Ductility Challenges of 4140 Steel in Low-Temperature Environments

JUL 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

4140 Steel Properties and Low-Temperature Goals

AISI 4140 steel is a medium carbon, low alloy steel known for its excellent combination of strength, toughness, and wear resistance. It contains chromium and molybdenum as primary alloying elements, which contribute to its superior mechanical properties. At room temperature, 4140 steel exhibits a tensile strength ranging from 850 to 1000 MPa and a yield strength of 655 to 758 MPa, depending on the heat treatment process.

The primary goal in low-temperature applications is to maintain the steel's ductility and toughness while preventing brittle fracture. As temperatures decrease, 4140 steel, like many other steels, experiences a ductile-to-brittle transition. This transition is characterized by a significant reduction in the material's ability to plastically deform before fracture, leading to a sudden and catastrophic failure mode.

In low-temperature environments, typically below -20°C (-4°F), 4140 steel faces several challenges. The material's yield strength and ultimate tensile strength tend to increase, but this comes at the cost of reduced ductility and impact toughness. The decrease in ductility is particularly concerning as it limits the steel's ability to redistribute stresses and absorb energy during loading, making it more susceptible to brittle fracture.

To address these challenges, several goals have been established for improving the low-temperature performance of 4140 steel. One primary objective is to lower the ductile-to-brittle transition temperature (DBTT), allowing the material to maintain its ductile behavior at lower temperatures. This can be achieved through various methods, including refining the grain structure, optimizing the heat treatment process, and carefully controlling the alloy composition.

Another important goal is to enhance the steel's notch toughness at low temperatures. This property is crucial for components that may contain stress concentrations or small defects, as it determines the material's ability to resist crack propagation under dynamic loading conditions. Improving the Charpy V-notch impact energy at sub-zero temperatures is a key metric for assessing progress in this area.

Researchers and engineers are also focusing on developing modified 4140 steel compositions that offer improved low-temperature performance without sacrificing the material's desirable properties at room temperature. This balancing act requires a deep understanding of the microstructural changes that occur during cooling and their effects on mechanical behavior.

The primary goal in low-temperature applications is to maintain the steel's ductility and toughness while preventing brittle fracture. As temperatures decrease, 4140 steel, like many other steels, experiences a ductile-to-brittle transition. This transition is characterized by a significant reduction in the material's ability to plastically deform before fracture, leading to a sudden and catastrophic failure mode.

In low-temperature environments, typically below -20°C (-4°F), 4140 steel faces several challenges. The material's yield strength and ultimate tensile strength tend to increase, but this comes at the cost of reduced ductility and impact toughness. The decrease in ductility is particularly concerning as it limits the steel's ability to redistribute stresses and absorb energy during loading, making it more susceptible to brittle fracture.

To address these challenges, several goals have been established for improving the low-temperature performance of 4140 steel. One primary objective is to lower the ductile-to-brittle transition temperature (DBTT), allowing the material to maintain its ductile behavior at lower temperatures. This can be achieved through various methods, including refining the grain structure, optimizing the heat treatment process, and carefully controlling the alloy composition.

Another important goal is to enhance the steel's notch toughness at low temperatures. This property is crucial for components that may contain stress concentrations or small defects, as it determines the material's ability to resist crack propagation under dynamic loading conditions. Improving the Charpy V-notch impact energy at sub-zero temperatures is a key metric for assessing progress in this area.

Researchers and engineers are also focusing on developing modified 4140 steel compositions that offer improved low-temperature performance without sacrificing the material's desirable properties at room temperature. This balancing act requires a deep understanding of the microstructural changes that occur during cooling and their effects on mechanical behavior.

Market Demand for Low-Temperature Steel Applications

The market demand for low-temperature steel applications has been steadily growing across various industries, driven by the need for materials that can maintain their structural integrity and performance in extreme cold environments. Industries such as oil and gas, aerospace, automotive, and cryogenic equipment manufacturing are particularly interested in steels that can withstand low temperatures without compromising their mechanical properties.

In the oil and gas sector, the exploration and production activities in Arctic regions and deep-sea environments have created a significant demand for low-temperature steels. These materials are crucial for constructing pipelines, offshore platforms, and drilling equipment that can operate reliably in sub-zero temperatures. The industry requires steels that can resist brittle fracture and maintain their ductility under severe cold conditions.

The aerospace industry also presents a substantial market for low-temperature steel applications. Aircraft components, particularly those used in high-altitude operations or space exploration missions, must withstand extremely low temperatures while maintaining their structural integrity. The demand for lightweight yet strong materials that can perform in these conditions continues to drive research and development in this field.

Automotive manufacturers are increasingly focusing on improving vehicle performance in cold climates. This has led to a growing demand for steels that can maintain their toughness and ductility in sub-zero temperatures, particularly for critical components such as suspension systems, chassis parts, and engine mounts. The push towards electric vehicles has further intensified the need for materials that can protect battery systems and other electrical components in extreme cold.

The cryogenic equipment industry, which includes applications in liquefied natural gas (LNG) storage and transportation, medical imaging, and scientific research, requires steels that can withstand temperatures as low as -196°C (the boiling point of liquid nitrogen). This sector demands materials with exceptional low-temperature toughness and resistance to thermal cycling.

Market analysts project that the global demand for low-temperature steels will continue to grow at a compound annual growth rate (CAGR) of 5-7% over the next five years. This growth is attributed to increasing industrial activities in cold regions, advancements in cryogenic technologies, and the expansion of LNG infrastructure worldwide.

The challenges faced by 4140 steel in low-temperature environments present both a problem and an opportunity for the market. While 4140 steel is widely used for its excellent combination of strength and toughness at room temperature, its performance degradation in cold conditions has created a demand for improved alloys or alternative materials. This has spurred research into developing new steel grades or modifying existing ones to enhance their low-temperature ductility without sacrificing other desirable properties.

In the oil and gas sector, the exploration and production activities in Arctic regions and deep-sea environments have created a significant demand for low-temperature steels. These materials are crucial for constructing pipelines, offshore platforms, and drilling equipment that can operate reliably in sub-zero temperatures. The industry requires steels that can resist brittle fracture and maintain their ductility under severe cold conditions.

The aerospace industry also presents a substantial market for low-temperature steel applications. Aircraft components, particularly those used in high-altitude operations or space exploration missions, must withstand extremely low temperatures while maintaining their structural integrity. The demand for lightweight yet strong materials that can perform in these conditions continues to drive research and development in this field.

Automotive manufacturers are increasingly focusing on improving vehicle performance in cold climates. This has led to a growing demand for steels that can maintain their toughness and ductility in sub-zero temperatures, particularly for critical components such as suspension systems, chassis parts, and engine mounts. The push towards electric vehicles has further intensified the need for materials that can protect battery systems and other electrical components in extreme cold.

The cryogenic equipment industry, which includes applications in liquefied natural gas (LNG) storage and transportation, medical imaging, and scientific research, requires steels that can withstand temperatures as low as -196°C (the boiling point of liquid nitrogen). This sector demands materials with exceptional low-temperature toughness and resistance to thermal cycling.

Market analysts project that the global demand for low-temperature steels will continue to grow at a compound annual growth rate (CAGR) of 5-7% over the next five years. This growth is attributed to increasing industrial activities in cold regions, advancements in cryogenic technologies, and the expansion of LNG infrastructure worldwide.

The challenges faced by 4140 steel in low-temperature environments present both a problem and an opportunity for the market. While 4140 steel is widely used for its excellent combination of strength and toughness at room temperature, its performance degradation in cold conditions has created a demand for improved alloys or alternative materials. This has spurred research into developing new steel grades or modifying existing ones to enhance their low-temperature ductility without sacrificing other desirable properties.

Current Limitations of 4140 Steel at Low Temperatures

4140 steel, renowned for its high strength and toughness, faces significant challenges when exposed to low-temperature environments. The primary limitation is the steel's susceptibility to brittle fracture, which becomes more pronounced as temperatures decrease. This phenomenon is attributed to the body-centered cubic (BCC) crystal structure of the ferrite phase in 4140 steel, which exhibits reduced mobility of dislocations at lower temperatures.

The ductile-to-brittle transition temperature (DBTT) of 4140 steel is a critical factor in its low-temperature performance. Below this temperature, the steel's ability to deform plastically before fracture is severely compromised. For 4140 steel, the DBTT typically falls within the range of -20°C to 0°C, depending on its heat treatment and microstructure. This relatively high DBTT limits its applicability in cryogenic applications or in regions with extreme cold climates.

Another significant limitation is the reduced impact toughness of 4140 steel at low temperatures. As the temperature drops, the energy required to initiate and propagate cracks decreases, making the material more susceptible to sudden failure under impact loads. This characteristic is particularly problematic in dynamic loading scenarios or in applications where sudden impacts are expected.

The low-temperature embrittlement of 4140 steel is further exacerbated by its alloying elements, particularly carbon and chromium. While these elements contribute to the steel's high strength, they also tend to segregate to grain boundaries at low temperatures, potentially weakening these regions and providing easy paths for crack propagation.

Hydrogen embrittlement is another concern for 4140 steel in low-temperature environments. The steel's susceptibility to hydrogen uptake increases at lower temperatures, leading to a reduction in ductility and toughness. This phenomenon is particularly problematic in applications where the steel may be exposed to hydrogen-rich environments or undergo electrochemical processes.

The microstructural stability of 4140 steel is also challenged at low temperatures. Thermal cycling between ambient and low temperatures can lead to the formation of microcracks and the accumulation of residual stresses, further compromising the material's mechanical properties over time.

Lastly, the reduced ductility of 4140 steel at low temperatures poses significant challenges in manufacturing and fabrication processes. Operations such as cold forming, bending, or welding become increasingly difficult and may require specialized techniques or equipment to prevent cracking or failure during processing.

The ductile-to-brittle transition temperature (DBTT) of 4140 steel is a critical factor in its low-temperature performance. Below this temperature, the steel's ability to deform plastically before fracture is severely compromised. For 4140 steel, the DBTT typically falls within the range of -20°C to 0°C, depending on its heat treatment and microstructure. This relatively high DBTT limits its applicability in cryogenic applications or in regions with extreme cold climates.

Another significant limitation is the reduced impact toughness of 4140 steel at low temperatures. As the temperature drops, the energy required to initiate and propagate cracks decreases, making the material more susceptible to sudden failure under impact loads. This characteristic is particularly problematic in dynamic loading scenarios or in applications where sudden impacts are expected.

The low-temperature embrittlement of 4140 steel is further exacerbated by its alloying elements, particularly carbon and chromium. While these elements contribute to the steel's high strength, they also tend to segregate to grain boundaries at low temperatures, potentially weakening these regions and providing easy paths for crack propagation.

Hydrogen embrittlement is another concern for 4140 steel in low-temperature environments. The steel's susceptibility to hydrogen uptake increases at lower temperatures, leading to a reduction in ductility and toughness. This phenomenon is particularly problematic in applications where the steel may be exposed to hydrogen-rich environments or undergo electrochemical processes.

The microstructural stability of 4140 steel is also challenged at low temperatures. Thermal cycling between ambient and low temperatures can lead to the formation of microcracks and the accumulation of residual stresses, further compromising the material's mechanical properties over time.

Lastly, the reduced ductility of 4140 steel at low temperatures poses significant challenges in manufacturing and fabrication processes. Operations such as cold forming, bending, or welding become increasingly difficult and may require specialized techniques or equipment to prevent cracking or failure during processing.

Existing Solutions for Enhancing Low-Temperature Ductility

01 Heat treatment processes for improving 4140 steel ductility

Various heat treatment processes can be applied to 4140 steel to enhance its ductility. These processes may include quenching, tempering, and annealing at specific temperatures and durations. The proper selection and application of these heat treatments can significantly improve the steel's ductility while maintaining its strength properties.- Heat treatment processes for improving ductility: Various heat treatment processes can be applied to 4140 steel to enhance its ductility. These processes may include quenching, tempering, and annealing, which can be optimized to achieve a balance between strength and ductility. The specific parameters of these heat treatments, such as temperature and duration, can be adjusted to tailor the mechanical properties of the steel.

- Alloying element modifications: The ductility of 4140 steel can be improved by modifying its alloying elements. This may involve adjusting the concentrations of elements such as carbon, manganese, chromium, and molybdenum. Fine-tuning the composition can help achieve a better balance between strength and ductility while maintaining other desirable properties of the steel.

- Microstructure control techniques: Controlling the microstructure of 4140 steel is crucial for enhancing its ductility. This can be achieved through various techniques such as grain refinement, phase transformation control, and precipitation hardening. These methods aim to create a favorable microstructure that promotes both strength and ductility in the steel.

- Thermomechanical processing: Thermomechanical processing techniques can be employed to improve the ductility of 4140 steel. These methods involve combining controlled deformation with heat treatment to optimize the steel's microstructure and mechanical properties. Processes such as controlled rolling, forging, and hot working can be used to enhance the steel's ductility while maintaining its strength.

- Surface treatment and coating methods: Various surface treatment and coating methods can be applied to 4140 steel to improve its ductility, particularly in specific applications. These techniques may include carburizing, nitriding, or applying specialized coatings. Such treatments can enhance the surface properties of the steel, potentially improving its overall ductility and performance in certain environments.

02 Alloying elements and their effects on 4140 steel ductility

The composition of alloying elements in 4140 steel plays a crucial role in determining its ductility. Careful control of elements such as carbon, manganese, chromium, and molybdenum can help achieve an optimal balance between strength and ductility. Adjusting the percentages of these elements within specified ranges can lead to improved ductile properties.Expand Specific Solutions03 Microstructure control for enhancing 4140 steel ductility

Controlling the microstructure of 4140 steel is essential for improving its ductility. Techniques such as grain refinement, phase transformation control, and precipitation hardening can be employed to achieve a desirable microstructure. These methods can result in a fine-grained structure with optimized distribution of phases, leading to enhanced ductility.Expand Specific Solutions04 Thermomechanical processing to improve 4140 steel ductility

Thermomechanical processing techniques can be applied to 4140 steel to improve its ductility. These processes involve controlled deformation and heat treatment steps, such as hot rolling, controlled cooling, and subsequent tempering. By optimizing these parameters, the steel's microstructure can be refined, resulting in improved ductility without compromising strength.Expand Specific Solutions05 Surface treatments for enhancing 4140 steel ductility

Various surface treatments can be applied to 4140 steel to improve its ductility, particularly in specific applications. These treatments may include carburizing, nitriding, or shot peening. By modifying the surface properties of the steel, these techniques can enhance the overall ductility and performance of 4140 steel components.Expand Specific Solutions

Key Players in Low-Temperature Steel Industry

The competitive landscape for addressing ductility challenges of 4140 steel in low-temperature environments is characterized by a mature industry in a growth phase. The market size is substantial, driven by demand from sectors like automotive, aerospace, and energy. Technologically, the field is advancing, with companies like NIPPON STEEL CORP., JFE Steel Corp., and POSCO Holdings leading innovation. These firms, along with others such as Angang Steel and Baoshan Iron & Steel, are investing in R&D to enhance low-temperature performance of 4140 steel. The competition is intense, with both established players and emerging companies like Nanyang Hanye Special Steel focusing on developing proprietary solutions to address ductility issues in extreme conditions.

NIPPON STEEL CORP.

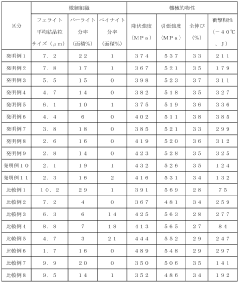

Technical Solution: NIPPON STEEL CORP. has developed advanced heat treatment processes to improve the low-temperature ductility of 4140 steel. Their approach involves a carefully controlled quenching and tempering process, which creates a fine-grained martensitic structure with optimized carbide distribution[1]. This microstructure enhances the steel's toughness at low temperatures while maintaining its high strength. Additionally, they have implemented a proprietary alloying strategy, slightly modifying the traditional 4140 composition to include trace amounts of nickel and molybdenum, which are known to improve low-temperature performance[3]. The company has also invested in advanced cryogenic testing facilities to accurately assess the material's behavior under extreme cold conditions, ensuring reliable performance in applications such as offshore oil and gas equipment[5].

Strengths: Improved low-temperature toughness without sacrificing strength, advanced testing capabilities for accurate performance prediction. Weaknesses: Potentially higher production costs due to specialized heat treatment and alloying additions, may require modifications to existing manufacturing processes.

JFE Steel Corp.

Technical Solution: JFE Steel Corp. has focused on microstructure control to address the ductility challenges of 4140 steel in low-temperature environments. Their approach involves a two-stage heat treatment process: initial quenching to form martensite, followed by a carefully controlled tempering regime[2]. This process results in a refined tempered martensitic structure with evenly distributed carbides, which enhances low-temperature toughness. JFE has also developed a proprietary surface treatment technique that introduces compressive residual stresses in the surface layer, further improving the steel's resistance to brittle fracture at low temperatures[4]. Additionally, they have implemented advanced non-destructive testing methods, including acoustic emission and ultrasonic techniques, to detect potential microstructural issues that could lead to low-temperature embrittlement[6].

Strengths: Enhanced low-temperature toughness through microstructure control and surface treatment, advanced quality control methods. Weaknesses: The specialized heat treatment and surface processes may increase production time and costs, potentially limiting large-scale application.

Core Innovations in 4140 Steel Composition and Processing

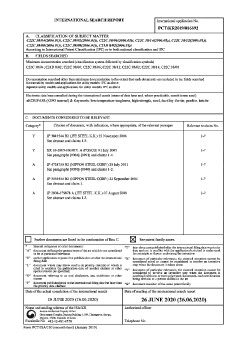

High-strength steel material with excellent ductility and low-temperature toughness, and method for producing the same

PatentActiveJP2022510212A

Innovation

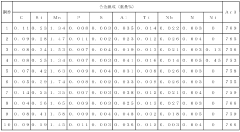

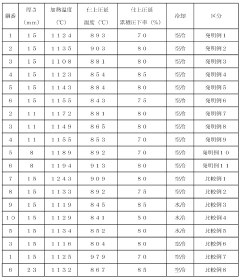

- A high-strength steel composition containing specific alloy elements (C, Si, Mn, P, S, Al, Ti, Nb, N, Ni) with a microstructure of polygonal ferrite and pearlite/bainite phases, produced through controlled heating, rolling, and cooling processes to achieve a balanced mechanical performance.

Extra low temperature use nonmagnetic austenitic stainless steel having excellent reheating resistance

PatentInactiveJP1990057668A

Innovation

- A non-magnetic austenitic stainless steel composition with specific chemical limits (C: 0.05%, Mn: 1-10%, Si: 0.5% or less, P: 0.03% or less, S: 0.01% or less, Cr: 13-20%, Ni: 10-15%, N: 0.02-0.10%, Mo: 1.5-4.5%, B: 0.002-0.006%, and optional Ca, Mg, Zr, Ce) is developed to stabilize the austenitic phase, suppress intergranular corrosion, and enhance low-temperature toughness without requiring expensive special components or treatments.

Environmental Impact of Low-Temperature Steel Production

The production of steel in low-temperature environments presents unique challenges and opportunities for environmental impact mitigation. The process of manufacturing 4140 steel, particularly in cold climates, requires careful consideration of energy consumption and emissions. Traditional steel production methods often rely on high-temperature processes, which can be energy-intensive and contribute significantly to greenhouse gas emissions. However, when operating in low-temperature environments, there is potential for innovative approaches that can reduce the overall environmental footprint.

One of the primary environmental concerns in low-temperature steel production is the increased energy demand for heating and maintaining optimal process temperatures. This additional energy requirement can lead to higher carbon emissions if not managed properly. However, the colder ambient temperatures also present opportunities for energy recovery and efficient heat management systems. By implementing advanced heat exchange technologies and thermal insulation techniques, manufacturers can minimize heat loss and reduce overall energy consumption.

Water usage and management are also critical factors in the environmental impact of low-temperature steel production. The need for cooling systems in steel manufacturing processes can be partially offset by the naturally cooler environment, potentially reducing water consumption. However, careful consideration must be given to preventing water pollution and managing wastewater in freezing conditions, which may require specialized treatment facilities and processes.

The transportation and logistics associated with steel production in cold climates can have significant environmental implications. The challenges of moving raw materials and finished products in harsh weather conditions may lead to increased fuel consumption and emissions. To mitigate these impacts, companies may need to invest in more efficient transportation methods and optimize supply chain logistics to reduce unnecessary movement of goods.

Air quality is another important environmental consideration in low-temperature steel production. While colder air can sometimes lead to reduced dispersion of pollutants, it can also create temperature inversions that trap emissions close to the ground. This necessitates more stringent air quality control measures and potentially the implementation of advanced filtration and scrubbing technologies to minimize the release of particulate matter and other pollutants.

The development of new alloys and production techniques specifically designed for low-temperature environments could lead to more environmentally friendly steel production. Research into materials that require less energy to process or maintain their properties in cold conditions could result in significant reductions in the overall environmental impact of steel manufacturing in these regions.

One of the primary environmental concerns in low-temperature steel production is the increased energy demand for heating and maintaining optimal process temperatures. This additional energy requirement can lead to higher carbon emissions if not managed properly. However, the colder ambient temperatures also present opportunities for energy recovery and efficient heat management systems. By implementing advanced heat exchange technologies and thermal insulation techniques, manufacturers can minimize heat loss and reduce overall energy consumption.

Water usage and management are also critical factors in the environmental impact of low-temperature steel production. The need for cooling systems in steel manufacturing processes can be partially offset by the naturally cooler environment, potentially reducing water consumption. However, careful consideration must be given to preventing water pollution and managing wastewater in freezing conditions, which may require specialized treatment facilities and processes.

The transportation and logistics associated with steel production in cold climates can have significant environmental implications. The challenges of moving raw materials and finished products in harsh weather conditions may lead to increased fuel consumption and emissions. To mitigate these impacts, companies may need to invest in more efficient transportation methods and optimize supply chain logistics to reduce unnecessary movement of goods.

Air quality is another important environmental consideration in low-temperature steel production. While colder air can sometimes lead to reduced dispersion of pollutants, it can also create temperature inversions that trap emissions close to the ground. This necessitates more stringent air quality control measures and potentially the implementation of advanced filtration and scrubbing technologies to minimize the release of particulate matter and other pollutants.

The development of new alloys and production techniques specifically designed for low-temperature environments could lead to more environmentally friendly steel production. Research into materials that require less energy to process or maintain their properties in cold conditions could result in significant reductions in the overall environmental impact of steel manufacturing in these regions.

Safety Standards for Low-Temperature Steel Applications

Safety standards for low-temperature steel applications are critical in ensuring the reliability and integrity of structures and components operating in harsh environments. These standards encompass a wide range of requirements, from material selection to design considerations and testing protocols. For 4140 steel, which is known for its high strength but faces ductility challenges at low temperatures, adherence to these standards is particularly crucial.

The primary safety standards governing low-temperature steel applications include ASTM A320, which specifies requirements for alloy-steel bolting materials for low-temperature service, and ASME Boiler and Pressure Vessel Code Section VIII, which provides guidelines for pressure vessels operating at sub-zero temperatures. These standards typically mandate specific mechanical properties, such as minimum tensile strength, yield strength, and impact toughness at the design temperature.

For 4140 steel applications in low-temperature environments, safety standards often require additional heat treatment processes to improve low-temperature ductility. Quenching and tempering procedures are carefully specified to achieve an optimal balance between strength and toughness. The standards may also dictate specific tempering temperatures and holding times to ensure the development of a microstructure that can withstand low-temperature service without brittle failure.

Nondestructive testing (NDT) requirements are another crucial aspect of safety standards for low-temperature steel applications. These may include ultrasonic testing, magnetic particle inspection, and radiographic examination to detect any flaws or defects that could compromise the material's integrity under low-temperature stress conditions. The frequency and extent of these inspections are often more stringent for components operating in critical low-temperature environments.

Safety standards also address design considerations specific to low-temperature applications. These include guidelines for stress analysis, fatigue assessment, and fracture mechanics evaluations tailored to the unique challenges posed by cold environments. For 4140 steel components, the standards may require more conservative design factors to account for the potential reduction in ductility at low temperatures.

Material traceability and quality control measures form an integral part of safety standards for low-temperature steel applications. These requirements ensure that the 4140 steel used in critical components meets all specified chemical composition and mechanical property criteria. Detailed documentation, including material certificates and test reports, is typically mandated to verify compliance with the standards throughout the manufacturing and installation processes.

The primary safety standards governing low-temperature steel applications include ASTM A320, which specifies requirements for alloy-steel bolting materials for low-temperature service, and ASME Boiler and Pressure Vessel Code Section VIII, which provides guidelines for pressure vessels operating at sub-zero temperatures. These standards typically mandate specific mechanical properties, such as minimum tensile strength, yield strength, and impact toughness at the design temperature.

For 4140 steel applications in low-temperature environments, safety standards often require additional heat treatment processes to improve low-temperature ductility. Quenching and tempering procedures are carefully specified to achieve an optimal balance between strength and toughness. The standards may also dictate specific tempering temperatures and holding times to ensure the development of a microstructure that can withstand low-temperature service without brittle failure.

Nondestructive testing (NDT) requirements are another crucial aspect of safety standards for low-temperature steel applications. These may include ultrasonic testing, magnetic particle inspection, and radiographic examination to detect any flaws or defects that could compromise the material's integrity under low-temperature stress conditions. The frequency and extent of these inspections are often more stringent for components operating in critical low-temperature environments.

Safety standards also address design considerations specific to low-temperature applications. These include guidelines for stress analysis, fatigue assessment, and fracture mechanics evaluations tailored to the unique challenges posed by cold environments. For 4140 steel components, the standards may require more conservative design factors to account for the potential reduction in ductility at low temperatures.

Material traceability and quality control measures form an integral part of safety standards for low-temperature steel applications. These requirements ensure that the 4140 steel used in critical components meets all specified chemical composition and mechanical property criteria. Detailed documentation, including material certificates and test reports, is typically mandated to verify compliance with the standards throughout the manufacturing and installation processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!