameter, typically conducted through pull-off tests (ASTM D4541) or cross-cut tests (ASTM D3359). These methods quantify the bonding strength between the coating and substrate, which directly correlates with service life and resistance to delamination under mechanical stress or thermal cycling.

Corrosion resistance evaluation employs accelerated testing methods including salt spray exposure (ASTM B117), electrochemical impedance spectroscopy, and cyclic corrosion tests. These procedures simulate aggressive environments to predict long-term performance and identify potential failure mechanisms. Modern standards increasingly emphasize the importance of testing under conditions that accurately represent actual service environments.

Wear resistance assessment utilizes pin-on-disk tribometers, taber abraser tests, and scratch testing to quantify material loss rates and surface damage mechanisms. The ASTM G99 and ASTM G65 standards provide methodologies for comparing different coating systems under controlled conditions, enabling objective performance rankings based on specific wear mechanisms.

Thermal performance standards evaluate coating stability across operational temperature ranges, including thermal shock resistance (ASTM D6944) and thermal cycling endurance. These tests are particularly crucial for applications in aerospace, automotive, and energy sectors where components experience extreme temperature variations.

Chemical resistance testing follows protocols such as ASTM D1308 and ISO 2812, exposing coatings to industry-specific chemicals to assess degradation, discoloration, or functional property changes. The development of application-specific testing standards has enhanced the relevance of performance data for specialized environments.

Quality control standards increasingly incorporate non-destructive evaluation techniques including ultrasonic testing, thermography, and spectroscopic methods. These approaches enable in-process monitoring and post-application inspection without compromising coating integrity, supporting both manufacturing quality assurance and in-service inspection protocols.

Emerging standards now address environmental impact and sustainability metrics, evaluating VOC content, leaching behavior, and end-of-life recyclability. This evolution reflects growing regulatory requirements and market demand for environmentally responsible coating technologies while maintaining performance requirements.

Adhesion testing stands as a fundamental quality parameter, typically conducted through pull-off tests (ASTM D4541) or cross-cut tests (ASTM D3359). These methods quantify the bonding strength between the coating and substrate, which directly correlates with service life and resistance to delamination under mechanical stress or thermal cycling.

Corrosion resistance evaluation employs accelerated testing methods including salt spray exposure (ASTM B117), electrochemical impedance spectroscopy, and cyclic corrosion tests. These procedures simulate aggressive environments to predict long-term performance and identify potential failure mechanisms. Modern standards increasingly emphasize the importance of testing under conditions that accurately represent actual service environments.

Wear resistance assessment utilizes pin-on-disk tribometers, taber abraser tests, and scratch testing to quantify material loss rates and surface damage mechanisms. The ASTM G99 and ASTM G65 standards provide methodologies for comparing different coating systems under controlled conditions, enabling objective performance rankings based on specific wear mechanisms.

Thermal performance standards evaluate coating stability across operational temperature ranges, including thermal shock resistance (ASTM D6944) and thermal cycling endurance. These tests are particularly crucial for applications in aerospace, automotive, and energy sectors where components experience extreme temperature variations.

Chemical resistance testing follows protocols such as ASTM D1308 and ISO 2812, exposing coatings to industry-specific chemicals to assess degradation, discoloration, or functional property changes. The development of application-specific testing standards has enhanced the relevance of performance data for specialized environments.

Quality control standards increasingly incorporate non-destructive evaluation techniques including ultrasonic testing, thermography, and spectroscopic methods. These approaches enable in-process monitoring and post-application inspection without compromising coating integrity, supporting both manufacturing quality assurance and in-service inspection protocols.

Emerging standards now address environmental impact and sustainability metrics, evaluating VOC content, leaching behavior, and end-of-life recyclability. This evolution reflects growing regulatory requirements and market demand for environmentally responsible coating technologies while maintaining performance requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!