Composite Cathode Processing: Mixing, Densification, And Binder Selection

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Cathode Technology Evolution and Objectives

Battery cathode technology has undergone significant evolution since the commercialization of lithium-ion batteries in the early 1990s. Initially, LiCoO2 (LCO) dominated the market due to its stable structure and reliable performance. However, concerns regarding cobalt's cost, toxicity, and supply chain vulnerabilities drove research toward alternative cathode materials. This led to the development of lithium manganese oxide (LMO), lithium iron phosphate (LFP), and later, nickel-rich cathodes like NCA (nickel-cobalt-aluminum) and NMC (nickel-manganese-cobalt).

The processing of composite cathodes has evolved in parallel with material innovations. Early manufacturing techniques focused on simple powder mixing and slurry casting, with limited control over microstructure. Modern approaches have progressed toward sophisticated mixing protocols that ensure homogeneous distribution of active materials, conductive additives, and binders. This evolution reflects the growing understanding of how processing parameters directly impact electrochemical performance.

Densification techniques have similarly advanced from basic calendering to precision-controlled processes that optimize porosity while maintaining structural integrity. The industry has recognized that optimal electrode density represents a critical balance between energy density and ion transport capabilities. Too dense electrodes restrict lithium-ion diffusion, while insufficient densification limits volumetric energy density.

Binder selection has evolved from conventional PVDF (polyvinylidene fluoride) systems to water-based alternatives like CMC (carboxymethyl cellulose) and SBR (styrene-butadiene rubber), addressing environmental concerns and processing costs. Recent research explores functional binders that contribute actively to electrochemical performance rather than serving merely as passive components.

The primary objectives in composite cathode processing development include enhancing energy density, improving rate capability, extending cycle life, and reducing manufacturing costs. Specifically, the industry aims to achieve higher active material loading while maintaining excellent electronic and ionic conductivity throughout the electrode structure. Optimizing the interface between active materials and conductive additives remains a central challenge.

Future objectives focus on developing scalable, environmentally sustainable processing techniques compatible with high-nickel and cobalt-free cathode chemistries. Additionally, there is growing interest in dry electrode manufacturing to eliminate solvent usage and associated environmental impacts. The ultimate goal is to establish processing protocols that enable consistent production of high-performance cathodes with minimal batch-to-batch variation, supporting the mass production of next-generation batteries for electric vehicles and grid storage applications.

The processing of composite cathodes has evolved in parallel with material innovations. Early manufacturing techniques focused on simple powder mixing and slurry casting, with limited control over microstructure. Modern approaches have progressed toward sophisticated mixing protocols that ensure homogeneous distribution of active materials, conductive additives, and binders. This evolution reflects the growing understanding of how processing parameters directly impact electrochemical performance.

Densification techniques have similarly advanced from basic calendering to precision-controlled processes that optimize porosity while maintaining structural integrity. The industry has recognized that optimal electrode density represents a critical balance between energy density and ion transport capabilities. Too dense electrodes restrict lithium-ion diffusion, while insufficient densification limits volumetric energy density.

Binder selection has evolved from conventional PVDF (polyvinylidene fluoride) systems to water-based alternatives like CMC (carboxymethyl cellulose) and SBR (styrene-butadiene rubber), addressing environmental concerns and processing costs. Recent research explores functional binders that contribute actively to electrochemical performance rather than serving merely as passive components.

The primary objectives in composite cathode processing development include enhancing energy density, improving rate capability, extending cycle life, and reducing manufacturing costs. Specifically, the industry aims to achieve higher active material loading while maintaining excellent electronic and ionic conductivity throughout the electrode structure. Optimizing the interface between active materials and conductive additives remains a central challenge.

Future objectives focus on developing scalable, environmentally sustainable processing techniques compatible with high-nickel and cobalt-free cathode chemistries. Additionally, there is growing interest in dry electrode manufacturing to eliminate solvent usage and associated environmental impacts. The ultimate goal is to establish processing protocols that enable consistent production of high-performance cathodes with minimal batch-to-batch variation, supporting the mass production of next-generation batteries for electric vehicles and grid storage applications.

Market Analysis for Advanced Composite Cathode Materials

The global market for advanced composite cathode materials is experiencing robust growth, driven primarily by the expanding electric vehicle (EV) sector and increasing demand for high-performance energy storage solutions. Current market valuations indicate that the composite cathode materials segment reached approximately $7.2 billion in 2022, with projections suggesting a compound annual growth rate (CAGR) of 12.3% through 2030.

Key market drivers include the push for higher energy density batteries, longer cycle life, and reduced production costs. Automotive manufacturers are particularly focused on cathode materials that can enable greater driving ranges while maintaining safety standards. This has accelerated demand for advanced nickel-rich NMC (nickel-manganese-cobalt) and NCA (nickel-cobalt-aluminum) cathode formulations, which collectively represent over 65% of the premium EV battery market.

Regional analysis reveals Asia-Pacific as the dominant market, accounting for approximately 58% of global production capacity. China leads manufacturing output, followed by South Korea and Japan. However, significant investments in North America and Europe are reshaping the geographical distribution, with both regions expected to increase their market share by 7-9% by 2025 due to localization strategies and government incentives.

Processing technologies represent a critical value-added segment within the supply chain. The market for specialized mixing equipment, densification processes, and binder systems has grown at 15.2% annually since 2019, outpacing the overall cathode materials market. This indicates increasing recognition of processing techniques as key differentiators in final battery performance.

Consumer electronics remains the second-largest application segment after automotive, representing approximately 22% of market demand. However, emerging applications in grid storage systems are expected to grow at the fastest rate (18.7% CAGR) through 2028, creating new opportunities for specialized cathode formulations optimized for stationary applications.

Price sensitivity analysis indicates that while raw material costs (particularly nickel and cobalt) remain significant factors, processing innovations that reduce material waste or enable higher loading densities can deliver substantial cost advantages. Manufacturers achieving 5-8% improvements in active material utilization through advanced processing techniques typically command 10-15% price premiums in the market.

Market consolidation is evident with the top five cathode material suppliers controlling approximately 54% of global production capacity. However, specialized processing technology providers remain more fragmented, creating partnership opportunities for companies with proprietary mixing, densification, or binder technologies.

Key market drivers include the push for higher energy density batteries, longer cycle life, and reduced production costs. Automotive manufacturers are particularly focused on cathode materials that can enable greater driving ranges while maintaining safety standards. This has accelerated demand for advanced nickel-rich NMC (nickel-manganese-cobalt) and NCA (nickel-cobalt-aluminum) cathode formulations, which collectively represent over 65% of the premium EV battery market.

Regional analysis reveals Asia-Pacific as the dominant market, accounting for approximately 58% of global production capacity. China leads manufacturing output, followed by South Korea and Japan. However, significant investments in North America and Europe are reshaping the geographical distribution, with both regions expected to increase their market share by 7-9% by 2025 due to localization strategies and government incentives.

Processing technologies represent a critical value-added segment within the supply chain. The market for specialized mixing equipment, densification processes, and binder systems has grown at 15.2% annually since 2019, outpacing the overall cathode materials market. This indicates increasing recognition of processing techniques as key differentiators in final battery performance.

Consumer electronics remains the second-largest application segment after automotive, representing approximately 22% of market demand. However, emerging applications in grid storage systems are expected to grow at the fastest rate (18.7% CAGR) through 2028, creating new opportunities for specialized cathode formulations optimized for stationary applications.

Price sensitivity analysis indicates that while raw material costs (particularly nickel and cobalt) remain significant factors, processing innovations that reduce material waste or enable higher loading densities can deliver substantial cost advantages. Manufacturers achieving 5-8% improvements in active material utilization through advanced processing techniques typically command 10-15% price premiums in the market.

Market consolidation is evident with the top five cathode material suppliers controlling approximately 54% of global production capacity. However, specialized processing technology providers remain more fragmented, creating partnership opportunities for companies with proprietary mixing, densification, or binder technologies.

Current Challenges in Cathode Processing Techniques

Despite significant advancements in lithium-ion battery technology, cathode processing techniques continue to face substantial challenges that limit performance optimization and manufacturing efficiency. The heterogeneous nature of composite cathodes, comprising active materials, conductive additives, and polymeric binders, creates inherent complexity in achieving uniform distribution and optimal microstructure. Current mixing processes often result in agglomeration of particles and non-uniform distribution of conductive additives, leading to inconsistent electrochemical performance across the electrode.

Densification techniques present another critical challenge area. While calendering improves volumetric energy density and electrical contact between particles, excessive compression can damage the electrode structure and block ion transport pathways. Finding the optimal densification parameters remains highly material-dependent and often requires extensive empirical testing, making it difficult to establish universal processing protocols across different cathode chemistries.

Binder selection continues to be problematic as traditional PVDF (polyvinylidene fluoride) binders require environmentally harmful NMP (N-Methyl-2-pyrrolidone) solvents. Water-based binder systems, while more environmentally friendly, often exhibit inferior adhesion properties and can cause transition metal dissolution from active materials during processing. This creates a significant trade-off between environmental considerations and electrochemical performance.

The slurry viscosity control during mixing represents another persistent challenge. Viscosity directly impacts coating quality, but achieving consistent rheological properties batch-to-batch remains difficult due to sensitivity to multiple processing variables including temperature, mixing speed, and material lot variations. This variability contributes to manufacturing inconsistencies and yield losses.

Scaling up laboratory processes to industrial production introduces additional complications. Techniques that work effectively at small scale often encounter unforeseen issues when implemented in high-volume manufacturing environments. The differences in mixing dynamics, drying kinetics, and material handling between lab and industrial settings create significant barriers to technology transfer.

Energy consumption during cathode processing, particularly in drying and solvent recovery steps, presents both economic and environmental challenges. Current techniques require substantial thermal energy input, contributing to the overall carbon footprint of battery production. More energy-efficient processing methods are needed to align with sustainability goals in the battery industry.

Finally, quality control methods for assessing mixing uniformity, densification consistency, and binder distribution remain largely inadequate. Current analytical techniques often provide only indirect measurements of these critical parameters, making it difficult to implement robust process control strategies in manufacturing environments.

Densification techniques present another critical challenge area. While calendering improves volumetric energy density and electrical contact between particles, excessive compression can damage the electrode structure and block ion transport pathways. Finding the optimal densification parameters remains highly material-dependent and often requires extensive empirical testing, making it difficult to establish universal processing protocols across different cathode chemistries.

Binder selection continues to be problematic as traditional PVDF (polyvinylidene fluoride) binders require environmentally harmful NMP (N-Methyl-2-pyrrolidone) solvents. Water-based binder systems, while more environmentally friendly, often exhibit inferior adhesion properties and can cause transition metal dissolution from active materials during processing. This creates a significant trade-off between environmental considerations and electrochemical performance.

The slurry viscosity control during mixing represents another persistent challenge. Viscosity directly impacts coating quality, but achieving consistent rheological properties batch-to-batch remains difficult due to sensitivity to multiple processing variables including temperature, mixing speed, and material lot variations. This variability contributes to manufacturing inconsistencies and yield losses.

Scaling up laboratory processes to industrial production introduces additional complications. Techniques that work effectively at small scale often encounter unforeseen issues when implemented in high-volume manufacturing environments. The differences in mixing dynamics, drying kinetics, and material handling between lab and industrial settings create significant barriers to technology transfer.

Energy consumption during cathode processing, particularly in drying and solvent recovery steps, presents both economic and environmental challenges. Current techniques require substantial thermal energy input, contributing to the overall carbon footprint of battery production. More energy-efficient processing methods are needed to align with sustainability goals in the battery industry.

Finally, quality control methods for assessing mixing uniformity, densification consistency, and binder distribution remain largely inadequate. Current analytical techniques often provide only indirect measurements of these critical parameters, making it difficult to implement robust process control strategies in manufacturing environments.

Current Mixing and Densification Methodologies

01 Mixing techniques for composite cathode materials

Various mixing techniques are employed to ensure homogeneous distribution of active materials, conductive additives, and binders in composite cathodes. These include ball milling, planetary mixing, and ultrasonic dispersion methods. Proper mixing is crucial for achieving uniform particle distribution, which directly impacts electrode performance, conductivity, and electrochemical properties. Advanced mixing protocols often involve specific sequences and controlled environments to prevent agglomeration and ensure optimal component integration.- Mixing techniques for composite cathode materials: Various mixing techniques are employed to ensure homogeneous distribution of active materials, conductive additives, and binders in composite cathodes. These include ball milling, planetary mixing, and ultrasonic dispersion methods. Proper mixing is crucial for achieving uniform particle distribution, which directly impacts the electrochemical performance and cycling stability of the battery. Advanced mixing protocols often involve controlled atmosphere conditions to prevent contamination and oxidation of sensitive cathode materials.

- Binder selection and optimization for cathode performance: The choice of binder significantly affects the mechanical integrity and electrochemical performance of composite cathodes. Common binders include PVDF (polyvinylidene fluoride), CMC (carboxymethyl cellulose), and water-soluble polymers. Binder selection depends on factors such as compatibility with active materials, electrochemical stability, and processing requirements. Optimizing binder content is essential to balance cohesion between particles while minimizing inactive material content that could reduce energy density. Novel binder systems are being developed to enhance adhesion, flexibility, and ionic conductivity.

- Densification processes for composite cathodes: Densification techniques such as calendering, pressing, and controlled drying are employed to optimize the porosity and volumetric energy density of composite cathodes. These processes enhance particle-to-particle contact, reduce internal resistance, and improve mechanical stability. The degree of densification must be carefully controlled to maintain sufficient porosity for electrolyte penetration while maximizing active material loading. Advanced densification methods include temperature-controlled pressing and gradient densification to optimize both electronic conductivity and ion transport properties.

- Solvent systems and slurry formulation: The selection of appropriate solvent systems is critical for creating stable cathode slurries with optimal rheological properties. Common solvents include N-methyl-2-pyrrolidone (NMP), water, and various organic solvents. The solvent system affects mixing efficiency, coating quality, and environmental impact of the manufacturing process. Slurry formulation parameters such as solid content, viscosity, and dispersion stability must be carefully controlled to ensure consistent electrode coating. Environmentally friendly water-based slurry systems are increasingly being developed to replace toxic organic solvents.

- Additives for enhanced cathode performance: Various additives are incorporated into composite cathodes to enhance specific properties. Conductive additives like carbon black, graphene, and carbon nanotubes improve electronic conductivity. Dispersants and surfactants enhance particle distribution and slurry stability. Processing aids modify rheological properties for better coating performance. Novel functional additives can improve adhesion, reduce interfacial resistance, and enhance cycling stability. The type and amount of additives must be optimized to maximize performance benefits while minimizing the inactive material content in the final electrode.

02 Densification processes for cathode materials

Densification techniques are essential for optimizing the volumetric energy density and mechanical integrity of composite cathodes. Methods include calendering, pressing, and controlled drying processes that help achieve target porosity levels while maintaining ion transport pathways. The degree of densification significantly affects the electrochemical performance, with optimal density balancing electronic conductivity and ionic diffusion. Advanced densification approaches incorporate temperature and pressure control to enhance interfacial contact between particles without damaging active materials.Expand Specific Solutions03 Binder selection and optimization for cathode performance

The choice of binder significantly impacts cathode performance, adhesion, and stability. Common binders include PVDF, CMC, SBR, and novel water-soluble polymers, each offering different advantages in terms of electrochemical stability, adhesion strength, and processing compatibility. Binder content optimization is crucial as it affects electrode flexibility, ionic conductivity, and volumetric capacity. Advanced formulations often incorporate functionalized binders that can form stronger bonds with active materials or contribute to improved cycling stability through enhanced mechanical properties.Expand Specific Solutions04 Solvent systems and slurry formulation

The selection of appropriate solvent systems is critical for effective slurry preparation in composite cathode processing. Factors such as solvent polarity, volatility, and compatibility with active materials and binders determine the quality of the resulting electrode. N-Methyl-2-pyrrolidone (NMP) is commonly used with PVDF binders, while water-based systems are increasingly adopted for environmental and safety reasons. Slurry viscosity control through solvent ratio adjustment and additive incorporation ensures proper coating behavior and uniform electrode thickness during manufacturing.Expand Specific Solutions05 Advanced processing additives and surface treatments

Incorporating specialized additives and surface treatments enhances composite cathode performance and processability. Conductive additives like carbon black, graphene, and carbon nanotubes improve electronic conductivity, while dispersants prevent agglomeration during mixing. Surface modification of active materials through coatings or functional groups can improve interfacial stability and cycling performance. Novel approaches include the use of rheology modifiers to optimize slurry properties and processing aids that facilitate better adhesion between components while reducing internal resistance in the final electrode.Expand Specific Solutions

Leading Companies in Cathode Material Processing

The composite cathode processing market is in a growth phase, characterized by increasing demand for advanced battery technologies. The market size is expanding rapidly due to the electric vehicle boom and renewable energy storage needs. Technologically, the field is moderately mature but still evolving, with significant innovations in mixing techniques, densification processes, and binder selection. Key players include established chemical companies like BASF, DuPont, and SGL Carbon providing specialized materials, while battery manufacturers such as Svolt Energy, EVE Energy, and Vision Power Technology are advancing application-specific solutions. Research institutions like Swinburne University and East China Normal University contribute fundamental knowledge, creating a competitive landscape balanced between material suppliers and end-product manufacturers.

BASF Corp.

Technical Solution: BASF has developed an advanced composite cathode processing system centered around their Licity® binder technology specifically engineered for lithium-ion battery applications. Their approach integrates specialized mixing protocols that utilize controlled shear forces to optimize particle distribution without damaging active materials. BASF's densification process employs a proprietary calendering technique with precise temperature and pressure control, achieving compression ratios that maximize energy density while maintaining essential porosity (typically 30-35%). The company's water-based binder systems feature functionalized polymers with enhanced adhesion properties and electrochemical stability, reducing environmental impact while improving battery performance. Their integrated approach includes tailored dispersants that prevent agglomeration during mixing, resulting in uniform cathode coatings with minimal defects and improved rate capability.

Strengths: Industry-leading binder formulations with excellent adhesion properties, environmentally friendly water-based processing, and comprehensive material compatibility across various cathode chemistries. Weaknesses: Higher material costs compared to standard binders, more complex processing parameters requiring precise control, and potential challenges with ultra-fast charging applications.

Svolt Energy Technology Co., Ltd.

Technical Solution: Svolt has developed an innovative dry electrode manufacturing process for composite cathodes that eliminates traditional N-Methyl-2-pyrrolidone (NMP) solvents. Their technology utilizes specialized dry mixing equipment that creates uniform distribution of active materials, conductive additives, and binders through mechanical activation. The process incorporates a proprietary densification technique that achieves optimal porosity (25-30%) while maintaining structural integrity. Svolt's binder selection focuses on water-soluble polymers like modified PVDF and CMC-SBR combinations, which reduce environmental impact while enhancing adhesion properties. Their cathode processing technology has demonstrated 10-15% higher energy density and 20% reduction in production costs compared to conventional wet processes.

Strengths: Environmentally friendly solvent-free process, reduced energy consumption (eliminates drying steps), improved production efficiency, and enhanced electrode performance. Weaknesses: Requires specialized equipment investment, potential challenges with ultra-thin electrode production, and limited compatibility with certain high-nickel cathode materials.

Key Patents in Composite Cathode Processing

Composite binder composition for secondary battery, cathode and lithium battery containing the binder composition

PatentActiveUS10109863B2

Innovation

- A binder composition combining a first fluorine-containing binder with a polar functional group, a second fluorine-containing binder without a polar group, and a non-fluorine-containing binder with polymerized acryl and olefin monomers, enhancing adhesiveness, flexibility, and dispersibility of the electrode active material and conducting agent.

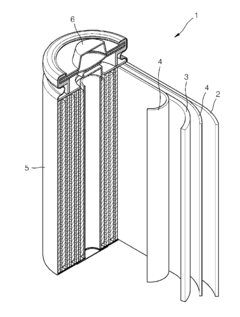

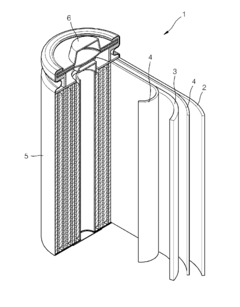

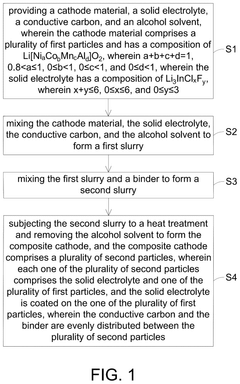

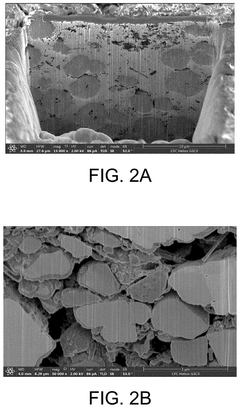

Composite cathode preparation method

PatentPendingUS20250023011A1

Innovation

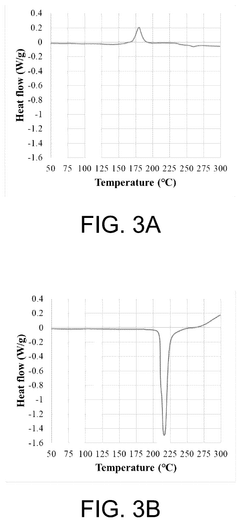

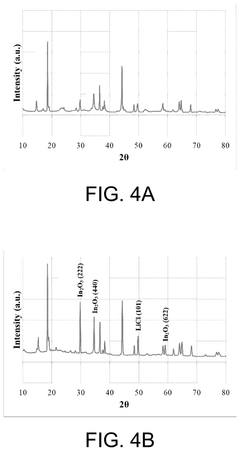

- A composite cathode preparation method involving mixing a cathode material, solid electrolyte, and alcohol solvent to form a slurry, followed by heat treatment, which eliminates moisture sensitivity and enhances electrochemical performance by forming a uniform core-shell structure with minimal impurities, using an alcohol solvent like ethanol and conductive carbon with a binder like PTFE, and optimizing heat treatment conditions between 160° C to 200° C.

Environmental Impact of Cathode Processing Methods

The environmental footprint of cathode processing methods has become increasingly significant as battery production scales globally. Traditional cathode processing techniques involve energy-intensive steps that contribute substantially to the overall environmental impact of battery manufacturing. Mixing processes, particularly those utilizing high-energy ball milling, consume considerable electricity and often require environmentally problematic solvents like N-Methyl-2-pyrrolidone (NMP), which is classified as a reproductive toxin and faces regulatory restrictions in many regions.

Densification methods, including calendering and pressing, while less directly polluting, contribute to the carbon footprint through their energy requirements. The environmental impact varies significantly based on the energy source powering these processes, with renewable energy integration showing promise for substantial footprint reduction. Studies indicate that the energy consumed during cathode processing can account for up to 20% of the total energy used in battery cell manufacturing.

Binder selection presents another critical environmental consideration. PVDF (polyvinylidene fluoride), the industry-standard binder, requires the aforementioned toxic NMP solvent for processing. Water-based alternatives using CMC (carboxymethyl cellulose) and SBR (styrene-butadiene rubber) offer significantly reduced environmental impact but face technical challenges in performance and processing compatibility with certain active materials.

Waste generation during cathode processing represents a substantial environmental concern. Material losses during mixing and coating processes can reach 5-10% in some manufacturing lines, creating hazardous waste streams containing heavy metals and organic solvents. Advanced recovery systems and closed-loop processing techniques have demonstrated potential to reduce these losses to below 2%, significantly decreasing environmental burden and raw material consumption.

Life cycle assessments (LCAs) of various cathode processing methods reveal that dry processing techniques, while still developing technologically, could reduce the global warming potential of cathode manufacturing by 30-40% compared to conventional wet processing. These solvent-free approaches eliminate emissions from solvent recovery systems and reduce energy consumption associated with drying steps.

Recent innovations in low-temperature processing and solvent recycling systems have shown promise in reducing both energy consumption and emissions. Manufacturers implementing advanced solvent recovery systems report recovery rates exceeding 95%, substantially reducing the environmental impact while maintaining economic viability. The industry trend toward more environmentally sustainable processing methods is accelerating as regulatory pressures increase and consumers demand greener battery technologies.

Densification methods, including calendering and pressing, while less directly polluting, contribute to the carbon footprint through their energy requirements. The environmental impact varies significantly based on the energy source powering these processes, with renewable energy integration showing promise for substantial footprint reduction. Studies indicate that the energy consumed during cathode processing can account for up to 20% of the total energy used in battery cell manufacturing.

Binder selection presents another critical environmental consideration. PVDF (polyvinylidene fluoride), the industry-standard binder, requires the aforementioned toxic NMP solvent for processing. Water-based alternatives using CMC (carboxymethyl cellulose) and SBR (styrene-butadiene rubber) offer significantly reduced environmental impact but face technical challenges in performance and processing compatibility with certain active materials.

Waste generation during cathode processing represents a substantial environmental concern. Material losses during mixing and coating processes can reach 5-10% in some manufacturing lines, creating hazardous waste streams containing heavy metals and organic solvents. Advanced recovery systems and closed-loop processing techniques have demonstrated potential to reduce these losses to below 2%, significantly decreasing environmental burden and raw material consumption.

Life cycle assessments (LCAs) of various cathode processing methods reveal that dry processing techniques, while still developing technologically, could reduce the global warming potential of cathode manufacturing by 30-40% compared to conventional wet processing. These solvent-free approaches eliminate emissions from solvent recovery systems and reduce energy consumption associated with drying steps.

Recent innovations in low-temperature processing and solvent recycling systems have shown promise in reducing both energy consumption and emissions. Manufacturers implementing advanced solvent recovery systems report recovery rates exceeding 95%, substantially reducing the environmental impact while maintaining economic viability. The industry trend toward more environmentally sustainable processing methods is accelerating as regulatory pressures increase and consumers demand greener battery technologies.

Scale-up Considerations for Industrial Production

Scaling up composite cathode processing from laboratory to industrial production presents significant engineering challenges that must be addressed systematically. The transition requires careful consideration of equipment capabilities, process parameters, and quality control measures to maintain consistent product specifications while achieving economic viability.

Industrial mixing operations for composite cathodes necessitate specialized high-volume equipment that can handle tonnage quantities while maintaining homogeneity. Planetary mixers and continuous twin-screw extruders have emerged as preferred technologies, though they require substantial modification of laboratory-established parameters. Mixing time, shear forces, and temperature profiles must be recalibrated to accommodate larger batch sizes without compromising material dispersion quality.

Densification processes face particular challenges during scale-up. Industrial calendering operations must maintain precise control over compression forces across wider electrode sheets, requiring sophisticated roller designs with improved temperature and pressure distribution systems. Variations exceeding 5% in density across the electrode surface can lead to significant capacity inconsistencies in final battery products.

Binder selection becomes increasingly critical at industrial scales. While PVDF remains common in laboratory settings, its cost and processing requirements (including NMP solvent handling) present environmental and economic challenges in mass production. Water-based binder systems using CMC and SBR combinations have gained traction, reducing VOC emissions by up to 95% and decreasing processing costs by 30-40%, though they require different drying protocols and equipment configurations.

Quality control infrastructure must evolve proportionally with production scale. In-line monitoring systems for slurry viscosity, particle size distribution, and coating thickness become essential rather than optional. Statistical process control methodologies must be implemented to detect deviations before they result in significant material waste.

Energy consumption represents another scale-up consideration, particularly for drying operations following electrode coating. Conventional convection ovens become prohibitively inefficient at industrial scales, driving adoption of infrared, microwave, or hybrid drying technologies that can reduce energy requirements by 40-60% while accelerating production rates.

Supply chain resilience must also be evaluated during scale-up planning. Single-source dependencies for specialized binders or processing additives can create production vulnerabilities. Qualification of multiple suppliers and development of material substitution protocols becomes necessary to ensure continuous production capability despite market fluctuations.

Industrial mixing operations for composite cathodes necessitate specialized high-volume equipment that can handle tonnage quantities while maintaining homogeneity. Planetary mixers and continuous twin-screw extruders have emerged as preferred technologies, though they require substantial modification of laboratory-established parameters. Mixing time, shear forces, and temperature profiles must be recalibrated to accommodate larger batch sizes without compromising material dispersion quality.

Densification processes face particular challenges during scale-up. Industrial calendering operations must maintain precise control over compression forces across wider electrode sheets, requiring sophisticated roller designs with improved temperature and pressure distribution systems. Variations exceeding 5% in density across the electrode surface can lead to significant capacity inconsistencies in final battery products.

Binder selection becomes increasingly critical at industrial scales. While PVDF remains common in laboratory settings, its cost and processing requirements (including NMP solvent handling) present environmental and economic challenges in mass production. Water-based binder systems using CMC and SBR combinations have gained traction, reducing VOC emissions by up to 95% and decreasing processing costs by 30-40%, though they require different drying protocols and equipment configurations.

Quality control infrastructure must evolve proportionally with production scale. In-line monitoring systems for slurry viscosity, particle size distribution, and coating thickness become essential rather than optional. Statistical process control methodologies must be implemented to detect deviations before they result in significant material waste.

Energy consumption represents another scale-up consideration, particularly for drying operations following electrode coating. Conventional convection ovens become prohibitively inefficient at industrial scales, driving adoption of infrared, microwave, or hybrid drying technologies that can reduce energy requirements by 40-60% while accelerating production rates.

Supply chain resilience must also be evaluated during scale-up planning. Single-source dependencies for specialized binders or processing additives can create production vulnerabilities. Qualification of multiple suppliers and development of material substitution protocols becomes necessary to ensure continuous production capability despite market fluctuations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!