Research on Composite coatings material properties and surface engineering

SEP 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Composite Coating Technology Evolution and Objectives

Composite coating technology has evolved significantly over the past several decades, transforming from simple protective layers to sophisticated engineered surfaces with multifunctional properties. The journey began in the 1950s with basic metal plating techniques and has now advanced to nanomaterial-enhanced composite coatings that offer unprecedented performance characteristics. This evolution has been driven by increasing industrial demands for materials that can withstand extreme conditions while providing additional functionalities beyond mere protection.

The development trajectory shows a clear shift from single-property coatings to multi-functional systems. Early composite coatings primarily focused on corrosion resistance and wear protection, whereas modern variants incorporate self-healing capabilities, antimicrobial properties, and smart responsive features. This progression reflects the growing understanding of surface engineering principles and material science fundamentals that govern coating performance.

Recent technological breakthroughs in polymer science, nanotechnology, and advanced manufacturing have accelerated innovation in composite coating formulations. The integration of nanoparticles, carbon-based materials, and ceramic components has enabled the creation of hybrid systems with synergistic properties that far exceed those of traditional coatings. These advancements have opened new possibilities for tailoring surface properties at the molecular level.

The primary objectives of current composite coating research center on enhancing durability, reducing environmental impact, and expanding functionality. Researchers aim to develop coatings that can maintain performance integrity under increasingly demanding conditions, including extreme temperatures, chemical exposure, and mechanical stress. Simultaneously, there is a strong push toward environmentally friendly formulations that eliminate toxic components while maintaining or improving performance metrics.

Another critical goal is the development of scalable manufacturing processes that can transition laboratory innovations to industrial applications. This includes addressing challenges related to uniform dispersion of reinforcement materials, adhesion optimization, and cost-effective production methods suitable for large-scale implementation across various industries.

Looking forward, the field is moving toward predictive design approaches that leverage computational modeling and artificial intelligence to accelerate the discovery of novel coating compositions. The integration of digital tools with experimental techniques promises to revolutionize how composite coatings are conceptualized, tested, and optimized. This represents a paradigm shift from traditional empirical methods to knowledge-based design strategies that can significantly reduce development time and resources.

The development trajectory shows a clear shift from single-property coatings to multi-functional systems. Early composite coatings primarily focused on corrosion resistance and wear protection, whereas modern variants incorporate self-healing capabilities, antimicrobial properties, and smart responsive features. This progression reflects the growing understanding of surface engineering principles and material science fundamentals that govern coating performance.

Recent technological breakthroughs in polymer science, nanotechnology, and advanced manufacturing have accelerated innovation in composite coating formulations. The integration of nanoparticles, carbon-based materials, and ceramic components has enabled the creation of hybrid systems with synergistic properties that far exceed those of traditional coatings. These advancements have opened new possibilities for tailoring surface properties at the molecular level.

The primary objectives of current composite coating research center on enhancing durability, reducing environmental impact, and expanding functionality. Researchers aim to develop coatings that can maintain performance integrity under increasingly demanding conditions, including extreme temperatures, chemical exposure, and mechanical stress. Simultaneously, there is a strong push toward environmentally friendly formulations that eliminate toxic components while maintaining or improving performance metrics.

Another critical goal is the development of scalable manufacturing processes that can transition laboratory innovations to industrial applications. This includes addressing challenges related to uniform dispersion of reinforcement materials, adhesion optimization, and cost-effective production methods suitable for large-scale implementation across various industries.

Looking forward, the field is moving toward predictive design approaches that leverage computational modeling and artificial intelligence to accelerate the discovery of novel coating compositions. The integration of digital tools with experimental techniques promises to revolutionize how composite coatings are conceptualized, tested, and optimized. This represents a paradigm shift from traditional empirical methods to knowledge-based design strategies that can significantly reduce development time and resources.

Market Analysis of Advanced Surface Engineering Solutions

The global market for advanced surface engineering solutions has experienced robust growth in recent years, driven by increasing demand across multiple industries for enhanced material performance and longevity. The composite coatings segment specifically has emerged as a high-growth area, with the market valued at approximately $1.5 billion in 2022 and projected to reach $2.3 billion by 2027, representing a compound annual growth rate of 8.9%.

Key industries driving this market expansion include aerospace, automotive, medical devices, and industrial manufacturing. In aerospace applications, the demand for lightweight yet durable components has spurred innovation in ceramic-metal composite coatings that can withstand extreme temperatures while providing corrosion resistance. The automotive sector increasingly requires wear-resistant coatings for engine components to improve fuel efficiency and reduce emissions, creating a substantial market opportunity.

Regional analysis reveals that North America and Europe currently dominate the advanced surface engineering market, collectively accounting for over 60% of global revenue. However, the Asia-Pacific region is witnessing the fastest growth rate at approximately 10.5% annually, primarily driven by rapid industrialization in China and India, along with significant investments in manufacturing infrastructure.

Customer requirements are evolving toward more specialized solutions, with growing emphasis on environmentally sustainable coating technologies. Water-based and powder coating systems are gaining market share over traditional solvent-based systems, reflecting stricter environmental regulations and corporate sustainability initiatives. This shift has created new market segments for eco-friendly composite coatings with reduced volatile organic compound (VOC) emissions.

Economic factors influencing market dynamics include raw material price volatility, particularly for rare earth elements and specialized ceramics used in high-performance coatings. Labor costs for skilled technicians capable of applying advanced coatings have also risen, impacting overall service pricing structures in the industry.

Market forecasts indicate particularly strong growth in nanocomposite coatings, which are expected to grow at 12.3% annually through 2027. These advanced materials offer unprecedented combinations of hardness, flexibility, and chemical resistance, opening new application possibilities across industries. Self-healing coatings represent another emerging segment with significant commercial potential, especially in infrastructure and transportation applications where maintenance costs are a major concern.

Customer adoption patterns show increasing preference for integrated surface engineering solutions that combine coating technologies with comprehensive testing and maintenance services, suggesting opportunities for value-added service offerings in this market space.

Key industries driving this market expansion include aerospace, automotive, medical devices, and industrial manufacturing. In aerospace applications, the demand for lightweight yet durable components has spurred innovation in ceramic-metal composite coatings that can withstand extreme temperatures while providing corrosion resistance. The automotive sector increasingly requires wear-resistant coatings for engine components to improve fuel efficiency and reduce emissions, creating a substantial market opportunity.

Regional analysis reveals that North America and Europe currently dominate the advanced surface engineering market, collectively accounting for over 60% of global revenue. However, the Asia-Pacific region is witnessing the fastest growth rate at approximately 10.5% annually, primarily driven by rapid industrialization in China and India, along with significant investments in manufacturing infrastructure.

Customer requirements are evolving toward more specialized solutions, with growing emphasis on environmentally sustainable coating technologies. Water-based and powder coating systems are gaining market share over traditional solvent-based systems, reflecting stricter environmental regulations and corporate sustainability initiatives. This shift has created new market segments for eco-friendly composite coatings with reduced volatile organic compound (VOC) emissions.

Economic factors influencing market dynamics include raw material price volatility, particularly for rare earth elements and specialized ceramics used in high-performance coatings. Labor costs for skilled technicians capable of applying advanced coatings have also risen, impacting overall service pricing structures in the industry.

Market forecasts indicate particularly strong growth in nanocomposite coatings, which are expected to grow at 12.3% annually through 2027. These advanced materials offer unprecedented combinations of hardness, flexibility, and chemical resistance, opening new application possibilities across industries. Self-healing coatings represent another emerging segment with significant commercial potential, especially in infrastructure and transportation applications where maintenance costs are a major concern.

Customer adoption patterns show increasing preference for integrated surface engineering solutions that combine coating technologies with comprehensive testing and maintenance services, suggesting opportunities for value-added service offerings in this market space.

Current Challenges in Composite Coating Development

Despite significant advancements in composite coating technologies, several critical challenges continue to impede further development and widespread industrial application. One of the most persistent issues is achieving consistent adhesion between the coating and substrate across diverse environmental conditions. Temperature fluctuations, chemical exposure, and mechanical stress often lead to delamination and coating failure, particularly in harsh industrial environments where performance requirements are most demanding.

Controlling microstructure uniformity presents another significant challenge. Current manufacturing processes struggle to maintain consistent particle distribution throughout the coating matrix, resulting in localized weaknesses and performance variability. This heterogeneity becomes particularly problematic when scaling production from laboratory to industrial levels, where maintaining quality across larger surface areas becomes exponentially more difficult.

Wear resistance optimization remains elusive, especially when balancing against other desirable properties. Engineers frequently encounter trade-offs between hardness and toughness, where increasing one property often diminishes the other. This fundamental materials science challenge requires innovative approaches to microstructure design and composition formulation that can simultaneously enhance multiple performance parameters.

Environmental concerns and regulatory compliance have emerged as increasingly significant barriers. Traditional composite coating processes often involve environmentally harmful substances such as hexavalent chromium, cadmium, and various volatile organic compounds. Developing eco-friendly alternatives that maintain or exceed performance specifications of conventional coatings represents a complex technical challenge requiring multidisciplinary approaches.

Cost-effectiveness continues to limit widespread adoption, particularly for advanced composite coatings. High-performance materials, specialized equipment, and complex application processes contribute to prohibitive costs that make implementation economically unfeasible for many potential applications. Reducing these costs without compromising performance remains a critical industry challenge.

Characterization and testing methodologies present additional hurdles. Current analytical techniques often provide insufficient resolution to fully understand nanoscale interactions within composite coatings, limiting the ability to optimize formulations based on fundamental material behavior. Furthermore, accelerated testing protocols frequently fail to accurately predict long-term performance in real-world conditions, creating uncertainty in lifetime predictions and reliability assessments.

Multifunctionality requirements have increased substantially, with modern applications demanding coatings that simultaneously provide corrosion protection, wear resistance, thermal management, and even self-healing capabilities. Developing composite systems that can effectively integrate these diverse functions without compromising individual performance metrics represents perhaps the most ambitious challenge facing researchers and engineers in this field.

Controlling microstructure uniformity presents another significant challenge. Current manufacturing processes struggle to maintain consistent particle distribution throughout the coating matrix, resulting in localized weaknesses and performance variability. This heterogeneity becomes particularly problematic when scaling production from laboratory to industrial levels, where maintaining quality across larger surface areas becomes exponentially more difficult.

Wear resistance optimization remains elusive, especially when balancing against other desirable properties. Engineers frequently encounter trade-offs between hardness and toughness, where increasing one property often diminishes the other. This fundamental materials science challenge requires innovative approaches to microstructure design and composition formulation that can simultaneously enhance multiple performance parameters.

Environmental concerns and regulatory compliance have emerged as increasingly significant barriers. Traditional composite coating processes often involve environmentally harmful substances such as hexavalent chromium, cadmium, and various volatile organic compounds. Developing eco-friendly alternatives that maintain or exceed performance specifications of conventional coatings represents a complex technical challenge requiring multidisciplinary approaches.

Cost-effectiveness continues to limit widespread adoption, particularly for advanced composite coatings. High-performance materials, specialized equipment, and complex application processes contribute to prohibitive costs that make implementation economically unfeasible for many potential applications. Reducing these costs without compromising performance remains a critical industry challenge.

Characterization and testing methodologies present additional hurdles. Current analytical techniques often provide insufficient resolution to fully understand nanoscale interactions within composite coatings, limiting the ability to optimize formulations based on fundamental material behavior. Furthermore, accelerated testing protocols frequently fail to accurately predict long-term performance in real-world conditions, creating uncertainty in lifetime predictions and reliability assessments.

Multifunctionality requirements have increased substantially, with modern applications demanding coatings that simultaneously provide corrosion protection, wear resistance, thermal management, and even self-healing capabilities. Developing composite systems that can effectively integrate these diverse functions without compromising individual performance metrics represents perhaps the most ambitious challenge facing researchers and engineers in this field.

Contemporary Composite Coating Methodologies

01 Ceramic-based composite coatings for enhanced durability

Ceramic-based composite coatings provide superior durability and resistance to harsh environments. These coatings typically incorporate ceramic particles or matrices combined with other materials to enhance properties such as wear resistance, thermal stability, and corrosion protection. The ceramic components often include alumina, zirconia, or silicon carbide, which contribute to the coating's hardness and longevity while maintaining relatively lightweight characteristics.- Ceramic-based composite coatings for enhanced durability: Ceramic-based composite coatings provide exceptional durability and resistance to harsh environments. These coatings typically incorporate ceramic particles or matrices combined with other materials to enhance properties such as wear resistance, thermal stability, and corrosion protection. The ceramic components often include alumina, zirconia, or silicon carbide, which contribute to the coating's hardness and resistance to degradation. These composite structures can be applied through various deposition methods to achieve optimal adhesion and performance characteristics.

- Polymer-metal hybrid coatings for corrosion resistance: Polymer-metal hybrid coatings combine the flexibility and processing advantages of polymers with the strength and conductivity of metals to create superior corrosion-resistant surfaces. These composite coatings typically feature metal particles or layers embedded within or bonded to polymer matrices, creating synergistic protection mechanisms. The polymer components provide barrier protection and flexibility, while the metallic elements contribute to electrochemical protection and mechanical strength. These hybrid systems can be tailored to specific environmental conditions and substrate materials for optimized performance.

- Nanocomposite coatings with enhanced mechanical properties: Nanocomposite coatings incorporate nanoscale particles or structures to significantly enhance mechanical properties beyond what conventional coatings can achieve. By dispersing nanoparticles such as carbon nanotubes, graphene, or metal oxide nanoparticles within a matrix material, these coatings exhibit improved hardness, tensile strength, and impact resistance while maintaining flexibility. The nanoscale reinforcement creates unique interfacial interactions that contribute to crack deflection and energy absorption mechanisms. These advanced materials can be engineered to provide multifunctional properties including self-healing capabilities and reduced friction coefficients.

- Thermal barrier composite coatings for high-temperature applications: Thermal barrier composite coatings are specifically designed to protect substrates from extreme temperature environments. These multilayered systems typically combine ceramic top layers with metallic bond coats to provide both thermal insulation and adhesion to the substrate. The composite structure creates controlled thermal gradients and accommodates differences in thermal expansion between components. Advanced formulations may incorporate porosity, phase-change materials, or reflective particles to enhance thermal management capabilities. These coatings are crucial for extending the service life of components in aerospace, power generation, and industrial processing applications.

- Self-healing composite coating technologies: Self-healing composite coatings represent an innovative approach to extending coating lifespan by autonomously repairing damage. These systems incorporate healing agents such as microencapsulated resins, shape memory polymers, or reversible chemical bonds that activate in response to damage. When cracks or scratches occur, the healing mechanisms are triggered by environmental stimuli or the damage itself, restoring the coating's protective properties. This technology significantly improves long-term durability by preventing small defects from propagating into catastrophic failures. Advanced formulations may combine multiple healing mechanisms to address different types of damage across varying environmental conditions.

02 Polymer-metal composite coatings for corrosion resistance

Polymer-metal composite coatings combine the flexibility and processing advantages of polymers with the strength and conductivity of metals to create protective layers with excellent corrosion resistance. These coatings typically incorporate metal particles or nanoparticles dispersed within a polymer matrix, creating a barrier that prevents moisture and corrosive agents from reaching the substrate. The polymer component provides adhesion and flexibility while the metallic elements enhance mechanical strength and provide sacrificial protection.Expand Specific Solutions03 Nanocomposite coatings for improved mechanical properties

Nanocomposite coatings incorporate nanoscale particles or structures to significantly enhance mechanical properties including hardness, toughness, and wear resistance. By dispersing nanoparticles such as carbon nanotubes, graphene, or metal oxide nanoparticles within a matrix material, these coatings achieve superior performance through mechanisms like crack deflection and load transfer. The nanoscale reinforcement creates a material with enhanced strength-to-weight ratio and improved resistance to mechanical deformation while maintaining good adhesion to substrates.Expand Specific Solutions04 Thermal barrier composite coatings for high-temperature applications

Thermal barrier composite coatings are designed to protect substrates from extreme temperatures by providing insulation and heat reflection properties. These coatings typically consist of multiple layers with different thermal expansion coefficients and thermal conductivities. They often incorporate ceramic top layers for heat resistance combined with bond coats that improve adhesion and provide oxidation protection. These specialized coatings are crucial for components operating in high-temperature environments such as gas turbines, aerospace applications, and industrial furnaces.Expand Specific Solutions05 Self-healing composite coatings for extended service life

Self-healing composite coatings incorporate active components that can repair damage automatically when it occurs, extending the service life of the protected substrate. These innovative coatings typically contain microcapsules filled with healing agents or utilize reversible chemical bonds that can reform after being broken. When the coating is damaged, the healing mechanism is triggered either by the damage itself or by external stimuli such as heat or light, allowing the coating to restore its protective properties without external intervention.Expand Specific Solutions

Key Innovations in Material Properties Enhancement

Composite coatings

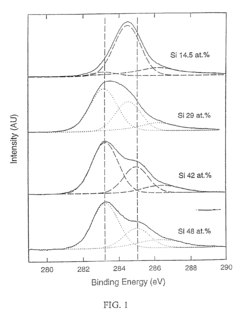

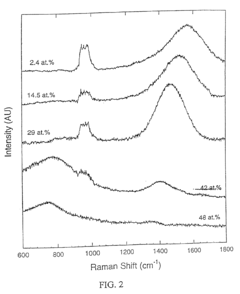

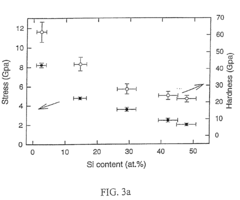

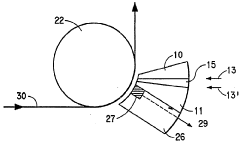

PatentInactiveUS6899828B2

Innovation

- A method using a cathode arc source with a composite target containing carbon and a metallic element, such as silicon or aluminum, to produce composite coatings with reduced stress and improved mechanical properties, achieving films with high sp3 content and low hydrogen content without the need for gaseous compounds.

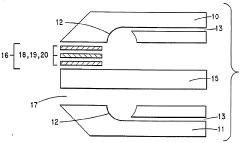

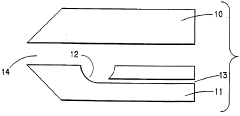

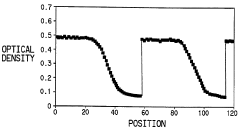

Process for the preparation of composite coatings with variable thickness in the cross-web direction

PatentInactiveCA2202996A1

Innovation

- An asymmetric, non-mirror image design for composite coatings with variable thickness and width in the cross-web direction, utilizing a dummy band for stability and a variable vacuum profile to enhance coating process control and flexibility.

Environmental Impact and Sustainability Considerations

The environmental impact of composite coatings has become a critical consideration in surface engineering research and development. Traditional coating processes often involve hazardous chemicals, high energy consumption, and significant waste generation. Recent studies indicate that approximately 30% of volatile organic compounds (VOCs) emissions in industrial manufacturing come from coating operations, contributing to air pollution and potential health risks for workers and surrounding communities.

Sustainable alternatives are emerging through the development of water-based and solvent-free composite coating systems. These environmentally friendly formulations reduce VOC emissions by up to 90% compared to conventional solvent-based systems while maintaining comparable performance characteristics. Additionally, bio-based components derived from renewable resources such as plant oils, cellulose, and chitosan are increasingly being incorporated into composite coating formulations, reducing dependence on petroleum-based raw materials.

Life cycle assessment (LCA) studies of composite coatings reveal significant opportunities for environmental improvement across the entire product lifecycle. From raw material extraction to end-of-life disposal, each phase presents unique sustainability challenges. Research indicates that extending coating service life through enhanced durability can reduce environmental impact by 40-60% by decreasing the frequency of reapplication and associated resource consumption.

Advanced manufacturing techniques like cold spray deposition and UV-curing systems have demonstrated energy savings of up to 70% compared to traditional thermal processing methods. These technologies not only reduce carbon footprint but also minimize thermal degradation of coating components, potentially improving performance and longevity.

Waste management and recyclability represent another frontier in sustainable composite coating development. Novel approaches include designing coatings with reversible crosslinking mechanisms that facilitate material recovery and reuse. Some research teams have successfully demonstrated recovery rates of up to 85% for certain composite coating materials through selective dissolution processes.

Regulatory frameworks worldwide are increasingly emphasizing environmental compliance for coating technologies. The European Union's REACH regulations, California's stringent VOC limits, and similar policies in Asia are driving innovation toward greener alternatives. Companies investing in sustainable coating technologies often report improved market positioning and customer satisfaction, with sustainability-focused products showing 15-25% higher growth rates than conventional alternatives.

Sustainable alternatives are emerging through the development of water-based and solvent-free composite coating systems. These environmentally friendly formulations reduce VOC emissions by up to 90% compared to conventional solvent-based systems while maintaining comparable performance characteristics. Additionally, bio-based components derived from renewable resources such as plant oils, cellulose, and chitosan are increasingly being incorporated into composite coating formulations, reducing dependence on petroleum-based raw materials.

Life cycle assessment (LCA) studies of composite coatings reveal significant opportunities for environmental improvement across the entire product lifecycle. From raw material extraction to end-of-life disposal, each phase presents unique sustainability challenges. Research indicates that extending coating service life through enhanced durability can reduce environmental impact by 40-60% by decreasing the frequency of reapplication and associated resource consumption.

Advanced manufacturing techniques like cold spray deposition and UV-curing systems have demonstrated energy savings of up to 70% compared to traditional thermal processing methods. These technologies not only reduce carbon footprint but also minimize thermal degradation of coating components, potentially improving performance and longevity.

Waste management and recyclability represent another frontier in sustainable composite coating development. Novel approaches include designing coatings with reversible crosslinking mechanisms that facilitate material recovery and reuse. Some research teams have successfully demonstrated recovery rates of up to 85% for certain composite coating materials through selective dissolution processes.

Regulatory frameworks worldwide are increasingly emphasizing environmental compliance for coating technologies. The European Union's REACH regulations, California's stringent VOC limits, and similar policies in Asia are driving innovation toward greener alternatives. Companies investing in sustainable coating technologies often report improved market positioning and customer satisfaction, with sustainability-focused products showing 15-25% higher growth rates than conventional alternatives.

Standardization and Quality Control Protocols

In the rapidly evolving field of composite coatings, standardization and quality control protocols have become increasingly critical for ensuring consistent performance and reliability. The development of comprehensive standards for composite coating materials requires systematic approaches that address both material properties and surface engineering aspects. Currently, international organizations such as ISO, ASTM, and NACE have established foundational standards, but these often lack specificity for advanced composite coating systems with multiple functionalities.

Quality control protocols for composite coatings typically involve multi-stage testing regimens that evaluate adhesion strength, wear resistance, corrosion protection, and thermal stability. These protocols must be tailored to specific application environments, as performance requirements vary significantly across industries such as aerospace, automotive, and marine applications. The challenge lies in developing universally applicable testing methodologies that can accurately predict long-term performance while remaining practical for industrial implementation.

Non-destructive testing (NDT) methods have gained prominence in quality assurance for composite coatings. Techniques such as ultrasonic inspection, thermography, and electrochemical impedance spectroscopy allow for real-time monitoring of coating integrity without compromising the protective layer. These methods are increasingly being standardized to ensure reproducibility across different manufacturing facilities and research institutions.

Statistical process control (SPC) frameworks specifically designed for composite coating production represent another critical aspect of quality assurance. These frameworks incorporate key performance indicators (KPIs) that track process variables such as deposition rate, temperature uniformity, and raw material consistency. Advanced manufacturing facilities have begun implementing digital twins and AI-based monitoring systems that can detect deviations from optimal processing conditions before they manifest as coating defects.

Certification programs for composite coating applicators and manufacturing facilities have emerged as an important component of the quality ecosystem. These programs establish minimum competency requirements and standardized operating procedures that help maintain consistency across the supply chain. Third-party verification systems provide additional assurance to end-users regarding coating performance and durability claims.

Emerging trends in standardization include the development of accelerated testing protocols that can reliably predict decades of service life within reasonable timeframes. These protocols typically combine environmental cycling with mechanical stressing to simulate real-world conditions. Additionally, there is growing emphasis on standardizing sustainability metrics for composite coatings, including life cycle assessment methodologies and recyclability standards that align with global environmental regulations.

Quality control protocols for composite coatings typically involve multi-stage testing regimens that evaluate adhesion strength, wear resistance, corrosion protection, and thermal stability. These protocols must be tailored to specific application environments, as performance requirements vary significantly across industries such as aerospace, automotive, and marine applications. The challenge lies in developing universally applicable testing methodologies that can accurately predict long-term performance while remaining practical for industrial implementation.

Non-destructive testing (NDT) methods have gained prominence in quality assurance for composite coatings. Techniques such as ultrasonic inspection, thermography, and electrochemical impedance spectroscopy allow for real-time monitoring of coating integrity without compromising the protective layer. These methods are increasingly being standardized to ensure reproducibility across different manufacturing facilities and research institutions.

Statistical process control (SPC) frameworks specifically designed for composite coating production represent another critical aspect of quality assurance. These frameworks incorporate key performance indicators (KPIs) that track process variables such as deposition rate, temperature uniformity, and raw material consistency. Advanced manufacturing facilities have begun implementing digital twins and AI-based monitoring systems that can detect deviations from optimal processing conditions before they manifest as coating defects.

Certification programs for composite coating applicators and manufacturing facilities have emerged as an important component of the quality ecosystem. These programs establish minimum competency requirements and standardized operating procedures that help maintain consistency across the supply chain. Third-party verification systems provide additional assurance to end-users regarding coating performance and durability claims.

Emerging trends in standardization include the development of accelerated testing protocols that can reliably predict decades of service life within reasonable timeframes. These protocols typically combine environmental cycling with mechanical stressing to simulate real-world conditions. Additionally, there is growing emphasis on standardizing sustainability metrics for composite coatings, including life cycle assessment methodologies and recyclability standards that align with global environmental regulations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!