How to Overcome Constraints in Cellophane Thermal Management?

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cellophane Thermal Challenges

Cellophane, a thin, transparent sheet made from regenerated cellulose, has long been used in various industries due to its unique properties. However, its thermal management capabilities present significant challenges that limit its applications in certain fields. The primary constraint in cellophane thermal management is its inherent thermal conductivity, which is relatively low compared to other materials commonly used in heat transfer applications.

One of the main challenges is the difficulty in efficiently dissipating heat through cellophane films. This limitation becomes particularly problematic in packaging applications where temperature control is crucial, such as in food preservation or electronic component protection. The poor heat dissipation can lead to localized hot spots, potentially compromising the integrity of the packaged contents or reducing the overall effectiveness of the thermal management system.

Another significant challenge is the thermal expansion of cellophane under varying temperature conditions. As temperatures fluctuate, cellophane may expand or contract, leading to dimensional instability. This property can cause issues in applications where precise dimensional control is necessary, such as in optical films or in multi-layer packaging structures where different materials are combined.

The moisture sensitivity of cellophane also poses a challenge in thermal management. Cellophane's hygroscopic nature means it can absorb moisture from the environment, which can affect its thermal properties. This moisture absorption can lead to changes in the material's thermal conductivity and heat capacity, making it difficult to maintain consistent thermal performance across different environmental conditions.

Furthermore, the limited temperature range in which cellophane maintains its desirable properties presents another constraint. At high temperatures, cellophane can soften and lose its structural integrity, while at very low temperatures, it may become brittle. This narrow operational temperature range restricts its use in extreme thermal environments and limits its potential applications in industries that require materials to withstand a wide range of temperatures.

The surface properties of cellophane also contribute to thermal management challenges. Its smooth surface can sometimes hinder heat transfer through convection, as it may not provide sufficient surface area for effective heat exchange with the surrounding environment. This limitation can be particularly problematic in applications where rapid heat dissipation is required.

Addressing these thermal management constraints in cellophane is crucial for expanding its potential applications and improving its performance in existing uses. Overcoming these challenges requires innovative approaches that may involve modifying the material's structure, developing composite materials, or creating novel surface treatments to enhance thermal properties while maintaining cellophane's beneficial characteristics.

One of the main challenges is the difficulty in efficiently dissipating heat through cellophane films. This limitation becomes particularly problematic in packaging applications where temperature control is crucial, such as in food preservation or electronic component protection. The poor heat dissipation can lead to localized hot spots, potentially compromising the integrity of the packaged contents or reducing the overall effectiveness of the thermal management system.

Another significant challenge is the thermal expansion of cellophane under varying temperature conditions. As temperatures fluctuate, cellophane may expand or contract, leading to dimensional instability. This property can cause issues in applications where precise dimensional control is necessary, such as in optical films or in multi-layer packaging structures where different materials are combined.

The moisture sensitivity of cellophane also poses a challenge in thermal management. Cellophane's hygroscopic nature means it can absorb moisture from the environment, which can affect its thermal properties. This moisture absorption can lead to changes in the material's thermal conductivity and heat capacity, making it difficult to maintain consistent thermal performance across different environmental conditions.

Furthermore, the limited temperature range in which cellophane maintains its desirable properties presents another constraint. At high temperatures, cellophane can soften and lose its structural integrity, while at very low temperatures, it may become brittle. This narrow operational temperature range restricts its use in extreme thermal environments and limits its potential applications in industries that require materials to withstand a wide range of temperatures.

The surface properties of cellophane also contribute to thermal management challenges. Its smooth surface can sometimes hinder heat transfer through convection, as it may not provide sufficient surface area for effective heat exchange with the surrounding environment. This limitation can be particularly problematic in applications where rapid heat dissipation is required.

Addressing these thermal management constraints in cellophane is crucial for expanding its potential applications and improving its performance in existing uses. Overcoming these challenges requires innovative approaches that may involve modifying the material's structure, developing composite materials, or creating novel surface treatments to enhance thermal properties while maintaining cellophane's beneficial characteristics.

Market Demand Analysis

The market demand for improved cellophane thermal management solutions has been steadily increasing in recent years, driven by the growing emphasis on sustainable packaging and the expanding applications of cellophane in various industries. As consumers and businesses alike become more environmentally conscious, the demand for biodegradable and compostable packaging materials has surged, positioning cellophane as a viable alternative to traditional plastics.

The food packaging industry, in particular, has shown significant interest in enhanced cellophane thermal management. With the rise of ready-to-eat meals, takeaway services, and food delivery platforms, there is a pressing need for packaging materials that can maintain food quality and safety across a wide range of temperatures. Improved thermal management in cellophane would allow for better preservation of hot and cold foods, potentially extending shelf life and reducing food waste.

In the pharmaceutical and medical sectors, the demand for cellophane with advanced thermal properties is also on the rise. These industries require packaging materials that can protect temperature-sensitive drugs and medical supplies during storage and transportation. Enhanced thermal management in cellophane could provide a more sustainable and cost-effective solution compared to current alternatives.

The electronics industry presents another significant market opportunity for cellophane with improved thermal management capabilities. As electronic devices become smaller and more powerful, effective heat dissipation becomes crucial. Cellophane-based materials with enhanced thermal conductivity could find applications in flexible electronics, wearable devices, and thermal interface materials.

Market research indicates that the global biodegradable packaging market, which includes cellophane, is expected to grow at a compound annual growth rate (CAGR) of over 17% from 2021 to 2026. This growth is largely attributed to stringent environmental regulations, increasing consumer awareness, and the adoption of sustainable practices by major corporations.

The Asia-Pacific region is anticipated to be the fastest-growing market for cellophane with improved thermal properties, driven by rapid industrialization, urbanization, and the expansion of e-commerce in countries like China and India. North America and Europe are also expected to show substantial growth, primarily due to strict environmental regulations and consumer preferences for eco-friendly packaging solutions.

However, the market demand for improved cellophane thermal management is not without challenges. The higher cost of production compared to traditional plastics remains a significant barrier to widespread adoption. Additionally, there is a need for education and awareness among consumers and businesses about the benefits and proper disposal methods of cellophane-based products.

The food packaging industry, in particular, has shown significant interest in enhanced cellophane thermal management. With the rise of ready-to-eat meals, takeaway services, and food delivery platforms, there is a pressing need for packaging materials that can maintain food quality and safety across a wide range of temperatures. Improved thermal management in cellophane would allow for better preservation of hot and cold foods, potentially extending shelf life and reducing food waste.

In the pharmaceutical and medical sectors, the demand for cellophane with advanced thermal properties is also on the rise. These industries require packaging materials that can protect temperature-sensitive drugs and medical supplies during storage and transportation. Enhanced thermal management in cellophane could provide a more sustainable and cost-effective solution compared to current alternatives.

The electronics industry presents another significant market opportunity for cellophane with improved thermal management capabilities. As electronic devices become smaller and more powerful, effective heat dissipation becomes crucial. Cellophane-based materials with enhanced thermal conductivity could find applications in flexible electronics, wearable devices, and thermal interface materials.

Market research indicates that the global biodegradable packaging market, which includes cellophane, is expected to grow at a compound annual growth rate (CAGR) of over 17% from 2021 to 2026. This growth is largely attributed to stringent environmental regulations, increasing consumer awareness, and the adoption of sustainable practices by major corporations.

The Asia-Pacific region is anticipated to be the fastest-growing market for cellophane with improved thermal properties, driven by rapid industrialization, urbanization, and the expansion of e-commerce in countries like China and India. North America and Europe are also expected to show substantial growth, primarily due to strict environmental regulations and consumer preferences for eco-friendly packaging solutions.

However, the market demand for improved cellophane thermal management is not without challenges. The higher cost of production compared to traditional plastics remains a significant barrier to widespread adoption. Additionally, there is a need for education and awareness among consumers and businesses about the benefits and proper disposal methods of cellophane-based products.

Current Limitations

Cellophane thermal management faces several significant constraints that hinder its widespread adoption and effectiveness in various applications. One of the primary limitations is the material's inherent thermal conductivity. While cellophane offers excellent barrier properties and transparency, its thermal conductivity is relatively low compared to other materials used in thermal management solutions. This limitation restricts its ability to efficiently dissipate heat, particularly in high-power density applications.

Another critical constraint is the material's temperature sensitivity. Cellophane's physical properties can change significantly when exposed to high temperatures, potentially leading to degradation or loss of functionality. This temperature limitation narrows the range of applications where cellophane can be effectively used for thermal management, especially in environments with extreme temperature fluctuations or sustained high-temperature operations.

The moisture sensitivity of cellophane presents an additional challenge in thermal management applications. When exposed to humidity or moisture, cellophane can absorb water, which may alter its thermal properties and potentially compromise its structural integrity. This sensitivity to environmental conditions can lead to inconsistent performance and reduced reliability in thermal management systems.

Cellophane's mechanical properties also pose limitations in certain thermal management scenarios. The material's relatively low tensile strength and flexibility can make it challenging to incorporate into complex thermal management designs or applications that require high structural integrity. This constraint may necessitate additional support structures or protective layers, potentially increasing system complexity and cost.

The scalability of cellophane-based thermal management solutions is another area of concern. While the material can be produced in thin films, creating larger or more complex structures for comprehensive thermal management systems may be challenging. This limitation can restrict the material's applicability in large-scale industrial or commercial thermal management applications.

Lastly, the integration of cellophane with other materials and components in thermal management systems presents technical challenges. Ensuring proper adhesion, maintaining thermal interfaces, and preventing delamination or separation under thermal stress are critical issues that need to be addressed. These integration challenges can limit the overall effectiveness and longevity of cellophane-based thermal management solutions in complex systems.

Another critical constraint is the material's temperature sensitivity. Cellophane's physical properties can change significantly when exposed to high temperatures, potentially leading to degradation or loss of functionality. This temperature limitation narrows the range of applications where cellophane can be effectively used for thermal management, especially in environments with extreme temperature fluctuations or sustained high-temperature operations.

The moisture sensitivity of cellophane presents an additional challenge in thermal management applications. When exposed to humidity or moisture, cellophane can absorb water, which may alter its thermal properties and potentially compromise its structural integrity. This sensitivity to environmental conditions can lead to inconsistent performance and reduced reliability in thermal management systems.

Cellophane's mechanical properties also pose limitations in certain thermal management scenarios. The material's relatively low tensile strength and flexibility can make it challenging to incorporate into complex thermal management designs or applications that require high structural integrity. This constraint may necessitate additional support structures or protective layers, potentially increasing system complexity and cost.

The scalability of cellophane-based thermal management solutions is another area of concern. While the material can be produced in thin films, creating larger or more complex structures for comprehensive thermal management systems may be challenging. This limitation can restrict the material's applicability in large-scale industrial or commercial thermal management applications.

Lastly, the integration of cellophane with other materials and components in thermal management systems presents technical challenges. Ensuring proper adhesion, maintaining thermal interfaces, and preventing delamination or separation under thermal stress are critical issues that need to be addressed. These integration challenges can limit the overall effectiveness and longevity of cellophane-based thermal management solutions in complex systems.

Existing Solutions

01 Thermal management in electronic devices

Cellophane-based materials are used in electronic devices for thermal management. These materials help in dissipating heat efficiently, improving device performance and longevity. The cellophane-based thermal management solutions can be integrated into various components of electronic devices, such as processors, batteries, and displays.- Thermal management in electronic devices: Cellophane-based materials are used in electronic devices for thermal management. These materials help dissipate heat efficiently, improving device performance and longevity. The cellophane layers can be engineered to have specific thermal properties, allowing for better heat distribution and cooling in compact electronic systems.

- Cellophane-based heat-resistant packaging: Cellophane is utilized in creating heat-resistant packaging solutions. The material's thermal properties are enhanced through various treatments and coatings, making it suitable for applications where temperature control is crucial. This includes food packaging, industrial packaging, and protective wraps for heat-sensitive items.

- Cellophane in thermal insulation systems: Cellophane is incorporated into thermal insulation systems for buildings and industrial applications. Its unique properties allow for the creation of thin, effective insulation layers that can be easily applied to various surfaces. These systems help in maintaining stable temperatures and reducing energy consumption in both residential and commercial structures.

- Cellophane-based thermal management in batteries: Cellophane materials are used in battery thermal management systems. They help in regulating temperature within battery cells, preventing overheating and improving overall battery performance and safety. This application is particularly important in electric vehicles and large-scale energy storage systems.

- Cellophane in thermal printing technologies: Cellophane is utilized in thermal printing technologies for its heat-responsive properties. It serves as a substrate or component in thermal transfer ribbons and printing media. The material's ability to withstand and conduct heat in a controlled manner makes it suitable for high-quality, durable thermal printing applications.

02 Cellophane-based heat-dissipating films

Heat-dissipating films made from cellophane or cellulose derivatives are developed for thermal management applications. These films offer excellent thermal conductivity and can be easily applied to various surfaces. They are particularly useful in flexible electronics and wearable devices where traditional heat sinks are not suitable.Expand Specific Solutions03 Biodegradable thermal management solutions

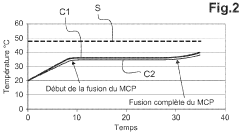

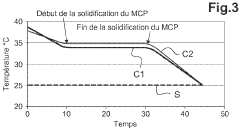

Cellophane, being a biodegradable material, is used to create environmentally friendly thermal management solutions. These solutions are designed to provide effective heat dissipation while minimizing environmental impact. They are particularly relevant in industries striving for sustainability and reduced carbon footprint.Expand Specific Solutions04 Cellophane-based phase change materials

Cellophane is utilized in the development of phase change materials for thermal management. These materials can absorb, store, and release thermal energy, providing effective temperature regulation in various applications. The cellophane-based phase change materials offer advantages such as flexibility, light weight, and ease of integration into existing systems.Expand Specific Solutions05 Nanocomposite cellophane for enhanced thermal properties

Nanocomposites incorporating cellophane are developed to enhance thermal management properties. These materials combine the benefits of cellophane with nanoparticles or nanostructures to achieve improved thermal conductivity, heat dissipation, and temperature regulation. The resulting nanocomposites find applications in advanced thermal management systems across various industries.Expand Specific Solutions

Key Industry Players

The thermal management of cellophane faces a competitive landscape in an emerging market with growing potential. The industry is in its early development stage, with market size expected to expand as demand for sustainable packaging solutions increases. Technical maturity varies among key players, with companies like Corning, Inc. and Saint-Gobain Isover G+H AG leading in material innovation. Hyundai Motor Co., Ltd. and Tesla, Inc. are exploring applications in the automotive sector, while Safran SA and General Electric Company focus on aerospace implementations. Emerging players like WATT Fuel Cell Corp. and Bramble Energy Ltd. are developing novel approaches, indicating a dynamic and evolving technological landscape with opportunities for breakthrough innovations.

Corning, Inc.

Technical Solution: Corning has developed advanced cellophane-based thermal management solutions for electronic devices. Their approach involves creating ultra-thin, flexible cellophane films with enhanced thermal conductivity. These films are engineered with nanoscale structures that efficiently dissipate heat while maintaining the transparency and flexibility of cellophane. Corning's technology incorporates heat-spreading layers within the cellophane structure, allowing for improved thermal distribution across the material's surface[1]. The company has also developed specialized coatings that can be applied to cellophane, further enhancing its heat transfer capabilities without compromising its other desirable properties[3].

Strengths: Expertise in materials science, particularly in thin films and coatings. Ability to maintain cellophane's transparency and flexibility while improving thermal properties. Weaknesses: Potential high production costs for advanced materials, which may limit widespread adoption.

Tesla, Inc.

Technical Solution: Tesla has pioneered innovative thermal management solutions for their electric vehicles, which can be adapted to cellophane-based systems. Their approach focuses on integrating cellophane materials into multi-layered thermal management structures. Tesla's technology utilizes cellophane's flexibility to create conformable heat-dissipating layers that can be applied to complex surfaces within their vehicles. The company has developed a proprietary method of treating cellophane to enhance its thermal conductivity while preserving its lightweight nature[2]. Tesla's system also incorporates active cooling elements that work in conjunction with the cellophane layers to provide dynamic thermal regulation in high-performance applications[5].

Strengths: Extensive experience in thermal management for high-performance electric vehicles. Ability to integrate cellophane into complex, multi-component systems. Weaknesses: Solutions may be overly specialized for automotive use, potentially limiting applicability in other industries.

Core Thermal Innovations

Battery and electric device

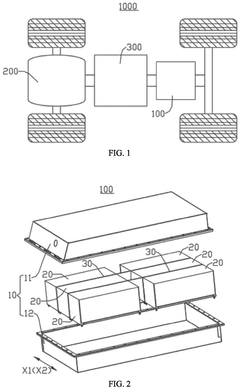

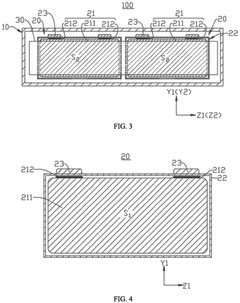

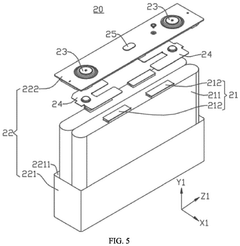

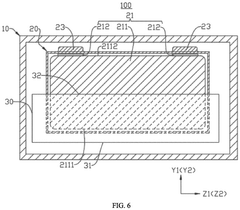

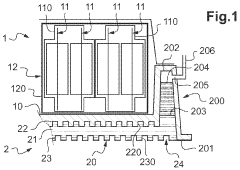

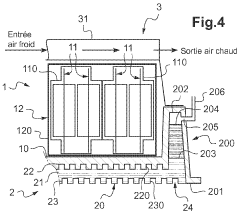

PatentPendingEP4517938A1

Innovation

- A battery design that incorporates a thermal management component overlapping with the battery cells, functioning as both a temperature regulator and a thermal insulation layer, to enhance space utilization and energy density.

Electric vehicle battery thermal management device

PatentWO2015001266A1

Innovation

- A thermal management device with an enclosure containing a phase change material and an expansion vessel to absorb volume changes, integrated with an active cooling system and heat exchange fins, allowing optimal thermal efficiency and pressure balance, maintaining battery temperature within an optimal range.

Environmental Impact

The environmental impact of cellophane thermal management is a critical consideration in the development and implementation of this technology. As the demand for efficient thermal management solutions grows, it is essential to assess the ecological footprint of cellophane-based systems throughout their lifecycle.

Cellophane, being a biodegradable material derived from renewable resources, offers several environmental advantages over traditional plastic-based thermal management solutions. Its production process typically involves less energy consumption and lower greenhouse gas emissions compared to synthetic polymers. Furthermore, the biodegradability of cellophane reduces the long-term environmental burden associated with waste disposal.

However, the environmental benefits of cellophane thermal management systems are not without challenges. The production of cellophane still requires significant water usage and may involve chemical treatments that can potentially impact local ecosystems if not properly managed. Additionally, the disposal of cellophane products, while biodegradable, may still contribute to short-term waste accumulation if not properly handled.

In terms of energy efficiency, cellophane thermal management systems have shown promising results in reducing overall energy consumption in various applications. By effectively regulating temperature and moisture, these systems can potentially decrease the need for energy-intensive cooling or heating processes in industries such as food packaging and electronics.

The recyclability of cellophane thermal management components is another crucial aspect to consider. While cellophane itself is biodegradable, the integration of other materials in thermal management systems may complicate the recycling process. Developing easily separable and recyclable components is essential for minimizing the environmental impact of these systems at the end of their lifecycle.

As the technology advances, there is a growing focus on enhancing the environmental performance of cellophane thermal management solutions. Research efforts are being directed towards improving the production processes to further reduce water and energy consumption. Additionally, innovations in bio-based additives and coatings are being explored to enhance the thermal properties of cellophane without compromising its environmental benefits.

The potential for cellophane thermal management to replace less environmentally friendly alternatives in various industries presents an opportunity for significant positive environmental impact. However, realizing this potential requires a holistic approach that considers the entire lifecycle of these systems, from raw material sourcing to end-of-life disposal.

Cellophane, being a biodegradable material derived from renewable resources, offers several environmental advantages over traditional plastic-based thermal management solutions. Its production process typically involves less energy consumption and lower greenhouse gas emissions compared to synthetic polymers. Furthermore, the biodegradability of cellophane reduces the long-term environmental burden associated with waste disposal.

However, the environmental benefits of cellophane thermal management systems are not without challenges. The production of cellophane still requires significant water usage and may involve chemical treatments that can potentially impact local ecosystems if not properly managed. Additionally, the disposal of cellophane products, while biodegradable, may still contribute to short-term waste accumulation if not properly handled.

In terms of energy efficiency, cellophane thermal management systems have shown promising results in reducing overall energy consumption in various applications. By effectively regulating temperature and moisture, these systems can potentially decrease the need for energy-intensive cooling or heating processes in industries such as food packaging and electronics.

The recyclability of cellophane thermal management components is another crucial aspect to consider. While cellophane itself is biodegradable, the integration of other materials in thermal management systems may complicate the recycling process. Developing easily separable and recyclable components is essential for minimizing the environmental impact of these systems at the end of their lifecycle.

As the technology advances, there is a growing focus on enhancing the environmental performance of cellophane thermal management solutions. Research efforts are being directed towards improving the production processes to further reduce water and energy consumption. Additionally, innovations in bio-based additives and coatings are being explored to enhance the thermal properties of cellophane without compromising its environmental benefits.

The potential for cellophane thermal management to replace less environmentally friendly alternatives in various industries presents an opportunity for significant positive environmental impact. However, realizing this potential requires a holistic approach that considers the entire lifecycle of these systems, from raw material sourcing to end-of-life disposal.

Cost-Benefit Analysis

When considering the implementation of thermal management solutions for cellophane, a comprehensive cost-benefit analysis is crucial to determine the economic viability and long-term value of such investments. The primary costs associated with enhancing cellophane's thermal management capabilities include research and development expenses, material costs for additives or coatings, and potential modifications to existing manufacturing processes. These upfront costs can be significant, especially for smaller manufacturers or those operating on tight margins.

However, the benefits of improved thermal management in cellophane can be substantial. Enhanced thermal properties can lead to increased product quality, reduced waste due to heat-related damage during production and transportation, and expanded applications in industries such as food packaging and electronics. This expansion into new markets can potentially offset initial investments through increased sales and market share.

Energy efficiency improvements resulting from better thermal management can lead to significant cost savings in the long run. Reduced energy consumption in manufacturing processes and during product use can lower operational costs and improve sustainability metrics, which is increasingly important for consumer perception and regulatory compliance. Additionally, improved thermal properties may extend the shelf life of packaged products, reducing spoilage and associated costs throughout the supply chain.

The potential for product differentiation and premium pricing should also be considered. Cellophane with superior thermal management properties may command higher prices in specialized markets, such as high-performance packaging or advanced industrial applications. This price premium can contribute to faster return on investment and higher profit margins.

Risk mitigation is another important factor in the cost-benefit equation. Improved thermal management can reduce the likelihood of product failures or recalls due to heat-related issues, potentially saving companies from significant financial and reputational damage. The long-term benefits of risk reduction, while difficult to quantify precisely, can be substantial.

When evaluating the cost-benefit ratio, it's essential to consider the time horizon for returns. While initial costs may be high, the cumulative benefits over the product lifecycle can often justify the investment. Companies should also factor in the potential for future cost reductions as technologies mature and economies of scale are achieved in production.

In conclusion, while the costs of implementing advanced thermal management solutions for cellophane can be significant, the potential benefits in terms of product performance, market expansion, energy savings, and risk reduction often outweigh these initial investments. A thorough analysis of both short-term costs and long-term benefits is crucial for making informed decisions about investing in cellophane thermal management technologies.

However, the benefits of improved thermal management in cellophane can be substantial. Enhanced thermal properties can lead to increased product quality, reduced waste due to heat-related damage during production and transportation, and expanded applications in industries such as food packaging and electronics. This expansion into new markets can potentially offset initial investments through increased sales and market share.

Energy efficiency improvements resulting from better thermal management can lead to significant cost savings in the long run. Reduced energy consumption in manufacturing processes and during product use can lower operational costs and improve sustainability metrics, which is increasingly important for consumer perception and regulatory compliance. Additionally, improved thermal properties may extend the shelf life of packaged products, reducing spoilage and associated costs throughout the supply chain.

The potential for product differentiation and premium pricing should also be considered. Cellophane with superior thermal management properties may command higher prices in specialized markets, such as high-performance packaging or advanced industrial applications. This price premium can contribute to faster return on investment and higher profit margins.

Risk mitigation is another important factor in the cost-benefit equation. Improved thermal management can reduce the likelihood of product failures or recalls due to heat-related issues, potentially saving companies from significant financial and reputational damage. The long-term benefits of risk reduction, while difficult to quantify precisely, can be substantial.

When evaluating the cost-benefit ratio, it's essential to consider the time horizon for returns. While initial costs may be high, the cumulative benefits over the product lifecycle can often justify the investment. Companies should also factor in the potential for future cost reductions as technologies mature and economies of scale are achieved in production.

In conclusion, while the costs of implementing advanced thermal management solutions for cellophane can be significant, the potential benefits in terms of product performance, market expansion, energy savings, and risk reduction often outweigh these initial investments. A thorough analysis of both short-term costs and long-term benefits is crucial for making informed decisions about investing in cellophane thermal management technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!