Composite coatings interface engineering for high temperature and chemical stability

SEP 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Composite Coating Interface Engineering Background and Objectives

Composite coating interface engineering has evolved significantly over the past decades, transitioning from simple protective layers to sophisticated multi-functional systems. The development trajectory shows a clear shift from empirical approaches to science-based design methodologies, with increasing focus on nanoscale interface control. This evolution has been driven by growing demands in aerospace, energy, and chemical processing industries where materials must withstand extreme conditions while maintaining structural integrity and functionality.

The fundamental challenge in composite coatings lies at the interface between dissimilar materials, where thermal expansion mismatches, chemical incompatibilities, and diffusion processes often lead to premature failure. Historical approaches relied heavily on trial-and-error optimization, but recent advances in characterization techniques and computational modeling have enabled more predictive and rational design strategies.

Current technological trends indicate a convergence of materials science, surface engineering, and computational methods to address interface stability. The integration of machine learning algorithms with high-throughput experimentation has accelerated the discovery of novel interface engineering solutions, particularly for high-temperature applications exceeding 1000°C and aggressive chemical environments with pH extremes or oxidizing conditions.

The primary objective of composite coating interface engineering is to develop robust coating systems that can maintain structural integrity and functional performance under combined thermal and chemical stresses. Specific goals include extending service lifetimes by at least 50% compared to conventional coatings, reducing interfacial delamination under thermal cycling, and minimizing interdiffusion phenomena that compromise coating performance.

Secondary objectives focus on developing scalable manufacturing processes that can reliably produce these engineered interfaces at industrial scales while maintaining precise control over interfacial chemistry and microstructure. This includes the development of in-situ monitoring techniques to ensure quality control during production.

Long-term research aims to establish fundamental design principles that can predict coating-substrate compatibility and interface evolution under extreme conditions. This knowledge framework would enable rapid development of tailored coating solutions for emerging applications in next-generation energy systems, hypersonic vehicles, and advanced manufacturing processes where materials are subjected to unprecedented combinations of thermal, mechanical, and chemical stresses.

The technological roadmap for achieving these objectives encompasses advances in atomic-level deposition techniques, gradient functional materials, self-healing interfaces, and computational tools capable of simulating long-term interface evolution under complex service conditions.

The fundamental challenge in composite coatings lies at the interface between dissimilar materials, where thermal expansion mismatches, chemical incompatibilities, and diffusion processes often lead to premature failure. Historical approaches relied heavily on trial-and-error optimization, but recent advances in characterization techniques and computational modeling have enabled more predictive and rational design strategies.

Current technological trends indicate a convergence of materials science, surface engineering, and computational methods to address interface stability. The integration of machine learning algorithms with high-throughput experimentation has accelerated the discovery of novel interface engineering solutions, particularly for high-temperature applications exceeding 1000°C and aggressive chemical environments with pH extremes or oxidizing conditions.

The primary objective of composite coating interface engineering is to develop robust coating systems that can maintain structural integrity and functional performance under combined thermal and chemical stresses. Specific goals include extending service lifetimes by at least 50% compared to conventional coatings, reducing interfacial delamination under thermal cycling, and minimizing interdiffusion phenomena that compromise coating performance.

Secondary objectives focus on developing scalable manufacturing processes that can reliably produce these engineered interfaces at industrial scales while maintaining precise control over interfacial chemistry and microstructure. This includes the development of in-situ monitoring techniques to ensure quality control during production.

Long-term research aims to establish fundamental design principles that can predict coating-substrate compatibility and interface evolution under extreme conditions. This knowledge framework would enable rapid development of tailored coating solutions for emerging applications in next-generation energy systems, hypersonic vehicles, and advanced manufacturing processes where materials are subjected to unprecedented combinations of thermal, mechanical, and chemical stresses.

The technological roadmap for achieving these objectives encompasses advances in atomic-level deposition techniques, gradient functional materials, self-healing interfaces, and computational tools capable of simulating long-term interface evolution under complex service conditions.

Market Analysis for High-Temperature Resistant Coatings

The global market for high-temperature resistant coatings has experienced significant growth in recent years, driven by increasing demand from aerospace, automotive, industrial machinery, and energy sectors. These coatings, particularly those engineered with composite interfaces for enhanced chemical stability, represent a critical segment within the specialty coatings industry.

Market valuation for high-temperature resistant coatings reached approximately 4.2 billion USD in 2022, with projections indicating a compound annual growth rate (CAGR) of 5.7% through 2028. The aerospace and defense sectors currently dominate market consumption, accounting for nearly 35% of total demand, followed by energy generation at 28% and automotive applications at 17%.

Regional analysis reveals North America and Europe as traditional market leaders, collectively holding about 58% market share. However, the Asia-Pacific region demonstrates the most aggressive growth trajectory, with China and India expanding their manufacturing capabilities and increasing adoption of advanced coating technologies in various industrial applications.

Key market drivers include stringent environmental regulations promoting longer-lasting protective solutions, growing demand for fuel-efficient transportation systems requiring lightweight materials with superior thermal protection, and the expansion of renewable energy infrastructure necessitating components with enhanced durability under extreme conditions.

The market segmentation shows ceramic-based composite coatings leading with approximately 42% market share, followed by metal-matrix composites at 31% and polymer-derived ceramic coatings at 18%. Interface-engineered composite coatings specifically designed for both high-temperature and chemical stability represent the fastest-growing segment, with 9% current market share but projected annual growth exceeding 12%.

Customer demand increasingly focuses on multifunctional coating solutions that simultaneously address thermal resistance, chemical stability, and mechanical durability. This trend has accelerated research into advanced interface engineering techniques that can deliver superior performance across multiple parameters.

Market challenges include high production costs associated with advanced composite formulations, technical difficulties in achieving consistent interface quality at scale, and competition from alternative materials solutions. Additionally, supply chain vulnerabilities exposed during recent global disruptions have prompted manufacturers to seek more resilient sourcing strategies for critical raw materials.

Market valuation for high-temperature resistant coatings reached approximately 4.2 billion USD in 2022, with projections indicating a compound annual growth rate (CAGR) of 5.7% through 2028. The aerospace and defense sectors currently dominate market consumption, accounting for nearly 35% of total demand, followed by energy generation at 28% and automotive applications at 17%.

Regional analysis reveals North America and Europe as traditional market leaders, collectively holding about 58% market share. However, the Asia-Pacific region demonstrates the most aggressive growth trajectory, with China and India expanding their manufacturing capabilities and increasing adoption of advanced coating technologies in various industrial applications.

Key market drivers include stringent environmental regulations promoting longer-lasting protective solutions, growing demand for fuel-efficient transportation systems requiring lightweight materials with superior thermal protection, and the expansion of renewable energy infrastructure necessitating components with enhanced durability under extreme conditions.

The market segmentation shows ceramic-based composite coatings leading with approximately 42% market share, followed by metal-matrix composites at 31% and polymer-derived ceramic coatings at 18%. Interface-engineered composite coatings specifically designed for both high-temperature and chemical stability represent the fastest-growing segment, with 9% current market share but projected annual growth exceeding 12%.

Customer demand increasingly focuses on multifunctional coating solutions that simultaneously address thermal resistance, chemical stability, and mechanical durability. This trend has accelerated research into advanced interface engineering techniques that can deliver superior performance across multiple parameters.

Market challenges include high production costs associated with advanced composite formulations, technical difficulties in achieving consistent interface quality at scale, and competition from alternative materials solutions. Additionally, supply chain vulnerabilities exposed during recent global disruptions have prompted manufacturers to seek more resilient sourcing strategies for critical raw materials.

Current Technical Challenges in Composite Interface Engineering

Despite significant advancements in composite coating technologies, several critical challenges persist in interface engineering for high-temperature and chemically aggressive environments. The interface between the coating and substrate represents the most vulnerable region where failure typically initiates, particularly under thermal cycling conditions. Thermal expansion coefficient mismatch between coating layers and substrates creates substantial interfacial stresses, leading to delamination and spallation during temperature fluctuations.

Chemical stability at elevated temperatures presents another formidable challenge. Interdiffusion of elements across interfaces accelerates at high temperatures, potentially forming brittle intermetallic compounds or depleting protective elements. This phenomenon compromises the coating's structural integrity and protective capabilities, particularly in applications exceeding 800°C where diffusion kinetics become significantly more pronounced.

Oxidation resistance remains problematic at interfaces where oxygen can penetrate through microcracks or along grain boundaries. The formation of voluminous oxide products at interfaces creates wedging stresses that propagate existing defects. Current coating systems struggle to maintain hermetic seals against oxygen ingress during thousands of hours of high-temperature exposure, especially when subjected to thermal cycling.

Interface adhesion degradation under combined thermal and chemical attack represents a complex challenge. Molten salts, combustion gases, and other corrosive media can penetrate coating defects and attack the interface preferentially. The synergistic effects of chemical attack and thermal stresses accelerate degradation beyond what would be predicted by considering each factor independently.

Manufacturing consistency presents significant technical hurdles in interface engineering. Achieving uniform, defect-free interfaces across complex geometries remains difficult with current deposition technologies. Surface preparation variability introduces inconsistencies in interface quality, while controlling precise interlayer composition during multi-layer coating deposition presents process control challenges.

Characterization and modeling of interfaces under extreme conditions pose methodological challenges. Real-time monitoring of interface evolution at high temperatures remains limited by available analytical techniques. Predictive models struggle to account for the complex physicochemical processes occurring at interfaces, particularly the coupled effects of mechanical stress, chemical diffusion, and phase transformations.

These challenges are further complicated by the increasing industrial demand for coatings that can withstand more extreme conditions while maintaining longer service lives. The push toward higher operating temperatures in energy generation, aerospace, and manufacturing processes continues to outpace advances in interface stability solutions.

Chemical stability at elevated temperatures presents another formidable challenge. Interdiffusion of elements across interfaces accelerates at high temperatures, potentially forming brittle intermetallic compounds or depleting protective elements. This phenomenon compromises the coating's structural integrity and protective capabilities, particularly in applications exceeding 800°C where diffusion kinetics become significantly more pronounced.

Oxidation resistance remains problematic at interfaces where oxygen can penetrate through microcracks or along grain boundaries. The formation of voluminous oxide products at interfaces creates wedging stresses that propagate existing defects. Current coating systems struggle to maintain hermetic seals against oxygen ingress during thousands of hours of high-temperature exposure, especially when subjected to thermal cycling.

Interface adhesion degradation under combined thermal and chemical attack represents a complex challenge. Molten salts, combustion gases, and other corrosive media can penetrate coating defects and attack the interface preferentially. The synergistic effects of chemical attack and thermal stresses accelerate degradation beyond what would be predicted by considering each factor independently.

Manufacturing consistency presents significant technical hurdles in interface engineering. Achieving uniform, defect-free interfaces across complex geometries remains difficult with current deposition technologies. Surface preparation variability introduces inconsistencies in interface quality, while controlling precise interlayer composition during multi-layer coating deposition presents process control challenges.

Characterization and modeling of interfaces under extreme conditions pose methodological challenges. Real-time monitoring of interface evolution at high temperatures remains limited by available analytical techniques. Predictive models struggle to account for the complex physicochemical processes occurring at interfaces, particularly the coupled effects of mechanical stress, chemical diffusion, and phase transformations.

These challenges are further complicated by the increasing industrial demand for coatings that can withstand more extreme conditions while maintaining longer service lives. The push toward higher operating temperatures in energy generation, aerospace, and manufacturing processes continues to outpace advances in interface stability solutions.

State-of-the-Art Interface Engineering Solutions

01 Interface engineering for enhanced adhesion and stability

Interface engineering techniques are employed to improve the adhesion between different layers of composite coatings, enhancing overall stability. These methods include surface modification, gradient interfaces, and interlayer design to reduce thermal expansion mismatch and improve bonding strength. Such engineering approaches minimize delamination and cracking under high temperature and chemical exposure, extending the coating's service life and performance in harsh environments.- Interface engineering for enhanced adhesion and stability: Interface engineering techniques are employed to improve the adhesion between different layers of composite coatings, enhancing both mechanical stability and durability. These methods include surface modification, gradient interfaces, and interlayer design to reduce thermal expansion mismatch and stress concentration at interfaces. Such engineering approaches significantly improve coating performance under high temperature and chemically aggressive environments by preventing delamination and crack propagation.

- High temperature resistant composite coating materials: Advanced materials are incorporated into composite coatings to withstand extreme temperature conditions. These include ceramic-metal composites, refractory compounds, and specialized alloys that maintain structural integrity and functional properties at elevated temperatures. The coatings are designed with thermal barrier properties and oxidation resistance, enabling applications in aerospace, power generation, and industrial processing where components are exposed to high thermal loads.

- Chemical stability enhancement through protective layers: Protective layers are integrated into composite coating systems to improve chemical stability against corrosive environments. These layers act as barriers against aggressive chemicals, acids, bases, and oxidizing agents. Multi-layer designs with chemically inert materials, passivation layers, and self-healing components provide long-term protection for substrates in harsh operating conditions, extending the service life of coated components in chemical processing and marine applications.

- Nanostructured composite coatings for enhanced properties: Nanostructured materials are utilized in composite coatings to achieve superior performance characteristics. By incorporating nanoparticles, nanofibers, or creating nanolayered structures, these coatings exhibit enhanced mechanical strength, thermal stability, and chemical resistance. The nanoscale features create unique interfaces that can dissipate energy, trap defects, and provide multiple protection mechanisms, resulting in coatings with exceptional durability under extreme conditions.

- Self-healing and adaptive composite coating systems: Advanced composite coatings with self-healing and adaptive capabilities are designed to respond to environmental changes and damage. These intelligent coating systems incorporate phase-change materials, shape memory components, or reactive agents that can repair microcracks, adjust properties based on temperature fluctuations, or form protective compounds when exposed to specific chemicals. This dynamic behavior significantly extends coating lifetime and maintains performance integrity under varying operational conditions.

02 High temperature resistant composite coating compositions

Specialized composite coating formulations are designed to withstand extreme temperature conditions while maintaining structural integrity. These compositions typically incorporate ceramic components, refractory metals, or advanced polymer matrices with high thermal stability. The coatings may include multiple functional layers that work synergistically to provide thermal barrier properties, oxidation resistance, and mechanical strength at elevated temperatures, making them suitable for aerospace, industrial processing, and energy generation applications.Expand Specific Solutions03 Chemical stability enhancement through protective layers

Protective layers are incorporated into composite coating systems to improve resistance against chemical attack, corrosion, and oxidation. These specialized layers often contain corrosion inhibitors, barrier materials, or sacrificial components that preferentially react with aggressive chemicals. Advanced multi-layer designs can provide self-healing capabilities or create impermeable barriers that prevent penetration of corrosive media to underlying substrates, significantly extending component lifetimes in chemically aggressive environments.Expand Specific Solutions04 Nanostructured materials for improved coating performance

Nanostructured materials are integrated into composite coatings to enhance thermal stability, mechanical properties, and chemical resistance. These nanomaterials include nanoparticles, nanofibers, and nanolaminates that can be dispersed within coating matrices or arranged in specific architectures. The nanoscale features create unique interfaces that can dissipate energy, block crack propagation, and provide enhanced barrier properties against thermal and chemical degradation, resulting in superior coating performance under extreme conditions.Expand Specific Solutions05 Novel deposition and processing techniques for optimized interfaces

Advanced deposition and processing techniques are developed to create optimized interfaces in composite coatings with superior high temperature and chemical stability. These methods include atomic layer deposition, plasma-enhanced chemical vapor deposition, solution-based approaches, and controlled thermal treatments. Such techniques enable precise control over coating microstructure, composition gradients, and interfacial bonding, resulting in enhanced coating durability, reduced residual stresses, and improved performance in demanding applications.Expand Specific Solutions

Leading Companies and Research Institutions in Coating Industry

The composite coatings interface engineering market for high temperature and chemical stability is in a growth phase, with increasing demand driven by aerospace and defense applications. The market is characterized by a mix of established aerospace giants like Rolls-Royce, RTX, and Boeing alongside specialized research institutions. Technology maturity varies across applications, with companies like Rolls-Royce High Temperature Composites and Oerlikon Surface Solutions leading in commercial applications, while research organizations such as Institute of Metal Research CAS and Purdue Research Foundation focus on next-generation solutions. The competitive landscape features strategic partnerships between industrial players and research institutions to overcome technical challenges in extreme environment applications, with estimated market growth of 6-8% annually through 2030.

RTX Corp.

Technical Solution: RTX Corporation (formerly Raytheon Technologies) has developed proprietary composite coating systems featuring engineered interfaces specifically designed for hypersonic and aerospace applications. Their technology utilizes a multi-layered approach with hafnium-based bond coats and zirconia-based thermal barrier top coats modified with rare earth elements. The interface engineering incorporates nanoscale alumina fibers at critical boundaries to enhance mechanical interlocking and improve adhesion during thermal cycling. RTX's coatings employ controlled porosity gradients across interfaces to manage stress distribution and thermal expansion differences. Their manufacturing process includes specialized plasma spray techniques combined with solution precursor methods to achieve precise control over interface microstructure. The coatings demonstrate exceptional resistance to oxidation at temperatures up to 1650°C while maintaining chemical stability against sulfate and vanadium contamination in combustion environments[3][4]. Recent advancements include the integration of phase-change materials at specific interfaces to absorb thermal energy during transient heating events.

Strengths: Exceptional performance in extreme thermal cycling conditions and superior resistance to chemical attack in combustion environments. Advanced manufacturing techniques allow precise control of interface properties. Weaknesses: High production costs and complex quality control requirements limit broader industrial application. Some specialized coatings require rare materials with supply chain vulnerabilities.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has pioneered advanced composite coating systems with sophisticated interface engineering for aerospace and industrial applications requiring exceptional temperature and chemical stability. Their proprietary technology utilizes a multi-layered approach incorporating metal-ceramic interfaces with engineered diffusion barriers to prevent detrimental interdiffusion between layers. Honeywell's coatings feature nanostructured bond coats with platinum group metal modifications that significantly enhance oxidation resistance at temperatures exceeding 1200°C. The interface design incorporates thermally grown oxide (TGO) layers with controlled growth kinetics, minimizing residual stresses during thermal cycling. Their manufacturing process employs both electron beam physical vapor deposition and solution precursor plasma spray techniques to achieve precise microstructural control at critical interfaces. Honeywell has also developed specialized surface treatments that create mechanical interlocking features at the substrate-coating interface, dramatically improving adhesion under thermal shock conditions. Recent innovations include the incorporation of self-diagnosing luminescent materials within specific interface layers to enable non-destructive monitoring of coating degradation in service[5][6].

Strengths: Exceptional thermal cycling durability due to advanced interface stress management. Non-destructive monitoring capabilities provide valuable predictive maintenance information. Comprehensive manufacturing expertise enables consistent quality at scale. Weaknesses: Higher production costs compared to conventional coating systems. Some specialized formulations have limited raw material availability, creating potential supply chain vulnerabilities.

Critical Patents and Research in Composite Coating Interfaces

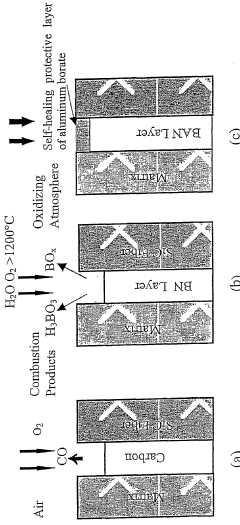

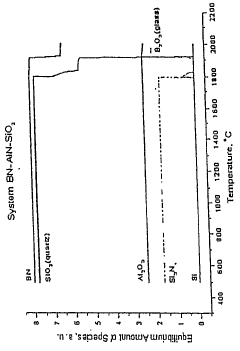

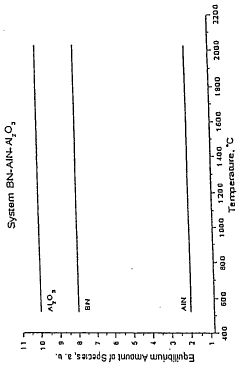

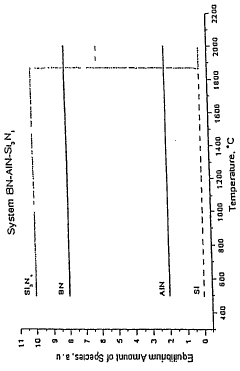

Boron nitride-aluminum (BAN) interfaces and coatings and methods for their production and use

PatentWO2005092610A1

Innovation

- A boron-aluminum-nitride (BAN) nanocomposite coating is applied to ceramic fibers, forming refractory aluminum borates and a boria-containing liquid phase that acts as a diffusion barrier and crack sealer, providing oxidation protection and maintaining debonding characteristics for extended periods.

High temperature stable compositionally modulated hard coatings

PatentWO2018145815A1

Innovation

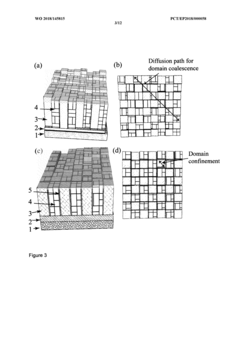

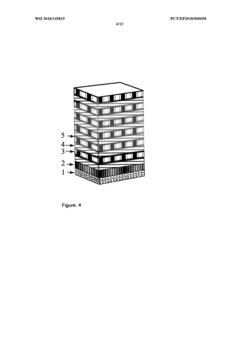

- A method for producing coatings with in-plane and out-of-plane chemically modulated structures featuring self-adapted coherent and diffusion barrier interfaces between c-TMN and w-AIN phases, using a seed layer and high plasma density to achieve adatom mobility, resulting in coatings with stable hardness and oxidation resistance up to 1100 °C, even on polycrystalline substrates.

Material Selection Strategies for Extreme Environments

Material selection for composite coatings in extreme environments requires strategic approaches that balance multiple performance criteria. When engineering interfaces for high temperature and chemical stability, materials must be selected based on their inherent properties and compatibility with the intended application environment.

Ceramic-based materials such as alumina (Al2O3), zirconia (ZrO2), and silicon carbide (SiC) offer exceptional thermal stability and chemical resistance, making them primary candidates for protective coatings in extreme environments. These materials maintain structural integrity at temperatures exceeding 1000°C while resisting oxidation and corrosion from aggressive chemical species.

Metal-ceramic combinations present another viable strategy, where metals provide ductility and thermal conductivity while ceramics contribute hardness and chemical inertness. MCrAlY (where M represents Ni, Co, or Fe) coatings exemplify this approach, offering excellent oxidation resistance through the formation of protective alumina scales at high temperatures.

Nanostructured materials represent an emerging selection strategy, as they can exhibit enhanced properties compared to their conventional counterparts. Nanocomposite coatings with dispersed nanoparticles in a matrix material have demonstrated superior hardness, wear resistance, and thermal stability due to the increased number of interfaces that can deflect cracks and inhibit dislocation movement.

Functionally graded materials (FGMs) offer a sophisticated selection approach by gradually transitioning composition and properties across the coating thickness. This strategy minimizes thermal expansion mismatch stress and enhances interfacial adhesion between dissimilar materials, crucial for preventing delamination during thermal cycling in extreme environments.

Self-healing materials incorporate components that can repair damage autonomously when exposed to specific stimuli. For high-temperature applications, materials containing boron or silicon that form liquid phases when oxidized can flow into cracks and re-solidify, maintaining coating integrity over extended service periods.

Environmental barrier coatings (EBCs) specifically designed for harsh chemical environments employ rare earth silicates and phosphates that resist volatilization and maintain phase stability when exposed to water vapor and molten salts at elevated temperatures.

Selection methodologies must also consider processing compatibility, as the deposition technique significantly influences coating microstructure and interfacial properties. Advanced techniques such as suspension plasma spraying and solution precursor plasma spraying enable precise control over coating architecture and composition gradients, expanding the range of viable material combinations.

Ceramic-based materials such as alumina (Al2O3), zirconia (ZrO2), and silicon carbide (SiC) offer exceptional thermal stability and chemical resistance, making them primary candidates for protective coatings in extreme environments. These materials maintain structural integrity at temperatures exceeding 1000°C while resisting oxidation and corrosion from aggressive chemical species.

Metal-ceramic combinations present another viable strategy, where metals provide ductility and thermal conductivity while ceramics contribute hardness and chemical inertness. MCrAlY (where M represents Ni, Co, or Fe) coatings exemplify this approach, offering excellent oxidation resistance through the formation of protective alumina scales at high temperatures.

Nanostructured materials represent an emerging selection strategy, as they can exhibit enhanced properties compared to their conventional counterparts. Nanocomposite coatings with dispersed nanoparticles in a matrix material have demonstrated superior hardness, wear resistance, and thermal stability due to the increased number of interfaces that can deflect cracks and inhibit dislocation movement.

Functionally graded materials (FGMs) offer a sophisticated selection approach by gradually transitioning composition and properties across the coating thickness. This strategy minimizes thermal expansion mismatch stress and enhances interfacial adhesion between dissimilar materials, crucial for preventing delamination during thermal cycling in extreme environments.

Self-healing materials incorporate components that can repair damage autonomously when exposed to specific stimuli. For high-temperature applications, materials containing boron or silicon that form liquid phases when oxidized can flow into cracks and re-solidify, maintaining coating integrity over extended service periods.

Environmental barrier coatings (EBCs) specifically designed for harsh chemical environments employ rare earth silicates and phosphates that resist volatilization and maintain phase stability when exposed to water vapor and molten salts at elevated temperatures.

Selection methodologies must also consider processing compatibility, as the deposition technique significantly influences coating microstructure and interfacial properties. Advanced techniques such as suspension plasma spraying and solution precursor plasma spraying enable precise control over coating architecture and composition gradients, expanding the range of viable material combinations.

Sustainability and Environmental Impact Assessment

The environmental impact of composite coating technologies has become increasingly significant as industries strive for sustainable development. Composite coatings engineered for high temperature and chemical stability often involve materials and processes that can pose substantial environmental challenges throughout their lifecycle. Traditional coating methods frequently utilize heavy metals, volatile organic compounds (VOCs), and energy-intensive manufacturing processes that contribute to environmental degradation.

Recent advancements in interface engineering for composite coatings have focused on developing more environmentally friendly alternatives. Water-based coating systems and powder coating technologies have emerged as sustainable options, significantly reducing VOC emissions compared to solvent-based counterparts. Additionally, the incorporation of bio-derived components and naturally occurring minerals has shown promise in decreasing the environmental footprint while maintaining high-temperature performance.

Life cycle assessment (LCA) studies reveal that the environmental impact of composite coatings extends beyond the production phase. The durability and longevity of high-temperature resistant coatings directly influence resource consumption and waste generation. Coatings with enhanced interface engineering demonstrate extended service life, thereby reducing the frequency of replacement and associated environmental costs. Quantitative analyses indicate that advanced composite coatings can reduce overall carbon footprint by 15-30% compared to conventional alternatives.

Waste management considerations are equally crucial in sustainability assessment. The end-of-life disposal of composite coatings presents challenges due to the heterogeneous nature of these materials. Research into recyclability and reclamation of valuable components from spent coatings is gaining momentum. Innovative approaches such as chemical delamination and selective dissolution techniques enable the recovery of substrate materials and certain coating constituents, promoting circular economy principles.

Energy efficiency improvements represent another significant environmental benefit of advanced interface engineering. Optimized composite coatings can reduce energy consumption in high-temperature applications by enhancing thermal management properties. Studies demonstrate that properly engineered thermal barrier coatings can decrease energy requirements by up to 20% in industrial furnaces and combustion systems, translating to substantial reductions in greenhouse gas emissions.

Regulatory frameworks worldwide are increasingly emphasizing environmental compliance for coating technologies. The Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) in Europe and similar regulations globally have accelerated the transition toward more sustainable coating formulations. Forward-thinking companies are proactively developing composite coatings that not only meet current environmental standards but anticipate future regulatory requirements, gaining competitive advantage in environmentally conscious markets.

Recent advancements in interface engineering for composite coatings have focused on developing more environmentally friendly alternatives. Water-based coating systems and powder coating technologies have emerged as sustainable options, significantly reducing VOC emissions compared to solvent-based counterparts. Additionally, the incorporation of bio-derived components and naturally occurring minerals has shown promise in decreasing the environmental footprint while maintaining high-temperature performance.

Life cycle assessment (LCA) studies reveal that the environmental impact of composite coatings extends beyond the production phase. The durability and longevity of high-temperature resistant coatings directly influence resource consumption and waste generation. Coatings with enhanced interface engineering demonstrate extended service life, thereby reducing the frequency of replacement and associated environmental costs. Quantitative analyses indicate that advanced composite coatings can reduce overall carbon footprint by 15-30% compared to conventional alternatives.

Waste management considerations are equally crucial in sustainability assessment. The end-of-life disposal of composite coatings presents challenges due to the heterogeneous nature of these materials. Research into recyclability and reclamation of valuable components from spent coatings is gaining momentum. Innovative approaches such as chemical delamination and selective dissolution techniques enable the recovery of substrate materials and certain coating constituents, promoting circular economy principles.

Energy efficiency improvements represent another significant environmental benefit of advanced interface engineering. Optimized composite coatings can reduce energy consumption in high-temperature applications by enhancing thermal management properties. Studies demonstrate that properly engineered thermal barrier coatings can decrease energy requirements by up to 20% in industrial furnaces and combustion systems, translating to substantial reductions in greenhouse gas emissions.

Regulatory frameworks worldwide are increasingly emphasizing environmental compliance for coating technologies. The Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) in Europe and similar regulations globally have accelerated the transition toward more sustainable coating formulations. Forward-thinking companies are proactively developing composite coatings that not only meet current environmental standards but anticipate future regulatory requirements, gaining competitive advantage in environmentally conscious markets.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!