Optical Projection Techniques For Volumetric Additive Manufacturing

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Volumetric AM Optical Projection Background & Objectives

Volumetric Additive Manufacturing (VAM) represents a paradigm shift in 3D printing technology, moving beyond traditional layer-by-layer approaches to simultaneous whole-volume solidification. The evolution of optical projection techniques within this domain traces back to early stereolithography methods developed in the 1980s, which laid the groundwork for more sophisticated volumetric approaches. The technological trajectory has accelerated significantly over the past decade, with breakthrough developments in computational tomography, holographic projection, and photosensitive resin chemistry.

The fundamental principle behind optical projection for VAM involves the controlled delivery of patterned light energy throughout a photosensitive volume to trigger simultaneous polymerization at specific spatial coordinates. This approach stands in stark contrast to conventional additive manufacturing methods that build objects sequentially, offering potentially revolutionary advantages in production speed, geometric complexity, and material isotropy.

Current technological trends indicate a convergence of advanced optics, computational algorithms, and materials science to overcome the historical limitations of volumetric fabrication. The development of tunable spatial light modulators, multi-wavelength projection systems, and advanced optical path manipulation techniques has expanded the theoretical capabilities of volumetric manufacturing significantly in recent years.

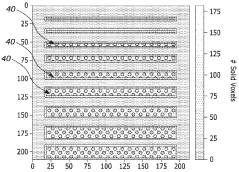

The primary technical objectives for optical projection in VAM include achieving sub-micron spatial resolution throughout the entire build volume, reducing total fabrication time to seconds rather than hours, and enabling multi-material capabilities with precise control over material transitions and properties. Additionally, there is a growing focus on increasing the maximum build volume while maintaining high resolution, which presents significant optical engineering challenges related to light penetration, scattering, and energy distribution.

Another critical objective involves the development of optical systems capable of addressing the inherent trade-offs between build volume, resolution, and fabrication speed. This includes innovations in optical hardware configurations, projection algorithms, and synchronization between multiple optical paths to achieve optimal energy distribution throughout the photosensitive medium.

The long-term technological vision encompasses the creation of versatile volumetric manufacturing platforms that can dynamically adjust optical parameters to accommodate diverse material systems and geometric complexities. This adaptability would position VAM as a transformative technology across multiple industries, from medical device manufacturing to aerospace components, where complex internal structures and high-performance requirements demand novel fabrication approaches.

The fundamental principle behind optical projection for VAM involves the controlled delivery of patterned light energy throughout a photosensitive volume to trigger simultaneous polymerization at specific spatial coordinates. This approach stands in stark contrast to conventional additive manufacturing methods that build objects sequentially, offering potentially revolutionary advantages in production speed, geometric complexity, and material isotropy.

Current technological trends indicate a convergence of advanced optics, computational algorithms, and materials science to overcome the historical limitations of volumetric fabrication. The development of tunable spatial light modulators, multi-wavelength projection systems, and advanced optical path manipulation techniques has expanded the theoretical capabilities of volumetric manufacturing significantly in recent years.

The primary technical objectives for optical projection in VAM include achieving sub-micron spatial resolution throughout the entire build volume, reducing total fabrication time to seconds rather than hours, and enabling multi-material capabilities with precise control over material transitions and properties. Additionally, there is a growing focus on increasing the maximum build volume while maintaining high resolution, which presents significant optical engineering challenges related to light penetration, scattering, and energy distribution.

Another critical objective involves the development of optical systems capable of addressing the inherent trade-offs between build volume, resolution, and fabrication speed. This includes innovations in optical hardware configurations, projection algorithms, and synchronization between multiple optical paths to achieve optimal energy distribution throughout the photosensitive medium.

The long-term technological vision encompasses the creation of versatile volumetric manufacturing platforms that can dynamically adjust optical parameters to accommodate diverse material systems and geometric complexities. This adaptability would position VAM as a transformative technology across multiple industries, from medical device manufacturing to aerospace components, where complex internal structures and high-performance requirements demand novel fabrication approaches.

Market Analysis for Volumetric 3D Printing Technologies

The volumetric 3D printing market is experiencing significant growth, driven by increasing demand for rapid prototyping and manufacturing solutions across various industries. Current market valuations place the global volumetric 3D printing sector at approximately $1.2 billion, with projections indicating a compound annual growth rate of 25-30% over the next five years. This growth trajectory significantly outpaces traditional additive manufacturing methods, reflecting the technology's superior production speeds and unique capabilities.

Healthcare represents the largest market segment for volumetric 3D printing technologies, accounting for roughly 35% of current applications. The ability to rapidly produce complex anatomical models, customized implants, and potentially functional tissues has positioned volumetric printing as a transformative technology in medical device manufacturing and bioprinting. Dental applications alone constitute a rapidly expanding sub-segment, growing at 32% annually.

The industrial manufacturing sector follows closely behind healthcare, representing approximately 28% of the market. Automotive, aerospace, and consumer electronics manufacturers are increasingly adopting volumetric techniques for producing complex components with internal features that would be challenging or impossible to create using conventional manufacturing methods. The reduced production time compared to layer-by-layer printing methods provides a compelling value proposition for time-sensitive manufacturing operations.

Academic and research institutions currently account for about 20% of the market, serving as critical innovation hubs and early adopters of emerging volumetric technologies. The remaining market share is distributed across various sectors including jewelry, architecture, and consumer products.

Geographically, North America leads the market with approximately 42% share, followed by Europe (30%) and Asia-Pacific (23%). However, the Asia-Pacific region is expected to demonstrate the highest growth rate over the next decade, driven by significant investments in advanced manufacturing technologies in China, Japan, and South Korea.

Key market drivers include increasing demand for faster production speeds, growing need for complex geometries in various applications, and the continuous push for more sustainable manufacturing processes. Volumetric techniques offer significant material efficiency advantages over traditional additive manufacturing, with some systems achieving up to 40% reduction in material waste.

Market barriers include high initial equipment costs, limited material compatibility compared to established 3D printing methods, and technical challenges related to resolution and accuracy at larger build volumes. Despite these challenges, the unique value proposition of volumetric printing—particularly its unprecedented speed advantages—continues to drive market expansion and attract significant investment in research and commercialization efforts.

Healthcare represents the largest market segment for volumetric 3D printing technologies, accounting for roughly 35% of current applications. The ability to rapidly produce complex anatomical models, customized implants, and potentially functional tissues has positioned volumetric printing as a transformative technology in medical device manufacturing and bioprinting. Dental applications alone constitute a rapidly expanding sub-segment, growing at 32% annually.

The industrial manufacturing sector follows closely behind healthcare, representing approximately 28% of the market. Automotive, aerospace, and consumer electronics manufacturers are increasingly adopting volumetric techniques for producing complex components with internal features that would be challenging or impossible to create using conventional manufacturing methods. The reduced production time compared to layer-by-layer printing methods provides a compelling value proposition for time-sensitive manufacturing operations.

Academic and research institutions currently account for about 20% of the market, serving as critical innovation hubs and early adopters of emerging volumetric technologies. The remaining market share is distributed across various sectors including jewelry, architecture, and consumer products.

Geographically, North America leads the market with approximately 42% share, followed by Europe (30%) and Asia-Pacific (23%). However, the Asia-Pacific region is expected to demonstrate the highest growth rate over the next decade, driven by significant investments in advanced manufacturing technologies in China, Japan, and South Korea.

Key market drivers include increasing demand for faster production speeds, growing need for complex geometries in various applications, and the continuous push for more sustainable manufacturing processes. Volumetric techniques offer significant material efficiency advantages over traditional additive manufacturing, with some systems achieving up to 40% reduction in material waste.

Market barriers include high initial equipment costs, limited material compatibility compared to established 3D printing methods, and technical challenges related to resolution and accuracy at larger build volumes. Despite these challenges, the unique value proposition of volumetric printing—particularly its unprecedented speed advantages—continues to drive market expansion and attract significant investment in research and commercialization efforts.

Current Challenges in Optical Projection for VAM

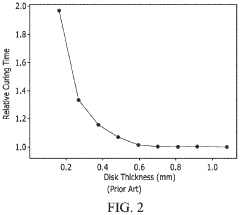

Despite significant advancements in Volumetric Additive Manufacturing (VAM) technologies, optical projection techniques continue to face several critical challenges that limit their widespread industrial adoption. Resolution constraints remain a primary concern, as current systems struggle to achieve sub-micron precision across large build volumes. The fundamental trade-off between build volume and resolution creates a technological bottleneck that restricts applications requiring both large-scale and high-precision components.

Light scattering and absorption phenomena present substantial obstacles in photopolymer-based VAM systems. As light penetrates deeper into the resin, scattering effects distort the projected patterns, while absorption reduces energy delivery to deeper regions. These optical phenomena result in non-uniform curing, dimensional inaccuracies, and limitations in achievable part thickness, particularly problematic for complex internal geometries.

Thermal management during high-intensity projection poses another significant challenge. The concentrated light energy necessary for rapid curing generates considerable heat, potentially causing thermal distortion, material degradation, and inconsistent mechanical properties throughout the printed structure. Current cooling systems and thermal compensation algorithms have not fully resolved these issues at industrial scales.

Optical aberrations and distortions in projection systems further complicate precise energy delivery. Lens imperfections, diffraction effects, and optical path variations can lead to spatial inconsistencies in the projected patterns. These distortions become increasingly problematic as build volumes expand, requiring sophisticated optical correction mechanisms that add complexity and cost to VAM systems.

Material compatibility constraints also limit the versatility of optical projection VAM. Many advanced engineering materials, particularly those with high viscosity or containing particulate additives, interact poorly with projected light patterns. Specialized photopolymers optimized for volumetric projection remain limited in their mechanical properties, thermal stability, and long-term durability compared to conventional manufacturing materials.

Control system limitations present additional hurdles, as synchronizing multiple projection sources with precise timing and spatial coordination requires sophisticated hardware and software integration. The computational demands of processing complex 3D models into optimized projection sequences create bottlenecks in the manufacturing workflow, particularly for geometrically complex parts requiring hundreds or thousands of projection steps.

Calibration and maintenance challenges further impede industrial adoption, as optical projection systems require frequent recalibration to maintain accuracy. Environmental factors such as temperature fluctuations, vibration, and dust accumulation can degrade projection quality over time, necessitating robust monitoring systems and maintenance protocols that increase operational complexity.

Light scattering and absorption phenomena present substantial obstacles in photopolymer-based VAM systems. As light penetrates deeper into the resin, scattering effects distort the projected patterns, while absorption reduces energy delivery to deeper regions. These optical phenomena result in non-uniform curing, dimensional inaccuracies, and limitations in achievable part thickness, particularly problematic for complex internal geometries.

Thermal management during high-intensity projection poses another significant challenge. The concentrated light energy necessary for rapid curing generates considerable heat, potentially causing thermal distortion, material degradation, and inconsistent mechanical properties throughout the printed structure. Current cooling systems and thermal compensation algorithms have not fully resolved these issues at industrial scales.

Optical aberrations and distortions in projection systems further complicate precise energy delivery. Lens imperfections, diffraction effects, and optical path variations can lead to spatial inconsistencies in the projected patterns. These distortions become increasingly problematic as build volumes expand, requiring sophisticated optical correction mechanisms that add complexity and cost to VAM systems.

Material compatibility constraints also limit the versatility of optical projection VAM. Many advanced engineering materials, particularly those with high viscosity or containing particulate additives, interact poorly with projected light patterns. Specialized photopolymers optimized for volumetric projection remain limited in their mechanical properties, thermal stability, and long-term durability compared to conventional manufacturing materials.

Control system limitations present additional hurdles, as synchronizing multiple projection sources with precise timing and spatial coordination requires sophisticated hardware and software integration. The computational demands of processing complex 3D models into optimized projection sequences create bottlenecks in the manufacturing workflow, particularly for geometrically complex parts requiring hundreds or thousands of projection steps.

Calibration and maintenance challenges further impede industrial adoption, as optical projection systems require frequent recalibration to maintain accuracy. Environmental factors such as temperature fluctuations, vibration, and dust accumulation can degrade projection quality over time, necessitating robust monitoring systems and maintenance protocols that increase operational complexity.

Current Optical Projection Solutions for VAM

01 Projection systems with optical components

Optical projection systems utilize various optical components such as lenses, mirrors, and filters to project images onto surfaces. These systems often incorporate specialized arrangements of optical elements to achieve desired projection characteristics including focus, clarity, and brightness. Advanced designs may include multiple optical paths, beam splitters, or compound lens arrays to optimize image quality and reduce distortion.- Projection systems with optical components: Optical projection systems utilize various optical components such as lenses, mirrors, and filters to project images onto surfaces. These systems can include specialized arrangements of optical elements to improve image quality, brightness, and resolution. Advanced optical designs may incorporate multiple light paths, beam splitters, or reflective surfaces to achieve desired projection characteristics.

- Digital projection technologies: Digital projection technologies involve the use of electronic devices to generate and project images. These systems may use digital light processing (DLP), liquid crystal display (LCD), or laser-based technologies to create high-resolution projections. Digital projectors can incorporate advanced image processing algorithms to enhance contrast, color accuracy, and overall image quality for various applications including entertainment, education, and professional presentations.

- Lithography and semiconductor projection systems: Specialized optical projection techniques are used in lithography for semiconductor manufacturing. These systems project precise patterns onto photosensitive materials to create integrated circuits and other microelectronic components. Advanced lithography projection systems may incorporate extreme ultraviolet light sources, sophisticated optical reduction systems, and precision alignment mechanisms to achieve nanometer-scale feature resolution.

- Projection measurement and calibration techniques: Optical projection systems for measurement applications require precise calibration and alignment techniques. These systems may project structured light patterns, reference grids, or other optical markers to enable dimensional measurements, surface profiling, or object recognition. Calibration methods ensure accurate projection geometry and compensate for optical distortions to maintain measurement precision across the projection field.

- Advanced projection optics design: The design of advanced projection optics involves specialized techniques to optimize image quality while managing optical aberrations, distortion, and light efficiency. These designs may incorporate aspheric elements, diffractive optics, or gradient-index materials to achieve superior performance. Computational optical design methods allow for the development of complex projection systems with optimized characteristics for specific applications such as wide-angle projection, short-throw projection, or high-brightness display systems.

02 Digital projection technologies

Digital projection technologies employ electronic image processing and display mechanisms to create projected images. These systems may use technologies such as Digital Light Processing (DLP), Liquid Crystal Display (LCD), or Liquid Crystal on Silicon (LCoS) to generate and project digital content. Modern digital projectors incorporate sophisticated algorithms for image correction, color management, and resolution enhancement to deliver high-quality visual presentations.Expand Specific Solutions03 Lithography and semiconductor projection systems

Specialized optical projection techniques are used in lithography for semiconductor manufacturing. These systems project precise patterns onto photosensitive materials to create integrated circuits and other microelectronic components. Advanced lithography projection systems employ extreme ultraviolet light sources, complex optical arrangements, and precision positioning mechanisms to achieve nanometer-scale feature resolution required for modern semiconductor fabrication.Expand Specific Solutions04 Projection alignment and calibration methods

Methods and systems for aligning and calibrating optical projection equipment ensure accurate image reproduction. These techniques may include automated alignment procedures, sensor-based feedback systems, and software algorithms that compensate for optical distortions. Calibration methods address issues such as keystone correction, color balance, and focus uniformity to maintain projection quality across various environmental conditions and projection surfaces.Expand Specific Solutions05 Innovative projection applications

Novel applications of optical projection technology extend beyond traditional display purposes. These include augmented reality systems, head-up displays, immersive environments, and specialized industrial applications. Innovative projection techniques may incorporate holographic elements, waveguide optics, or adaptive projection surfaces to create new visual experiences or solve specific technical challenges in fields ranging from entertainment to medical imaging.Expand Specific Solutions

Leading Companies in Volumetric Projection Technology

Volumetric Additive Manufacturing (VAM) using optical projection techniques is currently in an early growth phase, with the market expanding rapidly due to increasing applications in medical, aerospace, and consumer electronics sectors. The global market size for this technology is estimated to reach several billion dollars by 2030, driven by demand for faster, more precise 3D printing solutions. In terms of technical maturity, the field is transitioning from research to commercialization, with companies like Formlabs, Stratasys, and EOS leading in polymer-based systems. Readily3D and Evolve Additive Solutions are pioneering tomographic approaches, while established players such as ASML and EssilorLuxottica contribute optical expertise. Academic institutions including EPFL and Zhejiang University are advancing fundamental research, creating a competitive landscape balanced between startups and industry incumbents.

École Polytechnique Fédérale de Lausanne

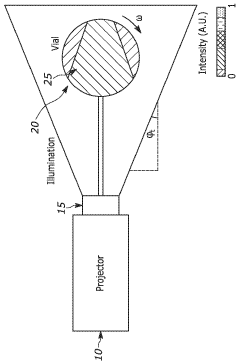

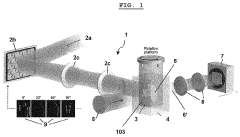

Technical Solution: École Polytechnique Fédérale de Lausanne (EPFL) has pioneered tomographic volumetric additive manufacturing technology that represents a fundamental shift from layer-by-layer approaches. Their system rotates a container of photosensitive resin while projecting computed tomographic images from multiple angles, creating complex 3D structures in seconds rather than hours. The technology employs sophisticated algorithms derived from medical CT imaging but in reverse - using projected light patterns to selectively cure volumes within the resin. EPFL researchers have achieved printing speeds up to 100 times faster than conventional techniques while maintaining resolution below 50 microns. Their approach enables the creation of structures with complex internal geometries impossible to produce with traditional methods. The technology has been particularly successful in biomedical applications, creating cell-laden hydrogel structures with embedded microchannels for tissue engineering applications. EPFL continues to advance the technology by developing specialized photopolymers with tunable mechanical properties and biocompatibility.

Strengths: Revolutionary speed improvements (seconds versus hours); ability to create truly volumetric structures without support materials; excellent for biomedical applications requiring complex internal geometries; elimination of mechanical layer interfaces improves optical and mechanical properties. Weaknesses: Currently limited build volumes compared to established technologies; requires specialized photopolymers with specific optical properties; computational complexity increases with object complexity.

Stratasys, Inc.

Technical Solution: Stratasys has developed a volumetric additive manufacturing approach called Programmable Photopolymerization (P³) that combines digital light processing with precise oxygen inhibition control. Their system projects patterned UV light into a transparent vat of photopolymer resin while simultaneously controlling oxygen concentration at different depths. This creates a "polymerization front" that can be precisely manipulated in three dimensions. Unlike traditional layer-by-layer methods, P³ technology enables continuous printing of complex structures with significantly reduced print times. The system incorporates advanced computational algorithms that calculate optimal light patterns and oxygen distribution to achieve desired geometries with minimal material stress. Stratasys has demonstrated the ability to produce parts with feature resolutions below 50 microns and complex internal structures that would be challenging or impossible with conventional techniques.

Strengths: Continuous printing process eliminates layer lines and associated mechanical weaknesses; superior surface finish quality; ability to create complex internal geometries and overhangs without support structures; significantly faster production times for certain geometries. Weaknesses: Currently optimized for a narrower range of materials compared to Stratasys' established FDM and PolyJet technologies; requires specialized photopolymers with specific oxygen inhibition properties; higher initial equipment investment.

Key Patents in Volumetric Optical Projection Systems

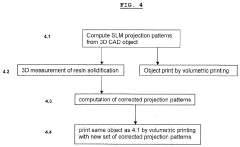

Method of volumetric additive manufacturing

PatentWO2024069272A1

Innovation

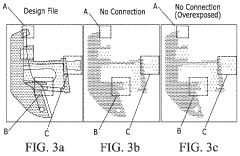

- The method involves rotating a vial of photocurable resin and projecting structured light images to cure only the shell and interior scaffolding of the object, using infilling and deconvolution to correct for diffusion effects, ensuring uniform curing of all features without over-exposure.

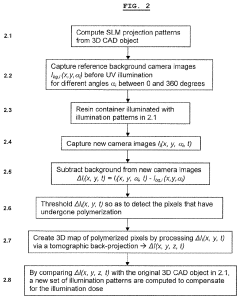

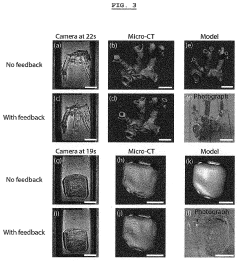

System and method of using feedback for correcting three dimensional objects in volumetric tomographic printers

PatentInactiveUS20220347929A1

Innovation

- A method involving real-time monitoring and feedback-enhanced tomographic reconstruction, where a 3D object being formed is imaged using an imaging system, and based on the images, new light patterns are generated to correct the photopolymerization process, allowing for higher resolution printing by adjusting the light dose distribution and stopping the process when complete.

Materials Compatibility with Optical VAM Techniques

The compatibility of materials with optical volumetric additive manufacturing (VAM) techniques represents a critical factor determining the practical applications and limitations of this emerging technology. Currently, photopolymer resins constitute the primary material class compatible with optical VAM systems, with specific formulations designed to respond to particular wavelengths of light. These photosensitive materials typically contain photoinitiators that absorb light energy and trigger polymerization reactions, converting liquid monomers into solid polymers with defined mechanical properties.

Material selection for optical VAM must balance several competing requirements. The resin must exhibit sufficient optical transparency at the working wavelength to allow light penetration throughout the build volume, while simultaneously containing enough photoinitiator to enable efficient polymerization. This delicate balance presents significant challenges, as higher photoinitiator concentrations improve reaction efficiency but reduce optical penetration depth due to increased light absorption.

Recent advances have expanded the range of compatible materials to include ceramic-loaded resins, where ceramic particles are suspended in photopolymer matrices. These composite materials enable the fabrication of ceramic parts after subsequent thermal processing to remove the polymer binder. Similarly, metal-loaded resins have been developed, though they face additional challenges related to light scattering from metal particles, which can compromise resolution and build accuracy.

The viscosity of materials represents another critical parameter affecting compatibility with optical VAM techniques. Lower viscosity formulations facilitate resin flow and recoating during the manufacturing process, but may compromise mechanical properties or dimensional stability. Conversely, higher viscosity materials may offer superior mechanical characteristics but present challenges in handling and processing within VAM systems.

Temperature sensitivity of materials must also be considered, as the heat generated during photopolymerization reactions can affect curing kinetics and final part properties. Materials with poor thermal management characteristics may experience uneven curing, internal stresses, or dimensional inaccuracies due to thermal gradients within the build volume.

Future material development for optical VAM will likely focus on expanding the range of achievable mechanical properties, improving biocompatibility for medical applications, and developing multi-material capabilities. The integration of stimuli-responsive materials that can change properties post-fabrication represents another promising direction, potentially enabling 4D printing applications where printed structures evolve over time in response to environmental triggers.

Material selection for optical VAM must balance several competing requirements. The resin must exhibit sufficient optical transparency at the working wavelength to allow light penetration throughout the build volume, while simultaneously containing enough photoinitiator to enable efficient polymerization. This delicate balance presents significant challenges, as higher photoinitiator concentrations improve reaction efficiency but reduce optical penetration depth due to increased light absorption.

Recent advances have expanded the range of compatible materials to include ceramic-loaded resins, where ceramic particles are suspended in photopolymer matrices. These composite materials enable the fabrication of ceramic parts after subsequent thermal processing to remove the polymer binder. Similarly, metal-loaded resins have been developed, though they face additional challenges related to light scattering from metal particles, which can compromise resolution and build accuracy.

The viscosity of materials represents another critical parameter affecting compatibility with optical VAM techniques. Lower viscosity formulations facilitate resin flow and recoating during the manufacturing process, but may compromise mechanical properties or dimensional stability. Conversely, higher viscosity materials may offer superior mechanical characteristics but present challenges in handling and processing within VAM systems.

Temperature sensitivity of materials must also be considered, as the heat generated during photopolymerization reactions can affect curing kinetics and final part properties. Materials with poor thermal management characteristics may experience uneven curing, internal stresses, or dimensional inaccuracies due to thermal gradients within the build volume.

Future material development for optical VAM will likely focus on expanding the range of achievable mechanical properties, improving biocompatibility for medical applications, and developing multi-material capabilities. The integration of stimuli-responsive materials that can change properties post-fabrication represents another promising direction, potentially enabling 4D printing applications where printed structures evolve over time in response to environmental triggers.

Energy Efficiency in Volumetric Projection Systems

Energy efficiency represents a critical consideration in the development and implementation of volumetric projection systems for additive manufacturing. Current volumetric projection technologies, while offering significant advantages in terms of speed and geometric freedom, often consume substantial amounts of energy during operation. This consumption primarily stems from high-powered light sources, such as lasers or specialized projectors, required to achieve photopolymerization within the resin volume.

The energy distribution in volumetric projection systems exhibits notable inefficiencies, with studies indicating that only 15-30% of input energy effectively contributes to the curing process. The remainder dissipates as heat or unused light, creating thermal management challenges and reducing overall system efficiency. These inefficiencies translate directly to increased operational costs and environmental impact, particularly in industrial-scale applications.

Recent advancements have focused on optimizing energy utilization through several approaches. Adaptive illumination strategies dynamically adjust light intensity based on specific curing requirements of different regions within the build volume, potentially reducing energy consumption by up to 40% compared to conventional uniform projection methods. Additionally, the development of more photosensitive resins has enabled curing at lower energy thresholds, further enhancing efficiency.

Wavelength-specific optimization represents another promising direction, with research demonstrating that carefully matched light sources and photoinitiators can significantly improve energy transfer efficiency. Some experimental systems utilizing narrow-band LEDs precisely aligned with photoinitiator absorption peaks have achieved energy savings of 25-35% compared to broadband sources, while maintaining comparable mechanical properties in the final parts.

Thermal management innovations also contribute to overall energy efficiency. Advanced cooling systems that recover and redirect waste heat have been implemented in prototype volumetric manufacturing systems, reducing the net energy footprint. Furthermore, computational approaches that optimize projection patterns and timing sequences minimize redundant exposures, resulting in more efficient energy utilization throughout the manufacturing process.

Looking forward, the integration of machine learning algorithms to predict optimal energy distribution patterns shows particular promise. Early implementations have demonstrated potential energy savings of 20-45% through intelligent projection sequencing and intensity modulation, adapting in real-time to specific part geometries and material properties. These developments suggest a pathway toward volumetric manufacturing systems that maintain high production speeds while significantly reducing energy consumption.

The energy distribution in volumetric projection systems exhibits notable inefficiencies, with studies indicating that only 15-30% of input energy effectively contributes to the curing process. The remainder dissipates as heat or unused light, creating thermal management challenges and reducing overall system efficiency. These inefficiencies translate directly to increased operational costs and environmental impact, particularly in industrial-scale applications.

Recent advancements have focused on optimizing energy utilization through several approaches. Adaptive illumination strategies dynamically adjust light intensity based on specific curing requirements of different regions within the build volume, potentially reducing energy consumption by up to 40% compared to conventional uniform projection methods. Additionally, the development of more photosensitive resins has enabled curing at lower energy thresholds, further enhancing efficiency.

Wavelength-specific optimization represents another promising direction, with research demonstrating that carefully matched light sources and photoinitiators can significantly improve energy transfer efficiency. Some experimental systems utilizing narrow-band LEDs precisely aligned with photoinitiator absorption peaks have achieved energy savings of 25-35% compared to broadband sources, while maintaining comparable mechanical properties in the final parts.

Thermal management innovations also contribute to overall energy efficiency. Advanced cooling systems that recover and redirect waste heat have been implemented in prototype volumetric manufacturing systems, reducing the net energy footprint. Furthermore, computational approaches that optimize projection patterns and timing sequences minimize redundant exposures, resulting in more efficient energy utilization throughout the manufacturing process.

Looking forward, the integration of machine learning algorithms to predict optimal energy distribution patterns shows particular promise. Early implementations have demonstrated potential energy savings of 20-45% through intelligent projection sequencing and intensity modulation, adapting in real-time to specific part geometries and material properties. These developments suggest a pathway toward volumetric manufacturing systems that maintain high production speeds while significantly reducing energy consumption.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!