What Determines Resolution In Volumetric Additive Manufacturing?

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Volumetric AM Resolution Fundamentals and Objectives

Volumetric Additive Manufacturing (VAM) represents a paradigm shift in 3D printing technology, moving beyond traditional layer-by-layer approaches to simultaneous solidification throughout an entire volume. This revolutionary technique has emerged over the past decade as researchers sought to overcome speed limitations inherent in conventional additive manufacturing methods.

The fundamental principle behind VAM involves projecting patterned light into a photosensitive resin, causing simultaneous polymerization throughout the volume. Unlike traditional methods that build objects sequentially, VAM creates entire structures in seconds to minutes, regardless of complexity. This technology evolved from computed tomography principles, essentially operating as "reverse CT scanning" where instead of capturing projections to reconstruct an image, multiple projections create a physical object.

Resolution in VAM represents a critical technical objective that determines the minimum feature size achievable and overall part quality. The industry aims to achieve sub-micron resolution while maintaining reasonable build volumes and processing speeds. Current technical objectives focus on optimizing the balance between resolution, build volume, and fabrication speed—three parameters that typically involve trade-offs.

The evolution of VAM technology shows a clear trend toward higher resolution capabilities, with early systems achieving only millimeter-scale features, while recent innovations approach micron-scale resolution. This progression has been driven by advances in light projection systems, resin chemistry, and computational algorithms that enable more precise control over the polymerization process.

Key technical goals in the field include developing systems capable of multi-material printing while maintaining high resolution, improving surface finish quality, and expanding the range of compatible materials beyond photopolymers to include ceramics, metals, and composites. Researchers are also working toward standardization of resolution metrics specific to volumetric processes, as traditional AM resolution parameters often prove inadequate for these novel techniques.

The pursuit of higher resolution in VAM has significant implications for applications in medical devices, microfluidics, optical components, and precision engineering. As resolution improves, entirely new application domains become accessible, driving continued investment in this technology area. Understanding the fundamental factors that determine resolution is therefore essential for advancing the capabilities and expanding the practical applications of volumetric additive manufacturing.

The fundamental principle behind VAM involves projecting patterned light into a photosensitive resin, causing simultaneous polymerization throughout the volume. Unlike traditional methods that build objects sequentially, VAM creates entire structures in seconds to minutes, regardless of complexity. This technology evolved from computed tomography principles, essentially operating as "reverse CT scanning" where instead of capturing projections to reconstruct an image, multiple projections create a physical object.

Resolution in VAM represents a critical technical objective that determines the minimum feature size achievable and overall part quality. The industry aims to achieve sub-micron resolution while maintaining reasonable build volumes and processing speeds. Current technical objectives focus on optimizing the balance between resolution, build volume, and fabrication speed—three parameters that typically involve trade-offs.

The evolution of VAM technology shows a clear trend toward higher resolution capabilities, with early systems achieving only millimeter-scale features, while recent innovations approach micron-scale resolution. This progression has been driven by advances in light projection systems, resin chemistry, and computational algorithms that enable more precise control over the polymerization process.

Key technical goals in the field include developing systems capable of multi-material printing while maintaining high resolution, improving surface finish quality, and expanding the range of compatible materials beyond photopolymers to include ceramics, metals, and composites. Researchers are also working toward standardization of resolution metrics specific to volumetric processes, as traditional AM resolution parameters often prove inadequate for these novel techniques.

The pursuit of higher resolution in VAM has significant implications for applications in medical devices, microfluidics, optical components, and precision engineering. As resolution improves, entirely new application domains become accessible, driving continued investment in this technology area. Understanding the fundamental factors that determine resolution is therefore essential for advancing the capabilities and expanding the practical applications of volumetric additive manufacturing.

Market Analysis for High-Resolution Volumetric Printing

The volumetric additive manufacturing market is experiencing significant growth, driven by increasing demand for high-resolution 3D printing capabilities across multiple industries. Current market projections indicate that the global volumetric 3D printing market is expected to grow substantially over the next decade, with particular acceleration in medical, aerospace, and consumer electronics sectors.

The healthcare segment represents the largest market share for high-resolution volumetric printing, with applications in tissue engineering, personalized implants, and medical device manufacturing. The ability to create complex biological structures with microscale features has positioned volumetric manufacturing as a revolutionary technology in regenerative medicine, with several leading hospitals and research institutions investing heavily in this technology.

Aerospace and defense industries form the second-largest market segment, where high-resolution volumetric printing enables the production of lightweight components with complex internal geometries that would be impossible to manufacture using traditional methods. These industries value the technology's ability to reduce part count, decrease weight, and improve performance characteristics of critical components.

Consumer electronics manufacturers are rapidly adopting high-resolution volumetric printing for prototyping and production of miniaturized components. The market demand in this sector is primarily driven by the need for faster product development cycles and the increasing complexity of electronic devices.

Regional analysis shows North America currently leads the market with approximately 40% share, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to witness the highest growth rate due to increasing industrial adoption in countries like China, Japan, and South Korea, supported by substantial government investments in advanced manufacturing technologies.

Market barriers for high-resolution volumetric printing include high equipment costs, limited material selection, and technical challenges in achieving consistent sub-micron resolution. These factors have restricted market penetration to primarily high-value applications where the benefits outweigh the costs.

Customer surveys indicate that end-users prioritize resolution capabilities, production speed, and material compatibility when evaluating volumetric printing technologies. The ability to achieve resolutions below 10 microns consistently is considered a critical purchasing factor for 78% of potential industrial customers.

The competitive landscape is characterized by a mix of established 3D printing companies expanding into volumetric technologies and specialized startups focused exclusively on high-resolution volumetric solutions. Strategic partnerships between equipment manufacturers, material suppliers, and software developers are becoming increasingly common as companies seek to offer comprehensive solutions to address complex customer requirements.

The healthcare segment represents the largest market share for high-resolution volumetric printing, with applications in tissue engineering, personalized implants, and medical device manufacturing. The ability to create complex biological structures with microscale features has positioned volumetric manufacturing as a revolutionary technology in regenerative medicine, with several leading hospitals and research institutions investing heavily in this technology.

Aerospace and defense industries form the second-largest market segment, where high-resolution volumetric printing enables the production of lightweight components with complex internal geometries that would be impossible to manufacture using traditional methods. These industries value the technology's ability to reduce part count, decrease weight, and improve performance characteristics of critical components.

Consumer electronics manufacturers are rapidly adopting high-resolution volumetric printing for prototyping and production of miniaturized components. The market demand in this sector is primarily driven by the need for faster product development cycles and the increasing complexity of electronic devices.

Regional analysis shows North America currently leads the market with approximately 40% share, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to witness the highest growth rate due to increasing industrial adoption in countries like China, Japan, and South Korea, supported by substantial government investments in advanced manufacturing technologies.

Market barriers for high-resolution volumetric printing include high equipment costs, limited material selection, and technical challenges in achieving consistent sub-micron resolution. These factors have restricted market penetration to primarily high-value applications where the benefits outweigh the costs.

Customer surveys indicate that end-users prioritize resolution capabilities, production speed, and material compatibility when evaluating volumetric printing technologies. The ability to achieve resolutions below 10 microns consistently is considered a critical purchasing factor for 78% of potential industrial customers.

The competitive landscape is characterized by a mix of established 3D printing companies expanding into volumetric technologies and specialized startups focused exclusively on high-resolution volumetric solutions. Strategic partnerships between equipment manufacturers, material suppliers, and software developers are becoming increasingly common as companies seek to offer comprehensive solutions to address complex customer requirements.

Technical Limitations and Challenges in Volumetric Resolution

Volumetric Additive Manufacturing (VAM) faces several critical technical limitations that directly impact achievable resolution. The primary challenge stems from the fundamental physics of light-material interactions. When photons penetrate photosensitive resins, scattering and absorption effects create a trade-off between depth penetration and lateral resolution. This phenomenon, known as the optical penetration depth dilemma, forces manufacturers to balance between achieving fine details and ensuring complete curing throughout the volume.

Material constraints represent another significant limitation. Current photopolymer formulations exhibit inherent resolution boundaries due to their photoinitiator diffusion characteristics and chain reaction propagation distances. Even with optimal optical setups, the chemical kinetics of polymerization reactions impose natural limits on feature size, typically in the range of 10-50 micrometers for commercial systems.

The optical projection systems themselves introduce resolution constraints. Diffraction limits, determined by the wavelength of light used and the numerical aperture of the optical system, establish a theoretical minimum feature size. Additionally, aberrations in projection optics can cause distortions that vary across the build volume, resulting in position-dependent resolution variations that are difficult to compensate for algorithmically.

Computational challenges further complicate resolution enhancement. The tomographic reconstruction algorithms used to generate projection patterns must process enormous datasets representing complex 3D geometries. Current computational methods struggle with the inverse problem of determining optimal light patterns for arbitrary geometries while maintaining high resolution throughout the volume, particularly for objects with internal features or varying densities.

Thermal management during the curing process presents another obstacle. Exothermic polymerization reactions generate heat that can cause material expansion, internal stresses, and distortions. These thermal effects become more pronounced at higher resolutions where feature density increases, potentially leading to dimensional inaccuracies that effectively limit practical resolution.

Motion control precision in systems utilizing rotating containers or dynamic optical elements introduces mechanical limitations. Vibrations, positioning errors, and synchronization issues between projection systems and mechanical components can degrade effective resolution, particularly in high-speed manufacturing scenarios.

Finally, metrology and quality control present significant challenges. As VAM pushes toward higher resolutions, the ability to accurately measure and verify these fine features becomes increasingly difficult, especially for internal structures that cannot be directly accessed for inspection without destroying the printed part.

Material constraints represent another significant limitation. Current photopolymer formulations exhibit inherent resolution boundaries due to their photoinitiator diffusion characteristics and chain reaction propagation distances. Even with optimal optical setups, the chemical kinetics of polymerization reactions impose natural limits on feature size, typically in the range of 10-50 micrometers for commercial systems.

The optical projection systems themselves introduce resolution constraints. Diffraction limits, determined by the wavelength of light used and the numerical aperture of the optical system, establish a theoretical minimum feature size. Additionally, aberrations in projection optics can cause distortions that vary across the build volume, resulting in position-dependent resolution variations that are difficult to compensate for algorithmically.

Computational challenges further complicate resolution enhancement. The tomographic reconstruction algorithms used to generate projection patterns must process enormous datasets representing complex 3D geometries. Current computational methods struggle with the inverse problem of determining optimal light patterns for arbitrary geometries while maintaining high resolution throughout the volume, particularly for objects with internal features or varying densities.

Thermal management during the curing process presents another obstacle. Exothermic polymerization reactions generate heat that can cause material expansion, internal stresses, and distortions. These thermal effects become more pronounced at higher resolutions where feature density increases, potentially leading to dimensional inaccuracies that effectively limit practical resolution.

Motion control precision in systems utilizing rotating containers or dynamic optical elements introduces mechanical limitations. Vibrations, positioning errors, and synchronization issues between projection systems and mechanical components can degrade effective resolution, particularly in high-speed manufacturing scenarios.

Finally, metrology and quality control present significant challenges. As VAM pushes toward higher resolutions, the ability to accurately measure and verify these fine features becomes increasingly difficult, especially for internal structures that cannot be directly accessed for inspection without destroying the printed part.

Current Resolution Enhancement Approaches and Methods

01 Resolution enhancement techniques in volumetric additive manufacturing

Various techniques can be employed to enhance resolution in volumetric additive manufacturing processes. These include advanced optical systems, computational algorithms for image processing, and specialized projection methods that can achieve finer feature resolution. By optimizing light delivery and control systems, manufacturers can achieve higher precision in the fabrication of complex three-dimensional structures, resulting in improved surface quality and dimensional accuracy of printed parts.- Resolution enhancement techniques in volumetric additive manufacturing: Various techniques can be employed to enhance the resolution in volumetric additive manufacturing processes. These include advanced optical systems, computational algorithms for image processing, and specialized projection methods that can achieve finer feature resolution. By optimizing light delivery and control systems, manufacturers can achieve higher precision in the fabrication of complex three-dimensional structures, resulting in improved surface quality and dimensional accuracy of printed parts.

- Materials and formulations for high-resolution volumetric printing: The choice of photosensitive materials and their formulations significantly impacts the achievable resolution in volumetric additive manufacturing. Advanced resin compositions with tailored photoinitiators, absorbers, and additives can control light penetration depth and curing characteristics. These specialized materials enable the creation of finer features and more precise structures by minimizing light scattering and optimizing the photopolymerization process, ultimately leading to higher resolution printed objects.

- Multi-beam and tomographic approaches for resolution improvement: Multi-beam projection systems and tomographic approaches represent advanced methods for improving resolution in volumetric additive manufacturing. By utilizing multiple light sources or computed tomography principles, these techniques allow for more precise control over the energy distribution within the printing volume. This enables the creation of complex internal structures and fine details that would be difficult to achieve with conventional single-beam systems, significantly enhancing the resolution capabilities of volumetric printing processes.

- Real-time monitoring and feedback systems for resolution control: Real-time monitoring and feedback systems play a crucial role in maintaining and enhancing resolution during the volumetric additive manufacturing process. These systems utilize sensors, cameras, and computational algorithms to continuously assess the printing progress and make adjustments as needed. By implementing closed-loop control mechanisms, manufacturers can detect and correct deviations in real-time, ensuring consistent resolution throughout the build process and compensating for material variations or environmental factors.

- Hybrid manufacturing approaches for multi-scale resolution: Hybrid manufacturing approaches combine volumetric additive manufacturing with other fabrication techniques to achieve multi-scale resolution capabilities. These integrated systems may incorporate different printing technologies, post-processing methods, or subtractive manufacturing steps to optimize resolution at various scales within the same part. By leveraging the strengths of complementary processes, manufacturers can produce components with both macro-scale structures and micro-scale features, expanding the application range of volumetric additive manufacturing.

02 Materials and formulations for high-resolution volumetric printing

The choice of photosensitive materials and their formulations significantly impacts the achievable resolution in volumetric additive manufacturing. Advanced resin compositions with tailored photoinitiators, absorbers, and reactive monomers can enable higher resolution printing by controlling light penetration depth and reaction kinetics. These specialized materials can minimize scattering effects and enhance the precision of the curing process, allowing for the fabrication of structures with finer details and improved mechanical properties.Expand Specific Solutions03 Multi-beam and tomographic approaches for resolution improvement

Multi-beam projection systems and tomographic approaches represent advanced methods for improving resolution in volumetric additive manufacturing. By utilizing multiple light sources or computed tomography principles, these techniques enable the creation of complex internal structures with high precision. The controlled intersection of multiple light beams can create localized polymerization points, while tomographic reconstruction algorithms allow for the generation of highly detailed volumetric objects with improved resolution throughout the entire build volume.Expand Specific Solutions04 Real-time monitoring and feedback systems for resolution control

Implementing real-time monitoring and feedback systems can significantly enhance resolution control in volumetric additive manufacturing. These systems utilize sensors and imaging technologies to continuously assess the printing process and make dynamic adjustments. By incorporating closed-loop control mechanisms, manufacturers can detect and correct deviations during fabrication, ensuring consistent resolution throughout the build. Advanced algorithms can analyze the data collected during printing to optimize exposure parameters and maintain high resolution across different geometries.Expand Specific Solutions05 Post-processing techniques for resolution enhancement

Various post-processing techniques can be employed to enhance the effective resolution of parts produced through volumetric additive manufacturing. These include chemical treatments, thermal processing, and mechanical finishing methods that can refine surface features and improve dimensional accuracy. By applying controlled etching processes or secondary curing steps, manufacturers can achieve sub-resolution features and remove artifacts that limit the apparent resolution of printed structures, resulting in higher quality final products with improved detail definition.Expand Specific Solutions

Leading Companies and Research Institutions in Volumetric AM

Volumetric Additive Manufacturing resolution is currently at a competitive inflection point, transitioning from early development to commercial application with a growing market projected to reach significant scale in precision manufacturing sectors. Resolution determinants include light source characteristics, photopolymer properties, and optical system design. Leading research institutions (École Polytechnique Fédérale de Lausanne, Tsinghua University, Huazhong University) are advancing fundamental technologies, while commercial players like Readily3D, EOS GmbH, and Fraunhofer-Gesellschaft are developing practical applications. Industry leaders RTX Corp. and Siemens Energy are integrating these capabilities into aerospace and energy applications, indicating technology maturation across multiple sectors with resolution capabilities now reaching sub-100μm precision in specialized applications.

École Polytechnique Fédérale de Lausanne

Technical Solution: EPFL has developed a groundbreaking volumetric additive manufacturing technology called tomographic volumetric 3D printing. This approach uses computed tomography principles to project multiple 2D light patterns from different angles into a photosensitive resin, creating complex 3D structures in seconds without layer-by-layer processing. Their research has identified that resolution in this technique is determined by several key factors: the optical setup (including the quality and focal length of projection lenses), light source wavelength (shorter wavelengths enable higher resolution), photopolymer properties (including light absorption coefficients and reaction kinetics), and the number and distribution of projection angles. EPFL has achieved resolutions down to 80 micrometers in all dimensions while maintaining print speeds 100 times faster than conventional methods.

Strengths: Extremely fast printing speeds (seconds instead of hours); ability to create complex internal structures without support materials; excellent resolution-to-speed ratio. Weaknesses: Limited build volume compared to some conventional methods; restricted to photopolymer materials; resolution still not comparable to the finest stereolithography systems.

Lawrence Livermore National Security LLC

Technical Solution: Lawrence Livermore National Laboratory (LLNL) has pioneered Computed Axial Lithography (CAL) for volumetric additive manufacturing, focusing extensively on resolution optimization. Their research has identified that resolution is determined by: the optical projection system (including numerical aperture and aberration control), photopolymer chemistry (developing resins with precise threshold behavior and minimal light scattering), and computational reconstruction algorithms. LLNL has developed sophisticated image processing techniques that pre-compensate for optical distortions and material nonlinearities, significantly enhancing achievable resolution. Their system rotates a cylindrical container of photosensitive resin while projecting computed patterns from different angles, creating complex structures in minutes rather than hours. LLNL has achieved resolutions approaching 35 micrometers in their latest systems, with particular focus on applications requiring complex internal geometries.

Strengths: Advanced computational algorithms for resolution enhancement; ability to create complex internal features impossible with conventional printing; strong integration with material science research. Weaknesses: Technology still primarily in research phase rather than commercial deployment; limited material selection; resolution still constrained by optical diffraction limits.

Critical Patents and Research on Volumetric Resolution

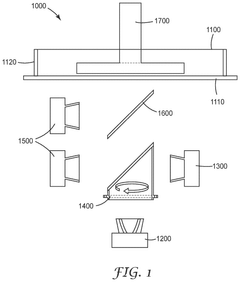

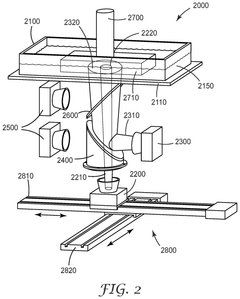

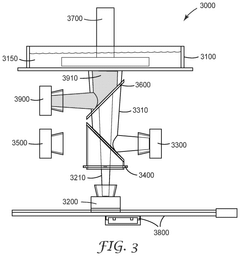

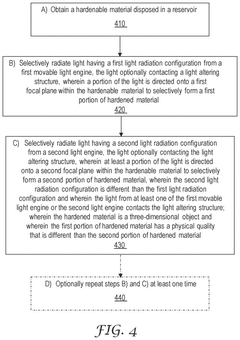

Additive manufacturing apparatus including two light engines and a light altering structure and a method of additive manufacturing a three-dimensional object

PatentActiveUS12397505B2

Innovation

- Employing at least two light engines with different configurations, one of which is movable, and a light altering structure, such as a rotatable mirror or beam splitter, to selectively radiate light onto multiple focal planes within a reservoir, allowing for blending and inline process control.

Materials Science Impact on Volumetric Printing Resolution

The material properties in volumetric additive manufacturing (VAM) play a crucial role in determining the achievable resolution of printed structures. The photosensitive resins used in VAM systems must balance several competing properties to enable high-resolution printing. Light absorption characteristics represent one of the most critical factors, as the resin must absorb enough light energy to initiate polymerization while avoiding excessive absorption that would limit light penetration depth and cause over-curing.

Resin viscosity significantly impacts resolution by affecting how quickly the material can respond to optical patterning. Lower viscosity formulations allow for more rapid molecular rearrangement during polymerization, potentially enabling finer features, but may suffer from reduced structural stability during the printing process. Conversely, higher viscosity resins provide better structural support but may limit the achievable resolution due to slower diffusion kinetics.

The photoinitiator system employed in the resin formulation directly influences resolution through its efficiency, activation wavelength, and concentration. More efficient photoinitiators can achieve polymerization with lower light doses, reducing light scattering effects that degrade resolution. The concentration must be carefully optimized, as excessive amounts can cause over-sensitivity and feature bloating, while insufficient amounts may result in incomplete polymerization.

Oxygen inhibition represents another critical material science challenge in VAM. Dissolved oxygen can quench the polymerization reaction, creating a threshold effect that can be beneficial for resolution but must be precisely controlled. Some advanced resin systems deliberately incorporate oxygen scavengers or utilize the inhibition effect to create sharper boundaries between polymerized and non-polymerized regions.

The mechanical properties of the cured material also influence the practical resolution limits. Materials that experience significant shrinkage during curing can distort fine features, while those with higher elastic moduli may better maintain their shape during the printing process. Recent advances in material science have focused on developing resins with minimal shrinkage stress and improved mechanical stability to preserve fine features.

Additives such as light absorbers, scattering agents, and chain transfer agents provide additional tools for resolution control. These components can be strategically incorporated to manipulate light propagation within the resin volume, creating sharper polymerization boundaries and enabling finer feature resolution. The development of specialized additives represents an active area of research aimed at pushing the resolution boundaries of volumetric printing technologies.

Resin viscosity significantly impacts resolution by affecting how quickly the material can respond to optical patterning. Lower viscosity formulations allow for more rapid molecular rearrangement during polymerization, potentially enabling finer features, but may suffer from reduced structural stability during the printing process. Conversely, higher viscosity resins provide better structural support but may limit the achievable resolution due to slower diffusion kinetics.

The photoinitiator system employed in the resin formulation directly influences resolution through its efficiency, activation wavelength, and concentration. More efficient photoinitiators can achieve polymerization with lower light doses, reducing light scattering effects that degrade resolution. The concentration must be carefully optimized, as excessive amounts can cause over-sensitivity and feature bloating, while insufficient amounts may result in incomplete polymerization.

Oxygen inhibition represents another critical material science challenge in VAM. Dissolved oxygen can quench the polymerization reaction, creating a threshold effect that can be beneficial for resolution but must be precisely controlled. Some advanced resin systems deliberately incorporate oxygen scavengers or utilize the inhibition effect to create sharper boundaries between polymerized and non-polymerized regions.

The mechanical properties of the cured material also influence the practical resolution limits. Materials that experience significant shrinkage during curing can distort fine features, while those with higher elastic moduli may better maintain their shape during the printing process. Recent advances in material science have focused on developing resins with minimal shrinkage stress and improved mechanical stability to preserve fine features.

Additives such as light absorbers, scattering agents, and chain transfer agents provide additional tools for resolution control. These components can be strategically incorporated to manipulate light propagation within the resin volume, creating sharper polymerization boundaries and enabling finer feature resolution. The development of specialized additives represents an active area of research aimed at pushing the resolution boundaries of volumetric printing technologies.

Standardization and Quality Control in Volumetric Manufacturing

Standardization and quality control represent critical components in the advancement of volumetric additive manufacturing (VAM) technology, directly impacting achievable resolution and reproducibility. As VAM technologies mature from laboratory demonstrations to industrial applications, establishing robust standardization frameworks becomes essential for consistent resolution outcomes across different systems and materials.

The current landscape of quality control in VAM reveals significant variability in measurement methodologies and reporting standards. This inconsistency creates challenges when comparing resolution capabilities between different volumetric manufacturing systems and research publications. Resolution in VAM is multidimensional, encompassing spatial resolution, feature fidelity, and material property consistency, necessitating standardized metrics that address all these aspects.

Industry leaders and research institutions have begun collaborative efforts to develop standardized test artifacts specifically designed for VAM processes. These artifacts incorporate features at varying scales and orientations to comprehensively evaluate resolution capabilities across the entire build volume. Unlike traditional layer-by-layer additive manufacturing, VAM requires unique consideration of optical effects such as light scattering and absorption gradients throughout the volume, which must be accounted for in standardization protocols.

Quality control systems for VAM increasingly incorporate in-situ monitoring technologies that provide real-time feedback on resolution-critical parameters. Advanced optical coherence tomography and computational imaging techniques enable continuous assessment of polymerization dynamics and structural formation during the manufacturing process. These monitoring systems help identify resolution-limiting factors as they occur, allowing for process adjustments that maintain consistent resolution throughout production runs.

Material certification standards represent another crucial aspect of quality control in VAM. The photosensitive resins used in volumetric manufacturing exhibit complex behaviors that significantly impact achievable resolution. Standardized characterization methods for properties such as photoinitiator concentration, light absorption coefficients, and polymerization kinetics provide manufacturers with reliable parameters for optimizing resolution performance.

International standards organizations including ISO and ASTM have established working groups focused specifically on VAM technologies, with resolution standardization as a primary objective. These efforts aim to develop globally recognized testing protocols and certification procedures that will facilitate technology transfer, regulatory approval, and broader industrial adoption of high-resolution volumetric manufacturing processes.

The current landscape of quality control in VAM reveals significant variability in measurement methodologies and reporting standards. This inconsistency creates challenges when comparing resolution capabilities between different volumetric manufacturing systems and research publications. Resolution in VAM is multidimensional, encompassing spatial resolution, feature fidelity, and material property consistency, necessitating standardized metrics that address all these aspects.

Industry leaders and research institutions have begun collaborative efforts to develop standardized test artifacts specifically designed for VAM processes. These artifacts incorporate features at varying scales and orientations to comprehensively evaluate resolution capabilities across the entire build volume. Unlike traditional layer-by-layer additive manufacturing, VAM requires unique consideration of optical effects such as light scattering and absorption gradients throughout the volume, which must be accounted for in standardization protocols.

Quality control systems for VAM increasingly incorporate in-situ monitoring technologies that provide real-time feedback on resolution-critical parameters. Advanced optical coherence tomography and computational imaging techniques enable continuous assessment of polymerization dynamics and structural formation during the manufacturing process. These monitoring systems help identify resolution-limiting factors as they occur, allowing for process adjustments that maintain consistent resolution throughout production runs.

Material certification standards represent another crucial aspect of quality control in VAM. The photosensitive resins used in volumetric manufacturing exhibit complex behaviors that significantly impact achievable resolution. Standardized characterization methods for properties such as photoinitiator concentration, light absorption coefficients, and polymerization kinetics provide manufacturers with reliable parameters for optimizing resolution performance.

International standards organizations including ISO and ASTM have established working groups focused specifically on VAM technologies, with resolution standardization as a primary objective. These efforts aim to develop globally recognized testing protocols and certification procedures that will facilitate technology transfer, regulatory approval, and broader industrial adoption of high-resolution volumetric manufacturing processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!