Computational Modeling Of Volumetric Additive Manufacturing Dynamics

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Volumetric AM Evolution and Research Objectives

Volumetric Additive Manufacturing (VAM) represents a paradigm shift in the field of 3D printing, evolving from traditional layer-by-layer approaches to simultaneous whole-volume solidification. This revolutionary technique emerged in the mid-2010s as researchers sought to overcome the speed limitations inherent in conventional additive manufacturing methods. The evolution began with early experiments in tomographic techniques, where patterns of light were projected into photosensitive resins from multiple angles simultaneously.

The technological progression of VAM has been marked by several key milestones. Initial proof-of-concept demonstrations achieved limited resolution and material compatibility. By 2018, researchers at Lawrence Livermore National Laboratory and the University of California demonstrated computed axial lithography, significantly advancing the field. Recent developments have focused on expanding material options beyond photopolymers and improving computational algorithms for precise energy distribution within the build volume.

Current research objectives in computational modeling of VAM dynamics center on several critical areas. First, there is a pressing need to develop more accurate multi-physics models that can simultaneously account for photochemical reactions, heat transfer, fluid dynamics, and mechanical stress during the solidification process. These models must capture the complex interplay between light propagation, absorption, and scattering in diverse material systems.

Another key objective is the optimization of projection patterns and energy delivery sequences. This requires sophisticated algorithms that can predict how multiple light paths interact within the volume and how these interactions affect the final part properties. Researchers aim to create predictive models that can determine optimal exposure parameters to achieve desired material properties throughout the printed object.

Real-time simulation capabilities represent another frontier in VAM research. The ability to dynamically adjust fabrication parameters based on in-process feedback could significantly enhance print quality and reliability. This necessitates the development of computationally efficient models that can run alongside the manufacturing process.

Material behavior prediction under volumetric curing conditions remains challenging. Research objectives include creating models that can accurately predict how different materials respond to simultaneous multi-directional energy input, particularly for composite materials and those with non-linear curing behaviors.

Finally, there is significant interest in scaling VAM technologies to larger build volumes while maintaining precision. This requires advanced computational approaches to manage the increased complexity of light path calculations and energy distribution in larger volumes, potentially leveraging machine learning techniques to optimize these processes.

The technological progression of VAM has been marked by several key milestones. Initial proof-of-concept demonstrations achieved limited resolution and material compatibility. By 2018, researchers at Lawrence Livermore National Laboratory and the University of California demonstrated computed axial lithography, significantly advancing the field. Recent developments have focused on expanding material options beyond photopolymers and improving computational algorithms for precise energy distribution within the build volume.

Current research objectives in computational modeling of VAM dynamics center on several critical areas. First, there is a pressing need to develop more accurate multi-physics models that can simultaneously account for photochemical reactions, heat transfer, fluid dynamics, and mechanical stress during the solidification process. These models must capture the complex interplay between light propagation, absorption, and scattering in diverse material systems.

Another key objective is the optimization of projection patterns and energy delivery sequences. This requires sophisticated algorithms that can predict how multiple light paths interact within the volume and how these interactions affect the final part properties. Researchers aim to create predictive models that can determine optimal exposure parameters to achieve desired material properties throughout the printed object.

Real-time simulation capabilities represent another frontier in VAM research. The ability to dynamically adjust fabrication parameters based on in-process feedback could significantly enhance print quality and reliability. This necessitates the development of computationally efficient models that can run alongside the manufacturing process.

Material behavior prediction under volumetric curing conditions remains challenging. Research objectives include creating models that can accurately predict how different materials respond to simultaneous multi-directional energy input, particularly for composite materials and those with non-linear curing behaviors.

Finally, there is significant interest in scaling VAM technologies to larger build volumes while maintaining precision. This requires advanced computational approaches to manage the increased complexity of light path calculations and energy distribution in larger volumes, potentially leveraging machine learning techniques to optimize these processes.

Market Analysis for Computational Modeling in AM

The computational modeling market for Additive Manufacturing (AM) is experiencing robust growth, driven by the increasing adoption of AM technologies across various industries. Currently valued at approximately $450 million, this specialized software segment is projected to grow at a CAGR of 17.3% through 2028, outpacing the broader AM market's growth rate of 14.4%.

The market demand is primarily fueled by industries requiring high precision manufacturing capabilities, including aerospace, automotive, healthcare, and industrial equipment. Aerospace and defense sectors represent the largest market share at 32%, followed by medical and dental applications at 28%. This distribution reflects the critical need for simulation tools that can predict material behavior, thermal dynamics, and structural integrity in high-stakes manufacturing environments.

Regional analysis reveals North America currently leads with 41% market share, followed by Europe (33%) and Asia-Pacific (21%). However, the Asia-Pacific region is demonstrating the fastest growth rate at 19.8% annually, driven by rapid industrialization in China, Japan, and South Korea, and significant government investments in advanced manufacturing technologies.

Customer segmentation shows large enterprises constitute 65% of the market revenue, while SMEs represent a rapidly growing segment with 22% annual growth as more affordable and accessible computational modeling solutions emerge. The remaining market share belongs to research institutions and educational facilities.

Key market drivers include the increasing complexity of AM parts, growing demand for first-time-right manufacturing, and the push toward digital twins in production environments. The shift from traditional trial-and-error approaches to simulation-driven design has reduced development costs by an average of 27% and time-to-market by 35% for early adopters.

Market challenges include the high computational requirements for accurate volumetric modeling, significant expertise needed to effectively utilize these tools, and interoperability issues between different software platforms. Additionally, the high cost of comprehensive modeling solutions presents a barrier to wider adoption, particularly among smaller manufacturers.

The subscription-based software model is gaining traction, growing at 24% annually compared to perpetual licensing models. Cloud-based deployment options are experiencing 31% year-over-year growth as they offer scalable computing resources for complex simulations without requiring substantial in-house hardware investments.

The market demand is primarily fueled by industries requiring high precision manufacturing capabilities, including aerospace, automotive, healthcare, and industrial equipment. Aerospace and defense sectors represent the largest market share at 32%, followed by medical and dental applications at 28%. This distribution reflects the critical need for simulation tools that can predict material behavior, thermal dynamics, and structural integrity in high-stakes manufacturing environments.

Regional analysis reveals North America currently leads with 41% market share, followed by Europe (33%) and Asia-Pacific (21%). However, the Asia-Pacific region is demonstrating the fastest growth rate at 19.8% annually, driven by rapid industrialization in China, Japan, and South Korea, and significant government investments in advanced manufacturing technologies.

Customer segmentation shows large enterprises constitute 65% of the market revenue, while SMEs represent a rapidly growing segment with 22% annual growth as more affordable and accessible computational modeling solutions emerge. The remaining market share belongs to research institutions and educational facilities.

Key market drivers include the increasing complexity of AM parts, growing demand for first-time-right manufacturing, and the push toward digital twins in production environments. The shift from traditional trial-and-error approaches to simulation-driven design has reduced development costs by an average of 27% and time-to-market by 35% for early adopters.

Market challenges include the high computational requirements for accurate volumetric modeling, significant expertise needed to effectively utilize these tools, and interoperability issues between different software platforms. Additionally, the high cost of comprehensive modeling solutions presents a barrier to wider adoption, particularly among smaller manufacturers.

The subscription-based software model is gaining traction, growing at 24% annually compared to perpetual licensing models. Cloud-based deployment options are experiencing 31% year-over-year growth as they offer scalable computing resources for complex simulations without requiring substantial in-house hardware investments.

Current Challenges in Volumetric AM Simulation

Despite significant advancements in volumetric additive manufacturing (VAM) technologies, computational simulation of these processes remains fraught with challenges. Current simulation frameworks struggle to accurately model the complex photopolymerization kinetics that occur during volumetric printing. The non-linear nature of light propagation through evolving resin properties creates a dynamic system that is computationally intensive to simulate with high fidelity.

One of the primary challenges is the multi-physics nature of the problem. Simulations must simultaneously account for photon transport, chemical reaction kinetics, heat transfer, and evolving material properties. These phenomena occur at vastly different time scales, making traditional time-stepping approaches either prohibitively expensive or inaccurate due to necessary simplifications.

Spatial resolution requirements present another significant hurdle. Current models often employ voxel-based approaches that require extremely fine discretization to capture microscale features, resulting in computational demands that exceed practical limits for most design applications. This creates a fundamental trade-off between simulation accuracy and computational feasibility.

The treatment of optical scattering and absorption in partially cured resins remains particularly problematic. As polymerization progresses, the optical properties of the material change dynamically, affecting subsequent light propagation in ways that are difficult to predict without extensive experimental characterization of specific resin formulations.

Validation of simulation results presents its own set of challenges. The opacity of most photopolymer resins makes in-situ measurement of the curing process difficult, limiting the availability of experimental data for model validation. This creates a circular problem where simulations cannot be fully trusted without validation, yet the phenomena being simulated are difficult to observe directly.

Commercial simulation tools have not yet fully incorporated the specialized physics required for volumetric AM processes. Most existing software packages were developed for traditional manufacturing methods and lack the specific modules needed to accurately represent the unique aspects of volumetric printing, such as computed axial lithography or holographic stereolithography.

Real-time simulation capabilities, which would enable on-the-fly process optimization and control, remain elusive due to the computational complexity involved. This limitation hinders the development of closed-loop control systems that could potentially improve print reliability and quality by adapting to process variations during fabrication.

One of the primary challenges is the multi-physics nature of the problem. Simulations must simultaneously account for photon transport, chemical reaction kinetics, heat transfer, and evolving material properties. These phenomena occur at vastly different time scales, making traditional time-stepping approaches either prohibitively expensive or inaccurate due to necessary simplifications.

Spatial resolution requirements present another significant hurdle. Current models often employ voxel-based approaches that require extremely fine discretization to capture microscale features, resulting in computational demands that exceed practical limits for most design applications. This creates a fundamental trade-off between simulation accuracy and computational feasibility.

The treatment of optical scattering and absorption in partially cured resins remains particularly problematic. As polymerization progresses, the optical properties of the material change dynamically, affecting subsequent light propagation in ways that are difficult to predict without extensive experimental characterization of specific resin formulations.

Validation of simulation results presents its own set of challenges. The opacity of most photopolymer resins makes in-situ measurement of the curing process difficult, limiting the availability of experimental data for model validation. This creates a circular problem where simulations cannot be fully trusted without validation, yet the phenomena being simulated are difficult to observe directly.

Commercial simulation tools have not yet fully incorporated the specialized physics required for volumetric AM processes. Most existing software packages were developed for traditional manufacturing methods and lack the specific modules needed to accurately represent the unique aspects of volumetric printing, such as computed axial lithography or holographic stereolithography.

Real-time simulation capabilities, which would enable on-the-fly process optimization and control, remain elusive due to the computational complexity involved. This limitation hinders the development of closed-loop control systems that could potentially improve print reliability and quality by adapting to process variations during fabrication.

State-of-the-Art Volumetric AM Modeling Approaches

01 Simulation models for additive manufacturing processes

Computational models are developed to simulate the dynamics of additive manufacturing processes, including material deposition, layer formation, and structural evolution. These models incorporate physical principles such as heat transfer, fluid dynamics, and material solidification to predict the behavior of materials during the manufacturing process. Advanced simulation techniques enable optimization of process parameters and prediction of final product properties before physical production.- Simulation models for additive manufacturing processes: Computational models are developed to simulate the dynamics of additive manufacturing processes, including material deposition, layer formation, and structural integrity. These simulations help predict how materials will behave during the manufacturing process, allowing for optimization of parameters such as deposition rate, temperature, and cooling time. Advanced algorithms enable real-time adjustments to manufacturing parameters based on simulation results, improving the quality and efficiency of the final product.

- Thermal and mechanical behavior modeling in volumetric printing: Computational models are used to predict the thermal and mechanical behavior of materials during volumetric additive manufacturing. These models account for heat transfer, thermal gradients, residual stresses, and material deformation during the printing process. By understanding these dynamics, manufacturers can optimize printing parameters to minimize defects, improve dimensional accuracy, and enhance the mechanical properties of printed parts.

- Multi-physics simulation frameworks for complex AM systems: Comprehensive multi-physics simulation frameworks are developed to model the complex interactions in volumetric additive manufacturing systems. These frameworks integrate fluid dynamics, heat transfer, material phase changes, and structural mechanics to provide a holistic understanding of the manufacturing process. By simulating these interdependent physical phenomena simultaneously, engineers can better predict manufacturing outcomes and develop more robust printing processes for complex geometries and multi-material structures.

- Machine learning approaches for process optimization: Machine learning algorithms are employed to analyze large datasets from additive manufacturing processes and optimize volumetric printing parameters. These computational approaches can identify patterns and correlations that might not be apparent through traditional modeling methods. By training on historical manufacturing data, these systems can predict optimal process parameters, detect potential defects before they occur, and continuously improve manufacturing outcomes through iterative learning processes.

- Real-time monitoring and adaptive control systems: Computational models enable real-time monitoring and adaptive control of volumetric additive manufacturing processes. These systems use sensor data and computational predictions to make dynamic adjustments to manufacturing parameters during the printing process. By continuously comparing actual manufacturing conditions with simulated predictions, these systems can detect deviations and implement corrective actions to maintain product quality and process efficiency, even when dealing with complex geometries or variable material properties.

02 Real-time monitoring and control systems

Systems for real-time monitoring and control of volumetric additive manufacturing processes utilize computational models to analyze sensor data and adjust manufacturing parameters dynamically. These systems employ feedback loops that compare actual manufacturing conditions with simulated predictions to maintain optimal process conditions. The integration of sensors, data processing algorithms, and control mechanisms enables adaptive manufacturing that responds to variations in material properties and environmental conditions.Expand Specific Solutions03 Multi-physics modeling for complex material behavior

Multi-physics computational models address the complex behavior of materials during volumetric additive manufacturing by simultaneously considering multiple physical phenomena. These models integrate thermal, mechanical, chemical, and phase transformation aspects to predict material behavior under various processing conditions. Advanced algorithms account for material heterogeneity, anisotropy, and non-linear responses to processing parameters, enabling more accurate prediction of final product properties.Expand Specific Solutions04 Machine learning approaches for process optimization

Machine learning techniques are applied to volumetric additive manufacturing to optimize process parameters and predict manufacturing outcomes. These approaches utilize historical manufacturing data to train predictive models that can identify optimal processing conditions for specific materials and geometries. Neural networks, genetic algorithms, and other AI methods help identify complex relationships between manufacturing parameters and product quality, reducing the need for extensive physical testing.Expand Specific Solutions05 Voxel-based modeling for heterogeneous structures

Voxel-based computational modeling techniques enable the design and simulation of heterogeneous structures in volumetric additive manufacturing. These methods divide the manufacturing volume into discrete volumetric elements (voxels) with assigned material properties and processing parameters. This approach allows for precise control over spatial material distribution, enabling the creation of functionally graded materials and complex internal structures with tailored mechanical, thermal, or electrical properties.Expand Specific Solutions

Leading Organizations in AM Simulation Technology

The computational modeling of volumetric additive manufacturing dynamics is evolving in a rapidly growing market, currently transitioning from early development to commercial application phases. The global market is expanding significantly, driven by industrial demands for more efficient manufacturing processes. Leading companies like HP Development, Stratasys, and Siemens Energy are advancing the technology's maturity through substantial R&D investments. Traditional manufacturing giants including Boeing, GE, and Rolls-Royce are integrating these solutions into their production workflows. Academic institutions such as Northwestern University and Nanyang Technological University collaborate with industry players to address technical challenges in simulation accuracy and material behavior prediction, accelerating the technology toward mainstream industrial adoption.

Stratasys, Inc.

Technical Solution: Stratasys has developed advanced computational models for volumetric additive manufacturing that integrate multi-physics simulations to predict material behavior during the printing process. Their approach combines thermal analysis, fluid dynamics, and structural mechanics to create comprehensive digital twins of the manufacturing process. The company's GrabCAD software incorporates these models to simulate how materials will behave during deposition, curing, and cooling phases, allowing for prediction of potential defects, warping, and internal stresses. Stratasys has particularly focused on modeling polymer extrusion processes with high fidelity, accounting for material phase changes, viscosity variations, and thermal gradients that occur during printing. Their models incorporate machine learning algorithms that continuously improve predictions based on empirical data collected from thousands of print jobs across their installed base of systems.

Strengths: Exceptional accuracy in predicting polymer behavior during printing, with validated models across multiple material types. Integration with design software creates a seamless workflow from design to manufacturing. Weaknesses: Models are primarily optimized for their proprietary materials and systems, limiting applicability to other platforms. Computational requirements can be significant for complex geometries.

General Electric Company

Technical Solution: GE has pioneered computational modeling for metal additive manufacturing through its GE Additive division. Their approach focuses on multi-scale modeling that spans from powder particle interactions to full component thermomechanical behavior. GE's models incorporate powder bed dynamics, melt pool physics, solidification kinetics, and microstructure evolution to create high-fidelity simulations of the entire manufacturing process. Their proprietary software can predict porosity formation, residual stress development, and microstructural characteristics based on process parameters. GE has invested heavily in validating these models through extensive experimental testing, including in-situ monitoring with high-speed cameras and thermal imaging. The company has applied these models to optimize critical aerospace components, reducing development cycles by up to 50% and enabling topology optimization that accounts for manufacturing constraints inherent to additive processes.

Strengths: Comprehensive multi-physics approach that captures complex interactions between thermal, mechanical, and metallurgical phenomena. Extensive validation with real-world aerospace applications provides high confidence in model predictions. Weaknesses: Extremely computationally intensive, often requiring high-performance computing resources. Models are primarily focused on metal powder bed fusion processes rather than other additive technologies.

Critical Algorithms and Mathematical Frameworks

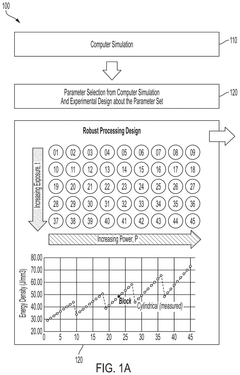

Simulation method for developing a production process

PatentWO2016082810A1

Innovation

- A method involving a multi-scale, physically based simulation chain to detach material-specific properties from component geometry and simulate the additive structure, allowing for a holistic view of the production chain, reducing the need for costly tests and trials by identifying parameter windows for new materials and process parameters.

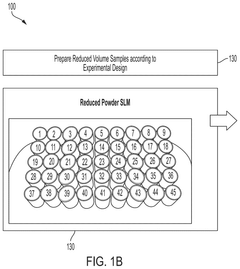

Rapid material development process for additive manufactured materials

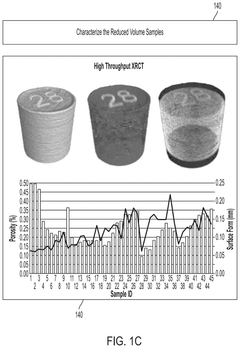

PatentActiveUS12115581B2

Innovation

- A computer-implemented process using computational fluid dynamics simulation and design of experiments to model melt pool solidification, generate a multi-factorial parameter space, and build reduced volume samples for mechanical characterization, correlating defect morphology with processing parameters to determine an optimal parameter set.

Material Science Implications for Volumetric AM

The material science implications for volumetric additive manufacturing (VAM) represent a critical frontier in advancing this technology. Unlike traditional layer-by-layer approaches, volumetric AM simultaneously solidifies entire volumes, creating unique material challenges and opportunities. The photosensitive resins used in VAM systems must balance rapid curing kinetics with appropriate mechanical properties, requiring precise formulation of photoinitiators, monomers, and additives.

Material selection significantly impacts the computational modeling accuracy of volumetric manufacturing processes. The optical properties of resins—including absorption coefficients, scattering behavior, and refractive indices—directly influence light propagation patterns and energy distribution throughout the volume. These parameters must be precisely characterized and incorporated into computational models to achieve predictable solidification outcomes.

Thermal considerations present another critical material science challenge. The exothermic nature of photopolymerization reactions can create temperature gradients within the volume, potentially leading to thermal stresses, material property variations, and dimensional inaccuracies. Advanced computational models must account for these thermodynamic effects to predict and mitigate potential defects.

The rheological behavior of materials during curing introduces additional complexity. As photopolymerization progresses, viscosity changes dramatically, affecting fluid dynamics and potentially creating internal stresses. Computational models must incorporate these time-dependent material property changes to accurately predict final part characteristics.

Post-processing requirements also influence material selection and computational modeling approaches. Shrinkage during curing, residual stress development, and post-cure material property evolution must be considered when designing both materials and process parameters. Materials that minimize these effects while maintaining desired mechanical properties are particularly valuable for volumetric AM applications.

Multi-material capabilities represent an emerging frontier in volumetric AM material science. Creating gradient materials or discrete material boundaries within a single volumetric print requires sophisticated material formulations and corresponding computational models that can predict interface behaviors and property transitions. These developments could enable unprecedented functional capabilities in printed components.

The development of sustainable, bio-compatible materials compatible with volumetric AM processes presents both challenges and opportunities. Computational models that can accurately predict the behavior of these novel materials will accelerate their adoption and expand application possibilities in medical, food science, and other sensitive domains.

Material selection significantly impacts the computational modeling accuracy of volumetric manufacturing processes. The optical properties of resins—including absorption coefficients, scattering behavior, and refractive indices—directly influence light propagation patterns and energy distribution throughout the volume. These parameters must be precisely characterized and incorporated into computational models to achieve predictable solidification outcomes.

Thermal considerations present another critical material science challenge. The exothermic nature of photopolymerization reactions can create temperature gradients within the volume, potentially leading to thermal stresses, material property variations, and dimensional inaccuracies. Advanced computational models must account for these thermodynamic effects to predict and mitigate potential defects.

The rheological behavior of materials during curing introduces additional complexity. As photopolymerization progresses, viscosity changes dramatically, affecting fluid dynamics and potentially creating internal stresses. Computational models must incorporate these time-dependent material property changes to accurately predict final part characteristics.

Post-processing requirements also influence material selection and computational modeling approaches. Shrinkage during curing, residual stress development, and post-cure material property evolution must be considered when designing both materials and process parameters. Materials that minimize these effects while maintaining desired mechanical properties are particularly valuable for volumetric AM applications.

Multi-material capabilities represent an emerging frontier in volumetric AM material science. Creating gradient materials or discrete material boundaries within a single volumetric print requires sophisticated material formulations and corresponding computational models that can predict interface behaviors and property transitions. These developments could enable unprecedented functional capabilities in printed components.

The development of sustainable, bio-compatible materials compatible with volumetric AM processes presents both challenges and opportunities. Computational models that can accurately predict the behavior of these novel materials will accelerate their adoption and expand application possibilities in medical, food science, and other sensitive domains.

Validation Methodologies for Computational Models

Validation of computational models for volumetric additive manufacturing (VAM) dynamics requires rigorous methodologies to ensure accuracy and reliability. These validation approaches can be categorized into experimental, analytical, and comparative methods, each serving distinct purposes in the verification process.

Experimental validation represents the gold standard, involving direct comparison between model predictions and physical measurements. For VAM processes, this typically includes monitoring resin curing profiles, temperature distributions, and final part geometries. Advanced imaging techniques such as high-speed cameras and tomography provide real-time visualization of polymerization fronts, enabling precise validation of spatio-temporal dynamics predicted by computational models.

Quantitative metrics form the backbone of validation protocols, with statistical measures like root mean square error (RMSE), coefficient of determination (R²), and normalized mean absolute error (NMAE) commonly employed to assess model accuracy. These metrics must be evaluated across multiple process parameters and geometries to establish model robustness and generalizability.

Multi-scale validation approaches address the inherent complexity of VAM processes, which span from molecular-level photochemistry to macroscopic part formation. Validation at each scale requires specialized techniques: rheological measurements for resin viscosity models, spectroscopic methods for photochemical reaction kinetics, and dimensional metrology for final part accuracy.

Uncertainty quantification represents an essential component of modern validation methodologies, acknowledging that both computational models and experimental measurements contain inherent uncertainties. Techniques such as Monte Carlo simulation, sensitivity analysis, and Bayesian inference help quantify confidence levels in model predictions and identify parameters requiring refinement.

Benchmark test cases have emerged as standardized validation tools within the VAM community. These include canonical geometries (spheres, thin walls, overhangs) and specific feature tests designed to challenge particular aspects of computational models. The development of open-access validation datasets has accelerated progress by enabling direct comparison between different modeling approaches.

Cross-validation between different modeling approaches provides additional confidence in simulation results. When independent models based on different underlying assumptions produce similar predictions, this convergence suggests the captured physics is accurate rather than an artifact of a particular modeling approach.

Experimental validation represents the gold standard, involving direct comparison between model predictions and physical measurements. For VAM processes, this typically includes monitoring resin curing profiles, temperature distributions, and final part geometries. Advanced imaging techniques such as high-speed cameras and tomography provide real-time visualization of polymerization fronts, enabling precise validation of spatio-temporal dynamics predicted by computational models.

Quantitative metrics form the backbone of validation protocols, with statistical measures like root mean square error (RMSE), coefficient of determination (R²), and normalized mean absolute error (NMAE) commonly employed to assess model accuracy. These metrics must be evaluated across multiple process parameters and geometries to establish model robustness and generalizability.

Multi-scale validation approaches address the inherent complexity of VAM processes, which span from molecular-level photochemistry to macroscopic part formation. Validation at each scale requires specialized techniques: rheological measurements for resin viscosity models, spectroscopic methods for photochemical reaction kinetics, and dimensional metrology for final part accuracy.

Uncertainty quantification represents an essential component of modern validation methodologies, acknowledging that both computational models and experimental measurements contain inherent uncertainties. Techniques such as Monte Carlo simulation, sensitivity analysis, and Bayesian inference help quantify confidence levels in model predictions and identify parameters requiring refinement.

Benchmark test cases have emerged as standardized validation tools within the VAM community. These include canonical geometries (spheres, thin walls, overhangs) and specific feature tests designed to challenge particular aspects of computational models. The development of open-access validation datasets has accelerated progress by enabling direct comparison between different modeling approaches.

Cross-validation between different modeling approaches provides additional confidence in simulation results. When independent models based on different underlying assumptions produce similar predictions, this convergence suggests the captured physics is accurate rather than an artifact of a particular modeling approach.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!