Comparative study of mechanical vs. electrical KERS

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

KERS Evolution & Objectives

Kinetic Energy Recovery Systems (KERS) have evolved significantly since their inception in the automotive industry, particularly in motorsports. The technology's primary objective is to capture and store kinetic energy that would otherwise be lost during braking, and then redeploy it to boost acceleration or improve fuel efficiency. This concept aligns with the growing global emphasis on energy conservation and sustainable transportation solutions.

The evolution of KERS can be traced back to the early 2000s when Formula 1 teams began exploring ways to enhance vehicle performance while adhering to increasingly stringent fuel consumption regulations. Initially, mechanical KERS systems were developed, utilizing flywheels to store rotational energy. These systems offered rapid energy storage and release capabilities but faced challenges in terms of weight and packaging within vehicles.

As technology progressed, electrical KERS systems emerged as a viable alternative. These systems employ electric motor-generators coupled with energy storage devices, typically high-power batteries or supercapacitors. Electrical KERS offered greater flexibility in energy management and integration with hybrid powertrains, leading to their widespread adoption in both racing and production vehicles.

The objectives of KERS technology have expanded beyond mere performance enhancement. In the context of road vehicles, KERS aims to improve overall energy efficiency, reduce emissions, and contribute to the electrification of transportation. For motorsports, KERS serves as a platform for developing and testing advanced energy recovery technologies that can later be adapted for consumer vehicles.

Comparing mechanical and electrical KERS reveals distinct advantages and challenges for each approach. Mechanical systems excel in power density and rapid energy transfer, making them suitable for high-performance applications. However, they often struggle with integration complexity and limited energy storage capacity. Electrical systems, on the other hand, offer greater versatility in energy management and easier integration with existing vehicle electrical systems, but may face challenges related to battery technology limitations and thermal management.

The ongoing evolution of KERS technology focuses on addressing these challenges while maximizing the benefits of energy recovery. Research efforts are directed towards improving energy storage density, reducing system weight, enhancing durability, and optimizing control strategies for various driving conditions. Additionally, there is a growing interest in developing hybrid KERS solutions that combine the strengths of both mechanical and electrical systems to achieve superior performance and efficiency.

As the automotive industry continues its transition towards electrification, the role of KERS is expected to evolve further. Future objectives may include seamless integration with autonomous driving systems, advanced predictive energy management algorithms, and exploration of novel energy storage technologies. The comparative study of mechanical and electrical KERS remains crucial for informing these developments and guiding the future direction of energy recovery systems in transportation.

The evolution of KERS can be traced back to the early 2000s when Formula 1 teams began exploring ways to enhance vehicle performance while adhering to increasingly stringent fuel consumption regulations. Initially, mechanical KERS systems were developed, utilizing flywheels to store rotational energy. These systems offered rapid energy storage and release capabilities but faced challenges in terms of weight and packaging within vehicles.

As technology progressed, electrical KERS systems emerged as a viable alternative. These systems employ electric motor-generators coupled with energy storage devices, typically high-power batteries or supercapacitors. Electrical KERS offered greater flexibility in energy management and integration with hybrid powertrains, leading to their widespread adoption in both racing and production vehicles.

The objectives of KERS technology have expanded beyond mere performance enhancement. In the context of road vehicles, KERS aims to improve overall energy efficiency, reduce emissions, and contribute to the electrification of transportation. For motorsports, KERS serves as a platform for developing and testing advanced energy recovery technologies that can later be adapted for consumer vehicles.

Comparing mechanical and electrical KERS reveals distinct advantages and challenges for each approach. Mechanical systems excel in power density and rapid energy transfer, making them suitable for high-performance applications. However, they often struggle with integration complexity and limited energy storage capacity. Electrical systems, on the other hand, offer greater versatility in energy management and easier integration with existing vehicle electrical systems, but may face challenges related to battery technology limitations and thermal management.

The ongoing evolution of KERS technology focuses on addressing these challenges while maximizing the benefits of energy recovery. Research efforts are directed towards improving energy storage density, reducing system weight, enhancing durability, and optimizing control strategies for various driving conditions. Additionally, there is a growing interest in developing hybrid KERS solutions that combine the strengths of both mechanical and electrical systems to achieve superior performance and efficiency.

As the automotive industry continues its transition towards electrification, the role of KERS is expected to evolve further. Future objectives may include seamless integration with autonomous driving systems, advanced predictive energy management algorithms, and exploration of novel energy storage technologies. The comparative study of mechanical and electrical KERS remains crucial for informing these developments and guiding the future direction of energy recovery systems in transportation.

Market Demand Analysis

The market demand for Kinetic Energy Recovery Systems (KERS) has been steadily growing, driven by the automotive industry's push towards improved fuel efficiency and reduced emissions. Both mechanical and electrical KERS have garnered significant interest from manufacturers and consumers alike, with each system offering unique advantages in different market segments.

In the passenger vehicle market, there is a strong demand for electrical KERS, particularly in hybrid and electric vehicles. This demand is fueled by the increasing adoption of electrification in the automotive sector, with many countries setting ambitious targets for phasing out internal combustion engines. Electrical KERS aligns well with the broader trend of vehicle electrification, offering seamless integration with existing electric powertrains.

On the other hand, mechanical KERS has found a niche in high-performance and motorsport applications. Formula 1 racing, for instance, has been a significant driver of mechanical KERS development, showcasing its potential for rapid energy storage and release. This has led to increased interest from sports car manufacturers and racing teams looking to leverage the technology for improved performance and efficiency.

The commercial vehicle sector presents a growing market for both mechanical and electrical KERS. Long-haul trucks and buses can benefit significantly from energy recovery systems, with the choice between mechanical and electrical solutions often depending on the specific application and route characteristics. Urban delivery vehicles, which frequently start and stop, show a particular demand for KERS technology to improve fuel economy and reduce emissions in city environments.

In the public transportation sector, there is a rising demand for KERS in buses and trams. Electrical KERS is often preferred in this context due to its compatibility with existing electric drive systems and the potential for zero-emission operation in urban areas. However, mechanical KERS still holds appeal for certain bus routes where its simplicity and robustness offer advantages.

The industrial sector also shows promising market potential for KERS technology. Heavy machinery, such as cranes and excavators, can benefit from energy recovery systems to improve efficiency and reduce fuel consumption. In this context, both mechanical and electrical KERS are being explored, with the choice often depending on the specific application and power requirements.

As environmental regulations become more stringent globally, the demand for KERS is expected to grow across various industries. The automotive sector remains the primary driver, but emerging applications in aerospace, marine, and renewable energy sectors are expanding the market potential. This diversification of applications is likely to sustain the demand for both mechanical and electrical KERS, with each finding its place in specific market niches based on their respective strengths and limitations.

In the passenger vehicle market, there is a strong demand for electrical KERS, particularly in hybrid and electric vehicles. This demand is fueled by the increasing adoption of electrification in the automotive sector, with many countries setting ambitious targets for phasing out internal combustion engines. Electrical KERS aligns well with the broader trend of vehicle electrification, offering seamless integration with existing electric powertrains.

On the other hand, mechanical KERS has found a niche in high-performance and motorsport applications. Formula 1 racing, for instance, has been a significant driver of mechanical KERS development, showcasing its potential for rapid energy storage and release. This has led to increased interest from sports car manufacturers and racing teams looking to leverage the technology for improved performance and efficiency.

The commercial vehicle sector presents a growing market for both mechanical and electrical KERS. Long-haul trucks and buses can benefit significantly from energy recovery systems, with the choice between mechanical and electrical solutions often depending on the specific application and route characteristics. Urban delivery vehicles, which frequently start and stop, show a particular demand for KERS technology to improve fuel economy and reduce emissions in city environments.

In the public transportation sector, there is a rising demand for KERS in buses and trams. Electrical KERS is often preferred in this context due to its compatibility with existing electric drive systems and the potential for zero-emission operation in urban areas. However, mechanical KERS still holds appeal for certain bus routes where its simplicity and robustness offer advantages.

The industrial sector also shows promising market potential for KERS technology. Heavy machinery, such as cranes and excavators, can benefit from energy recovery systems to improve efficiency and reduce fuel consumption. In this context, both mechanical and electrical KERS are being explored, with the choice often depending on the specific application and power requirements.

As environmental regulations become more stringent globally, the demand for KERS is expected to grow across various industries. The automotive sector remains the primary driver, but emerging applications in aerospace, marine, and renewable energy sectors are expanding the market potential. This diversification of applications is likely to sustain the demand for both mechanical and electrical KERS, with each finding its place in specific market niches based on their respective strengths and limitations.

KERS Tech Landscape

Kinetic Energy Recovery Systems (KERS) have emerged as a significant technological advancement in the automotive industry, particularly in the realm of energy efficiency and performance enhancement. The KERS technology landscape has evolved rapidly over the past decade, with two primary variants dominating the field: mechanical and electrical systems.

Mechanical KERS, pioneered in Formula 1 racing, utilizes a flywheel to store kinetic energy during braking. This stored energy is then released to provide additional power during acceleration. The technology has seen significant improvements in terms of weight reduction, efficiency, and integration with vehicle systems. Key players in this field include Flybrid Systems and Torotrak, who have made substantial advancements in flywheel design and energy transfer mechanisms.

Electrical KERS, on the other hand, employs electric motors and batteries to capture and store braking energy. This approach has gained traction due to its compatibility with hybrid and electric vehicle architectures. Companies like Bosch and Continental have been at the forefront of developing sophisticated electrical KERS solutions, integrating them seamlessly with existing powertrain systems.

The technological trajectory of KERS has been marked by continuous improvements in energy storage capacity, power density, and system integration. Mechanical systems have seen advancements in materials science, leading to lighter and more durable flywheels. Simultaneously, electrical systems have benefited from progress in battery technology and power electronics, resulting in more efficient energy conversion and storage.

A notable trend in the KERS landscape is the convergence of mechanical and electrical technologies. Hybrid systems that combine the strengths of both approaches are being explored, aiming to maximize energy recovery and utilization. This fusion is particularly evident in high-performance applications where every fraction of energy savings can translate to a competitive advantage.

The geographical distribution of KERS technology development shows concentrations in automotive hubs across Europe, North America, and Asia. Germany, with its strong automotive industry, has been a leader in electrical KERS development. The UK, leveraging its motorsport expertise, has made significant strides in mechanical KERS. Japan and South Korea have also emerged as key players, particularly in the integration of KERS with hybrid vehicle technologies.

As the automotive industry shifts towards electrification and sustainability, KERS technology is expected to play an increasingly crucial role. The focus is now on developing more compact, efficient, and cost-effective systems that can be deployed across a wider range of vehicles, from high-performance sports cars to everyday commuter vehicles.

Mechanical KERS, pioneered in Formula 1 racing, utilizes a flywheel to store kinetic energy during braking. This stored energy is then released to provide additional power during acceleration. The technology has seen significant improvements in terms of weight reduction, efficiency, and integration with vehicle systems. Key players in this field include Flybrid Systems and Torotrak, who have made substantial advancements in flywheel design and energy transfer mechanisms.

Electrical KERS, on the other hand, employs electric motors and batteries to capture and store braking energy. This approach has gained traction due to its compatibility with hybrid and electric vehicle architectures. Companies like Bosch and Continental have been at the forefront of developing sophisticated electrical KERS solutions, integrating them seamlessly with existing powertrain systems.

The technological trajectory of KERS has been marked by continuous improvements in energy storage capacity, power density, and system integration. Mechanical systems have seen advancements in materials science, leading to lighter and more durable flywheels. Simultaneously, electrical systems have benefited from progress in battery technology and power electronics, resulting in more efficient energy conversion and storage.

A notable trend in the KERS landscape is the convergence of mechanical and electrical technologies. Hybrid systems that combine the strengths of both approaches are being explored, aiming to maximize energy recovery and utilization. This fusion is particularly evident in high-performance applications where every fraction of energy savings can translate to a competitive advantage.

The geographical distribution of KERS technology development shows concentrations in automotive hubs across Europe, North America, and Asia. Germany, with its strong automotive industry, has been a leader in electrical KERS development. The UK, leveraging its motorsport expertise, has made significant strides in mechanical KERS. Japan and South Korea have also emerged as key players, particularly in the integration of KERS with hybrid vehicle technologies.

As the automotive industry shifts towards electrification and sustainability, KERS technology is expected to play an increasingly crucial role. The focus is now on developing more compact, efficient, and cost-effective systems that can be deployed across a wider range of vehicles, from high-performance sports cars to everyday commuter vehicles.

Current KERS Solutions

01 Energy recovery and storage systems in vehicles

KERS technology is implemented in vehicles to recover and store kinetic energy during braking or deceleration. This stored energy can then be used to provide additional power during acceleration, improving overall vehicle efficiency and performance. The system typically includes energy storage devices such as flywheels, batteries, or supercapacitors.- Energy recovery and storage systems in vehicles: KERS technology is implemented in vehicles to recover and store kinetic energy during braking or deceleration. This stored energy can then be used to provide additional power during acceleration, improving overall vehicle efficiency and performance. The system typically includes energy storage devices such as flywheels, batteries, or supercapacitors.

- Flywheel-based KERS: Flywheel-based KERS systems use a rotating mass to store recovered kinetic energy as rotational energy. These systems can quickly absorb and release large amounts of energy, making them particularly suitable for applications with frequent acceleration and deceleration cycles. Flywheel KERS can be mechanically or electrically coupled to the drivetrain.

- Electric KERS with regenerative braking: Electric KERS systems utilize regenerative braking to convert kinetic energy into electrical energy, which is then stored in batteries or supercapacitors. This stored electrical energy can be used to power electric motors, providing additional torque during acceleration or reducing the load on the main power source. This technology is commonly used in hybrid and electric vehicles.

- Hydraulic KERS: Hydraulic KERS systems use hydraulic accumulators to store recovered energy in the form of pressurized fluid. During braking, a hydraulic pump pressurizes the fluid, which can later be released to drive a hydraulic motor. This type of KERS is particularly suitable for heavy vehicles and construction equipment due to its high power density and durability.

- Integration of KERS with other vehicle systems: KERS technology is increasingly being integrated with other vehicle systems to maximize efficiency and performance. This includes combining KERS with advanced powertrain control systems, integrating it with hybrid powertrains, and using it in conjunction with other energy-saving technologies. Such integration allows for optimized energy management and improved overall vehicle efficiency.

02 Flywheel-based KERS

Flywheel-based KERS systems use a rotating mass to store recovered kinetic energy as rotational energy. These systems can quickly absorb and release large amounts of energy, making them particularly suitable for applications with frequent acceleration and deceleration cycles. Flywheel KERS can be mechanically or electrically coupled to the drivetrain.Expand Specific Solutions03 Electric KERS with regenerative braking

Electric KERS systems utilize regenerative braking to convert kinetic energy into electrical energy, which is then stored in batteries or supercapacitors. This recovered energy can be used to power electric motors for propulsion or to support auxiliary systems in the vehicle. Electric KERS is commonly used in hybrid and electric vehicles to improve overall energy efficiency.Expand Specific Solutions04 Hydraulic KERS

Hydraulic KERS systems use hydraulic accumulators to store recovered energy in the form of pressurized fluid. During braking, a hydraulic pump pressurizes the fluid, which can later be released to drive a hydraulic motor for propulsion. This type of KERS is particularly suitable for heavy-duty vehicles and construction equipment due to its high power density.Expand Specific Solutions05 KERS integration and control strategies

Advanced control strategies and integration techniques are developed to optimize KERS performance in various vehicle applications. These include intelligent energy management systems, adaptive control algorithms, and seamless integration with existing powertrain components. The focus is on maximizing energy recovery, improving system efficiency, and enhancing overall vehicle performance across different driving conditions.Expand Specific Solutions

Key KERS Players

The comparative study of mechanical vs. electrical Kinetic Energy Recovery Systems (KERS) reveals a competitive landscape in an evolving industry. The market is in a growth phase, with increasing adoption in automotive and motorsport sectors. Market size is expanding as more manufacturers integrate KERS into their vehicles. Technologically, both mechanical and electrical systems are maturing, with companies like Volvo, Punch Flybrid, and Marelli Europe leading development. Volvo focuses on heavy-duty applications, while Punch Flybrid specializes in flywheel-based systems. Marelli Europe contributes to electrical KERS advancements. The competition is intensifying as automotive giants like GM and emerging players such as Ampaire enter the field, driving innovation and efficiency improvements in both mechanical and electrical KERS technologies.

Volvo Lastvagnar AB

Technical Solution: Volvo Trucks has developed a unique hybrid KERS system specifically designed for heavy-duty vehicles. Their I-SAM (Integrated Starter Alternator Motor) technology combines a powerful electric motor with an automated manual transmission. The system can recover up to 150 kW of braking energy, which is stored in high-capacity lithium-ion batteries[13]. This recovered energy can be used to assist the diesel engine during acceleration, reducing fuel consumption by up to 30% in urban delivery applications[14]. Volvo's system also allows for short distances of pure electric driving, beneficial for operating in low-emission zones. The KERS technology is integrated with Volvo's I-See predictive cruise control, which uses topographical data to optimize energy recovery and usage based on the road ahead[15].

Strengths: Specifically optimized for heavy-duty vehicles, high fuel savings potential, and integration with predictive driving systems. Weaknesses: Limited pure electric range and potential for increased initial cost in commercial vehicles.

Punch Flybrid Ltd

Technical Solution: Punch Flybrid specializes in mechanical KERS using advanced flywheel technology. Their system employs a carbon fiber flywheel that can spin at speeds up to 60,000 RPM, storing energy as rotational kinetic energy[4]. The flywheel is connected to the drivetrain through a Continuously Variable Transmission (CVT), allowing for efficient energy transfer during both recovery and boost phases. This purely mechanical system can deliver power peaks of up to 60 kW and store around 600 kJ of energy[5]. Punch Flybrid's technology has been successfully applied in motorsports, including Formula 1 and endurance racing, demonstrating its effectiveness in high-performance applications[6].

Strengths: High power density, rapid energy transfer, and no reliance on battery technology. Weaknesses: Limited energy storage capacity compared to electrical systems and potential safety concerns with high-speed rotating masses.

Core KERS Innovations

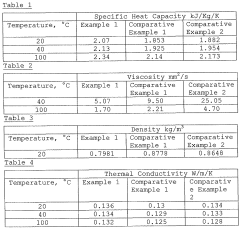

Lubricating composition

PatentWO2011113851A1

Innovation

- A lubricating composition comprising a base oil (such as mineral, synthetic, or vegetable oils) with specific heat capacity and kinematic viscosity properties, along with antioxidants and minimal water content, is used for cooling and insulating electric batteries or motors in KERS and hybrid vehicles.

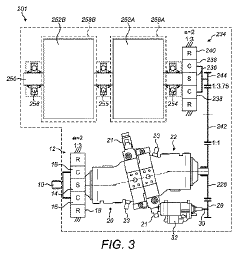

Kinetic energy regeneration system

PatentActiveJP2019521032A

Innovation

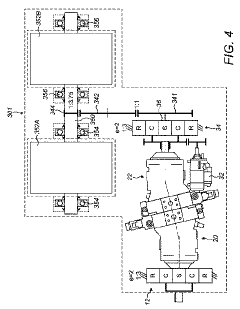

- A kinetic energy recovery system (KERS) incorporating a first speed increasing gear unit, hydraulic variator with oblique axis motors, and a flywheel positioned in a vacuum chamber, controlled by an electronic control unit (ECU) to manage energy storage and retrieval efficiently.

KERS Energy Efficiency

The energy efficiency of Kinetic Energy Recovery Systems (KERS) is a critical factor in evaluating their performance and potential for widespread adoption in automotive applications. Both mechanical and electrical KERS have shown promising results in improving vehicle fuel economy and reducing emissions.

Mechanical KERS, typically utilizing flywheel technology, has demonstrated high energy efficiency in short-term energy storage and release cycles. The direct mechanical connection between the flywheel and the drivetrain minimizes energy conversion losses, resulting in efficiency rates of up to 70-80% in ideal conditions. However, the efficiency can decrease over time due to friction and heat generation in the bearings and transmission system.

Electrical KERS, on the other hand, employs electric motor-generators and battery storage systems. While the energy conversion process from mechanical to electrical and back introduces some inherent losses, advancements in power electronics and battery technology have significantly improved overall system efficiency. Modern electrical KERS can achieve efficiency rates of 60-75%, with the added benefit of more flexible energy management and integration with hybrid and electric vehicle powertrains.

A comparative analysis of real-world performance data reveals that the efficiency gap between mechanical and electrical KERS has narrowed in recent years. Mechanical systems still hold a slight edge in short-duration, high-power applications, such as Formula 1 racing. However, electrical KERS demonstrates superior efficiency in longer-duration energy storage and in scenarios requiring frequent energy recuperation, such as urban driving cycles.

The energy density of the storage medium also plays a crucial role in overall system efficiency. Flywheels used in mechanical KERS offer high power density but limited energy storage capacity. In contrast, electrical KERS can leverage advancements in battery technology to provide both high power and energy density, albeit at the cost of increased system complexity and weight.

Environmental factors and operating conditions significantly impact the efficiency of both KERS types. Mechanical systems are more sensitive to temperature variations and vibrations, which can affect bearing performance and system alignment. Electrical KERS, while generally more robust in diverse operating conditions, may experience efficiency losses in extreme temperatures due to battery performance limitations.

Looking ahead, ongoing research and development efforts are focused on further improving the energy efficiency of both mechanical and electrical KERS. For mechanical systems, innovations in low-friction bearings, advanced materials for flywheel construction, and optimized transmission designs are being explored. In the electrical domain, the integration of wide-bandgap semiconductors, enhanced battery chemistries, and intelligent energy management algorithms promise to push efficiency boundaries even further.

Mechanical KERS, typically utilizing flywheel technology, has demonstrated high energy efficiency in short-term energy storage and release cycles. The direct mechanical connection between the flywheel and the drivetrain minimizes energy conversion losses, resulting in efficiency rates of up to 70-80% in ideal conditions. However, the efficiency can decrease over time due to friction and heat generation in the bearings and transmission system.

Electrical KERS, on the other hand, employs electric motor-generators and battery storage systems. While the energy conversion process from mechanical to electrical and back introduces some inherent losses, advancements in power electronics and battery technology have significantly improved overall system efficiency. Modern electrical KERS can achieve efficiency rates of 60-75%, with the added benefit of more flexible energy management and integration with hybrid and electric vehicle powertrains.

A comparative analysis of real-world performance data reveals that the efficiency gap between mechanical and electrical KERS has narrowed in recent years. Mechanical systems still hold a slight edge in short-duration, high-power applications, such as Formula 1 racing. However, electrical KERS demonstrates superior efficiency in longer-duration energy storage and in scenarios requiring frequent energy recuperation, such as urban driving cycles.

The energy density of the storage medium also plays a crucial role in overall system efficiency. Flywheels used in mechanical KERS offer high power density but limited energy storage capacity. In contrast, electrical KERS can leverage advancements in battery technology to provide both high power and energy density, albeit at the cost of increased system complexity and weight.

Environmental factors and operating conditions significantly impact the efficiency of both KERS types. Mechanical systems are more sensitive to temperature variations and vibrations, which can affect bearing performance and system alignment. Electrical KERS, while generally more robust in diverse operating conditions, may experience efficiency losses in extreme temperatures due to battery performance limitations.

Looking ahead, ongoing research and development efforts are focused on further improving the energy efficiency of both mechanical and electrical KERS. For mechanical systems, innovations in low-friction bearings, advanced materials for flywheel construction, and optimized transmission designs are being explored. In the electrical domain, the integration of wide-bandgap semiconductors, enhanced battery chemistries, and intelligent energy management algorithms promise to push efficiency boundaries even further.

KERS Safety Regulations

Safety regulations for Kinetic Energy Recovery Systems (KERS) are crucial to ensure the safe operation and implementation of these energy-saving technologies in vehicles. Both mechanical and electrical KERS systems are subject to stringent safety standards to protect drivers, passengers, and maintenance personnel.

For mechanical KERS, safety regulations primarily focus on the containment and management of high-speed rotating components. These systems typically use flywheels that spin at extremely high velocities, posing potential risks in case of failure. Regulations mandate robust containment structures to prevent flywheel fragmentation in the event of a malfunction. Additionally, safety measures are required to manage the gyroscopic effects of the spinning flywheel, which can impact vehicle handling and stability.

Electrical KERS systems, on the other hand, face different safety challenges. Regulations for these systems concentrate on electrical safety, battery management, and thermal control. High-voltage components must be properly insulated and protected against short circuits and electrical arcing. Battery systems are required to have advanced management systems to prevent overcharging, over-discharging, and thermal runaway. Cooling systems are mandated to maintain safe operating temperatures for electrical components and batteries.

Both types of KERS are subject to electromagnetic compatibility (EMC) regulations to ensure they do not interfere with other vehicle electronics or external communication systems. This is particularly critical for electrical KERS due to the high-power electrical systems involved.

Crash safety is another crucial aspect of KERS regulations. For mechanical systems, this involves ensuring that the flywheel containment can withstand impact forces without releasing high-energy components. Electrical KERS must have safeguards to disconnect high-voltage systems and prevent battery damage or fires in the event of a collision.

Maintenance and service safety regulations are also in place for both types of KERS. These include procedures for safely discharging stored energy before maintenance, proper handling of high-voltage components in electrical systems, and safe management of the high-speed components in mechanical systems.

Regulatory bodies such as the FIA (Fédération Internationale de l'Automobile) for motorsports and various national transportation safety agencies have developed specific guidelines for KERS implementation. These regulations are continuously evolving as technology advances and new safety considerations emerge.

In conclusion, while both mechanical and electrical KERS systems have unique safety challenges, the overarching goal of safety regulations is to ensure reliable operation, minimize risks to users and maintainers, and integrate these energy recovery systems seamlessly into vehicle designs without compromising overall safety standards.

For mechanical KERS, safety regulations primarily focus on the containment and management of high-speed rotating components. These systems typically use flywheels that spin at extremely high velocities, posing potential risks in case of failure. Regulations mandate robust containment structures to prevent flywheel fragmentation in the event of a malfunction. Additionally, safety measures are required to manage the gyroscopic effects of the spinning flywheel, which can impact vehicle handling and stability.

Electrical KERS systems, on the other hand, face different safety challenges. Regulations for these systems concentrate on electrical safety, battery management, and thermal control. High-voltage components must be properly insulated and protected against short circuits and electrical arcing. Battery systems are required to have advanced management systems to prevent overcharging, over-discharging, and thermal runaway. Cooling systems are mandated to maintain safe operating temperatures for electrical components and batteries.

Both types of KERS are subject to electromagnetic compatibility (EMC) regulations to ensure they do not interfere with other vehicle electronics or external communication systems. This is particularly critical for electrical KERS due to the high-power electrical systems involved.

Crash safety is another crucial aspect of KERS regulations. For mechanical systems, this involves ensuring that the flywheel containment can withstand impact forces without releasing high-energy components. Electrical KERS must have safeguards to disconnect high-voltage systems and prevent battery damage or fires in the event of a collision.

Maintenance and service safety regulations are also in place for both types of KERS. These include procedures for safely discharging stored energy before maintenance, proper handling of high-voltage components in electrical systems, and safe management of the high-speed components in mechanical systems.

Regulatory bodies such as the FIA (Fédération Internationale de l'Automobile) for motorsports and various national transportation safety agencies have developed specific guidelines for KERS implementation. These regulations are continuously evolving as technology advances and new safety considerations emerge.

In conclusion, while both mechanical and electrical KERS systems have unique safety challenges, the overarching goal of safety regulations is to ensure reliable operation, minimize risks to users and maintainers, and integrate these energy recovery systems seamlessly into vehicle designs without compromising overall safety standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!