How to Maintain Integrity in Cellophane's Recyclability?

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cellophane Recycling Background and Objectives

Cellophane, a transparent film made from regenerated cellulose, has been a staple in packaging since its invention in the early 20th century. Its unique properties, including transparency, biodegradability, and moisture resistance, have made it a popular choice for food packaging and various industrial applications. However, as environmental concerns have grown, the focus has shifted towards sustainable packaging solutions, bringing cellophane's recyclability into the spotlight.

The evolution of cellophane technology has been marked by continuous improvements in its production process and material properties. Initially developed as a moisture-proof coating for textiles, cellophane quickly found its way into the packaging industry due to its versatility and aesthetic appeal. Over the years, manufacturers have refined the production techniques, enhancing cellophane's barrier properties and expanding its applications across different sectors.

The current technological landscape presents both opportunities and challenges for cellophane recycling. While cellophane is inherently biodegradable, its recyclability has been a subject of debate. The primary goal in maintaining integrity in cellophane's recyclability is to develop efficient methods for separating cellophane from other materials in the waste stream and processing it in a way that preserves its valuable properties for reuse.

Market demands are driving the need for sustainable packaging solutions, with consumers and regulators alike pushing for reduced environmental impact. This has created a renewed interest in cellophane as a potentially eco-friendly alternative to petroleum-based plastics. However, to fully capitalize on this opportunity, the industry must address the challenges associated with cellophane recycling.

The objectives of this technical research are multifaceted. Firstly, it aims to assess the current state of cellophane recycling technologies and identify the key barriers to widespread implementation. Secondly, it seeks to explore innovative approaches to enhance the recyclability of cellophane without compromising its desirable properties. Thirdly, the research will investigate potential end-use applications for recycled cellophane, ensuring a closed-loop system that maintains the material's value throughout its lifecycle.

By examining the historical context, technological advancements, and market dynamics surrounding cellophane recycling, this research sets the foundation for developing sustainable solutions. The ultimate goal is to position cellophane as a viable, environmentally friendly packaging material that aligns with circular economy principles, thereby addressing both industry needs and environmental concerns.

The evolution of cellophane technology has been marked by continuous improvements in its production process and material properties. Initially developed as a moisture-proof coating for textiles, cellophane quickly found its way into the packaging industry due to its versatility and aesthetic appeal. Over the years, manufacturers have refined the production techniques, enhancing cellophane's barrier properties and expanding its applications across different sectors.

The current technological landscape presents both opportunities and challenges for cellophane recycling. While cellophane is inherently biodegradable, its recyclability has been a subject of debate. The primary goal in maintaining integrity in cellophane's recyclability is to develop efficient methods for separating cellophane from other materials in the waste stream and processing it in a way that preserves its valuable properties for reuse.

Market demands are driving the need for sustainable packaging solutions, with consumers and regulators alike pushing for reduced environmental impact. This has created a renewed interest in cellophane as a potentially eco-friendly alternative to petroleum-based plastics. However, to fully capitalize on this opportunity, the industry must address the challenges associated with cellophane recycling.

The objectives of this technical research are multifaceted. Firstly, it aims to assess the current state of cellophane recycling technologies and identify the key barriers to widespread implementation. Secondly, it seeks to explore innovative approaches to enhance the recyclability of cellophane without compromising its desirable properties. Thirdly, the research will investigate potential end-use applications for recycled cellophane, ensuring a closed-loop system that maintains the material's value throughout its lifecycle.

By examining the historical context, technological advancements, and market dynamics surrounding cellophane recycling, this research sets the foundation for developing sustainable solutions. The ultimate goal is to position cellophane as a viable, environmentally friendly packaging material that aligns with circular economy principles, thereby addressing both industry needs and environmental concerns.

Market Demand for Sustainable Packaging Solutions

The global market for sustainable packaging solutions has been experiencing significant growth in recent years, driven by increasing consumer awareness, stringent environmental regulations, and corporate sustainability initiatives. This trend has created a substantial demand for recyclable materials like cellophane, which offers both functionality and environmental benefits.

Consumer preferences have shifted dramatically towards eco-friendly packaging options. A recent survey revealed that over 70% of consumers are willing to pay more for products packaged in sustainable materials. This shift in consumer behavior has prompted major retailers and brands to commit to using recyclable packaging, creating a ripple effect throughout the supply chain.

The food and beverage industry, in particular, has shown a strong interest in sustainable packaging solutions. Cellophane, with its biodegradable properties and potential for recyclability, has emerged as a promising alternative to traditional plastic packaging in this sector. The market for cellophane in food packaging is projected to grow at a compound annual growth rate (CAGR) of 4.5% over the next five years.

E-commerce has also been a significant driver of demand for sustainable packaging solutions. With the rapid growth of online shopping, there is an increasing need for packaging materials that can withstand shipping while still being environmentally friendly. Cellophane's durability and potential for recyclability make it an attractive option for e-commerce packaging.

The pharmaceutical and personal care industries are also exploring sustainable packaging alternatives, including cellophane, to reduce their environmental footprint. These sectors require packaging materials that can maintain product integrity while meeting sustainability goals, presenting a unique opportunity for cellophane applications.

Government regulations and policies promoting circular economy principles have further bolstered the demand for recyclable packaging materials. Many countries have introduced legislation to reduce single-use plastics and improve recycling rates, creating a favorable market environment for materials like cellophane.

However, the market demand for sustainable packaging solutions, including cellophane, is not without challenges. The recycling infrastructure for cellophane is still developing in many regions, which can limit its perceived value as a sustainable option. Additionally, the cost of producing and processing recyclable cellophane remains higher than some conventional packaging materials, potentially slowing adoption rates in price-sensitive markets.

Despite these challenges, the overall market trajectory for sustainable packaging solutions remains positive. As technology advances and economies of scale are achieved, the demand for recyclable cellophane is expected to grow, particularly in industries where product protection and environmental considerations are paramount.

Consumer preferences have shifted dramatically towards eco-friendly packaging options. A recent survey revealed that over 70% of consumers are willing to pay more for products packaged in sustainable materials. This shift in consumer behavior has prompted major retailers and brands to commit to using recyclable packaging, creating a ripple effect throughout the supply chain.

The food and beverage industry, in particular, has shown a strong interest in sustainable packaging solutions. Cellophane, with its biodegradable properties and potential for recyclability, has emerged as a promising alternative to traditional plastic packaging in this sector. The market for cellophane in food packaging is projected to grow at a compound annual growth rate (CAGR) of 4.5% over the next five years.

E-commerce has also been a significant driver of demand for sustainable packaging solutions. With the rapid growth of online shopping, there is an increasing need for packaging materials that can withstand shipping while still being environmentally friendly. Cellophane's durability and potential for recyclability make it an attractive option for e-commerce packaging.

The pharmaceutical and personal care industries are also exploring sustainable packaging alternatives, including cellophane, to reduce their environmental footprint. These sectors require packaging materials that can maintain product integrity while meeting sustainability goals, presenting a unique opportunity for cellophane applications.

Government regulations and policies promoting circular economy principles have further bolstered the demand for recyclable packaging materials. Many countries have introduced legislation to reduce single-use plastics and improve recycling rates, creating a favorable market environment for materials like cellophane.

However, the market demand for sustainable packaging solutions, including cellophane, is not without challenges. The recycling infrastructure for cellophane is still developing in many regions, which can limit its perceived value as a sustainable option. Additionally, the cost of producing and processing recyclable cellophane remains higher than some conventional packaging materials, potentially slowing adoption rates in price-sensitive markets.

Despite these challenges, the overall market trajectory for sustainable packaging solutions remains positive. As technology advances and economies of scale are achieved, the demand for recyclable cellophane is expected to grow, particularly in industries where product protection and environmental considerations are paramount.

Current Challenges in Cellophane Recycling

Cellophane recycling faces several significant challenges that hinder its widespread adoption and efficiency. One of the primary obstacles is the lack of dedicated recycling infrastructure for cellophane. Unlike more common plastics, cellophane requires specialized processing facilities, which are currently limited in number and geographical distribution. This scarcity of appropriate recycling centers often results in cellophane being misdirected to landfills or incineration plants, negating its potential for recycling.

Another major challenge is the contamination of cellophane waste. Cellophane is frequently used in food packaging, which leads to contamination with food residues, oils, and other organic matter. These contaminants can significantly impair the recycling process, reducing the quality of the recycled material and increasing the cost of processing. The need for thorough cleaning and decontamination adds complexity and expense to the recycling chain, making it less economically viable for many recycling facilities.

The chemical composition of cellophane also presents recycling difficulties. While cellophane is biodegradable, its regenerated cellulose structure can be altered during use, particularly when exposed to moisture or certain chemicals. This alteration can affect the material's properties, making it challenging to recycle into a product with consistent quality. The variability in the condition of collected cellophane waste further complicates the recycling process, as it requires additional sorting and quality control measures.

Furthermore, the market demand for recycled cellophane is currently limited. Many industries prefer virgin cellophane for its superior clarity and barrier properties, which are often compromised in recycled versions. This lack of demand creates a circular problem: without a strong market for recycled cellophane, there is little incentive to invest in improving recycling technologies and infrastructure, which in turn keeps the quality of recycled cellophane lower and less attractive to potential buyers.

The identification and sorting of cellophane in mixed waste streams pose another significant challenge. Cellophane can be easily mistaken for other types of plastic films, leading to contamination of other recycling streams or improper disposal. Advanced sorting technologies, such as near-infrared spectroscopy, are needed to accurately identify cellophane, but these systems are not yet widely implemented in recycling facilities due to their high cost.

Lastly, the regulatory landscape surrounding cellophane recycling is often unclear or underdeveloped. Many regions lack specific guidelines or incentives for cellophane recycling, which contributes to its low recycling rates. The absence of standardized recycling symbols or labeling for cellophane products further complicates consumer education and proper disposal practices, leading to confusion and mishandling of cellophane waste.

Another major challenge is the contamination of cellophane waste. Cellophane is frequently used in food packaging, which leads to contamination with food residues, oils, and other organic matter. These contaminants can significantly impair the recycling process, reducing the quality of the recycled material and increasing the cost of processing. The need for thorough cleaning and decontamination adds complexity and expense to the recycling chain, making it less economically viable for many recycling facilities.

The chemical composition of cellophane also presents recycling difficulties. While cellophane is biodegradable, its regenerated cellulose structure can be altered during use, particularly when exposed to moisture or certain chemicals. This alteration can affect the material's properties, making it challenging to recycle into a product with consistent quality. The variability in the condition of collected cellophane waste further complicates the recycling process, as it requires additional sorting and quality control measures.

Furthermore, the market demand for recycled cellophane is currently limited. Many industries prefer virgin cellophane for its superior clarity and barrier properties, which are often compromised in recycled versions. This lack of demand creates a circular problem: without a strong market for recycled cellophane, there is little incentive to invest in improving recycling technologies and infrastructure, which in turn keeps the quality of recycled cellophane lower and less attractive to potential buyers.

The identification and sorting of cellophane in mixed waste streams pose another significant challenge. Cellophane can be easily mistaken for other types of plastic films, leading to contamination of other recycling streams or improper disposal. Advanced sorting technologies, such as near-infrared spectroscopy, are needed to accurately identify cellophane, but these systems are not yet widely implemented in recycling facilities due to their high cost.

Lastly, the regulatory landscape surrounding cellophane recycling is often unclear or underdeveloped. Many regions lack specific guidelines or incentives for cellophane recycling, which contributes to its low recycling rates. The absence of standardized recycling symbols or labeling for cellophane products further complicates consumer education and proper disposal practices, leading to confusion and mishandling of cellophane waste.

Existing Methods for Maintaining Cellophane Integrity

01 Cellophane packaging integrity testing

Methods and devices for testing the integrity of cellophane packaging are developed to ensure product safety and quality. These techniques may involve pressure testing, visual inspection, or automated systems to detect defects, tears, or seal failures in cellophane packaging materials.- Cellophane packaging integrity testing: Methods and devices for testing the integrity of cellophane packaging are developed to ensure product safety and quality. These techniques may involve pressure testing, visual inspection, or automated systems to detect defects or breaches in the cellophane material.

- Cellophane film manufacturing processes: Improved manufacturing processes for cellophane films focus on enhancing the material's integrity and durability. These advancements may include modifications to the production line, new chemical formulations, or innovative treatment methods to strengthen the cellophane structure.

- Cellophane coating and treatment techniques: Various coating and treatment techniques are applied to cellophane to improve its integrity, barrier properties, and overall performance. These may include the application of protective layers, chemical treatments, or surface modifications to enhance the material's resistance to environmental factors.

- Cellophane packaging design for improved integrity: Innovative packaging designs utilizing cellophane focus on maintaining product integrity and freshness. These designs may incorporate features such as reinforced seals, multi-layer structures, or specialized closures to enhance the overall integrity of the packaging system.

- Cellophane integrity monitoring systems: Advanced monitoring systems are developed to continuously assess and maintain cellophane integrity in various applications. These systems may employ sensors, imaging technologies, or data analysis to detect and prevent potential integrity issues in real-time.

02 Cellophane film composition improvements

Advancements in cellophane film composition focus on enhancing its physical properties, such as strength, flexibility, and barrier characteristics. These improvements may involve the incorporation of additives, modified cellulose derivatives, or novel processing techniques to create more durable and functional cellophane materials.Expand Specific Solutions03 Cellophane sealing and closure mechanisms

Innovative sealing and closure mechanisms for cellophane packaging are developed to maintain product freshness and prevent contamination. These may include heat-sealing techniques, adhesive applications, or specialized closure designs that ensure the integrity of cellophane-wrapped products.Expand Specific Solutions04 Cellophane degradation prevention

Strategies to prevent or minimize cellophane degradation are explored to extend the shelf life and maintain the integrity of cellophane-based products. These may involve the use of stabilizers, UV inhibitors, or protective coatings to enhance the material's resistance to environmental factors and mechanical stress.Expand Specific Solutions05 Cellophane recycling and biodegradability

Research into cellophane recycling processes and the development of biodegradable cellophane alternatives aim to improve the material's environmental impact. These efforts focus on creating more sustainable cellophane products while maintaining their functional integrity throughout their lifecycle.Expand Specific Solutions

Key Players in Cellophane Production and Recycling

The cellophane recyclability market is in a growth phase, driven by increasing environmental concerns and sustainability initiatives. The market size is expanding as more industries adopt recyclable packaging solutions. Technologically, the field is evolving rapidly, with companies like Kolon Industries, Eastman Chemical Co., and AGC, Inc. leading innovations in maintaining cellophane integrity during recycling processes. These firms are developing advanced chemical treatments and manufacturing techniques to enhance cellophane's recyclability without compromising its functional properties. The competition is intensifying as both established players and startups like Infinited Fiber Co. Oy enter the market with novel approaches to sustainable packaging materials.

Eastman Chemical Co.

Technical Solution: Eastman Chemical Co. has developed a molecular recycling technology called Carbon Renewal Technology (CRT) to address the recyclability of cellophane and other complex plastic materials. This process breaks down plastic waste into molecular building blocks, which can then be used to create new plastics with virgin-like performance. The CRT process can handle mixed plastic waste streams, including those containing cellophane, and does not require extensive sorting or cleaning of the input materials[1]. Eastman's technology also incorporates a depolymerization process that can specifically target cellulose-based materials like cellophane, converting them back into their base monomers for reuse in new products[2].

Strengths: Ability to recycle mixed plastic waste streams, including cellophane; produces high-quality recycled materials. Weaknesses: Energy-intensive process; may require significant infrastructure investment for large-scale implementation.

Unilever Plc

Technical Solution: Unilever Plc has been at the forefront of developing sustainable packaging solutions, including addressing the recyclability of cellophane-like materials. Their approach involves a combination of material science innovation and circular economy principles. Unilever has developed a CreaSolv® Process, which, while primarily designed for plastic sachets, can be adapted for cellophane recycling. This technology uses a solvent-based process to separate polymers from complex, multi-layer materials, allowing for the recovery and reuse of cellulose components[9]. Additionally, Unilever is investing in enzymatic recycling technologies that can break down cellulose-based materials like cellophane into their basic building blocks, which can then be used to create new packaging materials[10]. The company is also working on improving the design of cellophane packaging to enhance its recyclability and compatibility with existing recycling infrastructure.

Strengths: Comprehensive approach combining material recovery and redesign; potential for adaptation to various cellulose-based materials. Weaknesses: Some technologies still in development stage; may require significant changes to current recycling infrastructure.

Innovative Approaches to Enhance Recyclability

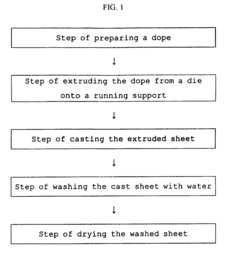

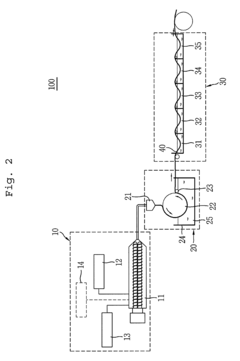

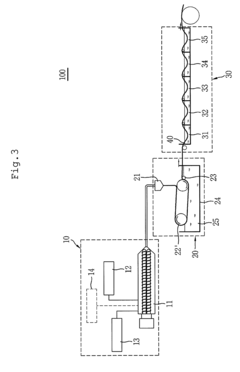

Method for preparing cellulose-based film and cellulose-based film

PatentActiveUS8883056B2

Innovation

- A method involving the preparation of a dope from alpha-cellulose pulp and an aqueous N-methylmorpholine-N-oxide solution, extrusion, casting, washing, and drying, which omits the use of NaOH or H2SO4 and avoids the use of CS2, allowing for the production of an environmentally friendly cellulose-based film with excellent properties.

SUSTAINABLE PROCESS OF SEPARATION, RECOVERY, IMPROVEMENT AND PURIFICATION OF CELLULOSE PULP CONTAINED IN HYGIENIC ABSORBENTS AND PERSONAL USE DIAPERS TO OBTAIN PURE CELLULOSE PULP

PatentPendingBR102015020518A2

Innovation

- A continuous and closed process for separating and purifying cellulose and gel from sanitary napkins and diapers, involving classification, chopping, cyclone separation, condensation, and pressing, followed by specific phases for gel extraction in diapers, to produce high-quality raw materials for reuse.

Environmental Impact Assessment

The environmental impact assessment of cellophane's recyclability is a critical aspect of maintaining its integrity throughout the recycling process. Cellophane, a biodegradable and compostable material derived from cellulose, presents both opportunities and challenges in terms of its environmental footprint.

One of the primary environmental benefits of cellophane is its biodegradability. When properly disposed of in composting facilities, cellophane breaks down naturally without leaving harmful residues. This characteristic significantly reduces its long-term environmental impact compared to conventional plastics that persist in ecosystems for hundreds of years.

However, the recycling process for cellophane poses certain environmental challenges. The production of cellophane involves chemical treatments to achieve its desired properties, which can complicate the recycling process. These treatments may introduce contaminants that need to be carefully managed during recycling to prevent environmental pollution.

Energy consumption is another factor to consider in the environmental impact assessment. The recycling of cellophane requires energy for collection, transportation, and processing. While this energy use contributes to carbon emissions, it is generally lower than the energy required for producing new cellophane from raw materials.

Water usage in the recycling process is also a significant environmental consideration. Cleaning and processing cellophane for recycling can be water-intensive, potentially straining local water resources if not managed efficiently. Implementing water recycling systems within recycling facilities can help mitigate this impact.

The potential for contamination during the recycling process is a key environmental concern. If cellophane is not properly separated from other materials or if it contains food residues, it can contaminate recycling streams and reduce the quality of recycled materials. This contamination may lead to increased waste and decreased efficiency in the recycling process.

Land use for recycling facilities and the transportation of recyclable materials also contribute to the overall environmental impact. While these impacts are not unique to cellophane, they are important considerations in assessing the full lifecycle environmental footprint of cellophane recycling.

Maintaining the integrity of cellophane's recyclability requires a holistic approach to minimize negative environmental impacts while maximizing the benefits of recycling. This includes optimizing collection and sorting processes, improving recycling technologies to reduce energy and water consumption, and educating consumers on proper disposal methods to prevent contamination.

One of the primary environmental benefits of cellophane is its biodegradability. When properly disposed of in composting facilities, cellophane breaks down naturally without leaving harmful residues. This characteristic significantly reduces its long-term environmental impact compared to conventional plastics that persist in ecosystems for hundreds of years.

However, the recycling process for cellophane poses certain environmental challenges. The production of cellophane involves chemical treatments to achieve its desired properties, which can complicate the recycling process. These treatments may introduce contaminants that need to be carefully managed during recycling to prevent environmental pollution.

Energy consumption is another factor to consider in the environmental impact assessment. The recycling of cellophane requires energy for collection, transportation, and processing. While this energy use contributes to carbon emissions, it is generally lower than the energy required for producing new cellophane from raw materials.

Water usage in the recycling process is also a significant environmental consideration. Cleaning and processing cellophane for recycling can be water-intensive, potentially straining local water resources if not managed efficiently. Implementing water recycling systems within recycling facilities can help mitigate this impact.

The potential for contamination during the recycling process is a key environmental concern. If cellophane is not properly separated from other materials or if it contains food residues, it can contaminate recycling streams and reduce the quality of recycled materials. This contamination may lead to increased waste and decreased efficiency in the recycling process.

Land use for recycling facilities and the transportation of recyclable materials also contribute to the overall environmental impact. While these impacts are not unique to cellophane, they are important considerations in assessing the full lifecycle environmental footprint of cellophane recycling.

Maintaining the integrity of cellophane's recyclability requires a holistic approach to minimize negative environmental impacts while maximizing the benefits of recycling. This includes optimizing collection and sorting processes, improving recycling technologies to reduce energy and water consumption, and educating consumers on proper disposal methods to prevent contamination.

Regulatory Framework for Packaging Recycling

The regulatory framework for packaging recycling plays a crucial role in maintaining the integrity of cellophane's recyclability. As governments and international organizations increasingly focus on environmental sustainability, regulations surrounding packaging materials and their recycling processes have become more stringent and comprehensive.

In the European Union, the Packaging and Packaging Waste Directive (PPWD) sets specific targets for the recycling of packaging materials, including cellophane. This directive requires member states to implement measures to prevent packaging waste and promote reuse and recycling. The PPWD also establishes essential requirements for the composition and reusable and recoverable nature of packaging.

The United States lacks a federal-level regulatory framework specifically for packaging recycling. However, several states have implemented their own regulations. For instance, California's Rigid Plastic Packaging Container (RPPC) program mandates that certain plastic packaging containers meet recycling rates or use recycled content. While cellophane is not directly covered under this program, it sets a precedent for potential future regulations on similar materials.

In Asia, countries like Japan and South Korea have implemented extended producer responsibility (EPR) systems for packaging materials. These systems require manufacturers to take responsibility for the entire lifecycle of their products, including disposal and recycling. Such regulations incentivize the use of easily recyclable materials like cellophane and promote the development of efficient recycling technologies.

International standards, such as ISO 18604:2013 for packaging and the environment, provide guidelines for material recycling. These standards help ensure that packaging materials, including cellophane, are designed and manufactured in a way that facilitates recycling and maintains material integrity throughout the process.

The regulatory landscape also includes restrictions on harmful substances in packaging materials. For example, the EU's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation impacts the composition of packaging materials, ensuring that potentially hazardous substances are not introduced into the recycling stream.

As the circular economy concept gains traction, many countries are adopting regulations that promote the use of recycled materials in new products. This creates a demand for high-quality recycled cellophane, driving innovations in recycling technologies and processes to maintain material integrity.

To ensure compliance with these regulations, manufacturers and recyclers must implement robust quality control measures and traceability systems. This includes proper labeling of cellophane packaging to facilitate sorting and recycling, as well as the development of advanced sorting technologies to maintain the purity of recycled cellophane streams.

In the European Union, the Packaging and Packaging Waste Directive (PPWD) sets specific targets for the recycling of packaging materials, including cellophane. This directive requires member states to implement measures to prevent packaging waste and promote reuse and recycling. The PPWD also establishes essential requirements for the composition and reusable and recoverable nature of packaging.

The United States lacks a federal-level regulatory framework specifically for packaging recycling. However, several states have implemented their own regulations. For instance, California's Rigid Plastic Packaging Container (RPPC) program mandates that certain plastic packaging containers meet recycling rates or use recycled content. While cellophane is not directly covered under this program, it sets a precedent for potential future regulations on similar materials.

In Asia, countries like Japan and South Korea have implemented extended producer responsibility (EPR) systems for packaging materials. These systems require manufacturers to take responsibility for the entire lifecycle of their products, including disposal and recycling. Such regulations incentivize the use of easily recyclable materials like cellophane and promote the development of efficient recycling technologies.

International standards, such as ISO 18604:2013 for packaging and the environment, provide guidelines for material recycling. These standards help ensure that packaging materials, including cellophane, are designed and manufactured in a way that facilitates recycling and maintains material integrity throughout the process.

The regulatory landscape also includes restrictions on harmful substances in packaging materials. For example, the EU's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation impacts the composition of packaging materials, ensuring that potentially hazardous substances are not introduced into the recycling stream.

As the circular economy concept gains traction, many countries are adopting regulations that promote the use of recycled materials in new products. This creates a demand for high-quality recycled cellophane, driving innovations in recycling technologies and processes to maintain material integrity.

To ensure compliance with these regulations, manufacturers and recyclers must implement robust quality control measures and traceability systems. This includes proper labeling of cellophane packaging to facilitate sorting and recycling, as well as the development of advanced sorting technologies to maintain the purity of recycled cellophane streams.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!