Comparison of KERS and traditional braking systems

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

KERS and Braking Evolution

The evolution of braking systems in automotive engineering has been a journey of continuous innovation, driven by the need for improved safety, efficiency, and performance. Traditional braking systems, which have been the standard for decades, rely on friction to convert kinetic energy into heat. These systems typically consist of brake pads, rotors, and hydraulic components that work together to slow or stop a vehicle.

In recent years, a significant advancement in braking technology has emerged in the form of Kinetic Energy Recovery Systems (KERS). KERS represents a paradigm shift in how vehicles manage energy during deceleration. Unlike traditional brakes that dissipate energy as heat, KERS captures and stores the kinetic energy that would otherwise be lost during braking. This stored energy can then be redeployed to assist acceleration, effectively improving overall vehicle efficiency.

The development of KERS can be traced back to Formula 1 racing, where it was introduced in 2009 as a means to enhance performance and promote energy efficiency. From there, the technology has gradually made its way into production vehicles, particularly in hybrid and electric cars. The adoption of KERS in consumer vehicles marks a significant milestone in the evolution of braking systems, as it transforms the act of braking from a purely energy-dissipating process to an energy-recuperating one.

As environmental concerns and fuel efficiency regulations have become more stringent, the automotive industry has increasingly focused on technologies that can reduce energy waste. KERS aligns perfectly with this goal, offering a way to recapture energy that would otherwise be lost. This has led to its integration into various hybrid powertrains and regenerative braking systems in electric vehicles.

The evolution from traditional braking to KERS has also spurred advancements in related technologies. For instance, the development of high-capacity, fast-charging batteries and supercapacitors has been crucial in making KERS more effective. Similarly, improvements in power electronics and control systems have enabled more sophisticated energy management strategies, further enhancing the benefits of KERS.

Looking ahead, the trajectory of braking system evolution points towards even greater integration of KERS principles. Future developments may include more advanced energy storage solutions, improved power density in electric motors used for regenerative braking, and smarter control systems that can optimize energy recovery based on driving conditions and driver behavior. As vehicles become more connected and autonomous, the potential for KERS to contribute to overall vehicle efficiency and performance will likely expand, marking a new chapter in the ongoing evolution of automotive braking technology.

In recent years, a significant advancement in braking technology has emerged in the form of Kinetic Energy Recovery Systems (KERS). KERS represents a paradigm shift in how vehicles manage energy during deceleration. Unlike traditional brakes that dissipate energy as heat, KERS captures and stores the kinetic energy that would otherwise be lost during braking. This stored energy can then be redeployed to assist acceleration, effectively improving overall vehicle efficiency.

The development of KERS can be traced back to Formula 1 racing, where it was introduced in 2009 as a means to enhance performance and promote energy efficiency. From there, the technology has gradually made its way into production vehicles, particularly in hybrid and electric cars. The adoption of KERS in consumer vehicles marks a significant milestone in the evolution of braking systems, as it transforms the act of braking from a purely energy-dissipating process to an energy-recuperating one.

As environmental concerns and fuel efficiency regulations have become more stringent, the automotive industry has increasingly focused on technologies that can reduce energy waste. KERS aligns perfectly with this goal, offering a way to recapture energy that would otherwise be lost. This has led to its integration into various hybrid powertrains and regenerative braking systems in electric vehicles.

The evolution from traditional braking to KERS has also spurred advancements in related technologies. For instance, the development of high-capacity, fast-charging batteries and supercapacitors has been crucial in making KERS more effective. Similarly, improvements in power electronics and control systems have enabled more sophisticated energy management strategies, further enhancing the benefits of KERS.

Looking ahead, the trajectory of braking system evolution points towards even greater integration of KERS principles. Future developments may include more advanced energy storage solutions, improved power density in electric motors used for regenerative braking, and smarter control systems that can optimize energy recovery based on driving conditions and driver behavior. As vehicles become more connected and autonomous, the potential for KERS to contribute to overall vehicle efficiency and performance will likely expand, marking a new chapter in the ongoing evolution of automotive braking technology.

Market Demand Analysis

The market demand for Kinetic Energy Recovery Systems (KERS) and traditional braking systems is undergoing significant shifts due to evolving automotive technologies and environmental concerns. Traditional braking systems have long been the standard in the automotive industry, with a mature market and widespread adoption across all vehicle types. However, the growing emphasis on energy efficiency and reduced emissions has sparked increased interest in KERS technology.

KERS offers a unique value proposition by capturing and repurposing kinetic energy that would otherwise be lost during braking. This technology aligns well with the automotive industry's push towards electrification and hybrid powertrains. As a result, the market for KERS is experiencing rapid growth, particularly in the high-performance and luxury vehicle segments.

The global automotive brake market, which includes both traditional and regenerative braking systems, is projected to expand significantly in the coming years. This growth is driven by increasing vehicle production, stringent safety regulations, and the rising demand for electric and hybrid vehicles. Traditional braking systems continue to dominate the market share due to their reliability, lower cost, and widespread use in conventional vehicles.

However, the market dynamics are shifting as automakers increasingly integrate KERS into their vehicle lineups. This trend is particularly evident in Formula 1 racing, where KERS has been mandatory since 2014, showcasing its performance benefits in high-stress environments. The success in motorsports has accelerated the adoption of KERS in consumer vehicles, especially in the premium and sports car segments.

The commercial vehicle sector is also showing growing interest in KERS technology. Fleet operators are recognizing the potential fuel savings and reduced maintenance costs associated with regenerative braking systems. This has led to increased demand for KERS in buses, trucks, and other heavy-duty vehicles, where the energy recovery potential is substantial due to frequent stops and starts.

Environmental regulations and government incentives are playing a crucial role in shaping market demand. Many countries have implemented stricter emissions standards and fuel efficiency requirements, pushing automakers to adopt innovative technologies like KERS. Additionally, government subsidies and tax incentives for eco-friendly vehicles are driving consumer interest in cars equipped with energy recovery systems.

Consumer awareness and preferences are also evolving. As environmental consciousness grows, car buyers are increasingly valuing fuel efficiency and reduced carbon footprints. This shift in consumer behavior is creating a favorable market environment for KERS-equipped vehicles, particularly in urban areas where stop-and-go traffic is common.

Despite the growing interest in KERS, traditional braking systems are expected to maintain a significant market share in the near future. The lower cost and established manufacturing infrastructure for conventional brakes ensure their continued relevance, especially in entry-level and mid-range vehicles. However, the long-term trend suggests a gradual shift towards hybrid braking systems that combine traditional friction brakes with energy recovery mechanisms.

KERS offers a unique value proposition by capturing and repurposing kinetic energy that would otherwise be lost during braking. This technology aligns well with the automotive industry's push towards electrification and hybrid powertrains. As a result, the market for KERS is experiencing rapid growth, particularly in the high-performance and luxury vehicle segments.

The global automotive brake market, which includes both traditional and regenerative braking systems, is projected to expand significantly in the coming years. This growth is driven by increasing vehicle production, stringent safety regulations, and the rising demand for electric and hybrid vehicles. Traditional braking systems continue to dominate the market share due to their reliability, lower cost, and widespread use in conventional vehicles.

However, the market dynamics are shifting as automakers increasingly integrate KERS into their vehicle lineups. This trend is particularly evident in Formula 1 racing, where KERS has been mandatory since 2014, showcasing its performance benefits in high-stress environments. The success in motorsports has accelerated the adoption of KERS in consumer vehicles, especially in the premium and sports car segments.

The commercial vehicle sector is also showing growing interest in KERS technology. Fleet operators are recognizing the potential fuel savings and reduced maintenance costs associated with regenerative braking systems. This has led to increased demand for KERS in buses, trucks, and other heavy-duty vehicles, where the energy recovery potential is substantial due to frequent stops and starts.

Environmental regulations and government incentives are playing a crucial role in shaping market demand. Many countries have implemented stricter emissions standards and fuel efficiency requirements, pushing automakers to adopt innovative technologies like KERS. Additionally, government subsidies and tax incentives for eco-friendly vehicles are driving consumer interest in cars equipped with energy recovery systems.

Consumer awareness and preferences are also evolving. As environmental consciousness grows, car buyers are increasingly valuing fuel efficiency and reduced carbon footprints. This shift in consumer behavior is creating a favorable market environment for KERS-equipped vehicles, particularly in urban areas where stop-and-go traffic is common.

Despite the growing interest in KERS, traditional braking systems are expected to maintain a significant market share in the near future. The lower cost and established manufacturing infrastructure for conventional brakes ensure their continued relevance, especially in entry-level and mid-range vehicles. However, the long-term trend suggests a gradual shift towards hybrid braking systems that combine traditional friction brakes with energy recovery mechanisms.

Technical Challenges

The comparison between Kinetic Energy Recovery Systems (KERS) and traditional braking systems reveals several technical challenges that need to be addressed. One of the primary obstacles is the integration of KERS into existing vehicle architectures. Unlike traditional braking systems, which are well-established and standardized, KERS requires significant modifications to the vehicle's powertrain and energy management systems. This integration challenge often leads to increased complexity in vehicle design and manufacturing processes.

Energy storage is another critical technical hurdle for KERS. While traditional braking systems simply dissipate kinetic energy as heat, KERS must efficiently capture, store, and release energy. Current energy storage technologies, such as batteries and supercapacitors, face limitations in terms of energy density, power density, and cycle life. These limitations can impact the overall performance and longevity of KERS-equipped vehicles.

Weight management presents a significant challenge for KERS implementation. The additional components required for energy recovery and storage add considerable mass to the vehicle, potentially offsetting the efficiency gains. Engineers must carefully balance the weight of KERS components against the energy recovery benefits to ensure a net positive impact on vehicle performance and fuel economy.

Thermal management is a crucial aspect that differs between KERS and traditional braking systems. While conventional brakes primarily focus on dissipating heat, KERS must manage both the heat generated during braking and the thermal loads associated with energy storage and power electronics. This dual thermal management requirement adds complexity to the cooling system design and can impact overall system efficiency.

Control systems and software integration pose unique challenges for KERS. The system must seamlessly coordinate between regenerative braking and traditional friction braking, ensuring optimal energy recovery without compromising vehicle stability or driver comfort. This requires sophisticated control algorithms and real-time data processing capabilities that are not necessary in conventional braking systems.

Durability and reliability are areas where KERS faces significant technical hurdles compared to traditional braking systems. The additional mechanical and electrical components in KERS are subject to high stress and frequent cycling, potentially leading to increased wear and maintenance requirements. Ensuring long-term reliability while maintaining cost-effectiveness remains a key challenge for KERS developers.

Lastly, the cost factor presents a substantial barrier to widespread KERS adoption. The complex technology and specialized components required for KERS significantly increase the overall cost of the braking system compared to traditional solutions. Achieving cost parity or demonstrating a clear return on investment is crucial for broader market acceptance of KERS technology.

Energy storage is another critical technical hurdle for KERS. While traditional braking systems simply dissipate kinetic energy as heat, KERS must efficiently capture, store, and release energy. Current energy storage technologies, such as batteries and supercapacitors, face limitations in terms of energy density, power density, and cycle life. These limitations can impact the overall performance and longevity of KERS-equipped vehicles.

Weight management presents a significant challenge for KERS implementation. The additional components required for energy recovery and storage add considerable mass to the vehicle, potentially offsetting the efficiency gains. Engineers must carefully balance the weight of KERS components against the energy recovery benefits to ensure a net positive impact on vehicle performance and fuel economy.

Thermal management is a crucial aspect that differs between KERS and traditional braking systems. While conventional brakes primarily focus on dissipating heat, KERS must manage both the heat generated during braking and the thermal loads associated with energy storage and power electronics. This dual thermal management requirement adds complexity to the cooling system design and can impact overall system efficiency.

Control systems and software integration pose unique challenges for KERS. The system must seamlessly coordinate between regenerative braking and traditional friction braking, ensuring optimal energy recovery without compromising vehicle stability or driver comfort. This requires sophisticated control algorithms and real-time data processing capabilities that are not necessary in conventional braking systems.

Durability and reliability are areas where KERS faces significant technical hurdles compared to traditional braking systems. The additional mechanical and electrical components in KERS are subject to high stress and frequent cycling, potentially leading to increased wear and maintenance requirements. Ensuring long-term reliability while maintaining cost-effectiveness remains a key challenge for KERS developers.

Lastly, the cost factor presents a substantial barrier to widespread KERS adoption. The complex technology and specialized components required for KERS significantly increase the overall cost of the braking system compared to traditional solutions. Achieving cost parity or demonstrating a clear return on investment is crucial for broader market acceptance of KERS technology.

Current KERS Solutions

01 Regenerative braking system optimization

KERS efficiency can be improved by optimizing the regenerative braking system. This involves enhancing the energy recovery during deceleration, fine-tuning the brake force distribution between regenerative and friction brakes, and implementing advanced control algorithms to maximize energy capture while maintaining vehicle stability and driver comfort.- Regenerative braking system optimization: KERS efficiency can be improved by optimizing the regenerative braking system. This involves enhancing the energy recovery during deceleration, fine-tuning the brake force distribution between regenerative and friction brakes, and implementing advanced control algorithms to maximize energy capture while maintaining vehicle stability and driver comfort.

- Energy storage system enhancements: Improving the energy storage components of KERS can significantly boost overall system efficiency. This includes developing high-capacity, fast-charging batteries or supercapacitors, optimizing thermal management of storage units, and implementing intelligent energy management strategies to balance power flow between storage and propulsion systems.

- Advanced motor-generator technology: Enhancing the efficiency of the motor-generator unit in KERS can lead to improved braking efficiency. This involves developing high-performance electric machines with better power density, reduced losses, and improved thermal characteristics. Advanced motor control techniques and integration with the vehicle's powertrain can further optimize energy recovery during braking events.

- Integrated vehicle dynamics control: KERS braking efficiency can be enhanced by integrating it with overall vehicle dynamics control systems. This approach involves coordinating KERS operation with stability control, traction control, and anti-lock braking systems to optimize energy recovery while maintaining vehicle handling and safety across various driving conditions.

- Predictive and adaptive KERS strategies: Implementing predictive and adaptive control strategies can improve KERS braking efficiency. These strategies utilize real-time data from vehicle sensors, GPS, and connected infrastructure to anticipate braking events and optimize energy recovery. Machine learning algorithms can be employed to continuously adapt the system's performance based on driving patterns and conditions.

02 Energy storage system improvements

Enhancing the energy storage system is crucial for KERS efficiency. This includes developing high-capacity, fast-charging batteries or supercapacitors, improving thermal management of storage devices, and optimizing the power electronics for rapid energy transfer between the storage system and the drivetrain.Expand Specific Solutions03 Integration with hybrid powertrains

KERS efficiency can be increased by integrating it with hybrid powertrains. This involves coordinating the operation of KERS with internal combustion engines and electric motors, optimizing power flow between different energy sources, and implementing intelligent energy management strategies to maximize overall system efficiency.Expand Specific Solutions04 Advanced control systems and algorithms

Implementing advanced control systems and algorithms can significantly improve KERS braking efficiency. This includes developing predictive control strategies based on route information, real-time optimization of energy recovery, and adaptive control systems that adjust to different driving conditions and driver behaviors.Expand Specific Solutions05 Mechanical system enhancements

Improving the mechanical components of KERS can enhance braking efficiency. This involves developing more efficient energy conversion mechanisms, reducing friction losses in the system, improving the design of flywheels or other mechanical energy storage devices, and optimizing the integration of KERS components with the vehicle's drivetrain.Expand Specific Solutions

Key Industry Players

The competition landscape for Kinetic Energy Recovery Systems (KERS) versus traditional braking systems is evolving rapidly. The market is in a growth phase, with increasing adoption in automotive and motorsport sectors. The global KERS market size is projected to expand significantly in the coming years, driven by the demand for fuel-efficient and environmentally friendly vehicles. Technologically, KERS is maturing, with companies like Volvo Lastvagnar AB, GM Global Technology Operations LLC, and Punch Flybrid Ltd leading innovation. Traditional brake manufacturers such as Brembo SpA and Robert Bosch GmbH are also adapting their technologies to integrate with KERS, indicating a convergence of these systems in future vehicle designs.

Brembo SpA

Technical Solution: Brembo, a leader in brake system technology, has developed a hybrid braking system that integrates KERS functionality with their high-performance friction brakes. Their system uses a combination of regenerative braking and advanced friction materials to maximize energy recovery while maintaining superior stopping power. Brembo's KERS-integrated brakes can recover up to 80% of kinetic energy during light to moderate braking[9], significantly higher than many competing systems. The recovered energy is stored in a compact supercapacitor, allowing for rapid charge and discharge cycles. Brembo's system also features adaptive brake force distribution, which optimizes the balance between regenerative and friction braking based on driving conditions and vehicle speed.

Strengths: Exceptional energy recovery rate, integration with high-performance braking systems, and adaptive brake force distribution. Weaknesses: May be more expensive than standard KERS solutions, and primarily focused on high-performance and luxury vehicle applications.

GM Global Technology Operations LLC

Technical Solution: General Motors has developed a KERS technology that focuses on integration with their existing hybrid and electric vehicle platforms. Their system utilizes a combination of regenerative braking and a small, high-power battery to capture and store energy. GM's KERS can recover up to 60% of the vehicle's kinetic energy during braking[5], which is then used to assist acceleration or power auxiliary systems. The system is designed to work in tandem with traditional friction brakes, using a blended braking strategy that optimizes energy recovery while maintaining consistent pedal feel. GM has also implemented a unique feature that allows the KERS to pre-charge the battery in anticipation of braking events, further improving energy capture efficiency[6].

Strengths: Seamless integration with existing hybrid and EV platforms, efficient energy recovery, and innovative pre-charging feature. Weaknesses: May be less effective in non-hybrid vehicles, and energy storage capacity is limited compared to some competitors.

Core KERS Innovations

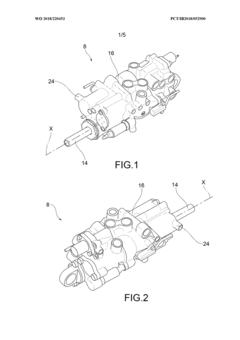

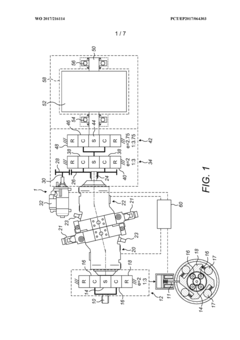

Integrated master-cylinder for brake-by-wire braking system and brake-by-wire braking system weith the same

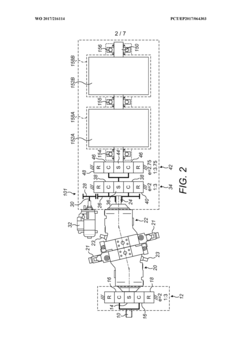

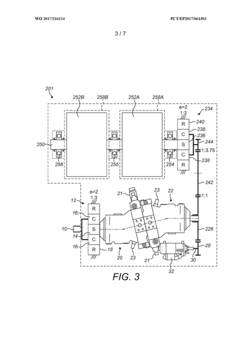

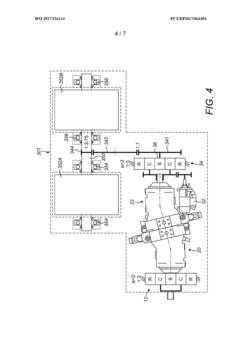

PatentWO2018220453A1

Innovation

- An integrated brake pump with a dual delivery circuit system, including a direct and indirect stage connected by a control valve, and an automatic hydraulic actuation unit, using separate fluids and floats to achieve high power and reduced mass, with a braking simulator for user feedback and safety in case of malfunctions.

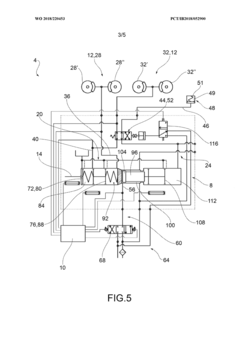

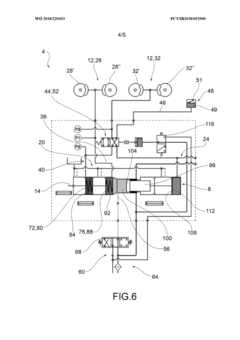

Kinetic energy recovery system

PatentWO2017216114A1

Innovation

- A kinetic energy recovery system utilizing a hydraulic variator with bent axis motors and a flywheel located in a vacuum chamber, connected through speed-up gear arrangements, allowing for efficient energy storage and retrieval by varying motor displacement in response to vehicle powertrain demands.

Energy Efficiency Impact

The energy efficiency impact of Kinetic Energy Recovery Systems (KERS) compared to traditional braking systems is significant and multifaceted. KERS technology has revolutionized the approach to energy conservation in vehicles, particularly in high-performance applications such as Formula 1 racing and, increasingly, in consumer automobiles.

Traditional braking systems convert kinetic energy into heat through friction, which is then dissipated into the environment. This process results in a complete loss of energy that could potentially be harnessed. In contrast, KERS captures a portion of this kinetic energy during braking and stores it for later use, thereby improving overall energy efficiency.

The primary advantage of KERS lies in its ability to recover energy that would otherwise be wasted. Studies have shown that KERS can recover up to 70% of the kinetic energy typically lost during braking. This recovered energy can then be used to provide additional power during acceleration, reducing the load on the main power source and consequently improving fuel efficiency.

In urban driving scenarios, where frequent braking is common, KERS has demonstrated potential fuel savings of 20-30%. This efficiency gain is particularly notable in stop-and-go traffic conditions, where traditional braking systems are least efficient. The energy recaptured by KERS can be used to power auxiliary systems or assist in acceleration, further reducing fuel consumption.

Moreover, KERS contributes to reduced carbon emissions. By decreasing the reliance on the primary engine for acceleration, KERS systems help lower overall fuel consumption and, consequently, reduce the vehicle's carbon footprint. This aspect is becoming increasingly important as automotive manufacturers strive to meet stringent emissions regulations worldwide.

The integration of KERS with hybrid and electric vehicle technologies has further amplified its energy efficiency benefits. In these applications, KERS can work in tandem with electric motors to optimize energy usage, extending the range of electric vehicles and improving the overall efficiency of hybrid powertrains.

However, it is important to note that the energy efficiency gains of KERS are not without challenges. The additional weight of KERS components can partially offset efficiency gains, especially in smaller vehicles. Additionally, the complexity of KERS systems can lead to increased manufacturing and maintenance costs, which must be balanced against the energy savings.

In conclusion, while traditional braking systems continue to be reliable and cost-effective, KERS offers a significant leap forward in energy efficiency. As the technology matures and becomes more widespread, its impact on overall vehicle energy efficiency is expected to grow, playing a crucial role in the automotive industry's pursuit of sustainability and improved performance.

Traditional braking systems convert kinetic energy into heat through friction, which is then dissipated into the environment. This process results in a complete loss of energy that could potentially be harnessed. In contrast, KERS captures a portion of this kinetic energy during braking and stores it for later use, thereby improving overall energy efficiency.

The primary advantage of KERS lies in its ability to recover energy that would otherwise be wasted. Studies have shown that KERS can recover up to 70% of the kinetic energy typically lost during braking. This recovered energy can then be used to provide additional power during acceleration, reducing the load on the main power source and consequently improving fuel efficiency.

In urban driving scenarios, where frequent braking is common, KERS has demonstrated potential fuel savings of 20-30%. This efficiency gain is particularly notable in stop-and-go traffic conditions, where traditional braking systems are least efficient. The energy recaptured by KERS can be used to power auxiliary systems or assist in acceleration, further reducing fuel consumption.

Moreover, KERS contributes to reduced carbon emissions. By decreasing the reliance on the primary engine for acceleration, KERS systems help lower overall fuel consumption and, consequently, reduce the vehicle's carbon footprint. This aspect is becoming increasingly important as automotive manufacturers strive to meet stringent emissions regulations worldwide.

The integration of KERS with hybrid and electric vehicle technologies has further amplified its energy efficiency benefits. In these applications, KERS can work in tandem with electric motors to optimize energy usage, extending the range of electric vehicles and improving the overall efficiency of hybrid powertrains.

However, it is important to note that the energy efficiency gains of KERS are not without challenges. The additional weight of KERS components can partially offset efficiency gains, especially in smaller vehicles. Additionally, the complexity of KERS systems can lead to increased manufacturing and maintenance costs, which must be balanced against the energy savings.

In conclusion, while traditional braking systems continue to be reliable and cost-effective, KERS offers a significant leap forward in energy efficiency. As the technology matures and becomes more widespread, its impact on overall vehicle energy efficiency is expected to grow, playing a crucial role in the automotive industry's pursuit of sustainability and improved performance.

Safety Considerations

Safety considerations are paramount when comparing Kinetic Energy Recovery Systems (KERS) and traditional braking systems in automotive applications. KERS, while offering significant energy efficiency benefits, introduces new safety challenges that must be carefully addressed.

One of the primary safety concerns with KERS is the high-voltage electrical systems involved. These systems can pose risks of electric shock to both vehicle occupants and maintenance personnel. Proper insulation, shielding, and safety interlocks are essential to mitigate these risks. Additionally, the potential for battery thermal runaway in electric KERS systems requires robust thermal management and fire suppression systems.

Traditional braking systems, while well-established, also have safety considerations. Brake fade during prolonged use, particularly in high-performance or heavy-duty applications, can lead to reduced stopping power. This issue is less prevalent in KERS, which can provide consistent braking performance through energy regeneration.

The integration of KERS with traditional braking systems introduces complexity that must be carefully managed. Ensuring seamless transition between regenerative and friction braking is crucial for maintaining vehicle stability and predictable brake feel. Failure modes in this integrated system must be thoroughly analyzed and fail-safe mechanisms implemented.

Electromagnetic compatibility (EMC) is another critical safety aspect for KERS. The high-power electrical systems can potentially interfere with other vehicle electronics, including safety-critical systems. Rigorous EMC testing and shielding are necessary to prevent such interference.

Weight distribution and vehicle dynamics are also affected by the addition of KERS components. The extra mass of batteries or flywheels can alter a vehicle's center of gravity and handling characteristics. Careful design and placement of these components are essential to maintain vehicle stability and crash safety performance.

In terms of maintenance safety, KERS introduces new challenges. Technicians must be properly trained to handle high-voltage systems and energy storage devices safely. Special tools and procedures are often required, and service facilities need to be equipped to handle these advanced systems.

Regulatory compliance is a crucial aspect of safety considerations. KERS must meet stringent safety standards, including those for electrical safety, electromagnetic emissions, and crash worthiness. These regulations are continually evolving as the technology becomes more widespread.

Overall, while KERS offers significant advantages in energy efficiency and performance, its implementation requires a comprehensive approach to safety that addresses both the inherent risks of the system and its integration with traditional vehicle systems. Continuous research and development in safety technologies are essential to ensure that the benefits of KERS can be realized without compromising vehicle safety.

One of the primary safety concerns with KERS is the high-voltage electrical systems involved. These systems can pose risks of electric shock to both vehicle occupants and maintenance personnel. Proper insulation, shielding, and safety interlocks are essential to mitigate these risks. Additionally, the potential for battery thermal runaway in electric KERS systems requires robust thermal management and fire suppression systems.

Traditional braking systems, while well-established, also have safety considerations. Brake fade during prolonged use, particularly in high-performance or heavy-duty applications, can lead to reduced stopping power. This issue is less prevalent in KERS, which can provide consistent braking performance through energy regeneration.

The integration of KERS with traditional braking systems introduces complexity that must be carefully managed. Ensuring seamless transition between regenerative and friction braking is crucial for maintaining vehicle stability and predictable brake feel. Failure modes in this integrated system must be thoroughly analyzed and fail-safe mechanisms implemented.

Electromagnetic compatibility (EMC) is another critical safety aspect for KERS. The high-power electrical systems can potentially interfere with other vehicle electronics, including safety-critical systems. Rigorous EMC testing and shielding are necessary to prevent such interference.

Weight distribution and vehicle dynamics are also affected by the addition of KERS components. The extra mass of batteries or flywheels can alter a vehicle's center of gravity and handling characteristics. Careful design and placement of these components are essential to maintain vehicle stability and crash safety performance.

In terms of maintenance safety, KERS introduces new challenges. Technicians must be properly trained to handle high-voltage systems and energy storage devices safely. Special tools and procedures are often required, and service facilities need to be equipped to handle these advanced systems.

Regulatory compliance is a crucial aspect of safety considerations. KERS must meet stringent safety standards, including those for electrical safety, electromagnetic emissions, and crash worthiness. These regulations are continually evolving as the technology becomes more widespread.

Overall, while KERS offers significant advantages in energy efficiency and performance, its implementation requires a comprehensive approach to safety that addresses both the inherent risks of the system and its integration with traditional vehicle systems. Continuous research and development in safety technologies are essential to ensure that the benefits of KERS can be realized without compromising vehicle safety.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!