Development Trajectories of Cellophane in Communication Devices

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cellophane Tech Evolution

Cellophane technology in communication devices has undergone significant evolution since its inception. Initially used as a protective layer for electronic components, cellophane has transformed into a multifunctional material with diverse applications in modern communication devices.

The early stages of cellophane's integration into communication devices focused primarily on its moisture-resistant properties. This characteristic made it an ideal choice for protecting sensitive electronic components from environmental factors. As technology progressed, researchers began to explore cellophane's potential beyond mere protection.

A pivotal moment in cellophane's evolution came with the development of conductive cellophane. This breakthrough allowed for the creation of flexible, transparent electrodes, opening up new possibilities in device design and functionality. The ability to conduct electricity while maintaining transparency made cellophane an attractive option for touchscreens and display technologies.

The miniaturization trend in communication devices further propelled cellophane's technological advancement. Engineers and material scientists worked on enhancing cellophane's mechanical properties, making it more durable and flexible. This led to the development of ultra-thin cellophane films capable of withstanding repeated bending and folding, a crucial feature for foldable smartphones and wearable devices.

Another significant milestone was the integration of cellophane with other advanced materials. Composite structures combining cellophane with graphene or carbon nanotubes emerged, offering enhanced conductivity and strength. These hybrid materials found applications in antennas, sensors, and energy storage components within communication devices.

The pursuit of sustainable technology also influenced cellophane's evolution. Biodegradable variants of cellophane were developed, addressing environmental concerns associated with electronic waste. These eco-friendly versions maintained the desired properties for use in communication devices while offering improved end-of-life disposal options.

Recent advancements have focused on imbuing cellophane with smart functionalities. Self-healing cellophane films capable of repairing minor damages autonomously have been developed, potentially increasing the lifespan of device components. Additionally, researchers have explored cellophane's potential in energy harvesting, creating films that can generate small amounts of electricity from ambient light or mechanical stress.

The trajectory of cellophane in communication devices continues to evolve, with ongoing research exploring its potential in emerging technologies such as 5G and beyond. As devices become more compact, flexible, and multifunctional, cellophane's role is expected to expand further, potentially revolutionizing the way we interact with and design communication devices in the future.

The early stages of cellophane's integration into communication devices focused primarily on its moisture-resistant properties. This characteristic made it an ideal choice for protecting sensitive electronic components from environmental factors. As technology progressed, researchers began to explore cellophane's potential beyond mere protection.

A pivotal moment in cellophane's evolution came with the development of conductive cellophane. This breakthrough allowed for the creation of flexible, transparent electrodes, opening up new possibilities in device design and functionality. The ability to conduct electricity while maintaining transparency made cellophane an attractive option for touchscreens and display technologies.

The miniaturization trend in communication devices further propelled cellophane's technological advancement. Engineers and material scientists worked on enhancing cellophane's mechanical properties, making it more durable and flexible. This led to the development of ultra-thin cellophane films capable of withstanding repeated bending and folding, a crucial feature for foldable smartphones and wearable devices.

Another significant milestone was the integration of cellophane with other advanced materials. Composite structures combining cellophane with graphene or carbon nanotubes emerged, offering enhanced conductivity and strength. These hybrid materials found applications in antennas, sensors, and energy storage components within communication devices.

The pursuit of sustainable technology also influenced cellophane's evolution. Biodegradable variants of cellophane were developed, addressing environmental concerns associated with electronic waste. These eco-friendly versions maintained the desired properties for use in communication devices while offering improved end-of-life disposal options.

Recent advancements have focused on imbuing cellophane with smart functionalities. Self-healing cellophane films capable of repairing minor damages autonomously have been developed, potentially increasing the lifespan of device components. Additionally, researchers have explored cellophane's potential in energy harvesting, creating films that can generate small amounts of electricity from ambient light or mechanical stress.

The trajectory of cellophane in communication devices continues to evolve, with ongoing research exploring its potential in emerging technologies such as 5G and beyond. As devices become more compact, flexible, and multifunctional, cellophane's role is expected to expand further, potentially revolutionizing the way we interact with and design communication devices in the future.

Market Demand Analysis

The market demand for cellophane in communication devices has been evolving rapidly, driven by the increasing need for flexible and transparent materials in modern electronics. As smartphones, tablets, and wearable devices become more prevalent, manufacturers are seeking innovative solutions to enhance user experience and device functionality.

Cellophane, with its unique properties of transparency, flexibility, and moisture resistance, has found growing applications in various components of communication devices. The touchscreen interface market, in particular, has shown significant interest in cellophane-based materials. These materials offer the potential for creating more responsive and durable touch surfaces, addressing the limitations of current technologies.

The global market for flexible display technologies, where cellophane plays a crucial role, is projected to experience substantial growth. This expansion is fueled by the rising demand for foldable smartphones and rollable displays, which require materials that can withstand repeated bending and folding without compromising performance or clarity.

In the realm of wearable technology, cellophane-derived materials are gaining traction for their ability to create lightweight, comfortable, and sweat-resistant interfaces. This trend aligns with the increasing consumer preference for health and fitness tracking devices that seamlessly integrate into daily life.

The automotive industry's shift towards smart, connected vehicles has also contributed to the demand for cellophane in communication devices. Heads-up displays and interactive dashboards benefit from the material's optical clarity and durability, enhancing both functionality and aesthetics in modern vehicle interiors.

Environmental concerns and sustainability initiatives are further driving the market demand for cellophane-based solutions in communication devices. As consumers and regulators push for more eco-friendly products, manufacturers are exploring biodegradable and recyclable alternatives to traditional plastics, positioning cellophane as a promising candidate.

The telecommunications infrastructure sector presents another avenue for cellophane application, particularly in the development of next-generation antennas and signal transmission components. The material's dielectric properties and potential for miniaturization make it attractive for 5G and future 6G network deployments.

As the Internet of Things (IoT) ecosystem expands, the demand for flexible, transparent, and durable materials in sensor technologies is increasing. Cellophane-based solutions are being explored for their potential to create unobtrusive, yet highly functional sensors that can be integrated into various environments and objects.

Cellophane, with its unique properties of transparency, flexibility, and moisture resistance, has found growing applications in various components of communication devices. The touchscreen interface market, in particular, has shown significant interest in cellophane-based materials. These materials offer the potential for creating more responsive and durable touch surfaces, addressing the limitations of current technologies.

The global market for flexible display technologies, where cellophane plays a crucial role, is projected to experience substantial growth. This expansion is fueled by the rising demand for foldable smartphones and rollable displays, which require materials that can withstand repeated bending and folding without compromising performance or clarity.

In the realm of wearable technology, cellophane-derived materials are gaining traction for their ability to create lightweight, comfortable, and sweat-resistant interfaces. This trend aligns with the increasing consumer preference for health and fitness tracking devices that seamlessly integrate into daily life.

The automotive industry's shift towards smart, connected vehicles has also contributed to the demand for cellophane in communication devices. Heads-up displays and interactive dashboards benefit from the material's optical clarity and durability, enhancing both functionality and aesthetics in modern vehicle interiors.

Environmental concerns and sustainability initiatives are further driving the market demand for cellophane-based solutions in communication devices. As consumers and regulators push for more eco-friendly products, manufacturers are exploring biodegradable and recyclable alternatives to traditional plastics, positioning cellophane as a promising candidate.

The telecommunications infrastructure sector presents another avenue for cellophane application, particularly in the development of next-generation antennas and signal transmission components. The material's dielectric properties and potential for miniaturization make it attractive for 5G and future 6G network deployments.

As the Internet of Things (IoT) ecosystem expands, the demand for flexible, transparent, and durable materials in sensor technologies is increasing. Cellophane-based solutions are being explored for their potential to create unobtrusive, yet highly functional sensors that can be integrated into various environments and objects.

Current Challenges

The integration of cellophane in communication devices faces several significant challenges that hinder its widespread adoption and full potential realization. One of the primary obstacles is the material's limited durability and susceptibility to environmental factors. While cellophane offers excellent transparency and flexibility, its vulnerability to moisture and temperature fluctuations can compromise its long-term performance in electronic devices.

Another critical challenge lies in achieving consistent and reliable electrical conductivity. Although cellophane can be modified to conduct electricity, maintaining uniform conductivity across large surface areas remains problematic. This inconsistency can lead to signal degradation and interference, particularly in high-frequency applications crucial for modern communication technologies.

The manufacturing process for cellophane-based components in communication devices also presents considerable hurdles. Current production methods struggle to meet the stringent quality control standards required for electronic components, especially in terms of thickness uniformity and surface smoothness. These manufacturing limitations can result in performance variations and increased production costs, making it less competitive compared to established materials.

Compatibility with existing electronic manufacturing processes and integration into current device architectures pose additional challenges. Many electronic components and assembly techniques are optimized for traditional materials, necessitating significant retooling and process adaptation to incorporate cellophane effectively. This compatibility issue extends to the development of suitable adhesives and bonding methods that can securely attach cellophane components without compromising their unique properties.

The scalability of cellophane production for high-volume electronic applications is another area of concern. Current cellophane manufacturing processes are primarily optimized for packaging applications, and scaling up production to meet the demands of the electronics industry while maintaining consistent quality and properties remains a significant challenge.

Environmental stability and long-term reliability of cellophane in electronic devices are also critical issues that need addressing. The material's biodegradability, while advantageous from an environmental perspective, raises questions about its longevity in electronic applications. Ensuring that cellophane-based components can withstand the operational lifespan of communication devices without degradation or performance loss is crucial for its adoption.

Lastly, the regulatory landscape and industry standards present challenges for the integration of cellophane in communication devices. Existing regulations and certifications may not adequately address the unique properties and potential risks associated with cellophane-based electronic components, necessitating the development of new standards and testing protocols.

Another critical challenge lies in achieving consistent and reliable electrical conductivity. Although cellophane can be modified to conduct electricity, maintaining uniform conductivity across large surface areas remains problematic. This inconsistency can lead to signal degradation and interference, particularly in high-frequency applications crucial for modern communication technologies.

The manufacturing process for cellophane-based components in communication devices also presents considerable hurdles. Current production methods struggle to meet the stringent quality control standards required for electronic components, especially in terms of thickness uniformity and surface smoothness. These manufacturing limitations can result in performance variations and increased production costs, making it less competitive compared to established materials.

Compatibility with existing electronic manufacturing processes and integration into current device architectures pose additional challenges. Many electronic components and assembly techniques are optimized for traditional materials, necessitating significant retooling and process adaptation to incorporate cellophane effectively. This compatibility issue extends to the development of suitable adhesives and bonding methods that can securely attach cellophane components without compromising their unique properties.

The scalability of cellophane production for high-volume electronic applications is another area of concern. Current cellophane manufacturing processes are primarily optimized for packaging applications, and scaling up production to meet the demands of the electronics industry while maintaining consistent quality and properties remains a significant challenge.

Environmental stability and long-term reliability of cellophane in electronic devices are also critical issues that need addressing. The material's biodegradability, while advantageous from an environmental perspective, raises questions about its longevity in electronic applications. Ensuring that cellophane-based components can withstand the operational lifespan of communication devices without degradation or performance loss is crucial for its adoption.

Lastly, the regulatory landscape and industry standards present challenges for the integration of cellophane in communication devices. Existing regulations and certifications may not adequately address the unique properties and potential risks associated with cellophane-based electronic components, necessitating the development of new standards and testing protocols.

Existing Applications

01 Cellophane production methods

Various methods for producing cellophane are described, including improvements in the manufacturing process to enhance the quality and properties of the final product. These methods may involve specific chemical treatments, extrusion techniques, or modifications to the cellulose raw material.- Cellophane in packaging applications: Cellophane is widely used in packaging applications due to its transparency, flexibility, and barrier properties. It is particularly useful for food packaging, where it can help preserve freshness and extend shelf life. Cellophane can be used alone or in combination with other materials to create various packaging solutions.

- Cellophane production and processing: The production and processing of cellophane involve various techniques to improve its properties and performance. This includes methods for enhancing its strength, flexibility, and barrier properties. Innovations in cellophane production focus on improving manufacturing efficiency and developing new formulations to meet specific application requirements.

- Cellophane in medical and pharmaceutical applications: Cellophane finds applications in the medical and pharmaceutical industries due to its biocompatibility and barrier properties. It can be used in wound dressings, drug delivery systems, and as a protective barrier in various medical devices. Research in this area focuses on enhancing the material's properties for specific medical applications.

- Cellophane-based composites and laminates: Cellophane can be combined with other materials to create composites and laminates with enhanced properties. These combinations can improve strength, barrier properties, and functionality for various applications. Research in this area focuses on developing new composite materials and improving the bonding between cellophane and other materials.

- Cellophane in electronic and energy applications: Cellophane is being explored for use in electronic and energy-related applications due to its unique properties. This includes its potential use in flexible electronics, energy storage devices, and as a substrate for various electronic components. Research in this area focuses on modifying cellophane to enhance its electrical and thermal properties for these applications.

02 Cellophane packaging applications

Cellophane is widely used in packaging applications due to its transparency, flexibility, and barrier properties. Innovations in this area include specialized cellophane films for food packaging, moisture-resistant cellophane for extended shelf life, and biodegradable cellophane alternatives for eco-friendly packaging solutions.Expand Specific Solutions03 Cellophane-based composite materials

Research and development efforts focus on creating composite materials that incorporate cellophane to enhance specific properties. These composites may combine cellophane with other materials to improve strength, flexibility, or functionality for various industrial and consumer applications.Expand Specific Solutions04 Cellophane modification techniques

Various techniques for modifying cellophane are explored to enhance its properties or add new functionalities. These modifications may include surface treatments, chemical alterations, or the incorporation of additives to improve characteristics such as moisture resistance, heat sealability, or antimicrobial properties.Expand Specific Solutions05 Cellophane recycling and environmental considerations

As environmental concerns grow, research is focused on developing methods for recycling cellophane and creating more sustainable alternatives. This includes studies on biodegradability, compostability, and the development of cellophane-like materials from renewable resources to reduce environmental impact.Expand Specific Solutions

Key Industry Players

The development of cellophane in communication devices is in a nascent stage, with the market still emerging and relatively small. The technology's maturity is low, as evidenced by the limited number of major players actively pursuing this area. Companies like Sharp Corp. and Corning, Inc. are likely at the forefront, leveraging their expertise in display technologies and materials science. Other potential contributors include Samsung Electronics and Apple, given their significant R&D capabilities in mobile device innovation. The competitive landscape is characterized by early-stage research and development, with few commercial applications currently available. As the technology progresses, we may see increased interest from both established electronics manufacturers and innovative startups seeking to capitalize on this novel application of cellophane in communication devices.

Corning, Inc.

Technical Solution: Corning has developed advanced cellophane-like materials for communication devices, focusing on ultra-thin, flexible glass substrates. Their Willow Glass technology, with a thickness of just 100 microns, offers a bendable and durable alternative to traditional cellophane[1]. This glass can be rolled up like a sheet of plastic while maintaining excellent optical and thermal properties. Corning has also integrated this technology with their Gorilla Glass, creating a hybrid material that combines flexibility with enhanced scratch and impact resistance[2]. The company has further explored the use of these materials in flexible displays and touch sensors for next-generation smartphones and wearable devices[3].

Strengths: Superior optical clarity, thermal stability, and chemical resistance compared to traditional cellophane. Weaknesses: Higher production costs and more complex manufacturing processes than conventional plastic films.

Apple, Inc.

Technical Solution: Apple has been researching cellophane-like materials for communication devices, focusing on flexible and foldable display technologies. While they haven't released a foldable device yet, patents suggest they're developing ultra-thin glass and polymer films for potential use in future iPhones and iPads[7]. Apple's approach includes exploring multi-layer structures that combine the flexibility of polymers with the durability of glass, aiming to create displays that can bend without breaking. They've also investigated self-healing display technologies, which could address the wear and tear issues associated with flexible screens[8]. Additionally, Apple has been working on flexible circuit boards and batteries to complement these display innovations[9].

Strengths: Strong focus on user experience and integration with existing ecosystem. Weaknesses: Later entry into the foldable device market compared to competitors.

Core Innovations

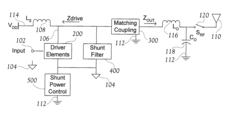

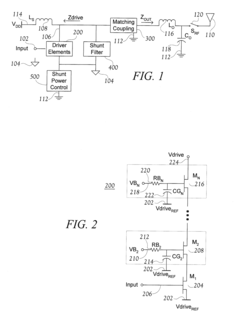

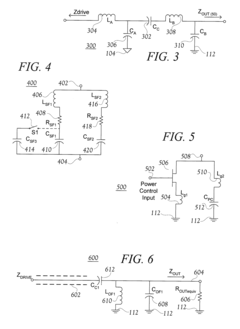

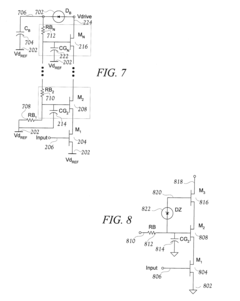

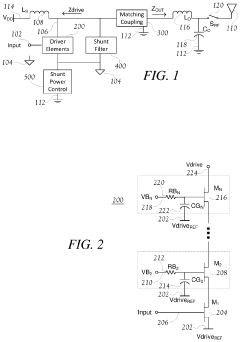

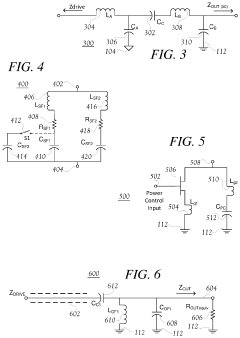

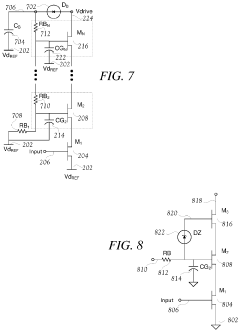

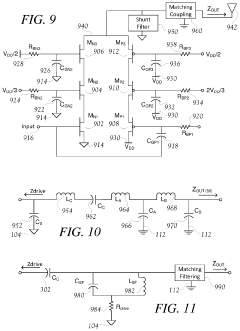

Integrated RF Front End with Stacked Transistor Switch

PatentInactiveUS20120252384A1

Innovation

- The integration of stacked-FET switches and specific PA topologies, such as the iClass PA, which includes a shunt filter and output amplitude regulation, allows for efficient power handling and protection against excessive voltages, enabling the fabrication of a self-protected monolithic integrated RF front-end circuit that can handle high voltages and reduce manufacturing costs.

Integrated RF Front End with Stacked Transistor Switch

PatentInactiveUS20220006484A1

Innovation

- The integration of stacked FETs and innovative PA topologies, such as the iClass PA, which includes a shunt filter and output power control mechanisms, to enhance voltage withstand capabilities and reduce power dissipation, along with self-protected monolithic integrated circuits that can handle excessive voltage standing waves and improper antenna impedance.

Environmental Impact

The environmental impact of cellophane in communication devices is a critical consideration as the technology evolves. Cellophane, a biodegradable material derived from cellulose, offers potential advantages in terms of sustainability compared to traditional plastic components. However, its production and disposal still present environmental challenges that must be addressed.

The manufacturing process of cellophane involves the use of chemicals and energy-intensive procedures, which can contribute to air and water pollution if not properly managed. The production of cellulose, the raw material for cellophane, often relies on wood pulp, raising concerns about deforestation and habitat destruction. Efforts to source cellulose from sustainable forests and agricultural waste can help mitigate these impacts.

In terms of disposal, cellophane's biodegradability is a significant advantage over conventional plastics. When properly disposed of in composting facilities, cellophane can break down into harmless organic compounds. However, the reality is that many cellophane products end up in landfills or incineration plants, where their environmental benefits are not fully realized.

The use of cellophane in communication devices presents an opportunity to reduce electronic waste. As devices become more modular and easier to repair, cellophane components could potentially be replaced or upgraded without discarding the entire device. This approach aligns with circular economy principles and could extend the lifespan of electronic products.

Water consumption is another environmental factor to consider in cellophane production. The manufacturing process requires significant amounts of water, which can strain local water resources in areas where production facilities are located. Implementing water recycling systems and improving production efficiency can help address this issue.

As cellophane technology advances, researchers are exploring ways to enhance its properties while minimizing environmental impact. This includes developing cellophane variants with improved barrier properties, which could reduce the need for additional protective layers in packaging applications. Such innovations could lead to thinner, more resource-efficient materials in communication devices.

The carbon footprint of cellophane production and transportation is an area that requires ongoing attention. While cellophane is generally lighter than many plastic alternatives, which can reduce transportation-related emissions, the overall life cycle assessment of cellophane in communication devices needs careful evaluation to ensure it offers a net environmental benefit.

The manufacturing process of cellophane involves the use of chemicals and energy-intensive procedures, which can contribute to air and water pollution if not properly managed. The production of cellulose, the raw material for cellophane, often relies on wood pulp, raising concerns about deforestation and habitat destruction. Efforts to source cellulose from sustainable forests and agricultural waste can help mitigate these impacts.

In terms of disposal, cellophane's biodegradability is a significant advantage over conventional plastics. When properly disposed of in composting facilities, cellophane can break down into harmless organic compounds. However, the reality is that many cellophane products end up in landfills or incineration plants, where their environmental benefits are not fully realized.

The use of cellophane in communication devices presents an opportunity to reduce electronic waste. As devices become more modular and easier to repair, cellophane components could potentially be replaced or upgraded without discarding the entire device. This approach aligns with circular economy principles and could extend the lifespan of electronic products.

Water consumption is another environmental factor to consider in cellophane production. The manufacturing process requires significant amounts of water, which can strain local water resources in areas where production facilities are located. Implementing water recycling systems and improving production efficiency can help address this issue.

As cellophane technology advances, researchers are exploring ways to enhance its properties while minimizing environmental impact. This includes developing cellophane variants with improved barrier properties, which could reduce the need for additional protective layers in packaging applications. Such innovations could lead to thinner, more resource-efficient materials in communication devices.

The carbon footprint of cellophane production and transportation is an area that requires ongoing attention. While cellophane is generally lighter than many plastic alternatives, which can reduce transportation-related emissions, the overall life cycle assessment of cellophane in communication devices needs careful evaluation to ensure it offers a net environmental benefit.

Regulatory Framework

The regulatory framework surrounding cellophane in communication devices has evolved significantly over the years, reflecting the changing technological landscape and environmental concerns. Initially, regulations primarily focused on safety standards and electromagnetic compatibility. However, as the use of cellophane in communication devices expanded, regulatory bodies began to address issues related to material composition, disposal, and recycling.

In many jurisdictions, cellophane used in communication devices must comply with Restriction of Hazardous Substances (RoHS) directives, which limit the use of certain hazardous materials such as lead, mercury, and cadmium. These regulations aim to reduce the environmental impact of electronic waste and protect human health. Additionally, the Waste Electrical and Electronic Equipment (WEEE) directive in the European Union mandates the proper disposal and recycling of electronic devices, including those containing cellophane components.

As concerns about electronic waste and sustainability have grown, some countries have implemented extended producer responsibility (EPR) programs. These programs require manufacturers to take responsibility for the entire lifecycle of their products, including the disposal and recycling of cellophane components. This has led to increased focus on designing devices with easily recyclable materials and improving the recyclability of cellophane used in communication devices.

The regulatory landscape also encompasses standards for biodegradability and compostability of cellophane materials. With the push towards more environmentally friendly products, some jurisdictions have introduced requirements for cellophane used in communication devices to meet specific biodegradability standards. This has prompted research into developing cellophane variants that can break down more easily in natural environments without leaving harmful residues.

International trade regulations have also impacted the use of cellophane in communication devices. Tariffs, import restrictions, and certification requirements can affect the global supply chain for cellophane materials and finished products. Manufacturers must navigate these complex regulatory environments to ensure compliance across different markets.

As the Internet of Things (IoT) and wearable technologies continue to advance, new regulatory challenges are emerging. The use of cellophane in flexible displays and smart textiles has raised questions about data privacy and security. Regulatory bodies are now considering how to address these concerns while fostering innovation in the field of cellophane-based communication devices.

Looking ahead, the regulatory framework for cellophane in communication devices is likely to continue evolving. Anticipated areas of focus include stricter environmental standards, enhanced recycling requirements, and regulations addressing the integration of cellophane with advanced technologies such as 5G and beyond. Manufacturers and researchers in this field must stay abreast of these regulatory developments to ensure compliance and drive innovation in cellophane-based communication devices.

In many jurisdictions, cellophane used in communication devices must comply with Restriction of Hazardous Substances (RoHS) directives, which limit the use of certain hazardous materials such as lead, mercury, and cadmium. These regulations aim to reduce the environmental impact of electronic waste and protect human health. Additionally, the Waste Electrical and Electronic Equipment (WEEE) directive in the European Union mandates the proper disposal and recycling of electronic devices, including those containing cellophane components.

As concerns about electronic waste and sustainability have grown, some countries have implemented extended producer responsibility (EPR) programs. These programs require manufacturers to take responsibility for the entire lifecycle of their products, including the disposal and recycling of cellophane components. This has led to increased focus on designing devices with easily recyclable materials and improving the recyclability of cellophane used in communication devices.

The regulatory landscape also encompasses standards for biodegradability and compostability of cellophane materials. With the push towards more environmentally friendly products, some jurisdictions have introduced requirements for cellophane used in communication devices to meet specific biodegradability standards. This has prompted research into developing cellophane variants that can break down more easily in natural environments without leaving harmful residues.

International trade regulations have also impacted the use of cellophane in communication devices. Tariffs, import restrictions, and certification requirements can affect the global supply chain for cellophane materials and finished products. Manufacturers must navigate these complex regulatory environments to ensure compliance across different markets.

As the Internet of Things (IoT) and wearable technologies continue to advance, new regulatory challenges are emerging. The use of cellophane in flexible displays and smart textiles has raised questions about data privacy and security. Regulatory bodies are now considering how to address these concerns while fostering innovation in the field of cellophane-based communication devices.

Looking ahead, the regulatory framework for cellophane in communication devices is likely to continue evolving. Anticipated areas of focus include stricter environmental standards, enhanced recycling requirements, and regulations addressing the integration of cellophane with advanced technologies such as 5G and beyond. Manufacturers and researchers in this field must stay abreast of these regulatory developments to ensure compliance and drive innovation in cellophane-based communication devices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!