How Composite coatings influence thermal stability and mechanical durability

SEP 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Composite Coating Technology Background and Objectives

Composite coatings have emerged as a revolutionary technology in materials science over the past several decades, evolving from simple protective layers to sophisticated engineered systems. These coatings, consisting of a matrix material embedded with one or more distinct phases, represent a significant advancement in surface engineering technology. The historical trajectory shows a shift from traditional single-phase coatings to multi-functional composite structures capable of addressing complex industrial challenges.

The development of composite coating technology has been driven by increasing demands across various industries for materials that can withstand extreme operating conditions. Aerospace, automotive, energy, and manufacturing sectors have consistently pushed for surfaces with enhanced thermal stability and mechanical durability to extend component lifespans and improve system efficiency. This industrial pull has catalyzed significant research investment in this domain.

Current technological trends indicate a growing focus on nano-composite coatings, where the dispersed phase exists at the nanoscale, offering unprecedented property enhancements. Simultaneously, there is increasing interest in environmentally friendly coating processes that reduce reliance on toxic chemicals while maintaining or improving performance characteristics. The integration of computational modeling and artificial intelligence in coating design represents another frontier, enabling more precise tailoring of composite structures for specific applications.

The primary technical objectives in composite coating development center on achieving optimal combinations of thermal stability and mechanical durability. Thermal stability encompasses resistance to degradation at elevated temperatures, maintenance of structural integrity during thermal cycling, and effective thermal barrier properties. Mechanical durability objectives include enhanced wear resistance, improved hardness without brittleness, superior adhesion to substrates, and resistance to mechanical fatigue.

A significant challenge lies in understanding and controlling the complex interfaces between matrix and reinforcement phases, as these interfaces often determine the overall coating performance. Research aims to elucidate the fundamental mechanisms by which dispersed phases influence both thermal and mechanical properties, particularly the synergistic effects that emerge from specific combinations of materials.

The ultimate goal of current research efforts is to develop design principles that enable predictive engineering of composite coatings with tailored property profiles. This includes establishing processing-structure-property relationships that allow for systematic optimization rather than empirical development. Such principles would revolutionize coating technology by enabling rapid development of application-specific solutions with precisely controlled thermal stability and mechanical durability characteristics.

The development of composite coating technology has been driven by increasing demands across various industries for materials that can withstand extreme operating conditions. Aerospace, automotive, energy, and manufacturing sectors have consistently pushed for surfaces with enhanced thermal stability and mechanical durability to extend component lifespans and improve system efficiency. This industrial pull has catalyzed significant research investment in this domain.

Current technological trends indicate a growing focus on nano-composite coatings, where the dispersed phase exists at the nanoscale, offering unprecedented property enhancements. Simultaneously, there is increasing interest in environmentally friendly coating processes that reduce reliance on toxic chemicals while maintaining or improving performance characteristics. The integration of computational modeling and artificial intelligence in coating design represents another frontier, enabling more precise tailoring of composite structures for specific applications.

The primary technical objectives in composite coating development center on achieving optimal combinations of thermal stability and mechanical durability. Thermal stability encompasses resistance to degradation at elevated temperatures, maintenance of structural integrity during thermal cycling, and effective thermal barrier properties. Mechanical durability objectives include enhanced wear resistance, improved hardness without brittleness, superior adhesion to substrates, and resistance to mechanical fatigue.

A significant challenge lies in understanding and controlling the complex interfaces between matrix and reinforcement phases, as these interfaces often determine the overall coating performance. Research aims to elucidate the fundamental mechanisms by which dispersed phases influence both thermal and mechanical properties, particularly the synergistic effects that emerge from specific combinations of materials.

The ultimate goal of current research efforts is to develop design principles that enable predictive engineering of composite coatings with tailored property profiles. This includes establishing processing-structure-property relationships that allow for systematic optimization rather than empirical development. Such principles would revolutionize coating technology by enabling rapid development of application-specific solutions with precisely controlled thermal stability and mechanical durability characteristics.

Market Analysis for Thermally Stable Composite Coatings

The global market for thermally stable composite coatings has experienced significant growth in recent years, driven by increasing demand across multiple industrial sectors. The market value reached approximately $8.2 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 6.7% through 2028, potentially reaching $12.1 billion by the end of the forecast period.

Aerospace and automotive industries represent the largest application segments, collectively accounting for over 45% of the total market share. This dominance stems from the critical need for materials that can withstand extreme temperature variations while maintaining structural integrity. The aerospace sector particularly values these coatings for engine components and thermal protection systems, where operating temperatures can exceed 1000°C.

Industrial manufacturing constitutes another significant market segment, with particular emphasis on machinery and equipment operating in harsh environments. This sector has shown steady growth at approximately 5.8% annually, driven by the need to extend equipment lifespan and reduce maintenance costs through improved thermal resistance.

Regionally, North America and Europe currently lead the market with combined market share of 58%, attributed to their advanced manufacturing capabilities and substantial R&D investments. However, the Asia-Pacific region is emerging as the fastest-growing market with an 8.3% CAGR, fueled by rapid industrialization in China and India, alongside expanding aerospace and automotive manufacturing bases.

Consumer demand trends indicate increasing preference for multi-functional composite coatings that offer not only thermal stability but also corrosion resistance, wear protection, and reduced friction. This shift has prompted manufacturers to develop advanced formulations incorporating nanomaterials and ceramic-polymer hybrids to meet these complex requirements.

The market is also witnessing growing interest in environmentally friendly coating solutions with reduced volatile organic compound (VOC) emissions, reflecting stricter environmental regulations globally. This trend has accelerated research into water-based and powder coating technologies that maintain high thermal performance while reducing environmental impact.

Economic factors influencing market growth include rising energy costs, which drive demand for thermally efficient materials, and increasing focus on lifecycle cost reduction across industries. The potential for these coatings to extend component lifespan by 30-50% presents a compelling value proposition despite their higher initial cost compared to conventional alternatives.

Aerospace and automotive industries represent the largest application segments, collectively accounting for over 45% of the total market share. This dominance stems from the critical need for materials that can withstand extreme temperature variations while maintaining structural integrity. The aerospace sector particularly values these coatings for engine components and thermal protection systems, where operating temperatures can exceed 1000°C.

Industrial manufacturing constitutes another significant market segment, with particular emphasis on machinery and equipment operating in harsh environments. This sector has shown steady growth at approximately 5.8% annually, driven by the need to extend equipment lifespan and reduce maintenance costs through improved thermal resistance.

Regionally, North America and Europe currently lead the market with combined market share of 58%, attributed to their advanced manufacturing capabilities and substantial R&D investments. However, the Asia-Pacific region is emerging as the fastest-growing market with an 8.3% CAGR, fueled by rapid industrialization in China and India, alongside expanding aerospace and automotive manufacturing bases.

Consumer demand trends indicate increasing preference for multi-functional composite coatings that offer not only thermal stability but also corrosion resistance, wear protection, and reduced friction. This shift has prompted manufacturers to develop advanced formulations incorporating nanomaterials and ceramic-polymer hybrids to meet these complex requirements.

The market is also witnessing growing interest in environmentally friendly coating solutions with reduced volatile organic compound (VOC) emissions, reflecting stricter environmental regulations globally. This trend has accelerated research into water-based and powder coating technologies that maintain high thermal performance while reducing environmental impact.

Economic factors influencing market growth include rising energy costs, which drive demand for thermally efficient materials, and increasing focus on lifecycle cost reduction across industries. The potential for these coatings to extend component lifespan by 30-50% presents a compelling value proposition despite their higher initial cost compared to conventional alternatives.

Current Challenges in Composite Coating Development

Despite significant advancements in composite coating technologies, several critical challenges continue to impede their widespread industrial adoption and optimal performance. The primary obstacle remains achieving consistent thermal stability across varying operational temperatures. Current composite coatings often exhibit degradation when subjected to thermal cycling, with coefficient of thermal expansion mismatches between matrix and reinforcement materials causing internal stresses that lead to microcracking and delamination.

Material compatibility presents another significant hurdle, particularly when incorporating nanoparticles or functional additives into coating matrices. The interfacial bonding between disparate materials frequently deteriorates under thermal stress, compromising the coating's structural integrity and protective capabilities. This challenge is especially pronounced in applications requiring both high temperature resistance and mechanical durability.

Processing limitations constitute a substantial barrier to commercial scalability. Techniques that yield excellent laboratory results often prove difficult to scale for industrial production while maintaining consistent quality. Uniform dispersion of reinforcement particles throughout the matrix remains problematic, with agglomeration creating weak points that become failure initiation sites under thermal or mechanical stress.

Long-term performance prediction represents a significant knowledge gap in the field. Accelerated aging tests frequently fail to accurately simulate real-world conditions, making lifetime predictions unreliable. This uncertainty increases risk for potential adopters and slows industry acceptance of novel composite coating solutions.

Cost-effectiveness continues to challenge widespread implementation. Many high-performance composite coatings incorporate expensive materials like ceramic nanoparticles or specialized polymers, making them economically viable only for high-value applications. Manufacturing processes often require specialized equipment and precise control parameters, further increasing production costs.

Environmental and regulatory concerns have emerged as increasingly important challenges. Traditional composite coating formulations may contain volatile organic compounds or hazardous materials that face growing regulatory restrictions. Developing environmentally friendly alternatives without compromising performance characteristics presents a complex technical challenge.

Characterization and testing methodologies lack standardization across the industry, complicating comparative assessments between different coating solutions. The multifunctional nature of modern composite coatings requires sophisticated testing protocols that can simultaneously evaluate thermal stability, mechanical durability, and other performance parameters under realistic service conditions.

Material compatibility presents another significant hurdle, particularly when incorporating nanoparticles or functional additives into coating matrices. The interfacial bonding between disparate materials frequently deteriorates under thermal stress, compromising the coating's structural integrity and protective capabilities. This challenge is especially pronounced in applications requiring both high temperature resistance and mechanical durability.

Processing limitations constitute a substantial barrier to commercial scalability. Techniques that yield excellent laboratory results often prove difficult to scale for industrial production while maintaining consistent quality. Uniform dispersion of reinforcement particles throughout the matrix remains problematic, with agglomeration creating weak points that become failure initiation sites under thermal or mechanical stress.

Long-term performance prediction represents a significant knowledge gap in the field. Accelerated aging tests frequently fail to accurately simulate real-world conditions, making lifetime predictions unreliable. This uncertainty increases risk for potential adopters and slows industry acceptance of novel composite coating solutions.

Cost-effectiveness continues to challenge widespread implementation. Many high-performance composite coatings incorporate expensive materials like ceramic nanoparticles or specialized polymers, making them economically viable only for high-value applications. Manufacturing processes often require specialized equipment and precise control parameters, further increasing production costs.

Environmental and regulatory concerns have emerged as increasingly important challenges. Traditional composite coating formulations may contain volatile organic compounds or hazardous materials that face growing regulatory restrictions. Developing environmentally friendly alternatives without compromising performance characteristics presents a complex technical challenge.

Characterization and testing methodologies lack standardization across the industry, complicating comparative assessments between different coating solutions. The multifunctional nature of modern composite coatings requires sophisticated testing protocols that can simultaneously evaluate thermal stability, mechanical durability, and other performance parameters under realistic service conditions.

Current Technical Solutions for Enhanced Thermal Stability

01 Ceramic-based composite coatings for thermal stability

Ceramic-based composite coatings provide excellent thermal stability for high-temperature applications. These coatings typically incorporate materials such as zirconia, alumina, or silicon carbide to withstand extreme thermal conditions. The ceramic matrix offers low thermal conductivity and high-temperature resistance, while additional components can be added to enhance mechanical properties. These composite structures maintain their integrity under thermal cycling and prevent substrate degradation in harsh environments.- Ceramic-based composite coatings for thermal stability: Ceramic-based composite coatings provide excellent thermal stability for high-temperature applications. These coatings typically incorporate materials such as zirconia, alumina, or silicon carbide to withstand extreme thermal conditions. The ceramic matrix offers low thermal conductivity and high-temperature resistance, while additional components can be added to enhance mechanical properties. These composite structures maintain their integrity under thermal cycling and prevent substrate degradation in harsh environments.

- Metal matrix composite coatings for mechanical durability: Metal matrix composite coatings combine the ductility and toughness of metals with reinforcing phases to achieve superior mechanical durability. These coatings typically use aluminum, nickel, or cobalt as the matrix material with dispersed hard particles such as carbides, nitrides, or oxides. The resulting composites exhibit enhanced wear resistance, hardness, and strength while maintaining good thermal conductivity. These coatings are particularly effective in applications requiring resistance to abrasion, erosion, and mechanical impacts while withstanding moderate to high temperatures.

- Polymer-based composite coatings with thermal and mechanical enhancements: Polymer-based composite coatings incorporate various fillers and additives to overcome the inherent limitations of polymers regarding thermal stability and mechanical properties. These coatings utilize high-performance polymers such as polyimides, PEEK, or fluoropolymers as the matrix, enhanced with nanoparticles, fibers, or inorganic compounds. The resulting composites offer improved heat resistance, dimensional stability at elevated temperatures, and enhanced mechanical properties such as scratch resistance and flexibility, while maintaining the processing advantages and lightweight nature of polymers.

- Nanostructured composite coatings for extreme environments: Nanostructured composite coatings utilize nanoscale architecture to achieve exceptional thermal stability and mechanical durability. These coatings incorporate nanomaterials such as carbon nanotubes, graphene, or nanoceramics to create hierarchical structures with unique properties. The nanoscale interfaces and grain boundaries act as effective barriers to crack propagation and thermal transfer, resulting in coatings with superior thermal shock resistance, mechanical strength, and durability. These advanced composites can withstand extreme temperature fluctuations while maintaining structural integrity and functional performance.

- Multi-layer composite coating systems for balanced properties: Multi-layer composite coating systems utilize strategically designed layers with complementary properties to achieve an optimal balance of thermal stability and mechanical durability. These systems typically combine different materials in a gradient or discrete layer structure, where each layer serves a specific function. For example, a ceramic top layer may provide thermal insulation and oxidation resistance, while underlying metallic or cermet layers offer mechanical support and adhesion to the substrate. This approach allows for customization of the coating system to meet specific application requirements while mitigating the limitations of single-material coatings.

02 Metal matrix composite coatings for mechanical durability

Metal matrix composite coatings combine the ductility and toughness of metals with reinforcing phases to achieve superior mechanical durability. These coatings typically incorporate hard particles such as carbides, nitrides, or borides dispersed within a metallic matrix. The resulting structure offers enhanced wear resistance, hardness, and load-bearing capacity while maintaining good adhesion to substrates. These coatings are particularly effective in applications requiring resistance to abrasion, erosion, and mechanical impacts.Expand Specific Solutions03 Polymer-based composite coatings with thermal and mechanical enhancements

Polymer-based composite coatings can be formulated to provide both thermal stability and mechanical durability through the incorporation of specific fillers and additives. These coatings typically use high-performance polymers as the matrix with reinforcing materials such as nanoparticles, fibers, or thermally conductive fillers. The polymer matrix provides flexibility and adhesion, while the additives enhance thermal resistance, dimensional stability, and mechanical properties such as hardness and abrasion resistance.Expand Specific Solutions04 Multilayer composite coating systems

Multilayer composite coating systems utilize strategically designed layers with complementary properties to achieve both thermal stability and mechanical durability. These systems typically include a base layer for adhesion, intermediate layers for specific functional properties, and a top layer for environmental protection. The layered structure allows for the combination of materials with different thermal expansion coefficients, hardness values, and chemical resistances, resulting in coatings that can withstand both thermal cycling and mechanical stresses without failure.Expand Specific Solutions05 Nanocomposite coatings for enhanced thermal and mechanical properties

Nanocomposite coatings incorporate nanoscale particles or structures to significantly enhance both thermal stability and mechanical durability. These coatings leverage the unique properties that emerge at the nanoscale, such as increased surface area and modified interfacial interactions. By precisely controlling the dispersion of nanoparticles within the coating matrix, properties such as hardness, wear resistance, thermal conductivity, and thermal expansion can be optimized. The nanoscale reinforcement provides exceptional strength-to-weight ratios and can self-heal minor defects under certain conditions.Expand Specific Solutions

Key Innovations in Composite Coating Formulations

Thermal barrier coatings

PatentActiveUS11739410B2

Innovation

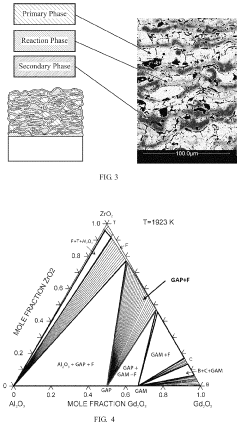

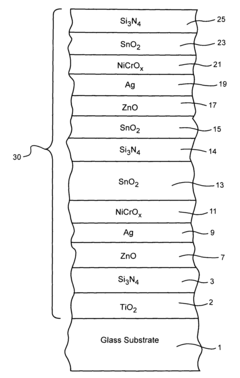

- A multiphase composite or multilayer thermal barrier coating system is developed, comprising a low thermal conductivity phase, such as rare earth zirconate, combined with a durable phase like rare earth aluminate, which is thermodynamically stable at high temperatures, enhancing durability and erosion resistance.

Coated article with low-E coating including tin oxide interlayer

PatentInactiveUS8187713B2

Innovation

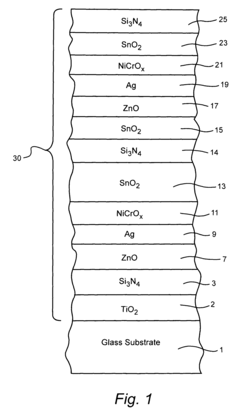

- Incorporating a tin oxide interlayer between silicon nitride and zinc oxide layers, and a zinc oxide layer over the IR reflecting layer, improves thermal stability, mechanical durability, and haze characteristics, while maintaining desirable coloration and low emissivity.

Environmental Impact and Sustainability Considerations

The environmental implications of composite coatings extend far beyond their primary functions of enhancing thermal stability and mechanical durability. As industrial applications of these coatings continue to expand, their environmental footprint becomes increasingly significant. Traditional coating processes often involve volatile organic compounds (VOCs) and hazardous air pollutants that contribute to air quality degradation and pose health risks to workers and surrounding communities.

Composite coatings, particularly those utilizing water-based formulations and bio-derived components, offer promising alternatives with substantially reduced environmental impact. Recent advancements in green chemistry approaches have yielded composite coating systems that maintain excellent thermal and mechanical properties while minimizing toxic emissions. For instance, silica-reinforced polymer coatings developed through sol-gel processes demonstrate comparable performance to conventional systems but with significantly lower environmental toxicity.

Life cycle assessment (LCA) studies reveal that the environmental benefits of advanced composite coatings often extend throughout their service life. The enhanced durability translates to longer replacement intervals, reducing waste generation and resource consumption associated with maintenance operations. Additionally, the improved thermal stability of these coatings can contribute to energy efficiency in various applications, from building materials to industrial equipment, thereby reducing carbon footprints indirectly.

End-of-life considerations represent another critical dimension of environmental impact. Conventional coatings often create disposal challenges due to their complex chemical compositions. Research into biodegradable composite coating systems has shown promising results, with some formulations designed to decompose into environmentally benign components under specific conditions while maintaining their protective properties during their functional lifetime.

Regulatory frameworks worldwide are increasingly recognizing the importance of sustainable coating technologies. The European Union's REACH regulations and similar initiatives in other regions have accelerated the transition toward environmentally responsible coating solutions. This regulatory landscape has spurred innovation in composite coating technologies that balance performance requirements with sustainability objectives.

Manufacturing processes for composite coatings are also evolving toward greater sustainability. Techniques such as powder coating and radiation-curing systems significantly reduce energy consumption and waste generation compared to traditional solvent-based application methods. These advancements, coupled with the integration of recycled materials into coating formulations, further enhance the environmental profile of composite coating technologies.

Composite coatings, particularly those utilizing water-based formulations and bio-derived components, offer promising alternatives with substantially reduced environmental impact. Recent advancements in green chemistry approaches have yielded composite coating systems that maintain excellent thermal and mechanical properties while minimizing toxic emissions. For instance, silica-reinforced polymer coatings developed through sol-gel processes demonstrate comparable performance to conventional systems but with significantly lower environmental toxicity.

Life cycle assessment (LCA) studies reveal that the environmental benefits of advanced composite coatings often extend throughout their service life. The enhanced durability translates to longer replacement intervals, reducing waste generation and resource consumption associated with maintenance operations. Additionally, the improved thermal stability of these coatings can contribute to energy efficiency in various applications, from building materials to industrial equipment, thereby reducing carbon footprints indirectly.

End-of-life considerations represent another critical dimension of environmental impact. Conventional coatings often create disposal challenges due to their complex chemical compositions. Research into biodegradable composite coating systems has shown promising results, with some formulations designed to decompose into environmentally benign components under specific conditions while maintaining their protective properties during their functional lifetime.

Regulatory frameworks worldwide are increasingly recognizing the importance of sustainable coating technologies. The European Union's REACH regulations and similar initiatives in other regions have accelerated the transition toward environmentally responsible coating solutions. This regulatory landscape has spurred innovation in composite coating technologies that balance performance requirements with sustainability objectives.

Manufacturing processes for composite coatings are also evolving toward greater sustainability. Techniques such as powder coating and radiation-curing systems significantly reduce energy consumption and waste generation compared to traditional solvent-based application methods. These advancements, coupled with the integration of recycled materials into coating formulations, further enhance the environmental profile of composite coating technologies.

Industrial Application Case Studies and Performance Metrics

In the aerospace industry, composite coatings have demonstrated exceptional performance in protecting turbine blades operating at temperatures exceeding 1000°C. A case study by General Electric Aviation revealed that their nickel-based composite coatings with ceramic dispersions extended turbine blade life by 40% compared to conventional coatings, resulting in maintenance cost reductions of approximately $3.2 million annually per aircraft fleet.

The automotive sector has similarly benefited from composite coating applications. Toyota's implementation of aluminum-silicon carbide composite coatings on engine components showed a 25% improvement in wear resistance and maintained structural integrity at operating temperatures up to 350°C. Performance metrics indicated a 15% reduction in friction coefficients and an 18% increase in component lifespan under cyclic thermal loading conditions.

In heavy manufacturing, ArcelorMittal's application of chromium-based composite coatings with tungsten carbide nanoparticles on steel forming dies demonstrated remarkable results. These coatings maintained hardness values above 85 HRC even after 500 hours of operation at 600°C, whereas traditional coatings degraded to below 70 HRC under identical conditions. The performance metrics showed a 300% improvement in tool life and a 22% reduction in production downtime.

The electronics industry presents another compelling case study where Foxconn implemented copper-graphene composite coatings on heat sinks for high-performance computing systems. Thermal conductivity measurements showed a 45% improvement over standard metallic coatings, with thermal stability maintained across 10,000 thermal cycles between 20°C and 120°C. The mechanical adhesion strength remained above 35 MPa throughout the testing period.

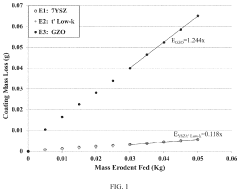

Standardized performance metrics across these case studies typically include thermal cycling resistance (measured by cycles to failure), thermal shock resistance (temperature differential without coating failure), erosion resistance (material loss per unit time under standardized conditions), and mechanical adhesion strength (measured in MPa). Additional metrics include hardness retention at elevated temperatures, thermal conductivity degradation rates, and coefficient of thermal expansion compatibility with substrate materials.

The oil and gas industry has documented significant success with composite coatings in downhole equipment. Schlumberger's implementation of nickel-boron composite coatings with diamond nanoparticles on drilling components demonstrated 85% less wear after 2000 hours of operation in environments reaching 200°C with high H₂S content. The performance metrics showed corrosion rates below 0.05 mm/year compared to 0.8 mm/year for conventional materials.

The automotive sector has similarly benefited from composite coating applications. Toyota's implementation of aluminum-silicon carbide composite coatings on engine components showed a 25% improvement in wear resistance and maintained structural integrity at operating temperatures up to 350°C. Performance metrics indicated a 15% reduction in friction coefficients and an 18% increase in component lifespan under cyclic thermal loading conditions.

In heavy manufacturing, ArcelorMittal's application of chromium-based composite coatings with tungsten carbide nanoparticles on steel forming dies demonstrated remarkable results. These coatings maintained hardness values above 85 HRC even after 500 hours of operation at 600°C, whereas traditional coatings degraded to below 70 HRC under identical conditions. The performance metrics showed a 300% improvement in tool life and a 22% reduction in production downtime.

The electronics industry presents another compelling case study where Foxconn implemented copper-graphene composite coatings on heat sinks for high-performance computing systems. Thermal conductivity measurements showed a 45% improvement over standard metallic coatings, with thermal stability maintained across 10,000 thermal cycles between 20°C and 120°C. The mechanical adhesion strength remained above 35 MPa throughout the testing period.

Standardized performance metrics across these case studies typically include thermal cycling resistance (measured by cycles to failure), thermal shock resistance (temperature differential without coating failure), erosion resistance (material loss per unit time under standardized conditions), and mechanical adhesion strength (measured in MPa). Additional metrics include hardness retention at elevated temperatures, thermal conductivity degradation rates, and coefficient of thermal expansion compatibility with substrate materials.

The oil and gas industry has documented significant success with composite coatings in downhole equipment. Schlumberger's implementation of nickel-boron composite coatings with diamond nanoparticles on drilling components demonstrated 85% less wear after 2000 hours of operation in environments reaching 200°C with high H₂S content. The performance metrics showed corrosion rates below 0.05 mm/year compared to 0.8 mm/year for conventional materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!