How to Innovate Anti-Microbial Capabilities in Cellophane?

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cellophane Antimicrobial Innovation Background

Cellophane, a transparent film made from regenerated cellulose, has been a staple in packaging and various industrial applications since its invention in the early 20th century. Its versatility, transparency, and biodegradability have made it a popular choice across multiple sectors. However, as consumer demands and environmental concerns evolve, there is a growing need for innovative solutions that can enhance cellophane's functionality, particularly in the realm of antimicrobial properties.

The quest for antimicrobial capabilities in cellophane stems from the increasing awareness of foodborne illnesses and the need for extended shelf life in packaged goods. Traditional cellophane, while effective as a barrier against moisture and air, lacks inherent antimicrobial properties. This limitation has become a focal point for research and development efforts in recent years, as manufacturers seek to address food safety concerns and reduce product waste.

The innovation of antimicrobial cellophane aligns with broader trends in smart packaging and sustainable materials. As the global population grows and urbanization increases, the demand for safe, long-lasting food packaging solutions has surged. Simultaneously, there is a push towards reducing synthetic additives and finding more natural, biodegradable alternatives for antimicrobial protection.

Recent advancements in nanotechnology and biomaterials have opened new avenues for enhancing cellophane's properties. Researchers are exploring various approaches, including the incorporation of natural antimicrobial agents, such as essential oils and plant extracts, as well as the integration of nanoparticles with antimicrobial properties. These innovations aim to create a new generation of cellophane that not only maintains its traditional benefits but also actively inhibits the growth of harmful microorganisms.

The development of antimicrobial cellophane also intersects with the circular economy concept, as it potentially extends the life cycle of packaged products and reduces food waste. This aligns with global sustainability goals and addresses consumer preferences for eco-friendly packaging solutions that do not compromise on functionality or safety.

As we delve into the specifics of innovating antimicrobial capabilities in cellophane, it is crucial to consider the regulatory landscape, market demands, and technological feasibility. The challenge lies in developing solutions that are effective, safe for consumer use, economically viable, and environmentally sustainable. This multifaceted approach to innovation sets the stage for a comprehensive exploration of potential strategies and their implications for the packaging industry and beyond.

The quest for antimicrobial capabilities in cellophane stems from the increasing awareness of foodborne illnesses and the need for extended shelf life in packaged goods. Traditional cellophane, while effective as a barrier against moisture and air, lacks inherent antimicrobial properties. This limitation has become a focal point for research and development efforts in recent years, as manufacturers seek to address food safety concerns and reduce product waste.

The innovation of antimicrobial cellophane aligns with broader trends in smart packaging and sustainable materials. As the global population grows and urbanization increases, the demand for safe, long-lasting food packaging solutions has surged. Simultaneously, there is a push towards reducing synthetic additives and finding more natural, biodegradable alternatives for antimicrobial protection.

Recent advancements in nanotechnology and biomaterials have opened new avenues for enhancing cellophane's properties. Researchers are exploring various approaches, including the incorporation of natural antimicrobial agents, such as essential oils and plant extracts, as well as the integration of nanoparticles with antimicrobial properties. These innovations aim to create a new generation of cellophane that not only maintains its traditional benefits but also actively inhibits the growth of harmful microorganisms.

The development of antimicrobial cellophane also intersects with the circular economy concept, as it potentially extends the life cycle of packaged products and reduces food waste. This aligns with global sustainability goals and addresses consumer preferences for eco-friendly packaging solutions that do not compromise on functionality or safety.

As we delve into the specifics of innovating antimicrobial capabilities in cellophane, it is crucial to consider the regulatory landscape, market demands, and technological feasibility. The challenge lies in developing solutions that are effective, safe for consumer use, economically viable, and environmentally sustainable. This multifaceted approach to innovation sets the stage for a comprehensive exploration of potential strategies and their implications for the packaging industry and beyond.

Market Demand Analysis

The market demand for innovative anti-microbial capabilities in cellophane has been steadily growing, driven by increasing consumer awareness of hygiene and food safety. This trend has been further accelerated by the global pandemic, which has heightened concerns about surface contamination and the spread of pathogens.

In the food packaging industry, there is a significant push towards extending shelf life and maintaining product freshness. Anti-microbial cellophane offers a solution to these challenges by inhibiting the growth of bacteria, molds, and other microorganisms that cause food spoilage. This capability is particularly valuable for perishable goods such as fresh produce, meats, and dairy products.

The healthcare sector represents another substantial market for anti-microbial cellophane. Hospitals, clinics, and other medical facilities are constantly seeking ways to reduce the risk of hospital-acquired infections. Anti-microbial packaging for medical devices, instruments, and supplies can play a crucial role in maintaining sterility and preventing cross-contamination.

Consumer goods manufacturers are also showing increased interest in anti-microbial cellophane for packaging personal care products, cosmetics, and household items. This demand is driven by consumers' desire for products that stay fresh longer and maintain their integrity throughout their shelf life.

The global market for active and intelligent packaging, which includes anti-microbial packaging, is experiencing robust growth. This sector is expected to continue expanding as companies invest in research and development to create more effective and sustainable anti-microbial solutions for cellophane.

Environmental concerns are shaping market demand as well. Consumers and regulatory bodies are pushing for more sustainable packaging options. As a result, there is a growing interest in biodegradable or compostable anti-microbial cellophane that can offer both protective properties and environmental benefits.

The e-commerce boom has further fueled the demand for anti-microbial packaging. With more products being shipped directly to consumers, there is an increased need for packaging that can protect goods from microbial contamination during transit and storage.

Geographically, developed markets in North America and Europe are currently leading the demand for anti-microbial cellophane. However, rapid urbanization and rising disposable incomes in emerging economies, particularly in Asia-Pacific and Latin America, are expected to drive significant market growth in these regions in the coming years.

As the technology advances, there is potential for expanding the application of anti-microbial cellophane beyond traditional packaging. Innovative uses in agriculture, textiles, and construction materials are being explored, potentially opening up new market segments and driving further demand for this technology.

In the food packaging industry, there is a significant push towards extending shelf life and maintaining product freshness. Anti-microbial cellophane offers a solution to these challenges by inhibiting the growth of bacteria, molds, and other microorganisms that cause food spoilage. This capability is particularly valuable for perishable goods such as fresh produce, meats, and dairy products.

The healthcare sector represents another substantial market for anti-microbial cellophane. Hospitals, clinics, and other medical facilities are constantly seeking ways to reduce the risk of hospital-acquired infections. Anti-microbial packaging for medical devices, instruments, and supplies can play a crucial role in maintaining sterility and preventing cross-contamination.

Consumer goods manufacturers are also showing increased interest in anti-microbial cellophane for packaging personal care products, cosmetics, and household items. This demand is driven by consumers' desire for products that stay fresh longer and maintain their integrity throughout their shelf life.

The global market for active and intelligent packaging, which includes anti-microbial packaging, is experiencing robust growth. This sector is expected to continue expanding as companies invest in research and development to create more effective and sustainable anti-microbial solutions for cellophane.

Environmental concerns are shaping market demand as well. Consumers and regulatory bodies are pushing for more sustainable packaging options. As a result, there is a growing interest in biodegradable or compostable anti-microbial cellophane that can offer both protective properties and environmental benefits.

The e-commerce boom has further fueled the demand for anti-microbial packaging. With more products being shipped directly to consumers, there is an increased need for packaging that can protect goods from microbial contamination during transit and storage.

Geographically, developed markets in North America and Europe are currently leading the demand for anti-microbial cellophane. However, rapid urbanization and rising disposable incomes in emerging economies, particularly in Asia-Pacific and Latin America, are expected to drive significant market growth in these regions in the coming years.

As the technology advances, there is potential for expanding the application of anti-microbial cellophane beyond traditional packaging. Innovative uses in agriculture, textiles, and construction materials are being explored, potentially opening up new market segments and driving further demand for this technology.

Current Antimicrobial Cellophane Technologies

Current antimicrobial cellophane technologies have made significant strides in addressing the growing demand for advanced packaging solutions that can inhibit microbial growth and extend product shelf life. The most prevalent approach involves incorporating antimicrobial agents directly into the cellophane matrix during the manufacturing process. This method ensures a uniform distribution of the active compounds throughout the material, providing long-lasting protection against a broad spectrum of microorganisms.

One of the leading technologies in this field utilizes silver nanoparticles as the primary antimicrobial agent. These nanoparticles are highly effective against bacteria, fungi, and certain viruses, making them ideal for food packaging applications. The silver ions released from the nanoparticles interfere with the cellular processes of microorganisms, inhibiting their growth and reproduction. This technology has shown remarkable efficacy in preserving perishable goods and reducing food waste.

Another prominent solution involves the use of natural antimicrobial compounds derived from plant extracts. Essential oils such as thyme, oregano, and cinnamon have demonstrated potent antimicrobial properties when incorporated into cellophane films. These natural alternatives appeal to consumers seeking eco-friendly and chemical-free packaging options. The volatile compounds in these essential oils disrupt the cell membranes of microorganisms, effectively inhibiting their growth on the packaged products.

Zinc oxide nanoparticles have also emerged as a promising antimicrobial agent for cellophane packaging. These nanoparticles exhibit broad-spectrum antimicrobial activity and are particularly effective against foodborne pathogens. The mechanism of action involves the generation of reactive oxygen species that damage microbial cell structures. Zinc oxide nanoparticles offer the added advantage of being generally recognized as safe (GRAS) by regulatory authorities, facilitating their adoption in food packaging applications.

Recent advancements in polymer science have led to the development of antimicrobial cellophane films with controlled release properties. These innovative materials incorporate antimicrobial agents within a secondary polymer matrix, allowing for a sustained and gradual release of the active compounds. This approach extends the effective lifespan of the antimicrobial properties and provides better protection against microbial contamination over prolonged periods.

Photocatalytic antimicrobial cellophane represents another cutting-edge technology in this field. By incorporating titanium dioxide nanoparticles into the cellophane structure, these materials can generate reactive oxygen species when exposed to light. This creates a self-cleaning surface that continuously combats microbial growth, even in challenging environmental conditions. The photocatalytic effect offers an additional layer of protection, particularly in applications where the packaging may be exposed to light during storage or display.

One of the leading technologies in this field utilizes silver nanoparticles as the primary antimicrobial agent. These nanoparticles are highly effective against bacteria, fungi, and certain viruses, making them ideal for food packaging applications. The silver ions released from the nanoparticles interfere with the cellular processes of microorganisms, inhibiting their growth and reproduction. This technology has shown remarkable efficacy in preserving perishable goods and reducing food waste.

Another prominent solution involves the use of natural antimicrobial compounds derived from plant extracts. Essential oils such as thyme, oregano, and cinnamon have demonstrated potent antimicrobial properties when incorporated into cellophane films. These natural alternatives appeal to consumers seeking eco-friendly and chemical-free packaging options. The volatile compounds in these essential oils disrupt the cell membranes of microorganisms, effectively inhibiting their growth on the packaged products.

Zinc oxide nanoparticles have also emerged as a promising antimicrobial agent for cellophane packaging. These nanoparticles exhibit broad-spectrum antimicrobial activity and are particularly effective against foodborne pathogens. The mechanism of action involves the generation of reactive oxygen species that damage microbial cell structures. Zinc oxide nanoparticles offer the added advantage of being generally recognized as safe (GRAS) by regulatory authorities, facilitating their adoption in food packaging applications.

Recent advancements in polymer science have led to the development of antimicrobial cellophane films with controlled release properties. These innovative materials incorporate antimicrobial agents within a secondary polymer matrix, allowing for a sustained and gradual release of the active compounds. This approach extends the effective lifespan of the antimicrobial properties and provides better protection against microbial contamination over prolonged periods.

Photocatalytic antimicrobial cellophane represents another cutting-edge technology in this field. By incorporating titanium dioxide nanoparticles into the cellophane structure, these materials can generate reactive oxygen species when exposed to light. This creates a self-cleaning surface that continuously combats microbial growth, even in challenging environmental conditions. The photocatalytic effect offers an additional layer of protection, particularly in applications where the packaging may be exposed to light during storage or display.

Existing Antimicrobial Cellophane Solutions

01 Incorporation of antimicrobial agents in cellophane

Cellophane can be enhanced with antimicrobial properties by incorporating various antimicrobial agents into the material during production or as a surface treatment. These agents can include silver compounds, organic acids, or natural extracts, which inhibit the growth of bacteria and other microorganisms on the cellophane surface.- Incorporation of antimicrobial agents in cellophane: Cellophane can be enhanced with antimicrobial properties by incorporating various agents during the manufacturing process or as a surface treatment. These agents can include silver compounds, organic acids, or natural extracts, which inhibit the growth of bacteria and fungi on the cellophane surface.

- Nanoparticle-based antimicrobial coatings for cellophane: Nanoparticles, such as silver, zinc oxide, or copper oxide, can be applied as coatings on cellophane to impart antimicrobial properties. These nanoparticle coatings provide a large surface area for interaction with microorganisms, effectively inhibiting their growth and proliferation on the cellophane surface.

- Biodegradable antimicrobial cellophane composites: Antimicrobial cellophane composites can be developed by blending cellophane with biodegradable polymers and antimicrobial agents. These composites offer both environmental sustainability and antimicrobial properties, making them suitable for various packaging applications in food and medical industries.

- UV-activated antimicrobial cellophane: Cellophane can be modified with photocatalytic materials that exhibit antimicrobial properties when exposed to UV light. This approach allows for the creation of cellophane products with on-demand antimicrobial capabilities, activated by exposure to sunlight or artificial UV sources.

- Natural antimicrobial additives for cellophane: Incorporating natural antimicrobial additives, such as essential oils or plant extracts, into cellophane can provide antimicrobial properties without the use of synthetic chemicals. These natural additives offer a more environmentally friendly and potentially safer alternative for antimicrobial cellophane production.

02 Use of nanoparticles for antimicrobial cellophane

Nanoparticles, such as silver nanoparticles or zinc oxide nanoparticles, can be integrated into cellophane to provide antimicrobial properties. These nanoparticles have a high surface area to volume ratio, allowing for effective microbial control while maintaining the transparency and other desirable properties of cellophane.Expand Specific Solutions03 Biodegradable antimicrobial cellophane

Development of biodegradable cellophane with antimicrobial properties involves the use of natural antimicrobial compounds or biodegradable polymers with inherent antimicrobial characteristics. This approach addresses both environmental concerns and the need for microbial control in packaging applications.Expand Specific Solutions04 Surface modification techniques for antimicrobial cellophane

Various surface modification techniques can be applied to cellophane to impart antimicrobial properties. These may include plasma treatment, UV irradiation, or chemical grafting of antimicrobial compounds onto the cellophane surface, enhancing its ability to resist microbial growth without altering its bulk properties.Expand Specific Solutions05 Multilayer antimicrobial cellophane structures

Antimicrobial capabilities can be achieved in cellophane through the development of multilayer structures. These structures may combine layers of cellophane with antimicrobial films or coatings, providing enhanced protection against microbial growth while maintaining the desirable properties of cellophane.Expand Specific Solutions

Key Players in Antimicrobial Packaging

The innovation of anti-microbial capabilities in cellophane is currently in a growth phase, with increasing market demand driven by heightened hygiene awareness. The global market for antimicrobial packaging is expanding, with projections indicating significant growth in the coming years. Technologically, the field is advancing rapidly, with various approaches being explored. Companies like Microban Products Co. and BASF Corp. are at the forefront, developing proprietary antimicrobial technologies. Academic institutions such as the University of Florida and South China University of Technology are contributing to fundamental research. Collaboration between industry leaders and research institutions is accelerating progress, with organizations like the Agency for Science, Technology & Research playing a crucial role in bridging the gap between academic research and commercial applications.

Dow Global Technologies LLC

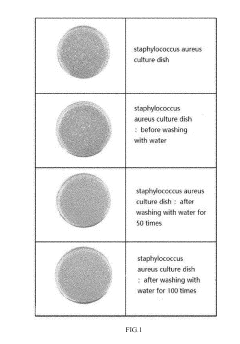

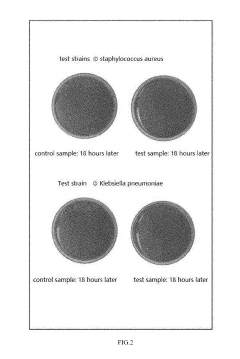

Technical Solution: Dow Global Technologies LLC has innovated in the field of antimicrobial cellophane by developing a novel polymer blend technology. Their approach involves incorporating antimicrobial polymers into the cellophane structure, creating a homogeneous material with inherent antimicrobial properties. The company has focused on using quaternary ammonium compounds (QACs) as the active antimicrobial agents, which are known for their broad-spectrum activity against bacteria and fungi[7]. Dow's technology allows for the controlled release of these compounds, providing sustained antimicrobial activity over time. Additionally, they have developed a surface modification technique that enhances the adhesion of antimicrobial agents to the cellophane surface, improving durability and wash resistance[9].

Strengths: Uniform distribution of antimicrobial agents, enhanced durability, and broad-spectrum antimicrobial activity. Weaknesses: Potential for antimicrobial resistance development and higher material costs.

Agency for Science, Technology & Research

Technical Solution: The Agency for Science, Technology & Research has developed a groundbreaking approach to antimicrobial cellophane using nanotechnology and natural compounds. Their research focuses on incorporating plant-derived essential oils, such as cinnamon and oregano oil, into nanocarriers that can be integrated into the cellophane structure[8]. These nanocarriers provide a controlled release mechanism for the essential oils, ensuring long-lasting antimicrobial activity. The agency has also explored the use of graphene oxide nanocomposites as a platform for antimicrobial functionality in cellophane. This approach not only provides antimicrobial properties but also enhances the mechanical strength and barrier properties of the cellophane[10]. The combination of natural antimicrobials and advanced nanotechnology offers a sustainable and effective solution for antimicrobial cellophane.

Strengths: Use of natural antimicrobial agents, enhanced material properties, and potential for eco-friendly packaging solutions. Weaknesses: Scalability challenges and potential regulatory hurdles for nanocomposite materials in food packaging.

Core Antimicrobial Cellophane Patents

Antimicrobial cellulosic fiber, production method and application thereof

PatentInactiveUS20190246634A1

Innovation

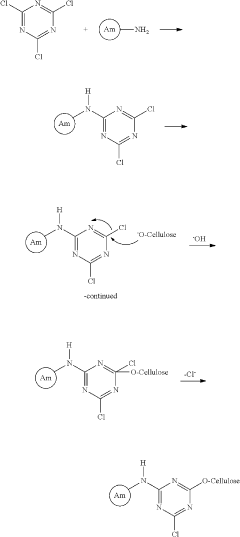

- A production method involving the preparation of a reactive antibacterial compound, which is chemically immobilized onto cellulosic fibers through chemical bonding, using a reactive compound and an antibacterial agent, followed by stabilization with a metal promoter or heat treatment to enhance bonding and maintain antibacterial efficacy.

Nanosilver coated bacterial cellulose

PatentInactiveUS20130211308A1

Innovation

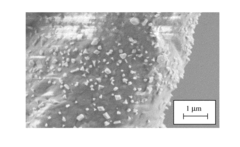

- A method for producing nano-silver coated bacterial cellulose fibers by oxidizing cellulose fibers, introducing thio-groups, and binding silver nanoparticles to the cellulose backbone, creating a durable and biocompatible material with enhanced antimicrobial properties suitable for various applications.

Environmental Impact Assessment

The environmental impact assessment of innovating anti-microbial capabilities in cellophane is a crucial aspect that requires thorough consideration. Cellophane, a biodegradable material derived from cellulose, already possesses certain eco-friendly characteristics. However, the addition of anti-microbial properties may alter its environmental profile.

One primary concern is the potential release of anti-microbial agents into the environment during the product's lifecycle. These agents, while beneficial for preserving food and extending shelf life, could have unintended consequences on soil microbiota and aquatic ecosystems if not properly managed. It is essential to evaluate the persistence and bioaccumulation potential of the chosen anti-microbial compounds to minimize long-term ecological impacts.

The manufacturing process for anti-microbial cellophane may require additional chemical treatments or incorporation of nanoparticles. This could lead to increased energy consumption and potentially harmful emissions. A comprehensive life cycle assessment (LCA) should be conducted to quantify the environmental footprint of the enhanced cellophane compared to traditional alternatives.

On the positive side, improved anti-microbial properties in cellophane could significantly reduce food waste by extending the shelf life of perishable goods. This indirect environmental benefit should be weighed against the direct impacts of production and disposal. Furthermore, if the anti-microbial cellophane can replace less environmentally friendly packaging materials, it may contribute to an overall reduction in plastic pollution.

The end-of-life management of anti-microbial cellophane is another critical consideration. While cellophane is biodegradable, the added anti-microbial components may affect its decomposition rate and the quality of resulting compost. Research should focus on ensuring that the innovative cellophane maintains its biodegradability without leaving persistent residues.

Water usage and potential contamination during production and disposal processes must also be carefully assessed. Implementing closed-loop systems and advanced wastewater treatment technologies could mitigate these concerns. Additionally, the sourcing of raw materials for both cellophane and anti-microbial agents should prioritize sustainable practices to minimize deforestation and habitat disruption.

In conclusion, the environmental impact assessment of anti-microbial cellophane innovation should adopt a holistic approach, considering direct and indirect effects throughout the product's lifecycle. Balancing the benefits of reduced food waste and potential replacement of less eco-friendly materials against the impacts of production and disposal will be key to ensuring a net positive environmental outcome.

One primary concern is the potential release of anti-microbial agents into the environment during the product's lifecycle. These agents, while beneficial for preserving food and extending shelf life, could have unintended consequences on soil microbiota and aquatic ecosystems if not properly managed. It is essential to evaluate the persistence and bioaccumulation potential of the chosen anti-microbial compounds to minimize long-term ecological impacts.

The manufacturing process for anti-microbial cellophane may require additional chemical treatments or incorporation of nanoparticles. This could lead to increased energy consumption and potentially harmful emissions. A comprehensive life cycle assessment (LCA) should be conducted to quantify the environmental footprint of the enhanced cellophane compared to traditional alternatives.

On the positive side, improved anti-microbial properties in cellophane could significantly reduce food waste by extending the shelf life of perishable goods. This indirect environmental benefit should be weighed against the direct impacts of production and disposal. Furthermore, if the anti-microbial cellophane can replace less environmentally friendly packaging materials, it may contribute to an overall reduction in plastic pollution.

The end-of-life management of anti-microbial cellophane is another critical consideration. While cellophane is biodegradable, the added anti-microbial components may affect its decomposition rate and the quality of resulting compost. Research should focus on ensuring that the innovative cellophane maintains its biodegradability without leaving persistent residues.

Water usage and potential contamination during production and disposal processes must also be carefully assessed. Implementing closed-loop systems and advanced wastewater treatment technologies could mitigate these concerns. Additionally, the sourcing of raw materials for both cellophane and anti-microbial agents should prioritize sustainable practices to minimize deforestation and habitat disruption.

In conclusion, the environmental impact assessment of anti-microbial cellophane innovation should adopt a holistic approach, considering direct and indirect effects throughout the product's lifecycle. Balancing the benefits of reduced food waste and potential replacement of less eco-friendly materials against the impacts of production and disposal will be key to ensuring a net positive environmental outcome.

Regulatory Compliance for Food Packaging

Regulatory compliance is a critical aspect of food packaging innovation, particularly when developing anti-microbial capabilities in cellophane. The food packaging industry is subject to stringent regulations aimed at ensuring consumer safety and product integrity. These regulations vary across different regions and countries, necessitating a comprehensive understanding of global standards.

In the United States, the Food and Drug Administration (FDA) oversees food packaging regulations. The FDA's Food Contact Substance Notification Program requires manufacturers to submit detailed information about new food contact substances, including those used in anti-microbial cellophane. This process involves rigorous safety assessments and toxicological evaluations to ensure that the materials do not pose any health risks to consumers.

The European Union (EU) has its own set of regulations governed by the European Food Safety Authority (EFSA). The EU's framework regulation EC 1935/2004 sets out general principles for all food contact materials, while specific measures for plastic materials are outlined in EU Regulation 10/2011. These regulations establish migration limits for substances that may transfer from packaging to food, a crucial consideration for anti-microbial cellophane development.

In addition to regional regulations, international standards such as ISO 22000 for food safety management systems play a significant role in ensuring compliance across global supply chains. These standards often incorporate Hazard Analysis and Critical Control Points (HACCP) principles, which are essential for identifying and mitigating potential risks associated with food packaging materials.

When innovating anti-microbial capabilities in cellophane, manufacturers must consider the specific regulatory requirements for active and intelligent packaging. These materials, designed to extend shelf life or monitor food quality, are subject to additional scrutiny. In the EU, for instance, Regulation EC 450/2009 specifically addresses active and intelligent materials and articles intended to come into contact with food.

Compliance with these regulations often requires extensive testing and documentation. This includes migration studies to assess the potential transfer of anti-microbial agents from cellophane to food, as well as efficacy tests to demonstrate the material's ability to inhibit microbial growth. Manufacturers must also provide detailed information on the chemical composition of the anti-microbial agents used and their potential environmental impact.

As sustainability becomes an increasingly important consideration in packaging design, regulatory bodies are also focusing on the environmental aspects of food packaging. This includes regulations on recyclability, biodegradability, and the use of sustainable materials. Innovators in anti-microbial cellophane must therefore balance antimicrobial efficacy with environmental compliance to meet both safety and sustainability requirements.

In the United States, the Food and Drug Administration (FDA) oversees food packaging regulations. The FDA's Food Contact Substance Notification Program requires manufacturers to submit detailed information about new food contact substances, including those used in anti-microbial cellophane. This process involves rigorous safety assessments and toxicological evaluations to ensure that the materials do not pose any health risks to consumers.

The European Union (EU) has its own set of regulations governed by the European Food Safety Authority (EFSA). The EU's framework regulation EC 1935/2004 sets out general principles for all food contact materials, while specific measures for plastic materials are outlined in EU Regulation 10/2011. These regulations establish migration limits for substances that may transfer from packaging to food, a crucial consideration for anti-microbial cellophane development.

In addition to regional regulations, international standards such as ISO 22000 for food safety management systems play a significant role in ensuring compliance across global supply chains. These standards often incorporate Hazard Analysis and Critical Control Points (HACCP) principles, which are essential for identifying and mitigating potential risks associated with food packaging materials.

When innovating anti-microbial capabilities in cellophane, manufacturers must consider the specific regulatory requirements for active and intelligent packaging. These materials, designed to extend shelf life or monitor food quality, are subject to additional scrutiny. In the EU, for instance, Regulation EC 450/2009 specifically addresses active and intelligent materials and articles intended to come into contact with food.

Compliance with these regulations often requires extensive testing and documentation. This includes migration studies to assess the potential transfer of anti-microbial agents from cellophane to food, as well as efficacy tests to demonstrate the material's ability to inhibit microbial growth. Manufacturers must also provide detailed information on the chemical composition of the anti-microbial agents used and their potential environmental impact.

As sustainability becomes an increasingly important consideration in packaging design, regulatory bodies are also focusing on the environmental aspects of food packaging. This includes regulations on recyclability, biodegradability, and the use of sustainable materials. Innovators in anti-microbial cellophane must therefore balance antimicrobial efficacy with environmental compliance to meet both safety and sustainability requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!