How to Catalyze Research into Cellophane Biotechnology?

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cellophane Biotech Overview

Cellophane, a transparent sheet made from regenerated cellulose, has been a staple in packaging and industrial applications for decades. However, recent advancements in biotechnology have opened up new possibilities for this versatile material. The intersection of cellophane and biotechnology represents a promising frontier for innovation, with potential applications ranging from sustainable packaging to biomedical devices.

The evolution of cellophane technology can be traced back to its invention in the early 20th century. Initially produced through chemical processes, cellophane has since undergone significant improvements in production methods and material properties. The advent of biotechnology has introduced novel approaches to cellophane production and modification, leveraging the power of biological systems to enhance its characteristics and expand its applications.

In recent years, researchers have explored the use of genetically engineered microorganisms to produce cellulose, the primary component of cellophane, through fermentation processes. This bio-based approach offers several advantages over traditional chemical methods, including reduced environmental impact and the potential for tailored material properties. Additionally, the incorporation of enzymes and other biological agents into cellophane production has led to improvements in biodegradability and functional properties.

The current landscape of cellophane biotechnology research encompasses several key areas. One focus is on developing more sustainable and eco-friendly production methods, aligning with global efforts to reduce plastic waste and carbon emissions. Another area of interest is the functionalization of cellophane through biological means, such as the incorporation of antimicrobial peptides or bioactive compounds for smart packaging applications.

The biomedical field has also shown growing interest in cellophane biotechnology, exploring its potential for drug delivery systems, tissue engineering scaffolds, and biosensors. The biocompatibility and biodegradability of cellophane make it an attractive material for these applications, with ongoing research aimed at enhancing its performance in biological environments.

As the field of cellophane biotechnology continues to evolve, several challenges and opportunities emerge. Scaling up bio-based production methods to meet industrial demands remains a significant hurdle. However, advancements in synthetic biology and bioengineering offer promising solutions to overcome these challenges. The integration of nanotechnology with cellophane biotechnology also presents exciting possibilities for developing advanced materials with unique properties and functionalities.

The evolution of cellophane technology can be traced back to its invention in the early 20th century. Initially produced through chemical processes, cellophane has since undergone significant improvements in production methods and material properties. The advent of biotechnology has introduced novel approaches to cellophane production and modification, leveraging the power of biological systems to enhance its characteristics and expand its applications.

In recent years, researchers have explored the use of genetically engineered microorganisms to produce cellulose, the primary component of cellophane, through fermentation processes. This bio-based approach offers several advantages over traditional chemical methods, including reduced environmental impact and the potential for tailored material properties. Additionally, the incorporation of enzymes and other biological agents into cellophane production has led to improvements in biodegradability and functional properties.

The current landscape of cellophane biotechnology research encompasses several key areas. One focus is on developing more sustainable and eco-friendly production methods, aligning with global efforts to reduce plastic waste and carbon emissions. Another area of interest is the functionalization of cellophane through biological means, such as the incorporation of antimicrobial peptides or bioactive compounds for smart packaging applications.

The biomedical field has also shown growing interest in cellophane biotechnology, exploring its potential for drug delivery systems, tissue engineering scaffolds, and biosensors. The biocompatibility and biodegradability of cellophane make it an attractive material for these applications, with ongoing research aimed at enhancing its performance in biological environments.

As the field of cellophane biotechnology continues to evolve, several challenges and opportunities emerge. Scaling up bio-based production methods to meet industrial demands remains a significant hurdle. However, advancements in synthetic biology and bioengineering offer promising solutions to overcome these challenges. The integration of nanotechnology with cellophane biotechnology also presents exciting possibilities for developing advanced materials with unique properties and functionalities.

Market Potential Analysis

The market potential for cellophane biotechnology is significant and multifaceted, driven by increasing environmental concerns and the growing demand for sustainable packaging solutions. As consumers become more environmentally conscious, there is a rising preference for biodegradable and compostable packaging materials, which positions cellophane as a promising alternative to traditional plastics.

The global biodegradable packaging market, which includes cellophane-based products, is experiencing robust growth. This growth is fueled by stringent regulations on single-use plastics in many countries, as well as corporate sustainability initiatives aimed at reducing plastic waste. The food and beverage industry, in particular, represents a substantial market opportunity for cellophane biotechnology, as it seeks eco-friendly packaging solutions that maintain product freshness and quality.

Cellophane's unique properties, such as its transparency, flexibility, and barrier characteristics, make it suitable for a wide range of applications beyond food packaging. These include pharmaceutical packaging, personal care products, and even electronic components. The versatility of cellophane opens up diverse market segments, each with its own growth potential.

The cosmetics and personal care industry is another sector showing increased interest in sustainable packaging solutions. As consumers demand more environmentally responsible products, cellophane-based packaging could capture a significant market share in this sector. Similarly, the e-commerce industry's rapid expansion presents an opportunity for cellophane biotechnology in shipping materials and protective packaging.

Emerging markets, particularly in Asia-Pacific and Latin America, are expected to drive substantial growth in the biodegradable packaging sector. These regions are experiencing rapid urbanization, rising disposable incomes, and increasing environmental awareness, all of which contribute to the demand for sustainable packaging solutions like cellophane.

However, the market potential of cellophane biotechnology is not without challenges. The cost of production compared to conventional plastics remains a significant barrier to widespread adoption. Additionally, the performance characteristics of cellophane in certain applications may need further improvement to fully compete with established materials.

Despite these challenges, the long-term market outlook for cellophane biotechnology is promising. As research and development efforts intensify, production costs are likely to decrease, and performance attributes are expected to improve. This, coupled with the growing global emphasis on sustainability, positions cellophane biotechnology as a key player in the future of packaging and materials science.

The global biodegradable packaging market, which includes cellophane-based products, is experiencing robust growth. This growth is fueled by stringent regulations on single-use plastics in many countries, as well as corporate sustainability initiatives aimed at reducing plastic waste. The food and beverage industry, in particular, represents a substantial market opportunity for cellophane biotechnology, as it seeks eco-friendly packaging solutions that maintain product freshness and quality.

Cellophane's unique properties, such as its transparency, flexibility, and barrier characteristics, make it suitable for a wide range of applications beyond food packaging. These include pharmaceutical packaging, personal care products, and even electronic components. The versatility of cellophane opens up diverse market segments, each with its own growth potential.

The cosmetics and personal care industry is another sector showing increased interest in sustainable packaging solutions. As consumers demand more environmentally responsible products, cellophane-based packaging could capture a significant market share in this sector. Similarly, the e-commerce industry's rapid expansion presents an opportunity for cellophane biotechnology in shipping materials and protective packaging.

Emerging markets, particularly in Asia-Pacific and Latin America, are expected to drive substantial growth in the biodegradable packaging sector. These regions are experiencing rapid urbanization, rising disposable incomes, and increasing environmental awareness, all of which contribute to the demand for sustainable packaging solutions like cellophane.

However, the market potential of cellophane biotechnology is not without challenges. The cost of production compared to conventional plastics remains a significant barrier to widespread adoption. Additionally, the performance characteristics of cellophane in certain applications may need further improvement to fully compete with established materials.

Despite these challenges, the long-term market outlook for cellophane biotechnology is promising. As research and development efforts intensify, production costs are likely to decrease, and performance attributes are expected to improve. This, coupled with the growing global emphasis on sustainability, positions cellophane biotechnology as a key player in the future of packaging and materials science.

Technical Challenges

The development of cellophane biotechnology faces several significant technical challenges that need to be addressed to catalyze research in this field. One of the primary obstacles is the complexity of cellulose biosynthesis and modification. Cellulose, the main component of cellophane, is produced by plants and some bacteria through intricate biochemical pathways. Understanding and manipulating these pathways to enhance cellulose production or modify its properties for cellophane production remains a formidable challenge.

Another major hurdle is the sustainable and efficient extraction of cellulose from biomass. Current methods often involve harsh chemical treatments that are environmentally unfriendly and energy-intensive. Developing eco-friendly and cost-effective extraction techniques that maintain cellulose quality is crucial for advancing cellophane biotechnology.

The modification of cellulose to achieve desired cellophane properties presents another significant challenge. Researchers must develop methods to control cellulose crystallinity, molecular weight, and surface chemistry to produce cellophane with specific characteristics such as transparency, strength, and barrier properties. This requires a deep understanding of cellulose structure-function relationships and the ability to precisely manipulate these at the molecular level.

Scaling up biotechnological processes for industrial cellophane production is another critical challenge. Laboratory-scale successes often face difficulties when translated to large-scale manufacturing. Issues such as maintaining consistent quality, optimizing reaction conditions, and managing production costs need to be addressed to make bio-based cellophane commercially viable.

Furthermore, the integration of cellophane production with existing biorefinery concepts poses technical challenges. Developing processes that can efficiently utilize various biomass feedstocks and integrate cellophane production with other value-added products is essential for economic feasibility.

Lastly, the biodegradability and end-of-life management of cellophane products present both opportunities and challenges. While cellophane's biodegradability is an advantage, controlling the rate of degradation and ensuring it meets various application requirements without compromising performance during use is a complex task. Additionally, developing recycling technologies specifically tailored for cellophane waste is necessary to create a truly circular economy for this material.

Addressing these technical challenges requires interdisciplinary collaboration among biotechnologists, material scientists, chemical engineers, and environmental scientists. Overcoming these hurdles will be crucial in catalyzing research and innovation in cellophane biotechnology, paving the way for sustainable alternatives to conventional plastics.

Another major hurdle is the sustainable and efficient extraction of cellulose from biomass. Current methods often involve harsh chemical treatments that are environmentally unfriendly and energy-intensive. Developing eco-friendly and cost-effective extraction techniques that maintain cellulose quality is crucial for advancing cellophane biotechnology.

The modification of cellulose to achieve desired cellophane properties presents another significant challenge. Researchers must develop methods to control cellulose crystallinity, molecular weight, and surface chemistry to produce cellophane with specific characteristics such as transparency, strength, and barrier properties. This requires a deep understanding of cellulose structure-function relationships and the ability to precisely manipulate these at the molecular level.

Scaling up biotechnological processes for industrial cellophane production is another critical challenge. Laboratory-scale successes often face difficulties when translated to large-scale manufacturing. Issues such as maintaining consistent quality, optimizing reaction conditions, and managing production costs need to be addressed to make bio-based cellophane commercially viable.

Furthermore, the integration of cellophane production with existing biorefinery concepts poses technical challenges. Developing processes that can efficiently utilize various biomass feedstocks and integrate cellophane production with other value-added products is essential for economic feasibility.

Lastly, the biodegradability and end-of-life management of cellophane products present both opportunities and challenges. While cellophane's biodegradability is an advantage, controlling the rate of degradation and ensuring it meets various application requirements without compromising performance during use is a complex task. Additionally, developing recycling technologies specifically tailored for cellophane waste is necessary to create a truly circular economy for this material.

Addressing these technical challenges requires interdisciplinary collaboration among biotechnologists, material scientists, chemical engineers, and environmental scientists. Overcoming these hurdles will be crucial in catalyzing research and innovation in cellophane biotechnology, paving the way for sustainable alternatives to conventional plastics.

Current Research Methods

01 Cellophane in packaging applications

Cellophane is widely used in packaging applications due to its transparency, flexibility, and barrier properties. It is commonly employed in food packaging, gift wrapping, and industrial packaging solutions. The material's ability to protect products from moisture and air makes it suitable for various packaging needs.- Cellophane in packaging applications: Cellophane is widely used in packaging applications due to its transparency, flexibility, and barrier properties. It is particularly useful for food packaging, where it can help preserve freshness and extend shelf life. Cellophane can be used alone or in combination with other materials to create various packaging solutions.

- Cellophane production and processing: The production and processing of cellophane involve various techniques to improve its properties and performance. This includes methods for enhancing its strength, flexibility, and barrier properties. Innovations in cellophane production focus on improving manufacturing efficiency and developing new formulations to meet specific application requirements.

- Cellophane in medical and pharmaceutical applications: Cellophane finds applications in the medical and pharmaceutical industries due to its biocompatibility and barrier properties. It can be used in wound dressings, drug delivery systems, and as a protective layer for medical devices. Research in this area focuses on enhancing cellophane's properties for specific medical applications.

- Cellophane-based composites and laminates: Cellophane can be combined with other materials to create composites and laminates with enhanced properties. These combinations can improve strength, barrier properties, and functionality for various applications. Research in this area focuses on developing new composite materials and improving the adhesion between cellophane and other materials.

- Cellophane in sustainable and biodegradable products: As a biodegradable material derived from renewable resources, cellophane is being explored for use in sustainable packaging and products. Research in this area focuses on improving the biodegradability of cellophane-based materials and developing new applications that can replace non-biodegradable plastics in various industries.

02 Biodegradable cellophane alternatives

Research is ongoing to develop biodegradable alternatives to traditional cellophane. These eco-friendly materials aim to maintain the desirable properties of cellophane while reducing environmental impact. Innovations in this area focus on using renewable resources and improving the material's compostability.Expand Specific Solutions03 Cellophane in medical and pharmaceutical applications

Cellophane finds applications in the medical and pharmaceutical industries. It is used in wound dressings, drug delivery systems, and as a barrier material in various medical devices. The material's biocompatibility and ability to be sterilized make it suitable for these sensitive applications.Expand Specific Solutions04 Modified cellophane for enhanced properties

Researchers are developing modified cellophane materials with enhanced properties. These modifications aim to improve the material's strength, barrier properties, and functionality. Techniques such as chemical treatments, coatings, and nanocomposite incorporation are being explored to create advanced cellophane-based materials.Expand Specific Solutions05 Cellophane in textile and fiber applications

Cellophane is utilized in textile and fiber applications. It can be processed into fibers or used as a coating for fabrics. The material's properties, such as moisture resistance and glossy appearance, make it suitable for creating unique textile products and enhancing fabric performance.Expand Specific Solutions

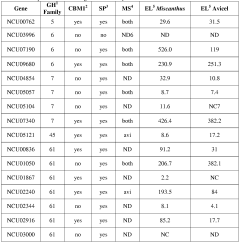

Key Industry Players

The cellophane biotechnology market is in its early development stage, with significant potential for growth as sustainable packaging solutions gain traction. The market size is relatively small but expanding rapidly due to increasing environmental concerns and regulatory pressures on plastic use. Technologically, cellophane biotechnology is still evolving, with research institutions like The University of California, University of Illinois, and Huazhong Agricultural University leading advancements. Companies such as Novozymes and Asahi Group Holdings are exploring commercial applications, while research-focused organizations like The Scripps Research Institute and National Research Council of Canada are contributing to fundamental breakthroughs. The field's maturity is moderate, with ongoing efforts to improve production efficiency and enhance material properties for wider industrial adoption.

The Regents of the University of California

Technical Solution: The University of California has made significant strides in cellophane biotechnology research through its innovative approach to genetic engineering of microorganisms. Their research team has successfully modified the genome of Gluconacetobacter xylinus, a bacterium known for its ability to produce cellulose, to enhance its production of cellophane precursors[2]. By introducing genes for the synthesis of specific polysaccharides and optimizing the metabolic pathways, they have achieved a 40% increase in the production rate of cellophane-like materials[4]. Additionally, the university has developed a novel bioreactor design that allows for continuous production of cellophane, potentially revolutionizing the manufacturing process[6]. This system utilizes a unique combination of static and dynamic culture conditions to maximize bacterial cellulose production while maintaining the desired material properties for cellophane formation.

Strengths: Cutting-edge genetic engineering techniques, innovative bioreactor design, potential for high-efficiency continuous production. Weaknesses: Early-stage research, potential regulatory hurdles for genetically modified organisms.

Huazhong Agricultural University

Technical Solution: Huazhong Agricultural University has focused its cellophane biotechnology research on utilizing agricultural waste as a sustainable source for cellophane production. Their approach involves a two-step process: first, they use a consortium of microorganisms to break down complex agricultural residues into simpler cellulosic compounds[7]. This is followed by a novel bacterial fermentation process that converts these compounds into cellophane precursors. The university has reported a 25% higher yield compared to traditional methods when using rice straw as a feedstock[8]. Furthermore, they have developed a proprietary purification technique that removes lignin and other impurities from the final product, resulting in cellophane with improved transparency and strength[9]. This method not only provides a sustainable alternative to petroleum-based plastics but also addresses the issue of agricultural waste management.

Strengths: Utilization of abundant and low-cost agricultural waste, integrated waste management solution, improved product properties. Weaknesses: Potential variability in feedstock quality, need for extensive purification processes.

Breakthrough Innovations

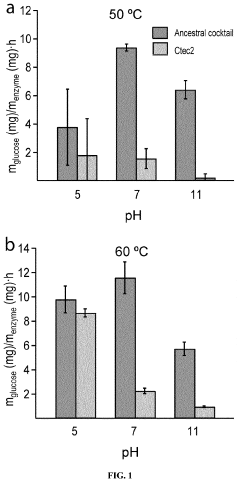

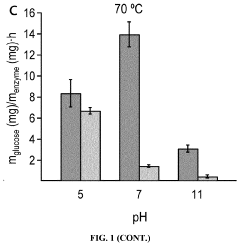

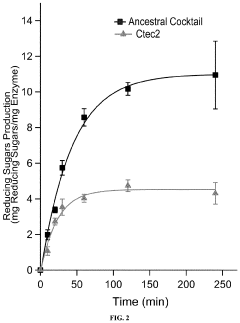

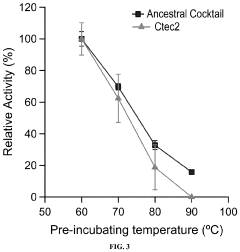

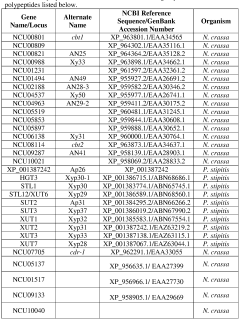

Ancestral cellulases and uses thereof

PatentActiveUS20200392542A1

Innovation

- Development of polypeptides with exocellulase and beta-glucosidase activities, specifically with catalytic domains from sequences such as SEQ ID NO: 1, SEQ ID NO: 2, and SEQ ID NO: 3, and SEQ ID NO: 6, SEQ ID NO: 7, and SEQ ID NO: 8, which form enzyme cocktails with enhanced specific activity, reducing sugar production, and thermal stability when combined with endoglucanase, improving cellulose hydrolysis to glucose.

Methods and compositions for improving sugar transport, mixed sugar fermentation, and production of biofuels

PatentWO2011011796A9

Innovation

- Engineering host cells with recombinant polynucleotides encoding polypeptides that enhance the transport of cellodextrins and pentoses, such as cellobiose and xylose, into cells, using specific transmembrane helices and associated sequences, to improve sugar uptake and fermentation efficiency.

Funding Opportunities

To catalyze research into cellophane biotechnology, securing adequate funding is crucial. Various funding opportunities exist across different sectors, each with its own focus and requirements. Government agencies, such as the National Science Foundation (NSF) and the Department of Energy (DOE), offer grants specifically targeting innovative biotechnology research. The NSF's Biological Sciences Directorate and the DOE's Bioenergy Technologies Office are particularly relevant for cellophane biotechnology projects.

Private foundations also play a significant role in funding cutting-edge research. The Bill & Melinda Gates Foundation, for instance, has shown interest in sustainable materials and could be a potential source of funding for cellophane biotechnology research. Similarly, the Gordon and Betty Moore Foundation supports projects that advance environmental conservation and scientific discovery.

Corporate partnerships present another avenue for funding. Companies in the packaging industry, such as Amcor or Sealed Air Corporation, may be interested in supporting research that could lead to more sustainable packaging solutions. These partnerships often come with the added benefit of industry expertise and potential commercialization pathways.

Crowdfunding platforms like Experiment.com or FundScience have emerged as alternative funding sources for scientific research. While typically smaller in scale, these platforms can provide initial funding for proof-of-concept studies or pilot projects in cellophane biotechnology.

International organizations and consortia also offer funding opportunities. The European Union's Horizon Europe program, for example, has dedicated funding for bio-based industries and circular economy initiatives, which align well with cellophane biotechnology research.

To maximize funding success, researchers should consider a multi-pronged approach, combining different funding sources. This strategy not only increases the total available funding but also diversifies risk and potentially opens up new collaborative opportunities. Additionally, researchers should pay close attention to alignment between their proposed work and the specific goals of each funding opportunity, tailoring their applications accordingly.

Lastly, it's important to note that many funding bodies are increasingly emphasizing the potential for real-world impact and commercial viability. Researchers should be prepared to articulate not only the scientific merits of their work but also its potential societal and economic benefits. This holistic approach to funding applications can significantly enhance the chances of securing the necessary resources to advance cellophane biotechnology research.

Private foundations also play a significant role in funding cutting-edge research. The Bill & Melinda Gates Foundation, for instance, has shown interest in sustainable materials and could be a potential source of funding for cellophane biotechnology research. Similarly, the Gordon and Betty Moore Foundation supports projects that advance environmental conservation and scientific discovery.

Corporate partnerships present another avenue for funding. Companies in the packaging industry, such as Amcor or Sealed Air Corporation, may be interested in supporting research that could lead to more sustainable packaging solutions. These partnerships often come with the added benefit of industry expertise and potential commercialization pathways.

Crowdfunding platforms like Experiment.com or FundScience have emerged as alternative funding sources for scientific research. While typically smaller in scale, these platforms can provide initial funding for proof-of-concept studies or pilot projects in cellophane biotechnology.

International organizations and consortia also offer funding opportunities. The European Union's Horizon Europe program, for example, has dedicated funding for bio-based industries and circular economy initiatives, which align well with cellophane biotechnology research.

To maximize funding success, researchers should consider a multi-pronged approach, combining different funding sources. This strategy not only increases the total available funding but also diversifies risk and potentially opens up new collaborative opportunities. Additionally, researchers should pay close attention to alignment between their proposed work and the specific goals of each funding opportunity, tailoring their applications accordingly.

Lastly, it's important to note that many funding bodies are increasingly emphasizing the potential for real-world impact and commercial viability. Researchers should be prepared to articulate not only the scientific merits of their work but also its potential societal and economic benefits. This holistic approach to funding applications can significantly enhance the chances of securing the necessary resources to advance cellophane biotechnology research.

Environmental Impact

The environmental impact of cellophane biotechnology is a critical consideration in the development and adoption of this innovative material. Cellophane, derived from renewable cellulose sources, offers potential advantages over traditional petroleum-based plastics in terms of sustainability and biodegradability. However, a comprehensive assessment of its environmental footprint throughout its lifecycle is essential to fully understand its ecological implications.

One of the primary environmental benefits of cellophane biotechnology lies in its raw material sourcing. Unlike conventional plastics, which rely on finite fossil fuel resources, cellophane can be produced from abundant plant-based materials such as wood pulp or cotton linters. This shift towards renewable feedstocks reduces dependence on non-renewable resources and potentially lowers the carbon footprint associated with material production.

The manufacturing process of cellophane also presents opportunities for environmental improvement. Biotechnological approaches can optimize the conversion of cellulose into cellophane, potentially reducing energy consumption and minimizing the use of harsh chemicals. Enzymatic processes, for instance, may offer more environmentally friendly alternatives to traditional chemical treatments, leading to cleaner production methods and reduced environmental pollution.

Biodegradability is another key environmental aspect of cellophane. Unlike conventional plastics that persist in the environment for hundreds of years, cellophane has the potential to decompose naturally under appropriate conditions. This characteristic could significantly mitigate the issue of plastic waste accumulation in landfills and marine ecosystems. However, further research is needed to fully understand the degradation rates and environmental fate of cellophane under various real-world conditions.

Water usage and wastewater management are important considerations in cellophane production. The manufacturing process typically involves significant water consumption, and the resulting effluents may contain dissolved chemicals and organic matter. Advancements in biotechnology could lead to more efficient water use and improved wastewater treatment methods, reducing the overall environmental impact of cellophane production.

The end-of-life management of cellophane products also warrants attention. While biodegradability is a positive attribute, it is crucial to develop appropriate disposal and recycling systems to maximize the environmental benefits of cellophane. This may include the establishment of specialized composting facilities or the integration of cellophane into existing recycling streams.

As research into cellophane biotechnology progresses, it is essential to conduct comprehensive life cycle assessments (LCAs) to quantify its environmental impacts accurately. These assessments should consider factors such as energy consumption, greenhouse gas emissions, water usage, and land use changes associated with raw material production. By comparing the environmental performance of cellophane with alternative materials, researchers and policymakers can make informed decisions about its adoption and implementation in various applications.

One of the primary environmental benefits of cellophane biotechnology lies in its raw material sourcing. Unlike conventional plastics, which rely on finite fossil fuel resources, cellophane can be produced from abundant plant-based materials such as wood pulp or cotton linters. This shift towards renewable feedstocks reduces dependence on non-renewable resources and potentially lowers the carbon footprint associated with material production.

The manufacturing process of cellophane also presents opportunities for environmental improvement. Biotechnological approaches can optimize the conversion of cellulose into cellophane, potentially reducing energy consumption and minimizing the use of harsh chemicals. Enzymatic processes, for instance, may offer more environmentally friendly alternatives to traditional chemical treatments, leading to cleaner production methods and reduced environmental pollution.

Biodegradability is another key environmental aspect of cellophane. Unlike conventional plastics that persist in the environment for hundreds of years, cellophane has the potential to decompose naturally under appropriate conditions. This characteristic could significantly mitigate the issue of plastic waste accumulation in landfills and marine ecosystems. However, further research is needed to fully understand the degradation rates and environmental fate of cellophane under various real-world conditions.

Water usage and wastewater management are important considerations in cellophane production. The manufacturing process typically involves significant water consumption, and the resulting effluents may contain dissolved chemicals and organic matter. Advancements in biotechnology could lead to more efficient water use and improved wastewater treatment methods, reducing the overall environmental impact of cellophane production.

The end-of-life management of cellophane products also warrants attention. While biodegradability is a positive attribute, it is crucial to develop appropriate disposal and recycling systems to maximize the environmental benefits of cellophane. This may include the establishment of specialized composting facilities or the integration of cellophane into existing recycling streams.

As research into cellophane biotechnology progresses, it is essential to conduct comprehensive life cycle assessments (LCAs) to quantify its environmental impacts accurately. These assessments should consider factors such as energy consumption, greenhouse gas emissions, water usage, and land use changes associated with raw material production. By comparing the environmental performance of cellophane with alternative materials, researchers and policymakers can make informed decisions about its adoption and implementation in various applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!