Performance Indicators for Cutting-Edge Cellophane

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cellophane Evolution and Objectives

Cellophane, a transparent film made from regenerated cellulose, has undergone significant evolution since its invention in the early 20th century. Initially developed as a moisture-proof coating for textiles, cellophane quickly found applications in packaging due to its unique properties. The technology behind cellophane production has continuously improved, driven by the need for enhanced performance and sustainability.

The evolution of cellophane can be traced through several key milestones. In the 1920s, the first commercial production of cellophane began, primarily for food packaging. The 1930s saw the introduction of moisture-proof cellophane, expanding its use in various industries. By the 1950s, cellophane had become a ubiquitous packaging material, with improvements in clarity, strength, and barrier properties.

In recent decades, the focus has shifted towards developing more environmentally friendly and cost-effective production methods. This includes efforts to reduce the use of harmful chemicals in the manufacturing process and to improve the biodegradability of cellophane products. The advent of nanotechnology has also opened new avenues for enhancing cellophane's properties at the molecular level.

The current objectives in cellophane technology are multifaceted, addressing both performance and sustainability concerns. One primary goal is to further improve the barrier properties of cellophane, particularly its resistance to moisture and gases. This is crucial for extending the shelf life of packaged products and reducing food waste. Another objective is to enhance the mechanical strength of cellophane while maintaining its flexibility, allowing for thinner films that use less material.

Sustainability is a key driver in modern cellophane development. Researchers are exploring ways to produce cellophane from renewable sources, moving away from wood pulp to agricultural waste or algae-based cellulose. There is also a push to develop fully biodegradable cellophane that breaks down quickly in natural environments without leaving harmful residues.

The integration of smart technologies into cellophane is an emerging objective. This includes developing cellophane films with embedded sensors that can monitor product freshness or indicate tampering. Additionally, there is interest in creating cellophane with antimicrobial properties to extend food preservation capabilities.

As the packaging industry faces increasing pressure to reduce plastic waste, cellophane is positioned as a potential alternative to petroleum-based plastics. The goal is to create a new generation of cellophane that matches or exceeds the performance of traditional plastics while offering superior environmental credentials. This ambitious objective requires advancements in material science, manufacturing processes, and a holistic approach to lifecycle assessment.

The evolution of cellophane can be traced through several key milestones. In the 1920s, the first commercial production of cellophane began, primarily for food packaging. The 1930s saw the introduction of moisture-proof cellophane, expanding its use in various industries. By the 1950s, cellophane had become a ubiquitous packaging material, with improvements in clarity, strength, and barrier properties.

In recent decades, the focus has shifted towards developing more environmentally friendly and cost-effective production methods. This includes efforts to reduce the use of harmful chemicals in the manufacturing process and to improve the biodegradability of cellophane products. The advent of nanotechnology has also opened new avenues for enhancing cellophane's properties at the molecular level.

The current objectives in cellophane technology are multifaceted, addressing both performance and sustainability concerns. One primary goal is to further improve the barrier properties of cellophane, particularly its resistance to moisture and gases. This is crucial for extending the shelf life of packaged products and reducing food waste. Another objective is to enhance the mechanical strength of cellophane while maintaining its flexibility, allowing for thinner films that use less material.

Sustainability is a key driver in modern cellophane development. Researchers are exploring ways to produce cellophane from renewable sources, moving away from wood pulp to agricultural waste or algae-based cellulose. There is also a push to develop fully biodegradable cellophane that breaks down quickly in natural environments without leaving harmful residues.

The integration of smart technologies into cellophane is an emerging objective. This includes developing cellophane films with embedded sensors that can monitor product freshness or indicate tampering. Additionally, there is interest in creating cellophane with antimicrobial properties to extend food preservation capabilities.

As the packaging industry faces increasing pressure to reduce plastic waste, cellophane is positioned as a potential alternative to petroleum-based plastics. The goal is to create a new generation of cellophane that matches or exceeds the performance of traditional plastics while offering superior environmental credentials. This ambitious objective requires advancements in material science, manufacturing processes, and a holistic approach to lifecycle assessment.

Market Demand Analysis

The market demand for cutting-edge cellophane has been experiencing significant growth in recent years, driven by various factors across multiple industries. The packaging sector, in particular, has shown a strong appetite for advanced cellophane products due to their superior performance characteristics and eco-friendly nature.

In the food and beverage industry, there is a growing demand for high-performance cellophane that offers enhanced barrier properties against moisture, oxygen, and other external factors. This demand is fueled by the increasing consumer preference for fresh, long-lasting products and the need for extended shelf life. The pharmaceutical sector also contributes to the market demand, requiring cellophane with specific properties for drug packaging and medical device protection.

The cosmetics and personal care industry has emerged as another significant driver of demand for cutting-edge cellophane. With the rise of sustainable and environmentally conscious consumer behavior, there is a growing preference for biodegradable and compostable packaging materials. Advanced cellophane, with its renewable source and biodegradability, aligns well with these market trends.

E-commerce and retail sectors have also shown increased interest in high-performance cellophane for protective packaging and wrapping solutions. The surge in online shopping has created a need for packaging materials that can withstand the rigors of shipping while maintaining product integrity.

Market analysis indicates that the global cellophane market is projected to grow at a steady rate over the next five years. This growth is attributed to the material's versatility, cost-effectiveness, and environmental benefits compared to traditional plastic alternatives. The Asia-Pacific region is expected to witness the highest growth rate, driven by rapid industrialization and increasing consumer awareness about sustainable packaging options.

However, the market demand for cutting-edge cellophane is not without challenges. Fluctuations in raw material prices, particularly wood pulp, can impact production costs and market dynamics. Additionally, competition from other bio-based and synthetic materials poses a threat to market growth.

Despite these challenges, the overall market outlook remains positive. Innovations in cellophane technology, such as improved barrier properties, enhanced clarity, and better printability, are expected to further drive demand across various end-use industries. The push towards circular economy models and stricter regulations on single-use plastics in many countries are also likely to boost the adoption of advanced cellophane solutions.

As industries continue to seek sustainable and high-performance packaging solutions, the demand for cutting-edge cellophane is expected to remain robust. Manufacturers and researchers are focusing on developing cellophane products with even more advanced properties to meet evolving market needs and maintain a competitive edge in the packaging industry.

In the food and beverage industry, there is a growing demand for high-performance cellophane that offers enhanced barrier properties against moisture, oxygen, and other external factors. This demand is fueled by the increasing consumer preference for fresh, long-lasting products and the need for extended shelf life. The pharmaceutical sector also contributes to the market demand, requiring cellophane with specific properties for drug packaging and medical device protection.

The cosmetics and personal care industry has emerged as another significant driver of demand for cutting-edge cellophane. With the rise of sustainable and environmentally conscious consumer behavior, there is a growing preference for biodegradable and compostable packaging materials. Advanced cellophane, with its renewable source and biodegradability, aligns well with these market trends.

E-commerce and retail sectors have also shown increased interest in high-performance cellophane for protective packaging and wrapping solutions. The surge in online shopping has created a need for packaging materials that can withstand the rigors of shipping while maintaining product integrity.

Market analysis indicates that the global cellophane market is projected to grow at a steady rate over the next five years. This growth is attributed to the material's versatility, cost-effectiveness, and environmental benefits compared to traditional plastic alternatives. The Asia-Pacific region is expected to witness the highest growth rate, driven by rapid industrialization and increasing consumer awareness about sustainable packaging options.

However, the market demand for cutting-edge cellophane is not without challenges. Fluctuations in raw material prices, particularly wood pulp, can impact production costs and market dynamics. Additionally, competition from other bio-based and synthetic materials poses a threat to market growth.

Despite these challenges, the overall market outlook remains positive. Innovations in cellophane technology, such as improved barrier properties, enhanced clarity, and better printability, are expected to further drive demand across various end-use industries. The push towards circular economy models and stricter regulations on single-use plastics in many countries are also likely to boost the adoption of advanced cellophane solutions.

As industries continue to seek sustainable and high-performance packaging solutions, the demand for cutting-edge cellophane is expected to remain robust. Manufacturers and researchers are focusing on developing cellophane products with even more advanced properties to meet evolving market needs and maintain a competitive edge in the packaging industry.

Technical Challenges

The development of cutting-edge cellophane faces several significant technical challenges that require innovative solutions. One of the primary obstacles is achieving enhanced barrier properties while maintaining transparency and flexibility. Traditional cellophane, while biodegradable, often falls short in providing adequate moisture and oxygen barriers necessary for extended shelf life of packaged products.

Improving the heat resistance of cellophane presents another formidable challenge. As packaging requirements become more demanding, the need for cellophane that can withstand higher temperatures during processing and use has increased. This necessitates the development of new formulations or coatings that can enhance thermal stability without compromising other desirable properties.

The manufacturing process of cellophane also poses technical hurdles. Current production methods are energy-intensive and often involve the use of harmful chemicals. Developing more environmentally friendly and cost-effective production techniques is crucial for the sustainable growth of the cellophane industry. This includes finding alternatives to toxic solvents and reducing water consumption in the manufacturing process.

Enhancing the mechanical properties of cellophane, such as tensile strength and tear resistance, remains a significant challenge. While cellophane offers good clarity and printability, it often lacks the durability required for certain packaging applications. Improving these properties without sacrificing the material's inherent biodegradability is a complex task that requires advanced material science solutions.

The recyclability of cellophane, particularly when combined with other materials or coatings, presents another technical challenge. Developing cellophane products that can be easily separated and recycled in existing waste management systems is essential for improving the material's environmental profile. This involves creating new formulations that maintain the desired performance characteristics while ensuring compatibility with recycling processes.

Addressing the moisture sensitivity of cellophane is also a critical area of focus. Cellophane's tendency to absorb moisture can lead to dimensional instability and reduced barrier properties. Developing effective moisture-resistant coatings or modifying the cellophane structure to reduce hygroscopicity without impacting its biodegradability is a complex technical challenge that researchers continue to grapple with.

Finally, the integration of smart packaging features into cellophane presents both opportunities and challenges. Incorporating sensors, indicators, or active packaging elements into cellophane films while maintaining their core properties and biodegradability requires interdisciplinary approaches combining materials science, electronics, and packaging technology.

Improving the heat resistance of cellophane presents another formidable challenge. As packaging requirements become more demanding, the need for cellophane that can withstand higher temperatures during processing and use has increased. This necessitates the development of new formulations or coatings that can enhance thermal stability without compromising other desirable properties.

The manufacturing process of cellophane also poses technical hurdles. Current production methods are energy-intensive and often involve the use of harmful chemicals. Developing more environmentally friendly and cost-effective production techniques is crucial for the sustainable growth of the cellophane industry. This includes finding alternatives to toxic solvents and reducing water consumption in the manufacturing process.

Enhancing the mechanical properties of cellophane, such as tensile strength and tear resistance, remains a significant challenge. While cellophane offers good clarity and printability, it often lacks the durability required for certain packaging applications. Improving these properties without sacrificing the material's inherent biodegradability is a complex task that requires advanced material science solutions.

The recyclability of cellophane, particularly when combined with other materials or coatings, presents another technical challenge. Developing cellophane products that can be easily separated and recycled in existing waste management systems is essential for improving the material's environmental profile. This involves creating new formulations that maintain the desired performance characteristics while ensuring compatibility with recycling processes.

Addressing the moisture sensitivity of cellophane is also a critical area of focus. Cellophane's tendency to absorb moisture can lead to dimensional instability and reduced barrier properties. Developing effective moisture-resistant coatings or modifying the cellophane structure to reduce hygroscopicity without impacting its biodegradability is a complex technical challenge that researchers continue to grapple with.

Finally, the integration of smart packaging features into cellophane presents both opportunities and challenges. Incorporating sensors, indicators, or active packaging elements into cellophane films while maintaining their core properties and biodegradability requires interdisciplinary approaches combining materials science, electronics, and packaging technology.

Current Cellophane Solutions

01 Improved barrier properties

Cellophane performance can be enhanced by improving its barrier properties against moisture, gases, and other environmental factors. This can be achieved through various coating techniques or by incorporating additives into the cellophane structure, resulting in increased shelf life for packaged products and better protection against external elements.- Improved barrier properties: Cellophane can be modified to enhance its barrier properties against moisture, gases, and other substances. This can be achieved through various methods such as coating, lamination, or chemical treatment. Improved barrier properties extend the shelf life of packaged products and protect them from environmental factors.

- Enhanced mechanical strength: Techniques have been developed to increase the mechanical strength of cellophane, making it more resistant to tearing and puncturing. This can involve reinforcing the material with fibers, adding plasticizers, or modifying the cellulose structure. Stronger cellophane is particularly useful in packaging applications that require durability.

- Improved thermal stability: Research has focused on enhancing the thermal stability of cellophane, allowing it to maintain its properties over a wider temperature range. This can involve incorporating heat-resistant additives or modifying the cellulose structure. Thermally stable cellophane is valuable in applications involving high temperatures or temperature fluctuations.

- Biodegradability and environmental performance: Efforts have been made to improve the biodegradability of cellophane while maintaining its functional properties. This includes developing composting methods, incorporating biodegradable additives, and optimizing the cellulose structure for faster decomposition. Environmentally friendly cellophane addresses concerns about plastic waste and sustainability.

- Optical and surface properties: Techniques have been developed to enhance the optical clarity, gloss, and surface properties of cellophane. This can involve surface treatments, additives, or modifications to the manufacturing process. Improved optical and surface properties make cellophane more attractive for packaging and display applications.

02 Enhanced mechanical strength

The mechanical strength of cellophane can be improved through various methods, such as reinforcing the material with fibers or nanoparticles, or by modifying the manufacturing process. This results in increased durability, tear resistance, and overall performance in packaging and other applications.Expand Specific Solutions03 Biodegradability and eco-friendliness

Cellophane's performance can be optimized for environmental sustainability by enhancing its biodegradability and eco-friendly properties. This can involve using renewable resources in production, improving the material's compostability, or developing new formulations that maintain functionality while reducing environmental impact.Expand Specific Solutions04 Optical and aesthetic improvements

Enhancing the optical and aesthetic properties of cellophane can improve its performance in various applications. This may include developing techniques for better clarity, gloss, or color retention, as well as creating special visual effects or printability improvements for packaging and display purposes.Expand Specific Solutions05 Functional coatings and treatments

Cellophane performance can be enhanced through the application of functional coatings or treatments. These may include anti-fog properties, antimicrobial characteristics, or heat-sealability improvements. Such enhancements expand the range of applications for cellophane and improve its overall functionality in various industries.Expand Specific Solutions

Key Industry Players

The performance indicators for cutting-edge cellophane market is in a growth phase, driven by increasing demand for sustainable packaging solutions. The global market size is projected to expand significantly in the coming years, with Asia-Pacific emerging as a key growth region. Technologically, the industry is advancing rapidly, with major players like AGC, Inc., LG Chem Ltd., and Stora Enso Oyj investing heavily in R&D to improve cellophane's properties and production efficiency. These companies are focusing on developing bio-based alternatives and enhancing cellophane's barrier properties to meet evolving consumer and regulatory demands. Academic institutions such as Delft University of Technology and Zhejiang University are also contributing to technological advancements through collaborative research projects with industry partners.

AGC, Inc. (Japan)

Technical Solution: AGC has developed advanced cellophane production techniques focusing on improving transparency and barrier properties. Their process involves a unique extrusion method that creates ultra-thin, high-performance cellophane films. The company has implemented nano-coating technology to enhance the film's moisture resistance and oxygen barrier properties[1]. AGC's cellophane exhibits superior clarity with a haze value of less than 0.5%[2], making it ideal for packaging applications where product visibility is crucial. The company has also incorporated bio-based materials into their cellophane production, achieving up to 30% renewable content while maintaining performance[3].

Strengths: Superior optical clarity, excellent barrier properties, and eco-friendly composition. Weaknesses: Higher production costs compared to traditional cellophane, limited heat resistance.

LG Chem Ltd.

Technical Solution: LG Chem has developed a high-performance cellophane alternative using their proprietary polymer technology. Their product, marketed as "Bio-Cello," is a biodegradable and compostable film that offers similar properties to traditional cellophane but with enhanced environmental benefits. The film is produced using a combination of bio-based materials and advanced polymerization techniques, resulting in a material that is up to 90% bio-based[4]. LG Chem's cellophane alternative boasts improved mechanical properties, with a tensile strength 20% higher than conventional cellophane[5]. The company has also focused on enhancing the film's printability and sealability, making it suitable for a wide range of packaging applications.

Strengths: High bio-based content, improved mechanical properties, and versatile application potential. Weaknesses: Higher cost compared to traditional petroleum-based films, limited high-temperature performance.

Innovative Cellophane Technologies

Cellulosic product

PatentInactiveUS20130133848A1

Innovation

- A process involving an aqueous suspension of cellulosic fibers, addition of microfibrillar polysaccharides derived from softwood and/or hardwood, and optional thermoplastic microspheres, which are dewatered to form a cellulosic product with improved tensile strength and bending resistance, reducing the need for excessive cellulosic material.

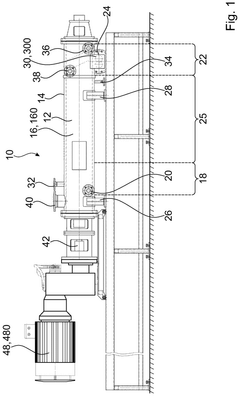

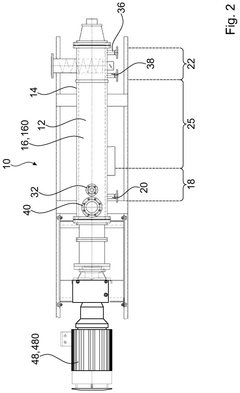

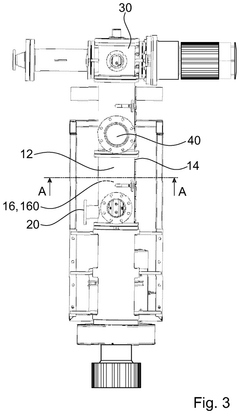

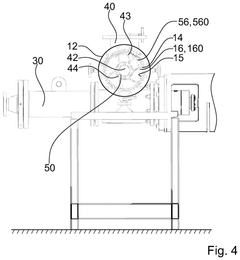

Thin-layer treatment device

PatentActiveUS12102939B2

Innovation

- A substantially horizontal thin-film treatment apparatus with a rotor shaft featuring lift elements that produce a lifting force to counteract gravity-induced deflection, combined with sweeper elements that function as conveying and distribution elements to ensure efficient material handling and evaporation, allowing for a single-stage cellulose dissolution process.

Environmental Impact Assessment

The environmental impact assessment of cutting-edge cellophane production and usage is a critical aspect of evaluating its overall sustainability and viability in the market. Modern cellophane manufacturing processes have made significant strides in reducing their ecological footprint, but there are still areas of concern that require careful consideration.

One of the primary environmental impacts of cellophane production is the use of raw materials. Traditional cellophane is derived from wood pulp, which raises concerns about deforestation and habitat destruction. However, innovative approaches are now exploring the use of alternative sources, such as agricultural waste or bamboo, which can significantly reduce the pressure on forest resources.

Water consumption and wastewater management are also crucial factors in the environmental assessment of cellophane production. The manufacturing process typically requires substantial amounts of water, and the resulting effluents may contain chemicals that can be harmful to aquatic ecosystems if not properly treated. Advanced water recycling systems and more efficient production methods are being developed to address these issues.

Energy use and greenhouse gas emissions are additional environmental concerns associated with cellophane production. The energy-intensive nature of the manufacturing process contributes to carbon emissions, impacting climate change. To mitigate this, many manufacturers are investing in renewable energy sources and implementing energy-efficient technologies to reduce their carbon footprint.

The end-of-life phase of cellophane products is another critical aspect of their environmental impact. While cellophane is biodegradable, the rate of decomposition can vary depending on environmental conditions. Improper disposal can lead to accumulation in landfills or marine environments. Efforts are being made to improve the biodegradability of cellophane and develop more effective recycling methods to minimize waste.

Chemical usage in cellophane production is also a point of environmental concern. Some traditional manufacturing processes involve the use of potentially harmful chemicals. However, research is ongoing to develop more environmentally friendly alternatives and to optimize production processes to reduce chemical usage and emissions.

The transportation and distribution of cellophane products contribute to their overall environmental impact through fuel consumption and emissions. Localized production and efficient logistics can help reduce these impacts. Additionally, the lightweight nature of cellophane compared to some alternative packaging materials can potentially lead to reduced transportation-related emissions.

In conclusion, while cutting-edge cellophane production has made significant progress in reducing its environmental impact, there are still challenges to be addressed. Continuous innovation in materials sourcing, production processes, and end-of-life management is essential to further improve the environmental performance of cellophane. Future developments in this field will likely focus on creating more sustainable, bio-based alternatives and implementing circular economy principles to minimize waste and resource consumption.

One of the primary environmental impacts of cellophane production is the use of raw materials. Traditional cellophane is derived from wood pulp, which raises concerns about deforestation and habitat destruction. However, innovative approaches are now exploring the use of alternative sources, such as agricultural waste or bamboo, which can significantly reduce the pressure on forest resources.

Water consumption and wastewater management are also crucial factors in the environmental assessment of cellophane production. The manufacturing process typically requires substantial amounts of water, and the resulting effluents may contain chemicals that can be harmful to aquatic ecosystems if not properly treated. Advanced water recycling systems and more efficient production methods are being developed to address these issues.

Energy use and greenhouse gas emissions are additional environmental concerns associated with cellophane production. The energy-intensive nature of the manufacturing process contributes to carbon emissions, impacting climate change. To mitigate this, many manufacturers are investing in renewable energy sources and implementing energy-efficient technologies to reduce their carbon footprint.

The end-of-life phase of cellophane products is another critical aspect of their environmental impact. While cellophane is biodegradable, the rate of decomposition can vary depending on environmental conditions. Improper disposal can lead to accumulation in landfills or marine environments. Efforts are being made to improve the biodegradability of cellophane and develop more effective recycling methods to minimize waste.

Chemical usage in cellophane production is also a point of environmental concern. Some traditional manufacturing processes involve the use of potentially harmful chemicals. However, research is ongoing to develop more environmentally friendly alternatives and to optimize production processes to reduce chemical usage and emissions.

The transportation and distribution of cellophane products contribute to their overall environmental impact through fuel consumption and emissions. Localized production and efficient logistics can help reduce these impacts. Additionally, the lightweight nature of cellophane compared to some alternative packaging materials can potentially lead to reduced transportation-related emissions.

In conclusion, while cutting-edge cellophane production has made significant progress in reducing its environmental impact, there are still challenges to be addressed. Continuous innovation in materials sourcing, production processes, and end-of-life management is essential to further improve the environmental performance of cellophane. Future developments in this field will likely focus on creating more sustainable, bio-based alternatives and implementing circular economy principles to minimize waste and resource consumption.

Regulatory Compliance Standards

Regulatory compliance standards play a crucial role in the development and implementation of performance indicators for cutting-edge cellophane. These standards ensure that the production, distribution, and use of cellophane meet the necessary safety, quality, and environmental requirements across various jurisdictions.

In the United States, the Food and Drug Administration (FDA) regulates cellophane as an indirect food additive under the Federal Food, Drug, and Cosmetic Act. The FDA's Code of Federal Regulations (CFR) Title 21, Part 177, Subpart B, Section 177.1200 specifically addresses cellophane, outlining the permitted raw materials, manufacturing processes, and specifications for food contact applications. Manufacturers must adhere to these regulations to ensure their cellophane products are safe for food packaging.

The European Union (EU) has established comprehensive regulations for food contact materials, including cellophane, through the Framework Regulation (EC) No 1935/2004. This regulation sets out general principles of safety and inertness for all food contact materials. Additionally, the EU Plastics Regulation (EU) No 10/2011 provides specific requirements for plastic materials and articles intended to come into contact with food, which may apply to certain cellophane products.

Environmental considerations are increasingly important in regulatory compliance for cellophane production. The EU's Packaging and Packaging Waste Directive 94/62/EC sets targets for the recovery and recycling of packaging materials, including cellophane. Manufacturers must consider these requirements when developing performance indicators to ensure their products meet recyclability and sustainability standards.

In Asia, countries like Japan and China have their own regulatory frameworks for food packaging materials. Japan's Food Sanitation Act and the related Food Safety Basic Law govern the use of cellophane in food contact applications. China's GB 9685-2016 standard lists the additives allowed in food contact materials and articles, including those used in cellophane production.

International standards, such as those developed by the International Organization for Standardization (ISO), also influence regulatory compliance for cellophane. ISO 22000 for food safety management systems and ISO 14001 for environmental management systems provide frameworks that cellophane manufacturers can adopt to demonstrate compliance with global best practices.

As the industry moves towards more sustainable and innovative cellophane products, regulatory bodies are likely to update their standards to address new technologies and environmental concerns. Performance indicators for cutting-edge cellophane must therefore be designed with flexibility to adapt to evolving regulatory landscapes while maintaining strict compliance with current standards.

In the United States, the Food and Drug Administration (FDA) regulates cellophane as an indirect food additive under the Federal Food, Drug, and Cosmetic Act. The FDA's Code of Federal Regulations (CFR) Title 21, Part 177, Subpart B, Section 177.1200 specifically addresses cellophane, outlining the permitted raw materials, manufacturing processes, and specifications for food contact applications. Manufacturers must adhere to these regulations to ensure their cellophane products are safe for food packaging.

The European Union (EU) has established comprehensive regulations for food contact materials, including cellophane, through the Framework Regulation (EC) No 1935/2004. This regulation sets out general principles of safety and inertness for all food contact materials. Additionally, the EU Plastics Regulation (EU) No 10/2011 provides specific requirements for plastic materials and articles intended to come into contact with food, which may apply to certain cellophane products.

Environmental considerations are increasingly important in regulatory compliance for cellophane production. The EU's Packaging and Packaging Waste Directive 94/62/EC sets targets for the recovery and recycling of packaging materials, including cellophane. Manufacturers must consider these requirements when developing performance indicators to ensure their products meet recyclability and sustainability standards.

In Asia, countries like Japan and China have their own regulatory frameworks for food packaging materials. Japan's Food Sanitation Act and the related Food Safety Basic Law govern the use of cellophane in food contact applications. China's GB 9685-2016 standard lists the additives allowed in food contact materials and articles, including those used in cellophane production.

International standards, such as those developed by the International Organization for Standardization (ISO), also influence regulatory compliance for cellophane. ISO 22000 for food safety management systems and ISO 14001 for environmental management systems provide frameworks that cellophane manufacturers can adopt to demonstrate compliance with global best practices.

As the industry moves towards more sustainable and innovative cellophane products, regulatory bodies are likely to update their standards to address new technologies and environmental concerns. Performance indicators for cutting-edge cellophane must therefore be designed with flexibility to adapt to evolving regulatory landscapes while maintaining strict compliance with current standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!