Emerging Technologies in Solar Inverter Production

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solar Inverter Tech Evolution and Objectives

Solar inverter technology has undergone significant evolution since its inception, driven by the rapid growth of the solar energy industry. The primary objective of solar inverter development has been to improve efficiency, reliability, and cost-effectiveness in converting DC power from solar panels to AC power for grid use or local consumption.

The early stages of solar inverter technology focused on basic power conversion, with relatively low efficiency and limited functionality. As the solar industry expanded, inverters evolved to incorporate more advanced features such as Maximum Power Point Tracking (MPPT) to optimize energy harvest from solar panels under varying conditions.

A major milestone in solar inverter evolution was the shift from central inverters to string inverters and microinverters. This transition allowed for more flexible system designs, improved performance in partial shading conditions, and enhanced monitoring capabilities at the module level.

The integration of smart grid functionalities has been a key objective in recent years. Modern solar inverters are designed to support grid stability through features like reactive power control, voltage regulation, and frequency response. This evolution aligns with the growing need for grid-interactive renewable energy systems.

Another significant development has been the focus on enhancing inverter durability and lifespan. Manufacturers have been working on improving thermal management, using more robust components, and implementing advanced protection mechanisms to ensure longer operational life and reduced maintenance requirements.

The miniaturization of inverter technology has also been a consistent goal, aiming to reduce the physical footprint and weight of inverters while maintaining or improving performance. This trend has been particularly important for residential and small commercial installations where space may be limited.

Looking forward, the objectives for solar inverter technology include further improvements in efficiency, with a focus on wide-bandgap semiconductors like silicon carbide (SiC) and gallium nitride (GaN). These materials promise higher switching frequencies, lower losses, and improved thermal performance.

Integration of energy storage capabilities is another key objective, with hybrid inverters becoming increasingly popular. These systems aim to provide seamless integration of solar power generation with battery storage, enabling greater energy independence and resilience for end-users.

Advancements in communication and IoT capabilities are also at the forefront of inverter development. The goal is to create more intelligent, interconnected systems that can optimize energy flow, predict maintenance needs, and provide valuable data for system owners and grid operators.

The early stages of solar inverter technology focused on basic power conversion, with relatively low efficiency and limited functionality. As the solar industry expanded, inverters evolved to incorporate more advanced features such as Maximum Power Point Tracking (MPPT) to optimize energy harvest from solar panels under varying conditions.

A major milestone in solar inverter evolution was the shift from central inverters to string inverters and microinverters. This transition allowed for more flexible system designs, improved performance in partial shading conditions, and enhanced monitoring capabilities at the module level.

The integration of smart grid functionalities has been a key objective in recent years. Modern solar inverters are designed to support grid stability through features like reactive power control, voltage regulation, and frequency response. This evolution aligns with the growing need for grid-interactive renewable energy systems.

Another significant development has been the focus on enhancing inverter durability and lifespan. Manufacturers have been working on improving thermal management, using more robust components, and implementing advanced protection mechanisms to ensure longer operational life and reduced maintenance requirements.

The miniaturization of inverter technology has also been a consistent goal, aiming to reduce the physical footprint and weight of inverters while maintaining or improving performance. This trend has been particularly important for residential and small commercial installations where space may be limited.

Looking forward, the objectives for solar inverter technology include further improvements in efficiency, with a focus on wide-bandgap semiconductors like silicon carbide (SiC) and gallium nitride (GaN). These materials promise higher switching frequencies, lower losses, and improved thermal performance.

Integration of energy storage capabilities is another key objective, with hybrid inverters becoming increasingly popular. These systems aim to provide seamless integration of solar power generation with battery storage, enabling greater energy independence and resilience for end-users.

Advancements in communication and IoT capabilities are also at the forefront of inverter development. The goal is to create more intelligent, interconnected systems that can optimize energy flow, predict maintenance needs, and provide valuable data for system owners and grid operators.

Market Demand Analysis for Advanced Solar Inverters

The global market for advanced solar inverters is experiencing robust growth, driven by the increasing adoption of solar energy systems across residential, commercial, and utility-scale applications. This surge in demand is primarily fueled by the declining costs of solar photovoltaic (PV) systems, supportive government policies, and growing environmental awareness.

In the residential sector, there is a rising trend towards smart home integration, leading to increased demand for inverters with advanced monitoring and control capabilities. Homeowners are seeking inverters that can seamlessly connect with home energy management systems, allowing for optimized energy consumption and storage. This trend is particularly strong in developed markets such as North America, Europe, and parts of Asia-Pacific.

The commercial and industrial sectors are showing a growing interest in solar-plus-storage solutions, driving demand for hybrid inverters that can manage both solar power generation and battery storage. These advanced inverters enable businesses to reduce their reliance on the grid, optimize energy costs, and ensure power reliability during outages.

In the utility-scale segment, there is a significant push towards higher capacity inverters with enhanced grid support features. Grid operators are increasingly requiring inverters to provide advanced grid services such as voltage regulation, frequency support, and fault ride-through capabilities. This trend is particularly evident in markets with high renewable energy penetration, such as Germany, California, and Australia.

Emerging markets in Asia, Africa, and Latin America are also contributing to the growing demand for advanced solar inverters. As these regions expand their solar energy infrastructure, there is a need for inverters that can operate reliably in diverse environmental conditions and withstand grid instabilities.

The market is also seeing increased demand for microinverters and power optimizers, especially in residential and small commercial installations. These module-level power electronics offer advantages in terms of system performance, flexibility, and safety, appealing to customers looking for maximized energy yield and simplified maintenance.

Technological advancements are further shaping market demand. There is growing interest in inverters with artificial intelligence and machine learning capabilities for predictive maintenance and performance optimization. Additionally, the shift towards wide-bandgap semiconductors, such as silicon carbide (SiC) and gallium nitride (GaN), is driving demand for more efficient and compact inverter designs.

As the electric vehicle (EV) market expands, there is an emerging opportunity for solar inverters with integrated EV charging capabilities. This convergence of solar power and e-mobility is creating a new segment within the advanced inverter market, particularly in regions with high EV adoption rates.

In the residential sector, there is a rising trend towards smart home integration, leading to increased demand for inverters with advanced monitoring and control capabilities. Homeowners are seeking inverters that can seamlessly connect with home energy management systems, allowing for optimized energy consumption and storage. This trend is particularly strong in developed markets such as North America, Europe, and parts of Asia-Pacific.

The commercial and industrial sectors are showing a growing interest in solar-plus-storage solutions, driving demand for hybrid inverters that can manage both solar power generation and battery storage. These advanced inverters enable businesses to reduce their reliance on the grid, optimize energy costs, and ensure power reliability during outages.

In the utility-scale segment, there is a significant push towards higher capacity inverters with enhanced grid support features. Grid operators are increasingly requiring inverters to provide advanced grid services such as voltage regulation, frequency support, and fault ride-through capabilities. This trend is particularly evident in markets with high renewable energy penetration, such as Germany, California, and Australia.

Emerging markets in Asia, Africa, and Latin America are also contributing to the growing demand for advanced solar inverters. As these regions expand their solar energy infrastructure, there is a need for inverters that can operate reliably in diverse environmental conditions and withstand grid instabilities.

The market is also seeing increased demand for microinverters and power optimizers, especially in residential and small commercial installations. These module-level power electronics offer advantages in terms of system performance, flexibility, and safety, appealing to customers looking for maximized energy yield and simplified maintenance.

Technological advancements are further shaping market demand. There is growing interest in inverters with artificial intelligence and machine learning capabilities for predictive maintenance and performance optimization. Additionally, the shift towards wide-bandgap semiconductors, such as silicon carbide (SiC) and gallium nitride (GaN), is driving demand for more efficient and compact inverter designs.

As the electric vehicle (EV) market expands, there is an emerging opportunity for solar inverters with integrated EV charging capabilities. This convergence of solar power and e-mobility is creating a new segment within the advanced inverter market, particularly in regions with high EV adoption rates.

Current Challenges in Solar Inverter Manufacturing

Solar inverter manufacturing faces several significant challenges in the current technological landscape. One of the primary issues is the need for increased efficiency in power conversion. As solar panels become more efficient, inverters must keep pace to ensure optimal energy harvesting. This requires continuous innovation in semiconductor technology and power electronics design to minimize energy losses during the DC to AC conversion process.

Another challenge lies in the integration of advanced grid support features. Modern solar inverters are expected to provide grid stability services, such as voltage regulation and frequency support. Implementing these features while maintaining high efficiency and reliability poses a significant engineering challenge. Manufacturers must develop sophisticated control algorithms and robust hardware capable of responding rapidly to grid fluctuations.

Reliability and longevity remain critical concerns in solar inverter production. Inverters are often considered the weakest link in solar power systems, with failure rates higher than other components. Improving the mean time between failures (MTBF) and extending the operational lifespan of inverters is crucial for reducing the overall cost of solar energy. This involves enhancing thermal management, using more durable components, and implementing advanced self-diagnostic capabilities.

The increasing demand for smart, connected inverters presents another hurdle. Integrating communication technologies, data analytics, and cybersecurity features into inverters adds complexity to the manufacturing process. Ensuring these smart features do not compromise the core functionality or reliability of the inverter is a delicate balance that manufacturers must strike.

Cost reduction remains a persistent challenge in the competitive solar market. While the price of solar panels has dropped significantly over the years, inverter costs have not decreased at the same rate. Manufacturers are under pressure to reduce production costs without sacrificing quality or performance. This often requires innovations in manufacturing processes, supply chain optimization, and material science.

Lastly, the rapid evolution of solar technology and changing grid requirements necessitate a flexible and adaptable manufacturing approach. Inverter designs must be able to accommodate various types of solar panels, energy storage systems, and grid configurations. This flexibility requirement complicates the manufacturing process and requires a more versatile production line capable of quick adjustments to meet diverse market demands.

Another challenge lies in the integration of advanced grid support features. Modern solar inverters are expected to provide grid stability services, such as voltage regulation and frequency support. Implementing these features while maintaining high efficiency and reliability poses a significant engineering challenge. Manufacturers must develop sophisticated control algorithms and robust hardware capable of responding rapidly to grid fluctuations.

Reliability and longevity remain critical concerns in solar inverter production. Inverters are often considered the weakest link in solar power systems, with failure rates higher than other components. Improving the mean time between failures (MTBF) and extending the operational lifespan of inverters is crucial for reducing the overall cost of solar energy. This involves enhancing thermal management, using more durable components, and implementing advanced self-diagnostic capabilities.

The increasing demand for smart, connected inverters presents another hurdle. Integrating communication technologies, data analytics, and cybersecurity features into inverters adds complexity to the manufacturing process. Ensuring these smart features do not compromise the core functionality or reliability of the inverter is a delicate balance that manufacturers must strike.

Cost reduction remains a persistent challenge in the competitive solar market. While the price of solar panels has dropped significantly over the years, inverter costs have not decreased at the same rate. Manufacturers are under pressure to reduce production costs without sacrificing quality or performance. This often requires innovations in manufacturing processes, supply chain optimization, and material science.

Lastly, the rapid evolution of solar technology and changing grid requirements necessitate a flexible and adaptable manufacturing approach. Inverter designs must be able to accommodate various types of solar panels, energy storage systems, and grid configurations. This flexibility requirement complicates the manufacturing process and requires a more versatile production line capable of quick adjustments to meet diverse market demands.

State-of-the-Art Solar Inverter Production Techniques

01 Grid-tied solar inverter systems

Grid-tied solar inverter systems are designed to connect photovoltaic arrays to the utility grid. These systems typically include features for maximum power point tracking, DC-to-AC conversion, and grid synchronization. They often incorporate safety mechanisms such as anti-islanding protection and may support bidirectional power flow for energy storage integration.- Grid-tied solar inverter systems: Grid-tied solar inverter systems are designed to connect solar panels to the utility grid. These systems convert DC power from solar panels to AC power compatible with the grid, allowing for bidirectional power flow. They often include features like maximum power point tracking (MPPT) and anti-islanding protection for safety and efficiency.

- Microinverter technology: Microinverters are small inverters attached to individual solar panels or small groups of panels. They convert DC to AC at the panel level, offering advantages such as improved efficiency, easier system design, and better performance in partial shading conditions. Microinverters also provide panel-level monitoring and can enhance system reliability.

- Power optimization and management: Solar inverters incorporate various power optimization and management techniques to maximize energy yield and system efficiency. These include advanced MPPT algorithms, reactive power control, and intelligent power management systems that can adapt to changing environmental conditions and grid requirements.

- Safety and protection features: Solar inverters integrate multiple safety and protection features to ensure reliable operation and prevent damage to the system or grid. These include ground fault detection, surge protection, anti-islanding capabilities, and automatic shutdown mechanisms in case of grid failure or other abnormal conditions.

- Smart grid integration and communication: Modern solar inverters are designed with smart grid integration capabilities, allowing for two-way communication between the inverter and the grid. This enables features such as remote monitoring, diagnostics, firmware updates, and grid support functions like voltage regulation and frequency response.

02 Microinverter technology

Microinverters are small inverters attached to individual solar panels or small groups of panels. They convert DC to AC at the panel level, offering advantages such as improved system efficiency, enhanced monitoring capabilities, and easier scalability. Microinverters can also mitigate the effects of partial shading on overall system performance.Expand Specific Solutions03 Power optimization and management

Solar inverters incorporate various power optimization and management techniques to enhance overall system efficiency. These may include advanced maximum power point tracking algorithms, reactive power control, and intelligent power management strategies. Some inverters also integrate energy storage management capabilities for improved grid stability and self-consumption.Expand Specific Solutions04 Inverter safety and protection features

Solar inverters incorporate various safety and protection features to ensure reliable operation and compliance with grid standards. These may include ground fault detection, arc fault protection, overvoltage and undervoltage protection, and anti-islanding capabilities. Advanced monitoring and diagnostic features are often integrated to facilitate maintenance and troubleshooting.Expand Specific Solutions05 Multi-level and modular inverter designs

Multi-level and modular inverter designs offer improved efficiency, power quality, and scalability for solar power systems. These architectures can reduce harmonic distortion, lower switching losses, and provide enhanced fault tolerance. Modular designs also allow for easier maintenance and system expansion.Expand Specific Solutions

Key Players in Solar Inverter Industry

The emerging technologies in solar inverter production are in a growth phase, with the market expanding rapidly due to increasing global demand for renewable energy solutions. The industry is characterized by intense competition among established players and innovative startups. Key companies like Enphase Energy, SMA Solar Technology, and Sungrow Power Supply are driving technological advancements, focusing on efficiency improvements, smart grid integration, and energy storage solutions. The market size is projected to reach significant levels in the coming years, driven by government incentives and declining solar panel costs. While the core inverter technology is mature, ongoing innovations in power electronics, software integration, and IoT connectivity are pushing the boundaries of performance and functionality, indicating a dynamic and evolving technological landscape.

Enphase Energy, Inc.

Technical Solution: Enphase Energy is pioneering microinverter technology for solar systems. Their IQ8 microinverters represent a significant advancement in solar inverter technology, capable of forming a microgrid during a power outage without the need for batteries[1]. This "sunlight-only" operation allows for continued power supply even when the grid is down. The company has also developed Ensemble technology, which integrates microinverters with energy storage and smart load control, enabling a more resilient and flexible home energy system[2]. Enphase's microinverters are designed with ASIC (Application-Specific Integrated Circuit) chips, which enhance reliability and performance while reducing size and cost[3].

Strengths: High efficiency, grid-forming capability, modular design for easy scalability, and enhanced system reliability. Weaknesses: Higher initial cost compared to string inverters, and potential for more complex installation.

Sungrow Power Supply Co., Ltd.

Technical Solution: Sungrow is advancing solar inverter technology with its focus on both utility-scale and residential solutions. Their latest utility-scale inverter, the SG350HX, boasts a maximum efficiency of 99% and supports large-format high-power modules up to 690W[4]. For residential applications, Sungrow has developed hybrid inverters that integrate solar and battery storage, such as the SH5.0/6.0RS series, which features a built-in PID recovery function to mitigate potential induced degradation in solar panels[5]. The company is also investing in AI and IoT technologies to enhance inverter performance and grid integration, with their iSolarCloud platform providing real-time monitoring and smart O&M for solar plants[6].

Strengths: High efficiency, wide range of products for different scales, advanced grid support features. Weaknesses: Less focus on microinverter technology compared to some competitors.

Innovative Solar Inverter Patents and Research

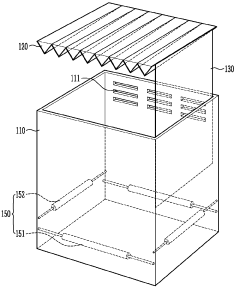

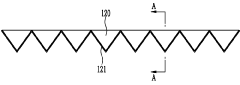

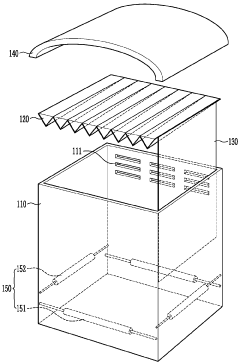

Inverter for solar power generation with heat dissipation and earthquake proof function(high voltage distribution board, high voltage distribution board, distribution board, motor control board, sunlight connection band, ESS)

PatentActiveKR1020190036603A

Innovation

- The integration of a carbon nano-coated aluminum heat sink with a concavo-convex structure and a vibration isolation unit that absorbs shocks in multiple directions, combined with ventilation holes, enhances heat dissipation and earthquake resistance.

Solar cell module with a power converter

PatentInactiveEP1202354A3

Innovation

- Attaching the power converter to a relatively low-temperature portion on the rear surface of the solar cell module, utilizing a rear-surface reinforcer with a color having higher light reflectance than the solar cells to minimize heat absorption, and employing a heat-insulating adhesive to reduce temperature rise.

Environmental Impact of Solar Inverter Production

The environmental impact of solar inverter production is a critical consideration in the renewable energy sector. As solar energy adoption continues to grow, the manufacturing processes for key components like inverters must be scrutinized for their ecological footprint.

The production of solar inverters involves several stages that can have significant environmental implications. Raw material extraction, particularly for metals and semiconductors, often requires energy-intensive mining operations. These activities can lead to habitat disruption, soil erosion, and water pollution if not managed responsibly.

Manufacturing processes for inverter components consume substantial amounts of energy, often derived from fossil fuel sources. This paradoxically contributes to greenhouse gas emissions in the short term, even as the final product aims to reduce carbon footprints. Water usage in manufacturing, especially for cleaning and cooling processes, is another environmental concern, particularly in water-stressed regions.

Chemical processes involved in the production of electronic components can generate hazardous waste. Proper disposal and treatment of these materials are essential to prevent soil and water contamination. Additionally, the use of rare earth elements in some inverter designs raises concerns about resource depletion and the environmental impact of their extraction.

However, emerging technologies are addressing these environmental challenges. Advanced manufacturing techniques are improving energy efficiency in production lines. Water recycling systems and closed-loop processes are reducing water consumption and minimizing wastewater discharge. The development of bio-based materials for certain components offers a more sustainable alternative to traditional petrochemical-derived plastics.

Lifecycle assessment (LCA) tools are increasingly being employed to evaluate and optimize the environmental performance of solar inverter production. These assessments consider the entire lifecycle, from raw material extraction to end-of-life disposal, helping manufacturers identify and mitigate environmental hotspots in their production processes.

The trend towards miniaturization and increased power density in inverter design is indirectly benefiting the environment by reducing material requirements and improving transportation efficiency. Furthermore, the integration of recycled materials in production and the implementation of take-back programs for end-of-life inverters are contributing to a more circular economy approach in the solar industry.

As the solar sector continues to mature, there is a growing emphasis on sustainable manufacturing practices. Industry leaders are setting ambitious targets for carbon-neutral production, driving innovation in clean energy use within their facilities and supply chains. These efforts, combined with ongoing technological advancements, are gradually reducing the environmental footprint of solar inverter production, aligning it more closely with the clean energy goals it serves.

The production of solar inverters involves several stages that can have significant environmental implications. Raw material extraction, particularly for metals and semiconductors, often requires energy-intensive mining operations. These activities can lead to habitat disruption, soil erosion, and water pollution if not managed responsibly.

Manufacturing processes for inverter components consume substantial amounts of energy, often derived from fossil fuel sources. This paradoxically contributes to greenhouse gas emissions in the short term, even as the final product aims to reduce carbon footprints. Water usage in manufacturing, especially for cleaning and cooling processes, is another environmental concern, particularly in water-stressed regions.

Chemical processes involved in the production of electronic components can generate hazardous waste. Proper disposal and treatment of these materials are essential to prevent soil and water contamination. Additionally, the use of rare earth elements in some inverter designs raises concerns about resource depletion and the environmental impact of their extraction.

However, emerging technologies are addressing these environmental challenges. Advanced manufacturing techniques are improving energy efficiency in production lines. Water recycling systems and closed-loop processes are reducing water consumption and minimizing wastewater discharge. The development of bio-based materials for certain components offers a more sustainable alternative to traditional petrochemical-derived plastics.

Lifecycle assessment (LCA) tools are increasingly being employed to evaluate and optimize the environmental performance of solar inverter production. These assessments consider the entire lifecycle, from raw material extraction to end-of-life disposal, helping manufacturers identify and mitigate environmental hotspots in their production processes.

The trend towards miniaturization and increased power density in inverter design is indirectly benefiting the environment by reducing material requirements and improving transportation efficiency. Furthermore, the integration of recycled materials in production and the implementation of take-back programs for end-of-life inverters are contributing to a more circular economy approach in the solar industry.

As the solar sector continues to mature, there is a growing emphasis on sustainable manufacturing practices. Industry leaders are setting ambitious targets for carbon-neutral production, driving innovation in clean energy use within their facilities and supply chains. These efforts, combined with ongoing technological advancements, are gradually reducing the environmental footprint of solar inverter production, aligning it more closely with the clean energy goals it serves.

Grid Integration Challenges for Solar Inverters

The integration of solar inverters into the existing power grid presents significant challenges that must be addressed to ensure the stability and reliability of the electrical system. One of the primary concerns is the intermittent nature of solar power generation, which can lead to voltage fluctuations and power quality issues. As the penetration of solar energy increases, grid operators face difficulties in maintaining a balance between supply and demand.

Inverters play a crucial role in mitigating these challenges by providing advanced grid support functions. Modern solar inverters are equipped with features such as reactive power control, voltage ride-through capabilities, and frequency regulation. These functionalities help stabilize the grid and improve overall system performance. However, the implementation of these features requires careful coordination between inverter manufacturers, utility companies, and regulatory bodies.

Another significant challenge is the potential for reverse power flow, which occurs when solar generation exceeds local demand. This phenomenon can lead to voltage rise issues and may require upgrades to existing grid infrastructure. To address this, smart inverters with advanced communication capabilities are being developed to enable better coordination with grid operators and facilitate dynamic power management.

Cybersecurity is an emerging concern in the context of grid-connected solar inverters. As these devices become more interconnected and rely on digital communication protocols, they become potential targets for cyber attacks. Ensuring the security and integrity of inverter control systems is crucial to prevent unauthorized access and maintain grid stability.

The increasing adoption of energy storage systems in conjunction with solar installations adds another layer of complexity to grid integration. While battery storage can help smooth out power fluctuations and provide additional grid services, it also requires sophisticated control algorithms and communication protocols to optimize its operation in harmony with solar inverters and the grid.

Standardization and interoperability remain ongoing challenges in the solar inverter industry. As different manufacturers develop proprietary technologies and communication protocols, ensuring seamless integration and compatibility across various systems becomes more difficult. Efforts are underway to establish industry-wide standards that will facilitate better grid integration and improve overall system reliability.

Inverters play a crucial role in mitigating these challenges by providing advanced grid support functions. Modern solar inverters are equipped with features such as reactive power control, voltage ride-through capabilities, and frequency regulation. These functionalities help stabilize the grid and improve overall system performance. However, the implementation of these features requires careful coordination between inverter manufacturers, utility companies, and regulatory bodies.

Another significant challenge is the potential for reverse power flow, which occurs when solar generation exceeds local demand. This phenomenon can lead to voltage rise issues and may require upgrades to existing grid infrastructure. To address this, smart inverters with advanced communication capabilities are being developed to enable better coordination with grid operators and facilitate dynamic power management.

Cybersecurity is an emerging concern in the context of grid-connected solar inverters. As these devices become more interconnected and rely on digital communication protocols, they become potential targets for cyber attacks. Ensuring the security and integrity of inverter control systems is crucial to prevent unauthorized access and maintain grid stability.

The increasing adoption of energy storage systems in conjunction with solar installations adds another layer of complexity to grid integration. While battery storage can help smooth out power fluctuations and provide additional grid services, it also requires sophisticated control algorithms and communication protocols to optimize its operation in harmony with solar inverters and the grid.

Standardization and interoperability remain ongoing challenges in the solar inverter industry. As different manufacturers develop proprietary technologies and communication protocols, ensuring seamless integration and compatibility across various systems becomes more difficult. Efforts are underway to establish industry-wide standards that will facilitate better grid integration and improve overall system reliability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!