Energy Efficiency In Volumetric Additive Manufacturing Processes

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Energy Efficiency Background and Objectives

Volumetric Additive Manufacturing (VAM) has emerged as a revolutionary approach in the field of 3D printing, offering unprecedented speed and geometric freedom compared to traditional layer-by-layer methods. The evolution of this technology can be traced back to the early 2000s, with significant advancements occurring in the past decade through the convergence of advanced optics, photochemistry, and computational techniques. The fundamental principle of VAM involves the simultaneous solidification of an entire volume of photosensitive resin, representing a paradigm shift from conventional sequential processing methods.

Energy efficiency in VAM processes has become increasingly critical as the technology scales toward industrial applications. Historically, early VAM systems prioritized proof-of-concept functionality over efficiency considerations, resulting in systems with substantial energy wastage. The energy intensity of these processes stems primarily from high-powered light sources, cooling systems, and material conversion inefficiencies, creating both economic and environmental sustainability challenges as adoption increases.

Current technological trends indicate a growing focus on optimizing energy utilization across the VAM workflow. This includes the development of more efficient photopolymerization chemistries that require less energy input, advanced optical systems that minimize light scattering and maximize useful energy delivery, and intelligent process control algorithms that optimize energy distribution temporally and spatially during fabrication.

The primary technical objectives for energy efficiency improvements in VAM include reducing the overall energy consumption per unit volume of printed material by at least 50% within the next five years, developing energy recuperation systems to capture and reuse thermal energy generated during the printing process, and creating standardized metrics for energy efficiency assessment across different VAM technologies and implementations.

Additionally, there are complementary objectives related to minimizing the embodied energy in photopolymer resins through formulation optimization and exploring hybrid approaches that combine the speed advantages of volumetric printing with the material efficiency of other additive manufacturing techniques. These objectives align with broader industry sustainability goals and increasingly stringent regulatory frameworks regarding industrial energy consumption.

The achievement of these objectives would position VAM as not only a high-speed manufacturing solution but also an environmentally responsible alternative to conventional manufacturing processes, potentially enabling new applications in sectors where energy considerations have previously limited adoption. The convergence of speed, quality, and energy efficiency represents the next frontier in volumetric additive manufacturing development.

Energy efficiency in VAM processes has become increasingly critical as the technology scales toward industrial applications. Historically, early VAM systems prioritized proof-of-concept functionality over efficiency considerations, resulting in systems with substantial energy wastage. The energy intensity of these processes stems primarily from high-powered light sources, cooling systems, and material conversion inefficiencies, creating both economic and environmental sustainability challenges as adoption increases.

Current technological trends indicate a growing focus on optimizing energy utilization across the VAM workflow. This includes the development of more efficient photopolymerization chemistries that require less energy input, advanced optical systems that minimize light scattering and maximize useful energy delivery, and intelligent process control algorithms that optimize energy distribution temporally and spatially during fabrication.

The primary technical objectives for energy efficiency improvements in VAM include reducing the overall energy consumption per unit volume of printed material by at least 50% within the next five years, developing energy recuperation systems to capture and reuse thermal energy generated during the printing process, and creating standardized metrics for energy efficiency assessment across different VAM technologies and implementations.

Additionally, there are complementary objectives related to minimizing the embodied energy in photopolymer resins through formulation optimization and exploring hybrid approaches that combine the speed advantages of volumetric printing with the material efficiency of other additive manufacturing techniques. These objectives align with broader industry sustainability goals and increasingly stringent regulatory frameworks regarding industrial energy consumption.

The achievement of these objectives would position VAM as not only a high-speed manufacturing solution but also an environmentally responsible alternative to conventional manufacturing processes, potentially enabling new applications in sectors where energy considerations have previously limited adoption. The convergence of speed, quality, and energy efficiency represents the next frontier in volumetric additive manufacturing development.

Market Demand Analysis for Efficient VAM

The global market for energy-efficient Volumetric Additive Manufacturing (VAM) processes is experiencing significant growth, driven by increasing industrial adoption and the pressing need for sustainable manufacturing solutions. Current market analysis indicates that the VAM segment is expanding at a compound annual growth rate of approximately 25%, outpacing traditional additive manufacturing methods which grow at 15-20% annually.

Energy efficiency has emerged as a critical market differentiator in the VAM sector, with industrial surveys revealing that 78% of potential adopters cite energy consumption as a top-three consideration factor when evaluating new manufacturing technologies. This represents a substantial shift from five years ago when energy efficiency ranked only sixth among decision criteria.

The automotive and aerospace industries currently represent the largest market segments for energy-efficient VAM solutions, collectively accounting for 47% of the total market share. These industries particularly value the ability to produce complex, lightweight components with reduced material waste and lower energy consumption compared to traditional manufacturing methods.

Healthcare and medical device manufacturing constitute the fastest-growing market segment, with demand increasing by 32% annually. This sector specifically requires precision manufacturing capabilities while maintaining strict regulatory compliance, making energy-efficient VAM processes particularly attractive as they offer reduced thermal stress on biocompatible materials.

Regional market analysis reveals that North America currently leads in VAM technology adoption, followed closely by Western Europe and East Asia. However, the most rapid growth is occurring in emerging economies, particularly in Southeast Asia and Eastern Europe, where manufacturing sectors are expanding while simultaneously facing increasing pressure to adopt sustainable practices.

Market research indicates a significant price sensitivity threshold, with industrial customers willing to pay a premium of up to 20% for VAM systems that demonstrate energy efficiency improvements of 30% or greater compared to conventional alternatives. This price-performance relationship creates a clear market incentive for continued innovation in energy-efficient VAM technologies.

The service and maintenance sector surrounding energy-efficient VAM systems is also experiencing substantial growth, with the aftermarket expected to reach 35% of the total market value within the next three years. This includes specialized training, software updates, and component replacements optimized for maintaining peak energy efficiency throughout the system lifecycle.

Consumer demand patterns show increasing preference for manufacturers utilizing energy-efficient production methods, with 65% of end-users in consumer goods markets expressing willingness to select products specifically manufactured using sustainable processes, creating additional market pull for energy-efficient VAM adoption throughout supply chains.

Energy efficiency has emerged as a critical market differentiator in the VAM sector, with industrial surveys revealing that 78% of potential adopters cite energy consumption as a top-three consideration factor when evaluating new manufacturing technologies. This represents a substantial shift from five years ago when energy efficiency ranked only sixth among decision criteria.

The automotive and aerospace industries currently represent the largest market segments for energy-efficient VAM solutions, collectively accounting for 47% of the total market share. These industries particularly value the ability to produce complex, lightweight components with reduced material waste and lower energy consumption compared to traditional manufacturing methods.

Healthcare and medical device manufacturing constitute the fastest-growing market segment, with demand increasing by 32% annually. This sector specifically requires precision manufacturing capabilities while maintaining strict regulatory compliance, making energy-efficient VAM processes particularly attractive as they offer reduced thermal stress on biocompatible materials.

Regional market analysis reveals that North America currently leads in VAM technology adoption, followed closely by Western Europe and East Asia. However, the most rapid growth is occurring in emerging economies, particularly in Southeast Asia and Eastern Europe, where manufacturing sectors are expanding while simultaneously facing increasing pressure to adopt sustainable practices.

Market research indicates a significant price sensitivity threshold, with industrial customers willing to pay a premium of up to 20% for VAM systems that demonstrate energy efficiency improvements of 30% or greater compared to conventional alternatives. This price-performance relationship creates a clear market incentive for continued innovation in energy-efficient VAM technologies.

The service and maintenance sector surrounding energy-efficient VAM systems is also experiencing substantial growth, with the aftermarket expected to reach 35% of the total market value within the next three years. This includes specialized training, software updates, and component replacements optimized for maintaining peak energy efficiency throughout the system lifecycle.

Consumer demand patterns show increasing preference for manufacturers utilizing energy-efficient production methods, with 65% of end-users in consumer goods markets expressing willingness to select products specifically manufactured using sustainable processes, creating additional market pull for energy-efficient VAM adoption throughout supply chains.

Current State and Challenges in VAM Energy Consumption

Volumetric Additive Manufacturing (VAM) processes currently face significant energy efficiency challenges despite their revolutionary potential in rapid 3D printing. The energy consumption in VAM systems primarily stems from high-powered light sources, typically utilizing lasers or projectors that operate at intensities between 1-10 W/cm². These systems often exhibit low energy conversion efficiency, with only 10-30% of input energy effectively contributing to the photopolymerization process, while the remainder dissipates as heat or unused light.

Recent assessments of VAM technologies reveal that energy utilization varies considerably across different implementation approaches. Tomographic VAM systems, which employ rotating resin vats, consume substantial energy in mechanical components and cooling systems. Conversely, holographic approaches eliminate moving parts but require more sophisticated optical arrangements with higher-powered light sources, resulting in different but equally challenging energy profiles.

A critical limitation in current VAM systems is the mismatch between light delivery and photopolymer absorption characteristics. Most commercial photopolymers exhibit absorption peaks that do not perfectly align with the emission spectra of standard light sources, necessitating higher power inputs to achieve adequate curing. This spectral inefficiency represents a significant opportunity for improvement through better-matched material-light source combinations.

Thermal management presents another major challenge, as excess heat generation can compromise dimensional accuracy and material properties. Current cooling solutions add considerable energy overhead, with some systems dedicating up to 40% of their total energy consumption to temperature regulation. This creates a compound inefficiency where energy is wasted twice—first in generating unused light and then in removing its thermal byproducts.

The scale-up of VAM processes introduces additional energy concerns. As build volumes increase, maintaining uniform light intensity throughout the resin becomes increasingly difficult, often requiring disproportionately higher energy inputs. Industry data suggests that doubling the build volume can result in a 2.5-3x increase in energy consumption due to these non-linear scaling effects.

Comparative analyses with traditional layer-by-layer additive manufacturing reveal that while VAM offers significant time advantages, its energy efficiency currently lags behind more established technologies. VAM systems typically consume 1.5-2 times more energy per unit volume of produced part compared to SLA or DLP systems, presenting a substantial barrier to widespread industrial adoption despite their speed benefits.

Recent assessments of VAM technologies reveal that energy utilization varies considerably across different implementation approaches. Tomographic VAM systems, which employ rotating resin vats, consume substantial energy in mechanical components and cooling systems. Conversely, holographic approaches eliminate moving parts but require more sophisticated optical arrangements with higher-powered light sources, resulting in different but equally challenging energy profiles.

A critical limitation in current VAM systems is the mismatch between light delivery and photopolymer absorption characteristics. Most commercial photopolymers exhibit absorption peaks that do not perfectly align with the emission spectra of standard light sources, necessitating higher power inputs to achieve adequate curing. This spectral inefficiency represents a significant opportunity for improvement through better-matched material-light source combinations.

Thermal management presents another major challenge, as excess heat generation can compromise dimensional accuracy and material properties. Current cooling solutions add considerable energy overhead, with some systems dedicating up to 40% of their total energy consumption to temperature regulation. This creates a compound inefficiency where energy is wasted twice—first in generating unused light and then in removing its thermal byproducts.

The scale-up of VAM processes introduces additional energy concerns. As build volumes increase, maintaining uniform light intensity throughout the resin becomes increasingly difficult, often requiring disproportionately higher energy inputs. Industry data suggests that doubling the build volume can result in a 2.5-3x increase in energy consumption due to these non-linear scaling effects.

Comparative analyses with traditional layer-by-layer additive manufacturing reveal that while VAM offers significant time advantages, its energy efficiency currently lags behind more established technologies. VAM systems typically consume 1.5-2 times more energy per unit volume of produced part compared to SLA or DLP systems, presenting a substantial barrier to widespread industrial adoption despite their speed benefits.

Current Energy Optimization Solutions for VAM

01 Energy-efficient light-based volumetric manufacturing

Light-based volumetric additive manufacturing techniques utilize photopolymerization processes that can be optimized for energy efficiency. These methods use projected light patterns to cure entire volumes of photosensitive resin simultaneously, significantly reducing the energy consumption compared to layer-by-layer approaches. Advanced light delivery systems and photopolymer formulations enable faster curing times with lower energy input, making the overall process more sustainable while maintaining high resolution and quality.- Energy-efficient light-based volumetric additive manufacturing: Light-based volumetric additive manufacturing techniques that optimize energy consumption through improved photopolymerization processes. These methods use specific light patterns and energy-efficient light sources to cure entire volumes of material simultaneously, reducing the energy required compared to layer-by-layer approaches. The techniques include optimized light delivery systems and photosensitive resin formulations that respond to lower energy inputs while maintaining high resolution and structural integrity.

- Thermal management systems for energy efficiency in volumetric manufacturing: Advanced thermal management systems designed specifically for volumetric additive manufacturing processes that minimize energy waste. These systems incorporate intelligent heat distribution, recovery mechanisms, and thermal monitoring to maintain optimal processing temperatures while reducing overall energy consumption. Innovations include closed-loop thermal control systems, insulation technologies, and heat recycling methods that capture and reuse thermal energy that would otherwise be lost during the manufacturing process.

- Material formulations for energy-efficient volumetric printing: Specialized material formulations developed to reduce energy requirements in volumetric additive manufacturing. These materials include photopolymers that cure at lower energy thresholds, thermally responsive composites that require less heat input, and hybrid materials designed to maximize energy transfer efficiency. The formulations enable faster processing times and lower power consumption while maintaining or improving the mechanical properties and resolution of printed objects.

- Process optimization algorithms for energy-efficient volumetric manufacturing: Computational methods and algorithms that optimize volumetric additive manufacturing processes for maximum energy efficiency. These include AI-driven process control systems, simulation tools that predict and minimize energy consumption, and adaptive manufacturing sequences that reduce idle time and energy waste. The algorithms dynamically adjust manufacturing parameters based on real-time feedback to maintain quality while minimizing the energy footprint of the production process.

- Hybrid energy systems for sustainable volumetric manufacturing: Integrated energy systems that combine multiple power sources to improve the overall efficiency of volumetric additive manufacturing processes. These systems incorporate renewable energy inputs, energy storage solutions, and smart grid technologies to optimize power usage and reduce reliance on conventional energy sources. The hybrid approach enables load balancing, peak shaving, and utilization of excess energy during off-peak periods, resulting in more sustainable and cost-effective manufacturing operations.

02 Thermal management systems for energy optimization

Thermal management innovations in volumetric additive manufacturing focus on reducing energy waste through efficient heat distribution and recovery systems. These technologies include advanced cooling mechanisms, thermal insulation designs, and heat recycling components that minimize energy loss during the manufacturing process. By precisely controlling temperature gradients and thermal cycles, these systems not only improve energy efficiency but also enhance print quality and material properties while reducing production time and operational costs.Expand Specific Solutions03 Material formulations for low-energy curing

Specialized material formulations are developed to require less energy for curing or solidification in volumetric manufacturing processes. These materials incorporate advanced photoinitiators, catalysts, and additives that respond to lower energy inputs while maintaining desired mechanical properties. Some formulations enable multi-wavelength curing that maximizes energy utilization across the electromagnetic spectrum. These innovations reduce the overall energy footprint of volumetric manufacturing while expanding the range of applicable materials and improving final product characteristics.Expand Specific Solutions04 Process optimization algorithms for energy efficiency

Computational algorithms and software solutions optimize volumetric manufacturing processes for maximum energy efficiency. These systems analyze build parameters, material properties, and energy consumption patterns to determine optimal manufacturing strategies. Machine learning approaches continuously refine process parameters based on performance data, reducing energy waste while maintaining quality standards. Advanced simulation tools predict energy requirements and identify opportunities for efficiency improvements before physical production begins, significantly reducing the energy footprint of volumetric manufacturing operations.Expand Specific Solutions05 Hybrid manufacturing approaches for energy conservation

Hybrid volumetric manufacturing systems combine multiple fabrication technologies to optimize energy usage throughout the production process. These approaches strategically integrate various additive techniques with conventional manufacturing methods, applying each where it offers the greatest energy efficiency. Some systems incorporate energy recovery mechanisms that capture and repurpose waste energy from one process stage to power another. By selectively employing the most efficient method for each aspect of production, these hybrid approaches minimize overall energy consumption while maintaining or improving manufacturing capabilities.Expand Specific Solutions

Key Industry Players in Energy-Efficient VAM

The energy efficiency landscape in Volumetric Additive Manufacturing (VAM) is currently in a growth phase, with the market expanding as industries recognize its potential for sustainable manufacturing. Key players include established industrial giants like General Electric, Siemens Energy, and RTX Corp, who leverage their extensive R&D capabilities to optimize energy consumption in large-scale applications. Specialized additive manufacturing companies such as EOS GmbH, VulcanForms, and Seurat Technologies are driving innovation through proprietary energy-efficient processes. Academic and research institutions, including Lawrence Livermore National Laboratory, Fraunhofer-Gesellschaft, and Beijing University of Technology, are advancing fundamental research in energy-efficient VAM technologies, creating a competitive ecosystem balancing commercial applications with scientific advancement.

General Electric Company

Technical Solution: General Electric has developed a comprehensive approach to energy efficiency in volumetric additive manufacturing through their Direct Metal Laser Melting (DMLM) technology. Their system incorporates multi-laser configurations with optimized scan patterns that reduce energy consumption by up to 40% compared to conventional single-laser systems. GE's proprietary thermal management systems monitor and regulate energy distribution throughout the build chamber, minimizing heat loss and improving overall process efficiency. The company has implemented predictive modeling software that simulates energy requirements before production, allowing for parameter optimization that reduces power consumption while maintaining part quality. Additionally, GE has pioneered recycling systems that capture and reuse up to 95% of unused metal powder, significantly reducing the embodied energy in the manufacturing process. Their latest systems incorporate machine learning algorithms that continuously adjust laser power and scanning strategies in real-time based on thermal feedback, further optimizing energy usage throughout the build process.

Strengths: Comprehensive integration of hardware and software solutions for energy management; extensive experience in industrial-scale implementation; strong capabilities in thermal modeling and simulation. Weaknesses: Higher initial capital investment required; systems primarily optimized for aerospace and medical applications rather than broader manufacturing sectors.

Siemens Energy AG

Technical Solution: Siemens Energy has developed an integrated energy management system for volumetric additive manufacturing that focuses on holistic efficiency across the entire production ecosystem. Their approach combines advanced hardware modifications with intelligent process control software. The company's AM Energy Optimization Suite incorporates predictive thermal modeling that simulates energy requirements before production begins, allowing for parameter optimization that can reduce overall energy consumption by up to 35%. Siemens has implemented variable power laser systems that dynamically adjust energy input based on material properties and geometry requirements, preventing overprocessing and energy waste. Their build chamber design incorporates advanced insulation materials and zoned heating systems that maintain precise thermal conditions while minimizing energy loss. Additionally, Siemens has developed energy recovery systems that capture waste heat from the manufacturing process and repurpose it for material preheating or facility heating needs. The company's digital twin technology creates virtual models of the entire manufacturing process, enabling engineers to identify energy inefficiencies and optimize parameters before physical production begins.

Strengths: Comprehensive integration with broader factory energy management systems; advanced simulation capabilities for process optimization; strong focus on industrial-scale implementation. Weaknesses: Solutions often require significant customization for specific manufacturing environments; higher implementation complexity compared to standalone systems.

Core Energy Efficiency Technologies and Patents

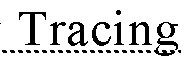

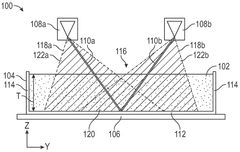

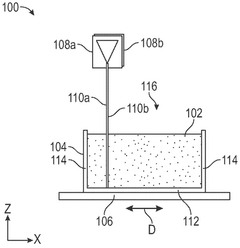

Scanning energy systems for additive manufacturing and associated methods

PatentWO2025050023A1

Innovation

- The use of scanning energy systems that employ multiple energy sources to selectively solidify curable materials within a reservoir, allowing for the formation of additively manufactured objects through the combination of energy dosages from multiple beams, thereby overcoming the limitations of conventional methods.

Systems and methods for volumetric powder bed fusion

PatentInactiveUS20170326816A1

Innovation

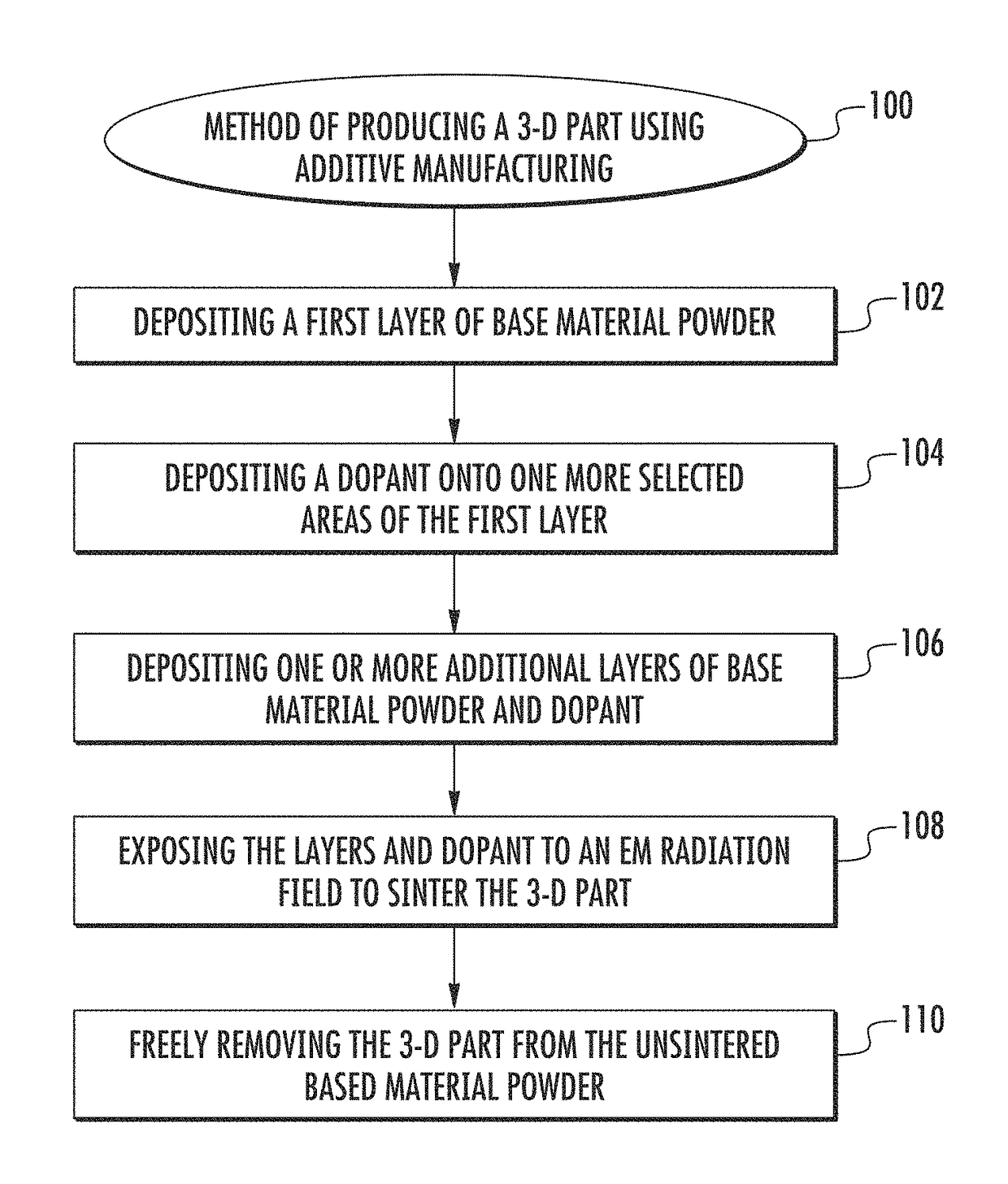

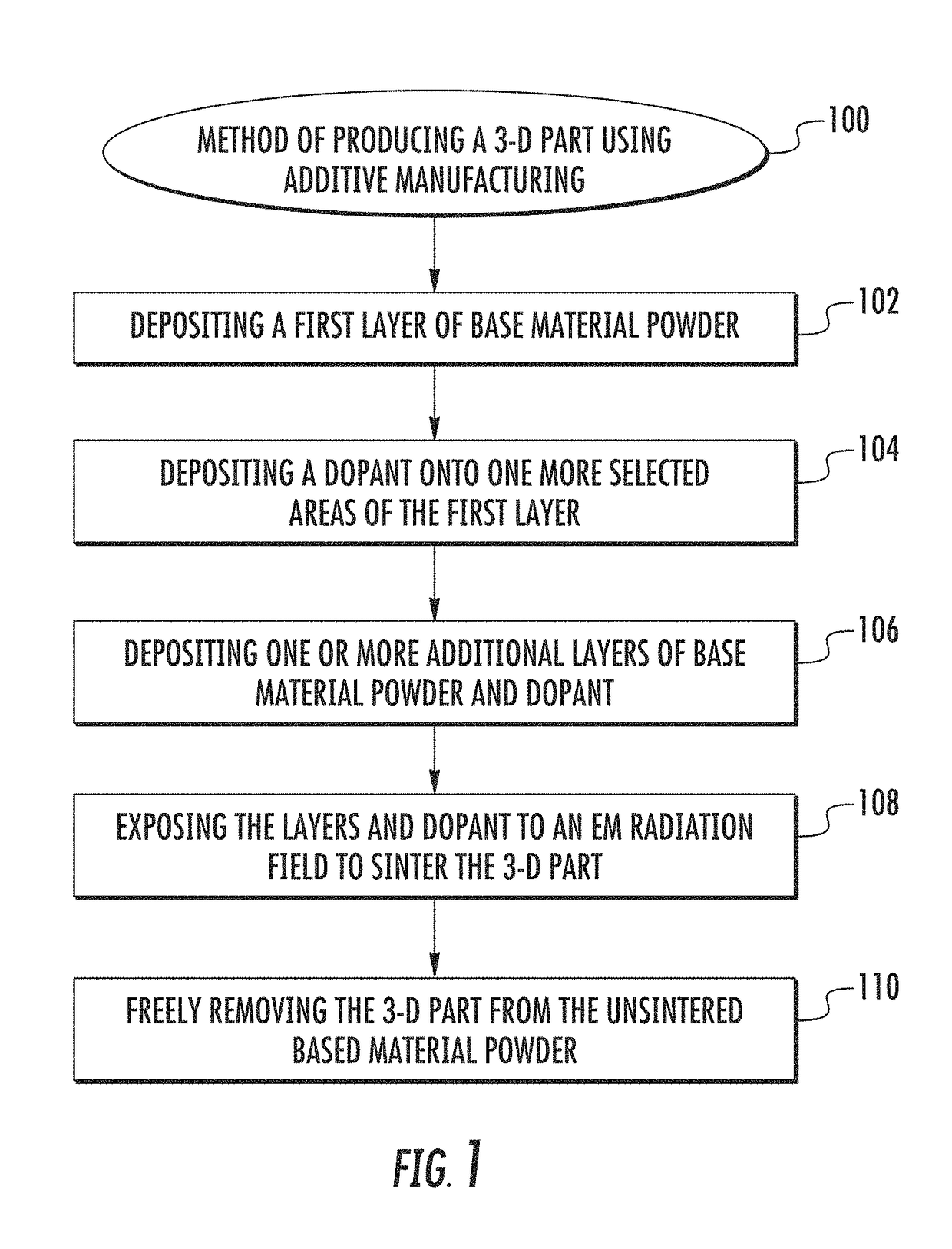

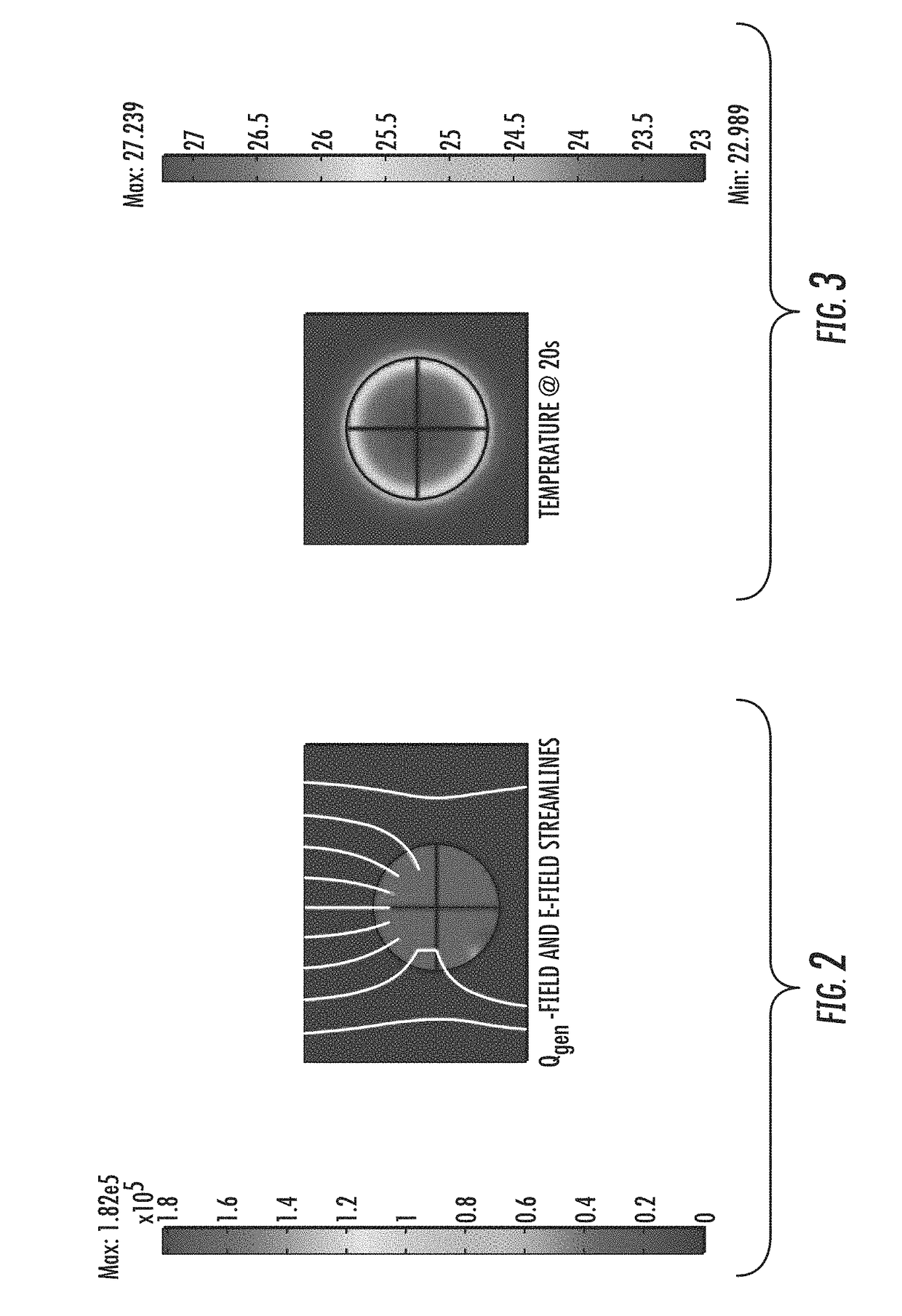

- The method involves depositing a dopant onto selected areas of a transparent base material powder and exposing it to an electromagnetic radiation field within the microwave or radio frequency spectrum, allowing for volumetric sintering of the entire 3D volume simultaneously, reducing cycle times and enabling the use of a broader range of materials.

Material Sustainability in Energy-Efficient VAM

Material sustainability represents a critical dimension in the evolution of energy-efficient Volumetric Additive Manufacturing (VAM) processes. The photopolymer resins traditionally used in VAM systems present significant environmental challenges, including their petroleum-based origins, limited biodegradability, and potential toxicity. Recent advancements have focused on developing bio-based alternatives derived from renewable resources such as cellulose, lignin, and vegetable oils, which demonstrate comparable mechanical properties while reducing environmental impact.

Energy consumption during material production constitutes approximately 30-40% of the total energy footprint in VAM processes. Research indicates that bio-based resins require 25-35% less energy to produce compared to conventional petroleum-based alternatives, representing a substantial opportunity for improving overall system efficiency. Additionally, these sustainable materials often cure at lower energy thresholds, further reducing the energy demands during the manufacturing process itself.

Material recyclability has emerged as another crucial aspect of sustainability in VAM. Current research focuses on developing photopolymer systems with reversible crosslinking mechanisms, allowing for the breakdown and reuse of printed materials at end-of-life. These developments could potentially create closed-loop material systems that significantly reduce waste and resource consumption, addressing one of the primary environmental concerns associated with additive manufacturing technologies.

The thermal properties of photopolymers also play a vital role in energy efficiency. Materials with optimized thermal conductivity can reduce cooling requirements during processing, while those with lower curing energy thresholds minimize the power needed for polymerization. Recent innovations in this area include the incorporation of thermally responsive nanoparticles that enhance energy transfer within the resin, potentially reducing curing times by up to 40%.

Material formulation advancements have also focused on reducing volatile organic compound (VOC) emissions during processing. Low-VOC and solvent-free formulations not only improve workplace safety but also decrease the energy required for ventilation and air treatment systems. Studies indicate that these environmentally friendly formulations can reduce associated energy costs by 15-20% compared to conventional alternatives.

The integration of lifecycle assessment (LCA) methodologies into material development processes has become increasingly important. Comprehensive LCA studies reveal that material selection can influence energy consumption throughout the entire product lifecycle, from manufacturing to disposal. This holistic approach enables manufacturers to make informed decisions that optimize both immediate processing efficiency and long-term environmental impact.

Energy consumption during material production constitutes approximately 30-40% of the total energy footprint in VAM processes. Research indicates that bio-based resins require 25-35% less energy to produce compared to conventional petroleum-based alternatives, representing a substantial opportunity for improving overall system efficiency. Additionally, these sustainable materials often cure at lower energy thresholds, further reducing the energy demands during the manufacturing process itself.

Material recyclability has emerged as another crucial aspect of sustainability in VAM. Current research focuses on developing photopolymer systems with reversible crosslinking mechanisms, allowing for the breakdown and reuse of printed materials at end-of-life. These developments could potentially create closed-loop material systems that significantly reduce waste and resource consumption, addressing one of the primary environmental concerns associated with additive manufacturing technologies.

The thermal properties of photopolymers also play a vital role in energy efficiency. Materials with optimized thermal conductivity can reduce cooling requirements during processing, while those with lower curing energy thresholds minimize the power needed for polymerization. Recent innovations in this area include the incorporation of thermally responsive nanoparticles that enhance energy transfer within the resin, potentially reducing curing times by up to 40%.

Material formulation advancements have also focused on reducing volatile organic compound (VOC) emissions during processing. Low-VOC and solvent-free formulations not only improve workplace safety but also decrease the energy required for ventilation and air treatment systems. Studies indicate that these environmentally friendly formulations can reduce associated energy costs by 15-20% compared to conventional alternatives.

The integration of lifecycle assessment (LCA) methodologies into material development processes has become increasingly important. Comprehensive LCA studies reveal that material selection can influence energy consumption throughout the entire product lifecycle, from manufacturing to disposal. This holistic approach enables manufacturers to make informed decisions that optimize both immediate processing efficiency and long-term environmental impact.

Thermal Management Strategies for VAM Systems

Thermal management represents a critical challenge in Volumetric Additive Manufacturing (VAM) systems, directly impacting both energy efficiency and final product quality. Conventional VAM processes generate significant heat during photopolymerization or material solidification, requiring sophisticated thermal control strategies to maintain optimal operating conditions while minimizing energy consumption.

The primary thermal management approaches in VAM systems can be categorized into active and passive strategies. Active cooling systems typically employ liquid circulation mechanisms that extract excess heat from critical components. Advanced VAM setups utilize microfluidic cooling channels integrated directly into build platforms, allowing for precise temperature regulation within ±0.5°C even during high-intensity manufacturing operations. These systems can reduce energy consumption by up to 30% compared to conventional air-cooling methods.

Passive thermal management techniques leverage materials with high thermal conductivity and specialized geometric designs to facilitate natural heat dissipation. Recent innovations include phase-change materials (PCMs) incorporated into VAM system components, which absorb excess thermal energy during peak operation and release it gradually during idle periods. This approach has demonstrated energy savings of 15-20% in laboratory settings while maintaining consistent build temperatures.

Computational fluid dynamics (CFD) modeling has emerged as an essential tool for optimizing thermal management in VAM systems. These simulations enable manufacturers to predict heat distribution patterns and identify potential hotspots before physical implementation. Studies indicate that CFD-optimized thermal management configurations can reduce energy requirements by 10-25% while simultaneously improving dimensional accuracy of printed components.

Hybrid approaches combining multiple thermal management strategies show particular promise. For instance, systems integrating selective active cooling with passive heat sinks have demonstrated superior energy efficiency in high-throughput industrial VAM applications. These hybrid solutions typically incorporate smart control systems that dynamically adjust cooling intensity based on real-time temperature monitoring, further optimizing energy usage.

Emerging research focuses on energy recovery systems that capture and repurpose waste heat from VAM processes. Thermoelectric generators integrated into cooling systems can convert thermal gradients into usable electricity, potentially reclaiming 5-8% of energy that would otherwise be lost. While still in experimental stages, these technologies represent a significant frontier in improving the overall energy efficiency of volumetric manufacturing operations.

The primary thermal management approaches in VAM systems can be categorized into active and passive strategies. Active cooling systems typically employ liquid circulation mechanisms that extract excess heat from critical components. Advanced VAM setups utilize microfluidic cooling channels integrated directly into build platforms, allowing for precise temperature regulation within ±0.5°C even during high-intensity manufacturing operations. These systems can reduce energy consumption by up to 30% compared to conventional air-cooling methods.

Passive thermal management techniques leverage materials with high thermal conductivity and specialized geometric designs to facilitate natural heat dissipation. Recent innovations include phase-change materials (PCMs) incorporated into VAM system components, which absorb excess thermal energy during peak operation and release it gradually during idle periods. This approach has demonstrated energy savings of 15-20% in laboratory settings while maintaining consistent build temperatures.

Computational fluid dynamics (CFD) modeling has emerged as an essential tool for optimizing thermal management in VAM systems. These simulations enable manufacturers to predict heat distribution patterns and identify potential hotspots before physical implementation. Studies indicate that CFD-optimized thermal management configurations can reduce energy requirements by 10-25% while simultaneously improving dimensional accuracy of printed components.

Hybrid approaches combining multiple thermal management strategies show particular promise. For instance, systems integrating selective active cooling with passive heat sinks have demonstrated superior energy efficiency in high-throughput industrial VAM applications. These hybrid solutions typically incorporate smart control systems that dynamically adjust cooling intensity based on real-time temperature monitoring, further optimizing energy usage.

Emerging research focuses on energy recovery systems that capture and repurpose waste heat from VAM processes. Thermoelectric generators integrated into cooling systems can convert thermal gradients into usable electricity, potentially reclaiming 5-8% of energy that would otherwise be lost. While still in experimental stages, these technologies represent a significant frontier in improving the overall energy efficiency of volumetric manufacturing operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!