Volumetric Additive Manufacturing For Rapid Fabrication Of Complex Geometries

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

VAM Technology Background and Objectives

Volumetric Additive Manufacturing (VAM) represents a paradigm shift in the field of 3D printing technology, emerging as a revolutionary approach to fabricate complex three-dimensional structures with unprecedented speed and precision. Unlike traditional layer-by-layer additive manufacturing methods, VAM enables the simultaneous solidification of an entire volume of photosensitive resin, dramatically reducing production time from hours to minutes or even seconds for complex geometries.

The evolution of VAM technology can be traced back to the early developments in stereolithography (SLA) during the 1980s, which laid the groundwork for photopolymerization-based 3D printing. However, the conceptual breakthrough for volumetric manufacturing occurred in the mid-2010s, with significant advancements in optical projection systems, photochemistry, and computational algorithms converging to make simultaneous volumetric solidification feasible.

The primary objective of VAM technology is to overcome the fundamental limitations of conventional additive manufacturing processes, particularly the time-consuming layer-by-layer approach that creates inherent trade-offs between resolution, build volume, and fabrication speed. By enabling the simultaneous curing of an entire volume, VAM aims to achieve production speeds that are orders of magnitude faster than traditional methods while maintaining or improving geometric complexity capabilities.

Current VAM technologies primarily utilize computed axial lithography (CAL), tomographic volumetric printing, or holographic approaches to project patterned light into photosensitive resins from multiple angles or with specific intensity distributions. These techniques rely on sophisticated algorithms to calculate the required light patterns that, when superimposed, selectively solidify the desired geometry within the resin volume.

The technological trajectory of VAM is moving toward higher resolution capabilities, larger build volumes, and compatibility with a broader range of materials beyond photopolymers. Recent research has demonstrated the potential for incorporating functional materials, such as those with electrical conductivity or specific mechanical properties, expanding the application scope of VAM technology.

The ultimate goal of VAM research and development is to establish a manufacturing platform that combines the geometric freedom of additive manufacturing with production speeds approaching those of traditional manufacturing methods like injection molding. This would enable rapid prototyping and small-batch production of complex parts for industries including medical devices, aerospace components, and customized consumer products, where both geometric complexity and production efficiency are critical requirements.

The evolution of VAM technology can be traced back to the early developments in stereolithography (SLA) during the 1980s, which laid the groundwork for photopolymerization-based 3D printing. However, the conceptual breakthrough for volumetric manufacturing occurred in the mid-2010s, with significant advancements in optical projection systems, photochemistry, and computational algorithms converging to make simultaneous volumetric solidification feasible.

The primary objective of VAM technology is to overcome the fundamental limitations of conventional additive manufacturing processes, particularly the time-consuming layer-by-layer approach that creates inherent trade-offs between resolution, build volume, and fabrication speed. By enabling the simultaneous curing of an entire volume, VAM aims to achieve production speeds that are orders of magnitude faster than traditional methods while maintaining or improving geometric complexity capabilities.

Current VAM technologies primarily utilize computed axial lithography (CAL), tomographic volumetric printing, or holographic approaches to project patterned light into photosensitive resins from multiple angles or with specific intensity distributions. These techniques rely on sophisticated algorithms to calculate the required light patterns that, when superimposed, selectively solidify the desired geometry within the resin volume.

The technological trajectory of VAM is moving toward higher resolution capabilities, larger build volumes, and compatibility with a broader range of materials beyond photopolymers. Recent research has demonstrated the potential for incorporating functional materials, such as those with electrical conductivity or specific mechanical properties, expanding the application scope of VAM technology.

The ultimate goal of VAM research and development is to establish a manufacturing platform that combines the geometric freedom of additive manufacturing with production speeds approaching those of traditional manufacturing methods like injection molding. This would enable rapid prototyping and small-batch production of complex parts for industries including medical devices, aerospace components, and customized consumer products, where both geometric complexity and production efficiency are critical requirements.

Market Demand Analysis for Rapid Complex Geometry Fabrication

The global market for advanced manufacturing technologies capable of producing complex geometries has experienced significant growth in recent years, driven by increasing demand across multiple industries. The Volumetric Additive Manufacturing (VAM) sector specifically addresses the need for rapid fabrication of intricate three-dimensional structures that traditional manufacturing methods struggle to produce efficiently.

Aerospace and defense industries represent major market segments, with demand for lightweight components featuring complex internal geometries that optimize strength-to-weight ratios. These sectors value VAM technologies for their ability to produce parts with internal cooling channels, lattice structures, and topology-optimized designs that reduce material usage while maintaining structural integrity.

Medical device manufacturing has emerged as another critical market driver, particularly in the production of patient-specific implants, prosthetics, and anatomical models. The market for customized medical devices is projected to grow substantially as healthcare providers increasingly adopt personalized treatment approaches. VAM technologies enable the rapid production of biocompatible components with precise geometries matched to individual patient anatomy.

The automotive industry's transition toward electric vehicles has created new demand for complex components that integrate multiple functions into single parts. Manufacturers seek to reduce assembly requirements and enhance thermal management through geometrically complex heat exchangers and structural components that traditional manufacturing cannot efficiently produce.

Consumer electronics represents another significant market segment, with manufacturers seeking to miniaturize components while increasing functionality. The ability to fabricate intricate internal structures enables more efficient cooling solutions and space utilization within compact devices.

Market analysis indicates that industries are willing to pay premium prices for manufacturing technologies that can reduce lead times from weeks to days or hours. Time-to-market advantages represent a key value proposition for VAM technologies, particularly in competitive industries where product development cycles continue to compress.

The global market for advanced manufacturing technologies capable of producing complex geometries was valued at approximately $12 billion in 2022, with projections suggesting compound annual growth rates exceeding 20% through 2028. North America currently represents the largest market share, followed by Europe and Asia-Pacific regions, though the latter shows the fastest growth trajectory.

Supply chain resilience has emerged as an additional market driver following recent global disruptions, with manufacturers increasingly seeking technologies that enable on-demand, localized production of complex components rather than relying on extended global supply networks.

Aerospace and defense industries represent major market segments, with demand for lightweight components featuring complex internal geometries that optimize strength-to-weight ratios. These sectors value VAM technologies for their ability to produce parts with internal cooling channels, lattice structures, and topology-optimized designs that reduce material usage while maintaining structural integrity.

Medical device manufacturing has emerged as another critical market driver, particularly in the production of patient-specific implants, prosthetics, and anatomical models. The market for customized medical devices is projected to grow substantially as healthcare providers increasingly adopt personalized treatment approaches. VAM technologies enable the rapid production of biocompatible components with precise geometries matched to individual patient anatomy.

The automotive industry's transition toward electric vehicles has created new demand for complex components that integrate multiple functions into single parts. Manufacturers seek to reduce assembly requirements and enhance thermal management through geometrically complex heat exchangers and structural components that traditional manufacturing cannot efficiently produce.

Consumer electronics represents another significant market segment, with manufacturers seeking to miniaturize components while increasing functionality. The ability to fabricate intricate internal structures enables more efficient cooling solutions and space utilization within compact devices.

Market analysis indicates that industries are willing to pay premium prices for manufacturing technologies that can reduce lead times from weeks to days or hours. Time-to-market advantages represent a key value proposition for VAM technologies, particularly in competitive industries where product development cycles continue to compress.

The global market for advanced manufacturing technologies capable of producing complex geometries was valued at approximately $12 billion in 2022, with projections suggesting compound annual growth rates exceeding 20% through 2028. North America currently represents the largest market share, followed by Europe and Asia-Pacific regions, though the latter shows the fastest growth trajectory.

Supply chain resilience has emerged as an additional market driver following recent global disruptions, with manufacturers increasingly seeking technologies that enable on-demand, localized production of complex components rather than relying on extended global supply networks.

Current State and Technical Challenges in VAM

Volumetric Additive Manufacturing (VAM) represents a paradigm shift in 3D printing technology, enabling the simultaneous solidification of an entire volume of photopolymer resin. Unlike traditional layer-by-layer approaches, VAM creates complex three-dimensional structures in seconds to minutes, dramatically accelerating production speeds while maintaining high resolution. Currently, VAM technology exists primarily in research laboratories and early commercial implementations, with significant advancements made in the past five years.

The state-of-the-art VAM systems utilize computed tomography principles in reverse, projecting patterned light from multiple angles into photosensitive resins. Leading research institutions including Lawrence Livermore National Laboratory, UC Berkeley, and ETH Zurich have demonstrated functional prototypes capable of producing centimeter-scale objects with sub-millimeter features in under 30 seconds. Commercial entities like Readily3D, Xolo, and Vitro3D have begun offering first-generation VAM systems with build volumes typically ranging from 5-50 cubic centimeters.

Despite promising advances, VAM faces several critical technical challenges. Foremost is the limited build volume, constrained by the optical penetration depth in photopolymer resins. Current systems struggle to maintain uniform light distribution throughout larger volumes, resulting in inconsistent curing and structural integrity issues. The development of specialized photoinitiators and resin formulations with controlled light scattering properties remains an active research area to address this limitation.

Resolution constraints present another significant challenge. While VAM can achieve feature sizes of approximately 80-100 micrometers, this falls short of the precision offered by some conventional additive manufacturing techniques. The fundamental trade-off between build speed, volume, and resolution continues to challenge researchers, with computational approaches like machine learning-based optimization showing promise for improvement.

Material diversity represents a substantial barrier to widespread adoption. Current VAM processes work primarily with transparent photopolymers, severely limiting application potential. Research efforts are underway to expand material compatibility to include ceramics, hydrogels, and composite materials, though significant formulation challenges remain in maintaining optical clarity while achieving desired mechanical properties.

Heat management during rapid polymerization presents additional complications, particularly for larger builds where exothermic reactions can cause thermal gradients leading to warping or internal stress. Advanced thermal modeling and staged curing approaches are being explored to mitigate these effects, but have yet to be fully implemented in commercial systems.

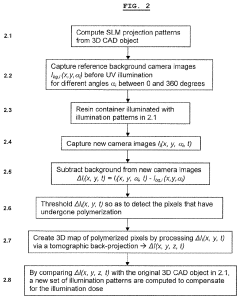

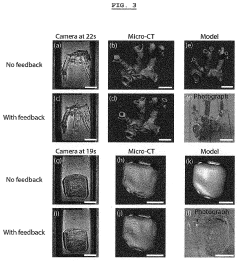

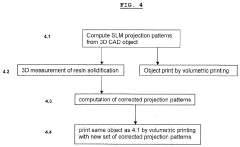

The computational demands of VAM also pose challenges, requiring sophisticated algorithms to calculate optimal projection patterns and account for light scattering effects. Real-time feedback systems that can adjust projections based on actual curing progress remain in early development stages but represent a promising direction for improving print reliability and quality.

The state-of-the-art VAM systems utilize computed tomography principles in reverse, projecting patterned light from multiple angles into photosensitive resins. Leading research institutions including Lawrence Livermore National Laboratory, UC Berkeley, and ETH Zurich have demonstrated functional prototypes capable of producing centimeter-scale objects with sub-millimeter features in under 30 seconds. Commercial entities like Readily3D, Xolo, and Vitro3D have begun offering first-generation VAM systems with build volumes typically ranging from 5-50 cubic centimeters.

Despite promising advances, VAM faces several critical technical challenges. Foremost is the limited build volume, constrained by the optical penetration depth in photopolymer resins. Current systems struggle to maintain uniform light distribution throughout larger volumes, resulting in inconsistent curing and structural integrity issues. The development of specialized photoinitiators and resin formulations with controlled light scattering properties remains an active research area to address this limitation.

Resolution constraints present another significant challenge. While VAM can achieve feature sizes of approximately 80-100 micrometers, this falls short of the precision offered by some conventional additive manufacturing techniques. The fundamental trade-off between build speed, volume, and resolution continues to challenge researchers, with computational approaches like machine learning-based optimization showing promise for improvement.

Material diversity represents a substantial barrier to widespread adoption. Current VAM processes work primarily with transparent photopolymers, severely limiting application potential. Research efforts are underway to expand material compatibility to include ceramics, hydrogels, and composite materials, though significant formulation challenges remain in maintaining optical clarity while achieving desired mechanical properties.

Heat management during rapid polymerization presents additional complications, particularly for larger builds where exothermic reactions can cause thermal gradients leading to warping or internal stress. Advanced thermal modeling and staged curing approaches are being explored to mitigate these effects, but have yet to be fully implemented in commercial systems.

The computational demands of VAM also pose challenges, requiring sophisticated algorithms to calculate optimal projection patterns and account for light scattering effects. Real-time feedback systems that can adjust projections based on actual curing progress remain in early development stages but represent a promising direction for improving print reliability and quality.

Current VAM Technical Solutions

01 Volumetric additive manufacturing techniques

Volumetric additive manufacturing involves creating 3D objects by solidifying material throughout a volume simultaneously, rather than layer-by-layer. These techniques include computed axial lithography (CAL), tomographic volumetric additive manufacturing, and holographic printing methods. By projecting patterned light into photosensitive resins from multiple angles, complex structures can be formed rapidly in seconds or minutes rather than hours, significantly accelerating the fabrication process compared to conventional layer-by-layer approaches.- Light-based volumetric additive manufacturing techniques: Light-based volumetric additive manufacturing involves using photopolymerization to create 3D objects in a single exposure. This technique utilizes projected light patterns or laser beams to cure photosensitive resins throughout a volume simultaneously, rather than layer by layer. The process significantly reduces fabrication time compared to traditional methods and enables the creation of complex geometries without support structures. Advanced optical systems and specialized photopolymers are key components that allow for precise control of the curing process throughout the entire volume.

- Materials and formulations for volumetric manufacturing: Specialized materials and formulations play a crucial role in volumetric additive manufacturing. These include photopolymer resins with tailored viscosity, curing characteristics, and optical properties that enable rapid volumetric solidification. Advanced formulations incorporate photoinitiators, absorbers, and other additives that control light penetration depth and reaction kinetics. Some materials are designed to change properties upon exposure to specific wavelengths of light, allowing for selective curing throughout a volume. These formulations must balance rapid curing with mechanical performance in the final parts.

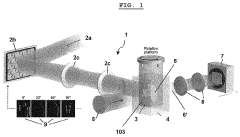

- Computed tomography-inspired volumetric printing: This approach to volumetric manufacturing draws inspiration from computed tomography principles, using multiple projections from different angles to create 3D objects. The technique involves rotating a container of photosensitive resin while projecting synchronized light patterns that selectively cure specific regions. By calculating the appropriate light patterns for each angle, complex internal structures can be created without the need for support materials. This method enables the fabrication of objects with intricate internal geometries that would be difficult or impossible to achieve with conventional layer-by-layer techniques.

- High-speed volumetric fabrication systems: High-speed volumetric fabrication systems focus on maximizing production throughput while maintaining precision. These systems incorporate advanced optical setups, high-powered light sources, and optimized control algorithms to reduce fabrication times from hours to minutes or even seconds. Some approaches use synchronized multiple light sources or specialized scanning techniques to cure larger volumes simultaneously. The systems often feature real-time monitoring and feedback mechanisms to ensure quality control during the rapid fabrication process, making them suitable for both prototyping and production applications.

- Hybrid and multi-material volumetric manufacturing: Hybrid and multi-material volumetric manufacturing combines different fabrication techniques or enables the creation of objects with varying material properties in a single process. These approaches may integrate volumetric printing with other additive manufacturing methods to leverage the advantages of each. Some systems allow for selective curing of different materials within the same volume, creating functionally graded parts with region-specific properties. Advanced control systems coordinate the deposition or activation of multiple materials to achieve precise spatial distribution, enabling the fabrication of complex devices with integrated functionality.

02 Materials for volumetric manufacturing

Advanced materials play a crucial role in volumetric additive manufacturing, including specialized photopolymers, hydrogels, and composite resins that can be rapidly cured with specific light wavelengths. These materials are formulated with photoinitiators and absorbers to control light penetration depth and curing characteristics. Recent developments include biocompatible resins for medical applications, high-performance engineering polymers, and materials with tunable mechanical properties that enable the creation of functional parts with specific performance characteristics.Expand Specific Solutions03 Optical systems and projection technologies

Sophisticated optical systems are essential for volumetric manufacturing, utilizing digital light processing (DLP), spatial light modulators, and holographic projection technologies. These systems generate precisely controlled light patterns that cure specific volumes within the resin. Advanced algorithms coordinate multiple projectors or rotating projection systems to achieve uniform curing throughout the volume. Innovations in optical components, including specialized lenses, mirrors, and light sources, enable higher resolution, faster processing speeds, and improved fabrication accuracy.Expand Specific Solutions04 Software and computational methods

Specialized software algorithms are critical for volumetric manufacturing, including tomographic reconstruction techniques, computational modeling of light propagation, and optimization methods for determining projection patterns. These computational approaches calculate the precise light dose distributions needed to achieve desired geometries while accounting for optical effects like scattering and absorption. Machine learning techniques are increasingly employed to predict and compensate for material behavior during curing, improving dimensional accuracy and surface quality of fabricated parts.Expand Specific Solutions05 Applications and industrial implementation

Volumetric additive manufacturing is finding applications across multiple industries due to its speed and ability to create complex structures. In the medical field, it enables rapid production of patient-specific implants, tissue scaffolds, and anatomical models. Industrial applications include rapid prototyping, production of complex components with internal features, and manufacturing of customized parts. The technology is particularly valuable for creating structures with embedded components, microfluidic devices, and parts with complex internal geometries that would be difficult to produce using conventional manufacturing methods.Expand Specific Solutions

Key Industry Players in VAM Technology

Volumetric Additive Manufacturing (VAM) for complex geometries is currently in the early growth stage of industry development, with the market expected to reach $2-3 billion by 2028. The technology maturity varies significantly across key players, with established companies like Carbon, Inc. and Stratasys leading commercial applications through proprietary light-based VAM technologies. Research institutions including EPFL, MIT, and Huazhong University are advancing fundamental capabilities in rapid volumetric fabrication. Major industrial players such as Siemens Energy, HP Development, and Xerox are integrating VAM into manufacturing workflows, while specialized innovators like Readily3D and Evolve Additive Solutions focus on niche applications requiring complex geometries. The competitive landscape shows a balance between academic innovation and industrial commercialization efforts, with increasing cross-sector collaborations accelerating technology adoption.

Carbon, Inc.

Technical Solution: Carbon has pioneered Digital Light Synthesis (DLS) technology for volumetric additive manufacturing, which uses digital light projection, oxygen-permeable optics, and programmable liquid resins to produce parts with exceptional mechanical properties. Their continuous liquid interface production (CLIP) process enables up to 100 times faster printing speeds compared to traditional methods by eliminating the layer-by-layer approach. Carbon's proprietary dual-cure resins undergo a secondary thermal cure after printing, resulting in high-strength, production-grade parts with isotropic properties. The company has developed a cloud-based software platform that optimizes build parameters and enables real-time monitoring of the manufacturing process, ensuring consistent quality across production runs. Carbon's technology has been successfully implemented in various industries including automotive, medical, and consumer products, with notable partnerships with companies like Adidas for the production of midsoles with complex lattice structures.

Strengths: Superior surface finish and isotropic mechanical properties; significantly faster production speeds; wide range of functional materials including biocompatible options. Weaknesses: Higher initial investment costs compared to traditional AM systems; proprietary materials ecosystem creates vendor lock-in; limited maximum part size compared to some competing technologies.

Lawrence Livermore National Security LLC

Technical Solution: Lawrence Livermore National Laboratory (LLNL) has pioneered Computed Axial Lithography (CAL) for volumetric additive manufacturing, which creates complex 3D structures all at once rather than layer by layer. This technique projects synchronized patterns of light from multiple angles into a rotating container of photosensitive resin, where the accumulated light energy selectively solidifies the desired geometry in a matter of minutes. LLNL researchers have demonstrated the ability to print objects with internal features, overhangs, and complex geometries without requiring support structures, achieving resolutions below 100 microns. The laboratory has also developed specialized algorithms for tomographic reconstruction that optimize the light patterns for specific geometries, improving print quality and reducing curing times. LLNL's approach enables the fabrication of structures with smooth surfaces that don't exhibit the "stair-stepping" artifacts common in layer-by-layer techniques, making it particularly valuable for optical and fluidic applications requiring precise internal channels and surfaces.

Strengths: Extremely fast printing speeds (30-120 seconds for centimeter-scale objects); excellent surface finish without layer lines; ability to create complex internal features without supports; isotropic mechanical properties. Weaknesses: Currently limited to smaller build volumes; requires specialized photopolymer formulations; technology still in research phase with limited commercial availability; resolution constraints compared to some other techniques.

Core Patents and Technical Literature in VAM

System and method of using feedback for correcting three dimensional objects in volumetric tomographic printers

PatentInactiveUS20220347929A1

Innovation

- A method involving real-time monitoring and feedback-enhanced tomographic reconstruction, where a 3D object being formed is imaged using an imaging system, and based on the images, new light patterns are generated to correct the photopolymerization process, allowing for higher resolution printing by adjusting the light dose distribution and stopping the process when complete.

Method for the production of a building component and use of the building component produced according to the method

PatentWO2009024258A1

Innovation

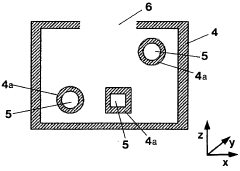

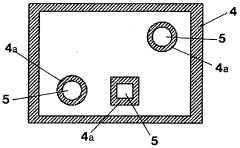

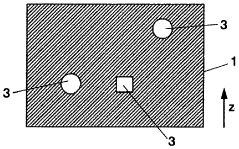

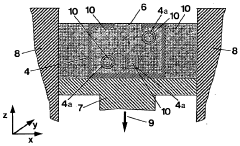

- The method divides the component volume into a shell area and a core area, where only the shell is built using additive manufacturing, and the core area is filled with a different material through an opening, combining generative and casting production techniques to reduce manufacturing time and enable the use of multiple materials.

Material Science Advancements for VAM

Recent advancements in material science have significantly propelled Volumetric Additive Manufacturing (VAM) capabilities. The development of photosensitive resins with enhanced optical properties has been crucial, allowing for more precise light penetration and energy distribution throughout the volume. These materials now feature carefully calibrated absorption coefficients and photoinitiator systems that enable controlled solidification at specific depths within the resin bath.

Dual-wavelength photopolymer systems represent a breakthrough innovation, utilizing different light frequencies to activate distinct chemical reactions within the same material. This approach has overcome previous limitations in creating complex internal structures by enabling selective curing without affecting surrounding areas. Additionally, the incorporation of nanoparticles into photopolymer matrices has yielded composite materials with superior mechanical properties while maintaining excellent optical characteristics necessary for volumetric processing.

Temperature-responsive materials have emerged as another significant advancement, offering the ability to modulate curing kinetics through thermal control. These smart materials exhibit different polymerization behaviors at varying temperatures, providing an additional parameter for controlling the fabrication process. This capability has proven particularly valuable when creating gradient structures with varying mechanical properties throughout a single printed object.

Self-healing photopolymers represent the cutting edge of VAM material development, incorporating dynamic chemical bonds that can reform after breakage. This property enhances the durability of printed components and provides opportunities for post-processing adjustments. Furthermore, bio-compatible photopolymers have expanded VAM applications into medical fields, enabling the direct fabrication of patient-specific implants and tissue scaffolds with complex internal architectures.

The development of multi-material VAM systems has been facilitated by innovations in resin formulations that allow for controlled phase separation or selective curing of different components within a single resin bath. These systems can produce objects with spatially varying material properties, such as rigid structures with flexible joints or components with embedded functional gradients.

Environmentally sustainable materials have also gained prominence, with research focusing on bio-derived precursors and biodegradable photopolymers that maintain the performance characteristics required for high-resolution VAM. These materials address growing concerns about the environmental impact of additive manufacturing while opening new application possibilities in fields requiring temporary or degradable structures.

Dual-wavelength photopolymer systems represent a breakthrough innovation, utilizing different light frequencies to activate distinct chemical reactions within the same material. This approach has overcome previous limitations in creating complex internal structures by enabling selective curing without affecting surrounding areas. Additionally, the incorporation of nanoparticles into photopolymer matrices has yielded composite materials with superior mechanical properties while maintaining excellent optical characteristics necessary for volumetric processing.

Temperature-responsive materials have emerged as another significant advancement, offering the ability to modulate curing kinetics through thermal control. These smart materials exhibit different polymerization behaviors at varying temperatures, providing an additional parameter for controlling the fabrication process. This capability has proven particularly valuable when creating gradient structures with varying mechanical properties throughout a single printed object.

Self-healing photopolymers represent the cutting edge of VAM material development, incorporating dynamic chemical bonds that can reform after breakage. This property enhances the durability of printed components and provides opportunities for post-processing adjustments. Furthermore, bio-compatible photopolymers have expanded VAM applications into medical fields, enabling the direct fabrication of patient-specific implants and tissue scaffolds with complex internal architectures.

The development of multi-material VAM systems has been facilitated by innovations in resin formulations that allow for controlled phase separation or selective curing of different components within a single resin bath. These systems can produce objects with spatially varying material properties, such as rigid structures with flexible joints or components with embedded functional gradients.

Environmentally sustainable materials have also gained prominence, with research focusing on bio-derived precursors and biodegradable photopolymers that maintain the performance characteristics required for high-resolution VAM. These materials address growing concerns about the environmental impact of additive manufacturing while opening new application possibilities in fields requiring temporary or degradable structures.

Sustainability Impact of VAM Technologies

Volumetric Additive Manufacturing (VAM) technologies represent a significant advancement in sustainable manufacturing practices compared to traditional manufacturing methods. The environmental footprint of VAM is substantially reduced through material efficiency, with precise volumetric fabrication minimizing waste by up to 30-40% compared to conventional subtractive manufacturing processes. This efficiency stems from VAM's ability to create complex geometries in a single process, eliminating the need for multiple manufacturing steps and associated material losses.

Energy consumption patterns in VAM systems demonstrate promising sustainability advantages. Recent studies indicate that volumetric approaches can reduce energy requirements by 15-25% compared to layer-by-layer additive manufacturing techniques. This efficiency derives from the elimination of repetitive mechanical movements and reduced processing times, with some VAM systems capable of producing complex parts in minutes rather than hours.

The lifecycle assessment of VAM-produced components reveals additional sustainability benefits. Components manufactured through volumetric techniques often exhibit enhanced structural integrity and optimized material distribution, resulting in lighter yet equally functional parts. This weight reduction translates to energy savings during the use phase, particularly relevant in transportation and aerospace applications where each gram of weight reduction contributes to fuel efficiency improvements.

Supply chain implications of VAM technologies further enhance sustainability profiles. The ability to manufacture complex parts on-demand and on-site reduces transportation requirements and associated carbon emissions. This localized production capability can decrease supply chain carbon footprints by up to 50% for certain applications, according to recent industry analyses.

Material innovation within the VAM ecosystem also contributes to sustainability goals. Research into bio-based and recyclable photopolymers compatible with volumetric techniques has accelerated, with several promising formulations demonstrating comparable performance to petroleum-based alternatives while offering improved end-of-life management options. These materials can potentially reduce the carbon footprint of manufacturing processes by 20-35% when considering full lifecycle impacts.

The circular economy potential of VAM technologies presents perhaps the most transformative sustainability impact. The precision and material efficiency inherent in volumetric approaches align perfectly with circular economy principles of resource optimization and waste minimization. As VAM systems mature, their integration with recycling technologies and renewable energy sources could establish new paradigms for sustainable manufacturing ecosystems with closed material loops and minimal environmental impact.

Energy consumption patterns in VAM systems demonstrate promising sustainability advantages. Recent studies indicate that volumetric approaches can reduce energy requirements by 15-25% compared to layer-by-layer additive manufacturing techniques. This efficiency derives from the elimination of repetitive mechanical movements and reduced processing times, with some VAM systems capable of producing complex parts in minutes rather than hours.

The lifecycle assessment of VAM-produced components reveals additional sustainability benefits. Components manufactured through volumetric techniques often exhibit enhanced structural integrity and optimized material distribution, resulting in lighter yet equally functional parts. This weight reduction translates to energy savings during the use phase, particularly relevant in transportation and aerospace applications where each gram of weight reduction contributes to fuel efficiency improvements.

Supply chain implications of VAM technologies further enhance sustainability profiles. The ability to manufacture complex parts on-demand and on-site reduces transportation requirements and associated carbon emissions. This localized production capability can decrease supply chain carbon footprints by up to 50% for certain applications, according to recent industry analyses.

Material innovation within the VAM ecosystem also contributes to sustainability goals. Research into bio-based and recyclable photopolymers compatible with volumetric techniques has accelerated, with several promising formulations demonstrating comparable performance to petroleum-based alternatives while offering improved end-of-life management options. These materials can potentially reduce the carbon footprint of manufacturing processes by 20-35% when considering full lifecycle impacts.

The circular economy potential of VAM technologies presents perhaps the most transformative sustainability impact. The precision and material efficiency inherent in volumetric approaches align perfectly with circular economy principles of resource optimization and waste minimization. As VAM systems mature, their integration with recycling technologies and renewable energy sources could establish new paradigms for sustainable manufacturing ecosystems with closed material loops and minimal environmental impact.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!