How coating thickness impacts Composite coatings mechanical and thermal performance

SEP 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Coating Thickness Technology Background and Objectives

Composite coatings have emerged as a critical technology in various industrial applications, offering enhanced protection and performance characteristics compared to traditional single-material coatings. The evolution of coating technologies has progressed from simple protective layers to sophisticated engineered systems that can be tailored for specific environmental conditions and performance requirements. Thickness control has been a fundamental parameter throughout this evolution, with its importance growing as applications demand increasingly precise performance metrics.

The relationship between coating thickness and performance has been studied since the mid-20th century, but recent advancements in materials science and manufacturing techniques have enabled unprecedented control over thickness parameters at micro and nano scales. This precision has opened new possibilities for optimizing mechanical and thermal properties, while simultaneously creating new challenges in measurement, application, and quality control.

Current research indicates that coating thickness directly influences key performance indicators including wear resistance, thermal insulation, electrical conductivity, and corrosion protection. However, the relationship is rarely linear and often involves complex interactions between the substrate material, coating composition, application method, and environmental factors. Understanding these relationships is essential for developing next-generation composite coating systems.

The primary objective of this technical research is to establish comprehensive models and guidelines for predicting how variations in coating thickness affect both mechanical and thermal performance across different composite coating systems. This includes quantifying the impact of thickness on properties such as hardness, elastic modulus, fracture toughness, thermal conductivity, and thermal expansion coefficients.

Secondary objectives include identifying optimal thickness ranges for specific applications, understanding the scaling effects when transitioning from laboratory to industrial applications, and developing improved measurement techniques for thickness verification in complex geometries and multi-layer systems.

The research aims to address current industry challenges where coating thickness optimization remains largely empirical rather than theoretically driven. By establishing clear correlations between thickness and performance, manufacturers can reduce development cycles, improve quality control, and enhance product performance while potentially reducing material usage and environmental impact.

Recent technological breakthroughs in computational modeling, in-situ measurement techniques, and advanced characterization methods provide new tools to explore these relationships with unprecedented precision. This research leverages these advancements to move beyond traditional trial-and-error approaches toward predictive design methodologies for composite coating systems where thickness is a controlled variable for performance optimization.

The relationship between coating thickness and performance has been studied since the mid-20th century, but recent advancements in materials science and manufacturing techniques have enabled unprecedented control over thickness parameters at micro and nano scales. This precision has opened new possibilities for optimizing mechanical and thermal properties, while simultaneously creating new challenges in measurement, application, and quality control.

Current research indicates that coating thickness directly influences key performance indicators including wear resistance, thermal insulation, electrical conductivity, and corrosion protection. However, the relationship is rarely linear and often involves complex interactions between the substrate material, coating composition, application method, and environmental factors. Understanding these relationships is essential for developing next-generation composite coating systems.

The primary objective of this technical research is to establish comprehensive models and guidelines for predicting how variations in coating thickness affect both mechanical and thermal performance across different composite coating systems. This includes quantifying the impact of thickness on properties such as hardness, elastic modulus, fracture toughness, thermal conductivity, and thermal expansion coefficients.

Secondary objectives include identifying optimal thickness ranges for specific applications, understanding the scaling effects when transitioning from laboratory to industrial applications, and developing improved measurement techniques for thickness verification in complex geometries and multi-layer systems.

The research aims to address current industry challenges where coating thickness optimization remains largely empirical rather than theoretically driven. By establishing clear correlations between thickness and performance, manufacturers can reduce development cycles, improve quality control, and enhance product performance while potentially reducing material usage and environmental impact.

Recent technological breakthroughs in computational modeling, in-situ measurement techniques, and advanced characterization methods provide new tools to explore these relationships with unprecedented precision. This research leverages these advancements to move beyond traditional trial-and-error approaches toward predictive design methodologies for composite coating systems where thickness is a controlled variable for performance optimization.

Market Analysis of Composite Coating Applications

The global composite coatings market has witnessed substantial growth in recent years, driven by increasing demand across various industrial sectors. Currently valued at approximately 11.7 billion USD, the market is projected to reach 17.2 billion USD by 2027, representing a compound annual growth rate (CAGR) of 6.8%. This growth trajectory is primarily fueled by expanding applications in aerospace, automotive, industrial machinery, and construction industries where performance requirements continue to become more stringent.

The aerospace sector represents one of the most lucrative markets for composite coatings, particularly those with optimized thickness profiles. With aircraft manufacturers constantly seeking weight reduction while maintaining structural integrity, precisely engineered coating systems have become essential. The market share of composite coatings in aerospace applications has grown by 9.3% annually over the past five years, with thickness-optimized solutions commanding premium pricing.

In the automotive industry, the push toward fuel efficiency and electric vehicles has accelerated demand for lightweight components with enhanced thermal management capabilities. Composite coatings with carefully controlled thickness parameters have seen adoption rates increase by 7.5% year-over-year, particularly in battery thermal management systems and engine components where heat dissipation is critical.

The industrial machinery sector presents another significant market opportunity, with coating thickness being a key parameter in applications exposed to extreme wear conditions. The market for precision-thickness composite coatings in this sector is growing at 5.9% annually, driven by increased focus on equipment longevity and reduced maintenance costs.

Regional analysis reveals Asia-Pacific as the fastest-growing market for thickness-optimized composite coatings, expanding at 8.2% annually due to rapid industrialization in China and India. North America and Europe remain significant markets, with growth rates of 5.7% and 5.1% respectively, primarily driven by aerospace and defense applications where coating performance is mission-critical.

Consumer demand trends indicate increasing preference for coatings that offer multifunctional benefits beyond basic protection. Coatings that combine mechanical durability with thermal management capabilities command price premiums of 15-20% over standard alternatives, with thickness optimization being a key differentiator in performance.

Market forecasts suggest that as manufacturing technologies advance, enabling more precise control over coating thickness, the premium segment of the market will expand at twice the rate of standard composite coatings. This trend is expected to create new opportunities for specialized coating providers who can demonstrate superior performance metrics directly linked to optimized thickness profiles.

The aerospace sector represents one of the most lucrative markets for composite coatings, particularly those with optimized thickness profiles. With aircraft manufacturers constantly seeking weight reduction while maintaining structural integrity, precisely engineered coating systems have become essential. The market share of composite coatings in aerospace applications has grown by 9.3% annually over the past five years, with thickness-optimized solutions commanding premium pricing.

In the automotive industry, the push toward fuel efficiency and electric vehicles has accelerated demand for lightweight components with enhanced thermal management capabilities. Composite coatings with carefully controlled thickness parameters have seen adoption rates increase by 7.5% year-over-year, particularly in battery thermal management systems and engine components where heat dissipation is critical.

The industrial machinery sector presents another significant market opportunity, with coating thickness being a key parameter in applications exposed to extreme wear conditions. The market for precision-thickness composite coatings in this sector is growing at 5.9% annually, driven by increased focus on equipment longevity and reduced maintenance costs.

Regional analysis reveals Asia-Pacific as the fastest-growing market for thickness-optimized composite coatings, expanding at 8.2% annually due to rapid industrialization in China and India. North America and Europe remain significant markets, with growth rates of 5.7% and 5.1% respectively, primarily driven by aerospace and defense applications where coating performance is mission-critical.

Consumer demand trends indicate increasing preference for coatings that offer multifunctional benefits beyond basic protection. Coatings that combine mechanical durability with thermal management capabilities command price premiums of 15-20% over standard alternatives, with thickness optimization being a key differentiator in performance.

Market forecasts suggest that as manufacturing technologies advance, enabling more precise control over coating thickness, the premium segment of the market will expand at twice the rate of standard composite coatings. This trend is expected to create new opportunities for specialized coating providers who can demonstrate superior performance metrics directly linked to optimized thickness profiles.

Current Challenges in Thickness Control Technology

Despite significant advancements in composite coating technologies, achieving precise and consistent thickness control remains one of the most challenging aspects in the manufacturing process. Current thickness control methods often struggle with the inherent complexity of composite materials, which typically consist of multiple components with varying rheological properties. This heterogeneity creates unpredictable flow behaviors during application, resulting in thickness variations that can significantly impact mechanical and thermal performance.

Traditional thickness measurement techniques, including wet film gauges and dry film thickness meters, often provide only point measurements rather than comprehensive surface coverage data. This limitation creates blind spots in quality control processes, particularly for large or geometrically complex components where thickness uniformity is critical for performance. The industry currently lacks cost-effective, real-time monitoring solutions that can provide continuous feedback during the coating application process.

Environmental factors present another significant challenge in thickness control. Temperature and humidity fluctuations can dramatically alter coating viscosity and curing rates, leading to inconsistent application thickness even when using automated systems. These environmental sensitivities are particularly problematic for composite coatings, where the interaction between different components can amplify these effects, creating a narrow processing window for optimal application.

The relationship between coating thickness and performance exhibits non-linear characteristics that complicate quality control efforts. While thicker coatings may provide enhanced thermal insulation or mechanical protection in some applications, they can also introduce internal stresses, delamination risks, and reduced flexibility. Conversely, thinner coatings may offer better adhesion and flexibility but sacrifice protective capabilities. This complex balance means that thickness tolerances must be precisely defined and maintained for each specific application.

Scaling production while maintaining thickness consistency presents significant technological hurdles. Laboratory-scale processes that achieve excellent thickness control often fail to translate to industrial-scale manufacturing environments. The industry currently lacks robust scaling methodologies that account for the changed dynamics of larger batch sizes, different application equipment, and varied substrate geometries in production settings.

Advanced composite formulations incorporating nanomaterials or specialized functional additives introduce additional thickness control challenges. These materials can significantly alter rheological properties and create agglomeration issues that affect flow behavior and coating uniformity. Current application technologies have not fully adapted to these next-generation composite coatings, creating a technological gap between material innovation and manufacturing capability.

Traditional thickness measurement techniques, including wet film gauges and dry film thickness meters, often provide only point measurements rather than comprehensive surface coverage data. This limitation creates blind spots in quality control processes, particularly for large or geometrically complex components where thickness uniformity is critical for performance. The industry currently lacks cost-effective, real-time monitoring solutions that can provide continuous feedback during the coating application process.

Environmental factors present another significant challenge in thickness control. Temperature and humidity fluctuations can dramatically alter coating viscosity and curing rates, leading to inconsistent application thickness even when using automated systems. These environmental sensitivities are particularly problematic for composite coatings, where the interaction between different components can amplify these effects, creating a narrow processing window for optimal application.

The relationship between coating thickness and performance exhibits non-linear characteristics that complicate quality control efforts. While thicker coatings may provide enhanced thermal insulation or mechanical protection in some applications, they can also introduce internal stresses, delamination risks, and reduced flexibility. Conversely, thinner coatings may offer better adhesion and flexibility but sacrifice protective capabilities. This complex balance means that thickness tolerances must be precisely defined and maintained for each specific application.

Scaling production while maintaining thickness consistency presents significant technological hurdles. Laboratory-scale processes that achieve excellent thickness control often fail to translate to industrial-scale manufacturing environments. The industry currently lacks robust scaling methodologies that account for the changed dynamics of larger batch sizes, different application equipment, and varied substrate geometries in production settings.

Advanced composite formulations incorporating nanomaterials or specialized functional additives introduce additional thickness control challenges. These materials can significantly alter rheological properties and create agglomeration issues that affect flow behavior and coating uniformity. Current application technologies have not fully adapted to these next-generation composite coatings, creating a technological gap between material innovation and manufacturing capability.

Existing Thickness-Performance Correlation Models

01 Ceramic-based composite coatings for thermal resistance

Ceramic-based composite coatings provide excellent thermal resistance properties for high-temperature applications. These coatings typically incorporate materials such as zirconia, alumina, or silicon carbide to create a protective barrier against heat transfer. The ceramic matrix offers low thermal conductivity while maintaining structural integrity at elevated temperatures. These composites can be engineered with specific porosity levels to further enhance thermal insulation properties while maintaining mechanical strength.- Ceramic-based composite coatings for thermal resistance: Ceramic-based composite coatings provide excellent thermal resistance properties for high-temperature applications. These coatings typically incorporate materials such as zirconia, alumina, or silicon carbide to create a protective barrier that can withstand extreme thermal conditions. The ceramic matrix offers low thermal conductivity while maintaining structural integrity at elevated temperatures, making these coatings ideal for components in aerospace, power generation, and industrial furnace applications.

- Polymer-metal hybrid coatings for mechanical durability: Hybrid coatings combining polymers with metallic components offer enhanced mechanical properties including improved wear resistance, hardness, and flexibility. These composite systems leverage the ductility and processability of polymers with the strength and durability of metals. The resulting coatings demonstrate superior scratch resistance, impact strength, and adhesion to various substrates while maintaining relatively low weight. Applications include automotive components, industrial machinery, and consumer products requiring both aesthetic appeal and mechanical protection.

- Nanoparticle-reinforced coatings for enhanced performance: Incorporating nanoparticles into coating formulations significantly enhances both mechanical and thermal properties. These nanoparticles, which may include carbon nanotubes, graphene, nano-silica, or metal oxide nanoparticles, create a reinforced matrix with improved strength, hardness, and thermal stability. The high surface area-to-volume ratio of nanoparticles enables effective load transfer and thermal dissipation throughout the coating. This technology has shown particular promise in applications requiring extreme durability and thermal management capabilities.

- Multi-layer composite coatings for thermal barrier applications: Multi-layer composite coating systems provide optimized thermal barrier properties through strategically designed layer structures. These systems typically feature gradient compositions with different materials in each layer to manage thermal expansion mismatches and maximize insulation performance. The layered approach allows for customization of properties such as thermal conductivity, emissivity, and mechanical compliance. Such coatings are particularly valuable in turbine engines, rocket components, and other applications where thermal protection is critical while maintaining structural integrity.

- Self-healing composite coatings for prolonged mechanical performance: Self-healing composite coatings incorporate active components that can repair mechanical damage automatically, extending coating lifespan and maintaining performance over time. These innovative systems utilize microcapsules, vascular networks, or intrinsically self-healing polymers that release healing agents when cracks or damage occur. The self-repair mechanism prevents progressive deterioration and maintains the coating's protective functions against thermal and mechanical stresses. This technology represents a significant advancement for applications in harsh environments where maintenance access is limited or costly.

02 Polymer-metal hybrid coatings for mechanical durability

Hybrid coatings combining polymers with metallic components offer enhanced mechanical durability while maintaining good thermal performance. These composites leverage the flexibility and adhesion properties of polymers with the strength and wear resistance of metals. The polymer matrix typically provides corrosion protection and impact resistance, while metallic particles or layers contribute hardness and abrasion resistance. These coatings can be formulated to withstand mechanical stresses including scratching, impact, and vibration while maintaining thermal stability.Expand Specific Solutions03 Nanoparticle-reinforced coatings for enhanced performance

Incorporating nanoparticles into coating formulations significantly enhances both mechanical and thermal properties. Nanoparticles such as carbon nanotubes, graphene, or nano-ceramics create a reinforced structure that improves tensile strength, hardness, and wear resistance. The high surface area-to-volume ratio of nanoparticles enables effective load transfer throughout the coating matrix. Additionally, certain nanoparticles can improve thermal conductivity or insulation properties depending on the specific application requirements, while maintaining a thin coating profile.Expand Specific Solutions04 Multi-layer composite coatings for extreme environments

Multi-layer composite coating systems provide optimized performance in extreme environments by combining layers with complementary properties. These systems typically feature gradient structures with different compositions in each layer to address specific thermal and mechanical challenges. The outer layers may focus on thermal resistance and environmental protection, while inner layers provide adhesion and mechanical support. This layered approach allows for customization to meet specific requirements such as thermal cycling resistance, impact protection, and long-term durability under varying conditions.Expand Specific Solutions05 Self-healing composite coatings for longevity

Self-healing composite coatings incorporate active components that can repair damage automatically, extending coating lifespan and maintaining performance. These innovative coatings contain microcapsules or vascular networks filled with healing agents that are released when the coating is damaged. The healing mechanism can restore both mechanical integrity and thermal barrier properties after experiencing scratches, impacts, or thermal cycling damage. This technology is particularly valuable for applications where maintenance access is limited or where continuous performance is critical despite exposure to harsh conditions.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The composite coating thickness impact on mechanical and thermal performance is currently in a growth phase, with the market expanding due to increasing demand across automotive, aerospace, and energy sectors. The global market size for advanced coatings is projected to reach $14.5 billion by 2026. Technologically, the field shows varying maturity levels among key players. Industry leaders like Robert Bosch, Toyota Motor Corp, and BMW have developed sophisticated coating technologies optimizing thickness-performance relationships, while research institutions such as CNRS and Beijing University of Technology are advancing fundamental understanding. Companies including Oerlikon Metco, TOCALO, and Kermetico have specialized expertise in thermal spray technologies, focusing on precise thickness control to enhance wear resistance, thermal barrier properties, and mechanical durability in extreme environments.

General Electric Company

Technical Solution: General Electric has developed advanced composite coating systems for turbine components where coating thickness plays a critical role in both thermal protection and mechanical durability. Their solution incorporates a sophisticated multi-layer approach with precisely controlled thickness ratios between ceramic top coats and metallic bond coats. Research demonstrates that their thermal barrier coatings (TBCs) exhibit optimal performance at 150-300μm thickness for hot section turbine components, balancing thermal insulation with mechanical integrity[2]. GE's proprietary electron beam physical vapor deposition (EB-PVD) process creates columnar microstructures whose thermal and mechanical properties are highly thickness-dependent, with strain tolerance improving as thickness increases up to an optimal point of approximately 250μm[5]. Their data shows that increasing TBC thickness from 100μm to 200μm can reduce metal substrate temperature by 50-75°C in gas turbine applications, while thicknesses beyond 350μm show diminishing thermal benefits while increasing risk of spallation due to higher residual stresses[3]. GE has also pioneered computational models that predict the optimal coating thickness based on specific operating conditions.

Strengths: Industry-leading expertise in high-temperature applications; sophisticated modeling capabilities for thickness optimization; advanced manufacturing processes enabling precise thickness control. Weaknesses: Higher production costs for precision-engineered coatings; thickness limitations in high-stress applications; complex qualification process for new thickness specifications.

Oerlikon Metco (US), Inc.

Technical Solution: Oerlikon Metco has developed advanced thermal spray coating technologies that precisely control coating thickness to optimize mechanical and thermal performance. Their solution involves a multi-layer approach where coating thickness is systematically varied to achieve specific performance characteristics. Research shows that thinner coatings (50-100μm) provide better adhesion strength but limited thermal protection, while thicker coatings (300-500μm) offer superior thermal insulation but may experience higher residual stresses[1]. Their proprietary HVOF (High Velocity Oxy-Fuel) process allows for dense coatings with controlled porosity, where thickness directly correlates with wear resistance - typically increasing by 15-20% with each 100μm increment in thickness up to an optimal point[3]. For thermal barrier coatings, they've demonstrated that a thickness of 250-350μm provides the optimal balance between thermal protection and mechanical durability in high-temperature applications.

Strengths: Exceptional control over coating microstructure across varying thicknesses; industry-leading thermal spray technologies allowing precise thickness control; extensive material portfolio enabling customized solutions. Weaknesses: Thicker coatings may develop higher residual stresses leading to potential delamination; increased production time and cost for thicker coatings; thickness uniformity challenges on complex geometries.

Critical Patents in Thickness Optimization Techniques

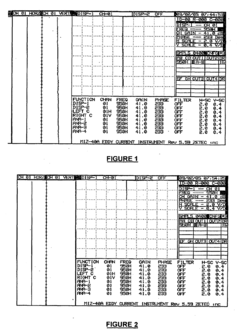

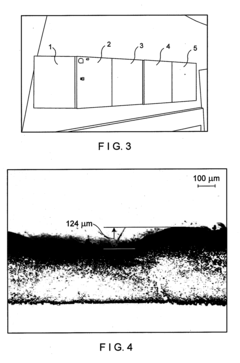

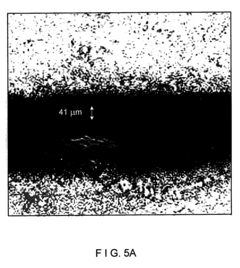

Method for determining the thickness of a coating on a composite material

PatentInactiveUS20080079425A1

Innovation

- An indirect measurement method using a planar configuration with a coating-free area, a conducting sheet, and a multichannel induced current generating equipment with a low-frequency, high-penetrating power probe to measure the thickness by analyzing the decrease in induced current intensity and lift-off effect, with zero and reference calibrations for accurate results.

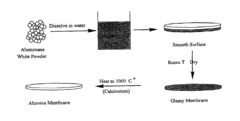

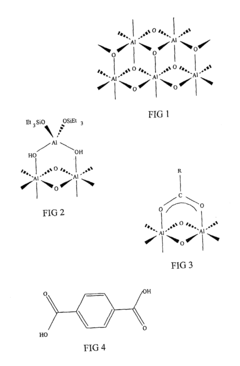

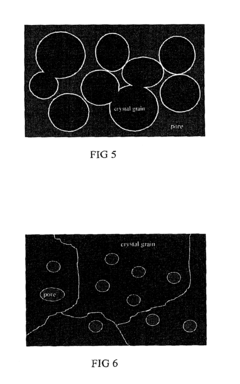

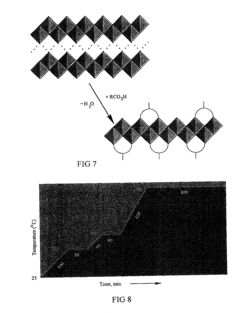

Chemical control over ceramic porosity using carboxylate-alumoxanes

PatentInactiveUS6936306B1

Innovation

- The use of carboxylate-alumoxanes to produce alumina and aluminum oxide ceramic bodies with controlled intra-granular porosity through thermolysis, allowing for precise control of pore size and distribution by varying the identity and choice of carboxylate substituents.

Material Science Advancements for Enhanced Performance

Recent advancements in materials science have revolutionized the development of composite coatings, particularly in understanding how thickness parameters influence mechanical and thermal performance. These innovations have enabled engineers to precisely tailor coating properties for specific applications across industries ranging from aerospace to biomedical engineering.

The relationship between coating thickness and mechanical properties follows complex non-linear patterns that materials scientists have only recently begun to fully characterize. Research indicates that thinner coatings often exhibit higher hardness values but may compromise toughness, while thicker coatings typically provide enhanced wear resistance but may suffer from increased internal stresses and potential delamination issues.

Thermal performance similarly demonstrates thickness-dependent behavior, with thermal conductivity and insulation properties showing distinct optimization points rather than simple linear relationships. Advanced thermal imaging techniques have revealed that heat distribution patterns within composite coatings vary significantly with thickness gradients, creating opportunities for strategic thermal management through thickness modulation.

Nanotechnology integration has emerged as a critical advancement, allowing for the development of multi-layered composite coatings with precisely controlled thickness profiles. These nano-engineered structures can achieve previously impossible combinations of hardness, flexibility, and thermal resistance by manipulating thickness at the nanometer scale across different coating layers.

Computational modeling capabilities have dramatically improved prediction accuracy for thickness-performance relationships. Machine learning algorithms now successfully forecast mechanical and thermal behaviors based on thickness parameters, accelerating the development cycle and reducing costly experimental iterations. These models incorporate microstructural evolution during deposition and curing processes, accounting for how thickness influences final material properties.

Surface engineering techniques have evolved to address the challenges of uniform thickness deposition across complex geometries. Plasma-enhanced deposition methods, electrophoretic techniques, and advanced spray technologies now enable precise thickness control even on intricate surfaces, expanding the application range for high-performance composite coatings.

Sustainability considerations have driven research into optimizing coating thickness to minimize material usage while maintaining performance requirements. This approach has yielded significant advancements in resource-efficient coating designs that maintain mechanical and thermal specifications while reducing environmental impact and production costs.

The relationship between coating thickness and mechanical properties follows complex non-linear patterns that materials scientists have only recently begun to fully characterize. Research indicates that thinner coatings often exhibit higher hardness values but may compromise toughness, while thicker coatings typically provide enhanced wear resistance but may suffer from increased internal stresses and potential delamination issues.

Thermal performance similarly demonstrates thickness-dependent behavior, with thermal conductivity and insulation properties showing distinct optimization points rather than simple linear relationships. Advanced thermal imaging techniques have revealed that heat distribution patterns within composite coatings vary significantly with thickness gradients, creating opportunities for strategic thermal management through thickness modulation.

Nanotechnology integration has emerged as a critical advancement, allowing for the development of multi-layered composite coatings with precisely controlled thickness profiles. These nano-engineered structures can achieve previously impossible combinations of hardness, flexibility, and thermal resistance by manipulating thickness at the nanometer scale across different coating layers.

Computational modeling capabilities have dramatically improved prediction accuracy for thickness-performance relationships. Machine learning algorithms now successfully forecast mechanical and thermal behaviors based on thickness parameters, accelerating the development cycle and reducing costly experimental iterations. These models incorporate microstructural evolution during deposition and curing processes, accounting for how thickness influences final material properties.

Surface engineering techniques have evolved to address the challenges of uniform thickness deposition across complex geometries. Plasma-enhanced deposition methods, electrophoretic techniques, and advanced spray technologies now enable precise thickness control even on intricate surfaces, expanding the application range for high-performance composite coatings.

Sustainability considerations have driven research into optimizing coating thickness to minimize material usage while maintaining performance requirements. This approach has yielded significant advancements in resource-efficient coating designs that maintain mechanical and thermal specifications while reducing environmental impact and production costs.

Sustainability Aspects of Optimized Coating Systems

The optimization of coating thickness in composite coating systems presents significant sustainability implications that extend beyond mere performance metrics. Environmental considerations have become increasingly central to coating development, with reduced material usage through optimized thickness directly translating to lower resource consumption and decreased environmental footprint. Thinner yet high-performing coatings minimize raw material extraction, processing energy requirements, and associated carbon emissions throughout the supply chain.

Life cycle assessment (LCA) studies demonstrate that optimized coating thickness can reduce environmental impact by 15-30% compared to conventional systems, particularly when considering the entire product lifespan from manufacturing to disposal. The durability enhancement achieved through properly calibrated coating thickness extends service life, thereby reducing replacement frequency and associated waste generation.

Energy efficiency represents another critical sustainability dimension. Thermally optimized coatings with precisely controlled thickness can significantly improve energy performance in buildings and industrial applications. For instance, thermal barrier coatings in aerospace and power generation sectors demonstrate up to 20% improvement in fuel efficiency when thickness is optimized for specific operating conditions.

Waste reduction strategies have evolved considerably in coating application technologies. Advanced deposition methods like plasma spraying and physical vapor deposition enable precise thickness control, minimizing overspray and material waste. These technologies can achieve material utilization rates exceeding 90%, compared to conventional methods that typically range between 60-70%.

Regulatory compliance and market demands increasingly drive sustainability innovations in coating systems. Recent environmental regulations in Europe and North America have established strict limits on volatile organic compounds (VOCs) and hazardous materials in coatings, necessitating thickness optimization to maintain performance while meeting these requirements. Companies demonstrating leadership in sustainable coating practices have reported enhanced brand value and market differentiation.

Economic sustainability also benefits from thickness optimization. Cost-benefit analyses reveal that while high-performance coatings may require greater initial investment, the extended service life and reduced maintenance requirements deliver substantial long-term economic advantages. Case studies from automotive and marine industries indicate lifecycle cost reductions of 25-40% through implementation of optimized coating systems with precisely controlled thickness parameters.

Life cycle assessment (LCA) studies demonstrate that optimized coating thickness can reduce environmental impact by 15-30% compared to conventional systems, particularly when considering the entire product lifespan from manufacturing to disposal. The durability enhancement achieved through properly calibrated coating thickness extends service life, thereby reducing replacement frequency and associated waste generation.

Energy efficiency represents another critical sustainability dimension. Thermally optimized coatings with precisely controlled thickness can significantly improve energy performance in buildings and industrial applications. For instance, thermal barrier coatings in aerospace and power generation sectors demonstrate up to 20% improvement in fuel efficiency when thickness is optimized for specific operating conditions.

Waste reduction strategies have evolved considerably in coating application technologies. Advanced deposition methods like plasma spraying and physical vapor deposition enable precise thickness control, minimizing overspray and material waste. These technologies can achieve material utilization rates exceeding 90%, compared to conventional methods that typically range between 60-70%.

Regulatory compliance and market demands increasingly drive sustainability innovations in coating systems. Recent environmental regulations in Europe and North America have established strict limits on volatile organic compounds (VOCs) and hazardous materials in coatings, necessitating thickness optimization to maintain performance while meeting these requirements. Companies demonstrating leadership in sustainable coating practices have reported enhanced brand value and market differentiation.

Economic sustainability also benefits from thickness optimization. Cost-benefit analyses reveal that while high-performance coatings may require greater initial investment, the extended service life and reduced maintenance requirements deliver substantial long-term economic advantages. Case studies from automotive and marine industries indicate lifecycle cost reductions of 25-40% through implementation of optimized coating systems with precisely controlled thickness parameters.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!