Latest Developments in Solar Inverter Heat Dissipation

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solar Inverter Thermal Management Evolution

The evolution of solar inverter thermal management has been a critical aspect of photovoltaic system development. In the early stages of solar technology, inverters were relatively simple and operated at lower power levels, resulting in minimal heat generation. As solar installations grew in size and efficiency, the need for more advanced thermal management solutions became apparent.

During the 1990s and early 2000s, passive cooling methods dominated the industry. These primarily relied on natural convection and radiation to dissipate heat from the inverter components. Aluminum heat sinks with large surface areas were commonly used to enhance heat transfer to the surrounding air. However, as power densities increased, these passive methods proved insufficient for maintaining optimal operating temperatures.

The mid-2000s saw a shift towards active cooling techniques. Forced-air cooling systems, utilizing fans to circulate air over heat sinks, became prevalent. This approach allowed for more effective heat removal and enabled inverters to handle higher power outputs. Manufacturers began incorporating temperature sensors and control systems to regulate fan speeds based on thermal conditions, optimizing energy consumption and noise levels.

As inverter efficiencies continued to improve, the focus shifted to more sophisticated thermal management strategies. Liquid cooling systems emerged as a promising solution for high-power applications. These systems circulate a coolant through channels or plates in direct contact with heat-generating components, offering superior heat transfer capabilities compared to air-based methods.

In recent years, the integration of advanced materials and design techniques has further enhanced thermal management. The use of thermally conductive polymers and phase-change materials has allowed for more efficient and compact cooling solutions. Additionally, computational fluid dynamics (CFD) simulations have become instrumental in optimizing inverter designs for improved heat dissipation.

The latest developments in solar inverter thermal management include the adoption of wide-bandgap semiconductors, such as silicon carbide (SiC) and gallium nitride (GaN). These materials offer higher temperature tolerance and lower switching losses, reducing overall heat generation. This has led to the development of more compact and efficient inverters with simplified cooling requirements.

Furthermore, the integration of artificial intelligence and machine learning algorithms has enabled predictive thermal management. These systems can anticipate temperature fluctuations based on environmental conditions and power output, allowing for proactive adjustments to cooling strategies and optimizing overall system performance.

During the 1990s and early 2000s, passive cooling methods dominated the industry. These primarily relied on natural convection and radiation to dissipate heat from the inverter components. Aluminum heat sinks with large surface areas were commonly used to enhance heat transfer to the surrounding air. However, as power densities increased, these passive methods proved insufficient for maintaining optimal operating temperatures.

The mid-2000s saw a shift towards active cooling techniques. Forced-air cooling systems, utilizing fans to circulate air over heat sinks, became prevalent. This approach allowed for more effective heat removal and enabled inverters to handle higher power outputs. Manufacturers began incorporating temperature sensors and control systems to regulate fan speeds based on thermal conditions, optimizing energy consumption and noise levels.

As inverter efficiencies continued to improve, the focus shifted to more sophisticated thermal management strategies. Liquid cooling systems emerged as a promising solution for high-power applications. These systems circulate a coolant through channels or plates in direct contact with heat-generating components, offering superior heat transfer capabilities compared to air-based methods.

In recent years, the integration of advanced materials and design techniques has further enhanced thermal management. The use of thermally conductive polymers and phase-change materials has allowed for more efficient and compact cooling solutions. Additionally, computational fluid dynamics (CFD) simulations have become instrumental in optimizing inverter designs for improved heat dissipation.

The latest developments in solar inverter thermal management include the adoption of wide-bandgap semiconductors, such as silicon carbide (SiC) and gallium nitride (GaN). These materials offer higher temperature tolerance and lower switching losses, reducing overall heat generation. This has led to the development of more compact and efficient inverters with simplified cooling requirements.

Furthermore, the integration of artificial intelligence and machine learning algorithms has enabled predictive thermal management. These systems can anticipate temperature fluctuations based on environmental conditions and power output, allowing for proactive adjustments to cooling strategies and optimizing overall system performance.

Market Demand for Efficient Solar Inverters

The global solar energy market has experienced significant growth in recent years, driven by increasing environmental concerns and the push for renewable energy sources. This growth has led to a surge in demand for efficient solar inverters, which play a crucial role in converting direct current (DC) from solar panels into alternating current (AC) for use in homes and businesses. As the efficiency of solar inverters directly impacts the overall performance of solar power systems, there is a strong market demand for inverters with improved heat dissipation capabilities.

The market for solar inverters is expected to continue its upward trajectory, with a particular emphasis on efficiency and reliability. Consumers and businesses alike are seeking inverters that can maximize energy output while minimizing losses due to heat generation. This demand is further fueled by the increasing adoption of large-scale solar installations and the integration of solar power into smart grid systems.

One of the key drivers for efficient solar inverters is the potential for cost savings. Improved heat dissipation allows inverters to operate at higher efficiencies, resulting in increased energy yield and reduced operational costs. This is particularly important for commercial and utility-scale solar projects, where even small improvements in efficiency can translate to significant financial benefits over the system's lifetime.

Another factor contributing to the market demand is the growing trend towards compact and lightweight inverter designs. As solar installations become more prevalent in urban and residential settings, there is a need for inverters that can be easily integrated into existing spaces. Efficient heat dissipation technologies enable manufacturers to develop smaller inverters without compromising on performance or reliability.

The market is also seeing increased demand for inverters with advanced monitoring and diagnostic capabilities. These features allow for real-time performance tracking and early detection of potential issues, including those related to heat management. This proactive approach to maintenance and optimization aligns with the overall industry focus on maximizing system uptime and longevity.

Regulatory requirements and industry standards are further driving the demand for efficient solar inverters. Many countries have implemented or are in the process of implementing stricter efficiency standards for solar equipment. Inverters with superior heat dissipation capabilities are better positioned to meet these evolving requirements, making them more attractive to both installers and end-users.

As the solar energy market continues to mature, there is a growing emphasis on the total cost of ownership rather than just the initial purchase price. This shift in perspective favors inverters with advanced heat dissipation technologies, as they tend to offer better long-term performance and reliability, potentially reducing maintenance costs and extending the inverter's operational lifespan.

The market for solar inverters is expected to continue its upward trajectory, with a particular emphasis on efficiency and reliability. Consumers and businesses alike are seeking inverters that can maximize energy output while minimizing losses due to heat generation. This demand is further fueled by the increasing adoption of large-scale solar installations and the integration of solar power into smart grid systems.

One of the key drivers for efficient solar inverters is the potential for cost savings. Improved heat dissipation allows inverters to operate at higher efficiencies, resulting in increased energy yield and reduced operational costs. This is particularly important for commercial and utility-scale solar projects, where even small improvements in efficiency can translate to significant financial benefits over the system's lifetime.

Another factor contributing to the market demand is the growing trend towards compact and lightweight inverter designs. As solar installations become more prevalent in urban and residential settings, there is a need for inverters that can be easily integrated into existing spaces. Efficient heat dissipation technologies enable manufacturers to develop smaller inverters without compromising on performance or reliability.

The market is also seeing increased demand for inverters with advanced monitoring and diagnostic capabilities. These features allow for real-time performance tracking and early detection of potential issues, including those related to heat management. This proactive approach to maintenance and optimization aligns with the overall industry focus on maximizing system uptime and longevity.

Regulatory requirements and industry standards are further driving the demand for efficient solar inverters. Many countries have implemented or are in the process of implementing stricter efficiency standards for solar equipment. Inverters with superior heat dissipation capabilities are better positioned to meet these evolving requirements, making them more attractive to both installers and end-users.

As the solar energy market continues to mature, there is a growing emphasis on the total cost of ownership rather than just the initial purchase price. This shift in perspective favors inverters with advanced heat dissipation technologies, as they tend to offer better long-term performance and reliability, potentially reducing maintenance costs and extending the inverter's operational lifespan.

Current Challenges in Inverter Heat Dissipation

Solar inverter heat dissipation remains a critical challenge in the photovoltaic industry, impacting system efficiency, reliability, and longevity. As inverters handle increasing power capacities, the heat generated during operation has become a significant concern for manufacturers and system integrators alike.

One of the primary challenges is the limited space available for cooling systems within compact inverter designs. As the industry trends towards more power-dense solutions, engineers struggle to implement effective cooling mechanisms without compromising the inverter's form factor. This constraint often leads to suboptimal thermal management, potentially reducing the inverter's lifespan and overall system performance.

Another major hurdle is the diverse environmental conditions in which solar inverters operate. From scorching deserts to humid tropical climates, inverters must maintain optimal performance across a wide range of temperatures and humidity levels. Designing a universal cooling solution that can adapt to these varied conditions while remaining cost-effective has proven to be a complex engineering task.

The increasing adoption of wide-bandgap semiconductors, such as silicon carbide (SiC) and gallium nitride (GaN), introduces new thermal management challenges. While these materials offer improved efficiency and higher switching frequencies, they also operate at higher temperatures, necessitating more advanced cooling strategies to prevent thermal runaway and ensure long-term reliability.

Balancing cost and performance in heat dissipation solutions is another ongoing challenge. High-performance cooling systems, such as liquid cooling or advanced heat pipe designs, can significantly improve thermal management but often come with increased manufacturing costs and complexity. Finding the right trade-off between cooling efficiency and economic viability remains a key focus for inverter manufacturers.

The integration of energy storage systems with solar inverters adds another layer of complexity to heat dissipation. As hybrid inverters become more prevalent, managing the combined heat output from both inverter and battery operations presents new challenges in thermal design and management.

Lastly, the industry faces challenges in accurately modeling and predicting thermal behavior in complex inverter systems. Developing sophisticated simulation tools and methodologies that can account for various operating conditions, component interactions, and long-term degradation effects is crucial for advancing heat dissipation technologies.

Addressing these challenges requires a multidisciplinary approach, combining innovations in materials science, thermal engineering, and power electronics. As the solar industry continues to evolve, overcoming these heat dissipation hurdles will be essential for developing more efficient, reliable, and cost-effective inverter solutions.

One of the primary challenges is the limited space available for cooling systems within compact inverter designs. As the industry trends towards more power-dense solutions, engineers struggle to implement effective cooling mechanisms without compromising the inverter's form factor. This constraint often leads to suboptimal thermal management, potentially reducing the inverter's lifespan and overall system performance.

Another major hurdle is the diverse environmental conditions in which solar inverters operate. From scorching deserts to humid tropical climates, inverters must maintain optimal performance across a wide range of temperatures and humidity levels. Designing a universal cooling solution that can adapt to these varied conditions while remaining cost-effective has proven to be a complex engineering task.

The increasing adoption of wide-bandgap semiconductors, such as silicon carbide (SiC) and gallium nitride (GaN), introduces new thermal management challenges. While these materials offer improved efficiency and higher switching frequencies, they also operate at higher temperatures, necessitating more advanced cooling strategies to prevent thermal runaway and ensure long-term reliability.

Balancing cost and performance in heat dissipation solutions is another ongoing challenge. High-performance cooling systems, such as liquid cooling or advanced heat pipe designs, can significantly improve thermal management but often come with increased manufacturing costs and complexity. Finding the right trade-off between cooling efficiency and economic viability remains a key focus for inverter manufacturers.

The integration of energy storage systems with solar inverters adds another layer of complexity to heat dissipation. As hybrid inverters become more prevalent, managing the combined heat output from both inverter and battery operations presents new challenges in thermal design and management.

Lastly, the industry faces challenges in accurately modeling and predicting thermal behavior in complex inverter systems. Developing sophisticated simulation tools and methodologies that can account for various operating conditions, component interactions, and long-term degradation effects is crucial for advancing heat dissipation technologies.

Addressing these challenges requires a multidisciplinary approach, combining innovations in materials science, thermal engineering, and power electronics. As the solar industry continues to evolve, overcoming these heat dissipation hurdles will be essential for developing more efficient, reliable, and cost-effective inverter solutions.

Existing Heat Dissipation Solutions

01 Heat sink design for solar inverters

Innovative heat sink designs are employed to enhance heat dissipation in solar inverters. These designs may include optimized fin structures, increased surface area, and improved airflow patterns to efficiently remove heat from critical components. Advanced materials and manufacturing techniques are utilized to create more effective heat sinks, resulting in better thermal management and improved inverter performance.- Heat sink design for solar inverters: Efficient heat sink designs are crucial for solar inverter heat dissipation. These designs often incorporate fins or other structures to increase surface area for better heat transfer. Advanced materials and geometries are used to optimize thermal conductivity and airflow, enhancing overall cooling performance.

- Liquid cooling systems for solar inverters: Liquid cooling systems offer superior heat dissipation for high-power solar inverters. These systems typically use coolants circulated through channels or pipes to efficiently remove heat from critical components. This approach allows for more compact inverter designs and improved thermal management in challenging environments.

- Ventilation and airflow management: Effective ventilation and airflow management are essential for solar inverter cooling. This includes the strategic placement of fans, vents, and air channels to optimize air circulation and heat removal. Some designs incorporate smart control systems to adjust airflow based on temperature and load conditions.

- Thermal management through component layout: Optimizing the internal layout of solar inverter components can significantly improve heat dissipation. This involves strategically positioning heat-generating elements, using thermal interfaces, and creating thermal zones to manage heat flow effectively. Proper component arrangement can reduce hotspots and improve overall thermal performance.

- Advanced materials for thermal management: The use of advanced materials with high thermal conductivity and low thermal resistance is crucial for effective heat dissipation in solar inverters. These materials, which may include specialized alloys, ceramics, or composite materials, are employed in various components such as heat sinks, enclosures, and thermal interfaces to enhance overall cooling efficiency.

02 Liquid cooling systems for solar inverters

Liquid cooling systems are implemented in solar inverters to achieve superior heat dissipation. These systems typically involve circulating a coolant through channels or pipes in contact with heat-generating components. The liquid efficiently absorbs and transfers heat away from the inverter, allowing for more effective cooling compared to traditional air-based methods. This approach enables higher power density and improved reliability in solar inverter designs.Expand Specific Solutions03 Ventilation and airflow management

Effective ventilation and airflow management strategies are employed to enhance heat dissipation in solar inverters. These may include the use of strategically placed fans, optimized air intake and exhaust designs, and intelligent control systems to regulate airflow based on temperature and load conditions. Improved airflow patterns help to remove heat more efficiently from internal components, maintaining optimal operating temperatures.Expand Specific Solutions04 Thermal management through component layout and PCB design

Optimized component layout and PCB design techniques are utilized to improve heat dissipation in solar inverters. This involves strategic placement of heat-generating components, use of thermal vias and copper planes for better heat spreading, and implementation of thermal isolation techniques. Advanced PCB materials with improved thermal conductivity may also be employed to enhance overall thermal management.Expand Specific Solutions05 Smart thermal management systems

Intelligent thermal management systems are integrated into solar inverters to optimize heat dissipation. These systems may incorporate temperature sensors, microcontrollers, and adaptive algorithms to dynamically adjust cooling mechanisms based on real-time operating conditions. Features such as variable fan speeds, selective component shutdown, and load balancing are implemented to maintain optimal temperatures and improve overall efficiency and reliability of the inverter.Expand Specific Solutions

Key Players in Solar Inverter Industry

The solar inverter heat dissipation market is in a growth phase, driven by increasing adoption of solar energy systems globally. The market size is expanding rapidly, with projections indicating significant growth in the coming years. Technologically, the field is advancing, with companies like Huawei Digital Power, Sungrow Power Supply, and Delta Electronics leading innovation. These firms are developing more efficient and compact heat dissipation solutions, incorporating advanced materials and designs. Emerging players such as Goodwe Technologies and SolaX Power are also contributing to technological advancements, focusing on smart cooling systems and integrated thermal management. The competitive landscape is diverse, with established electronics giants and specialized solar technology firms vying for market share, indicating a maturing but still dynamic sector.

Huawei Digital Power Technologies Co Ltd

Technical Solution: Huawei has developed an innovative heat dissipation solution for solar inverters using AI-driven smart cooling technology. Their system employs advanced thermal management algorithms to optimize cooling efficiency based on real-time operating conditions. The inverter uses a combination of natural convection and forced air cooling, with intelligent fan speed control to minimize energy consumption. Huawei's solution also incorporates phase-change materials (PCMs) to absorb excess heat during peak operation, releasing it gradually during lower load periods[1][3]. This approach has reportedly increased overall cooling efficiency by up to 30% compared to traditional methods.

Strengths: High cooling efficiency, energy-saving operation, and adaptive thermal management. Weaknesses: Potentially higher initial cost and complexity in implementation.

Sungrow Power Supply Co., Ltd.

Technical Solution: Sungrow has introduced a novel liquid cooling system for their high-power solar inverters. This solution utilizes a non-conductive coolant that circulates through specially designed channels within the inverter's power modules. The liquid cooling system allows for more efficient heat transfer compared to air-based methods, enabling higher power density and improved reliability. Sungrow's approach also incorporates a smart temperature control system that adjusts coolant flow rates based on inverter load and ambient conditions[2][4]. This technology has demonstrated the ability to maintain consistent performance even in extreme temperature environments, with reported improvements in inverter lifespan of up to 20%.

Strengths: Excellent thermal performance, increased power density, and improved reliability. Weaknesses: Higher system complexity and potential for coolant leaks.

Innovative Cooling Techniques Analysis

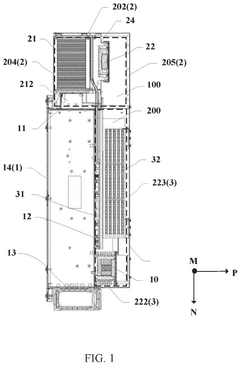

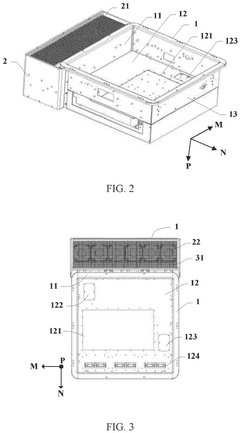

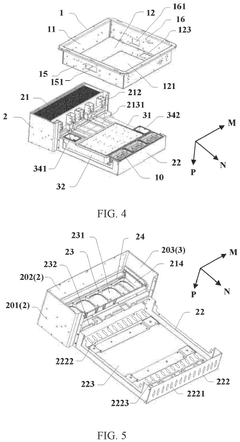

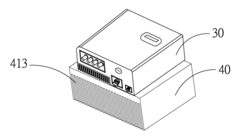

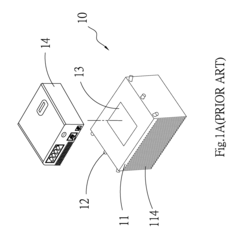

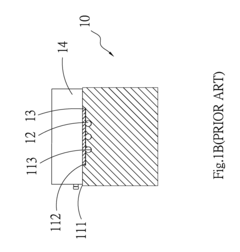

Top-mounted heat dissipation photovoltaic inverter device

PatentPendingEP4465783A1

Innovation

- A top-mounted heat dissipation photovoltaic inverter device with a modular design incorporating a top-installed heat dissipation assembly featuring a condenser and fan assembly, and a back-mounted heat dissipation assembly with an evaporator and air-cooled heat sink, arranged in a compact L-shaped configuration to enhance heat dissipation efficiency and maintainability.

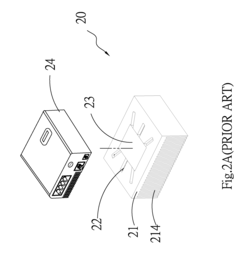

Heat dissipation structure for photovoltaic inverter

PatentInactiveUS20120227937A1

Innovation

- A heat dissipation structure for photovoltaic inverters that eliminates the need for heat conduction media by using a D-shaped heat pipe directly attached to the inverter, with the plane face of the pipe flush with the backboard and an arcuate face snugly fitting into grooves, enhancing heat transfer efficiency and simplifying assembly.

Environmental Impact of Cooling Methods

The environmental impact of cooling methods for solar inverters is a critical consideration in the ongoing development of sustainable energy technologies. As the demand for solar power continues to grow, so does the need for efficient and environmentally friendly cooling solutions for inverters.

Traditional cooling methods, such as forced air cooling and liquid cooling, have been widely used in solar inverter systems. However, these methods often come with significant environmental drawbacks. Forced air cooling systems, while relatively simple and cost-effective, can consume substantial amounts of energy, particularly in large-scale installations. This increased energy consumption contributes to higher carbon emissions, potentially offsetting some of the environmental benefits of solar power generation.

Liquid cooling systems, on the other hand, offer improved thermal management but introduce additional environmental concerns. The use of coolants, especially those containing harmful chemicals, poses risks of leakage and contamination. Proper disposal of these coolants at the end of the system's lifecycle is crucial to prevent environmental damage.

Recent developments in solar inverter cooling technologies have focused on more sustainable approaches. Passive cooling methods, such as heat sink designs and natural convection systems, have gained traction due to their low energy requirements and minimal environmental impact. These solutions leverage the natural flow of air or utilize advanced materials with high thermal conductivity to dissipate heat effectively without the need for additional energy input.

Phase change materials (PCMs) have emerged as a promising cooling solution with reduced environmental impact. PCMs absorb and release thermal energy during phase transitions, providing efficient temperature regulation without continuous energy consumption. This technology not only improves the overall efficiency of solar inverters but also minimizes the carbon footprint associated with cooling processes.

Another environmentally friendly approach gaining attention is the integration of thermoelectric cooling devices. These solid-state heat pumps operate without harmful refrigerants and can be powered directly by the solar panels themselves, further reducing the system's reliance on external energy sources.

The development of bio-based and biodegradable cooling fluids represents a significant step towards more sustainable liquid cooling systems. These fluids offer comparable thermal performance to traditional coolants while being less harmful to the environment in case of leaks or during disposal.

As the solar industry continues to evolve, the focus on environmentally responsible cooling methods for inverters is likely to intensify. Future research and development efforts are expected to prioritize solutions that not only enhance the performance and longevity of solar inverters but also minimize their ecological footprint throughout their lifecycle.

Traditional cooling methods, such as forced air cooling and liquid cooling, have been widely used in solar inverter systems. However, these methods often come with significant environmental drawbacks. Forced air cooling systems, while relatively simple and cost-effective, can consume substantial amounts of energy, particularly in large-scale installations. This increased energy consumption contributes to higher carbon emissions, potentially offsetting some of the environmental benefits of solar power generation.

Liquid cooling systems, on the other hand, offer improved thermal management but introduce additional environmental concerns. The use of coolants, especially those containing harmful chemicals, poses risks of leakage and contamination. Proper disposal of these coolants at the end of the system's lifecycle is crucial to prevent environmental damage.

Recent developments in solar inverter cooling technologies have focused on more sustainable approaches. Passive cooling methods, such as heat sink designs and natural convection systems, have gained traction due to their low energy requirements and minimal environmental impact. These solutions leverage the natural flow of air or utilize advanced materials with high thermal conductivity to dissipate heat effectively without the need for additional energy input.

Phase change materials (PCMs) have emerged as a promising cooling solution with reduced environmental impact. PCMs absorb and release thermal energy during phase transitions, providing efficient temperature regulation without continuous energy consumption. This technology not only improves the overall efficiency of solar inverters but also minimizes the carbon footprint associated with cooling processes.

Another environmentally friendly approach gaining attention is the integration of thermoelectric cooling devices. These solid-state heat pumps operate without harmful refrigerants and can be powered directly by the solar panels themselves, further reducing the system's reliance on external energy sources.

The development of bio-based and biodegradable cooling fluids represents a significant step towards more sustainable liquid cooling systems. These fluids offer comparable thermal performance to traditional coolants while being less harmful to the environment in case of leaks or during disposal.

As the solar industry continues to evolve, the focus on environmentally responsible cooling methods for inverters is likely to intensify. Future research and development efforts are expected to prioritize solutions that not only enhance the performance and longevity of solar inverters but also minimize their ecological footprint throughout their lifecycle.

Reliability and Lifespan Considerations

The reliability and lifespan of solar inverters are critically dependent on effective heat dissipation. As inverters play a crucial role in converting DC power from solar panels to AC power for grid use, their performance and longevity directly impact the overall efficiency and cost-effectiveness of solar energy systems.

Recent advancements in heat dissipation technologies have significantly improved the reliability of solar inverters. Traditional cooling methods, such as forced air cooling and liquid cooling, have been enhanced with innovative materials and designs. For instance, the integration of phase-change materials (PCMs) into inverter cooling systems has shown promising results in maintaining stable operating temperatures, thereby reducing thermal stress on components.

The use of wide-bandgap semiconductors, particularly silicon carbide (SiC) and gallium nitride (GaN), has revolutionized inverter design. These materials can operate at higher temperatures and switching frequencies compared to traditional silicon-based semiconductors. This capability not only improves efficiency but also reduces the overall thermal load, extending the lifespan of the inverter.

Advanced thermal management techniques, such as heat pipe technology and micro-channel cooling, have been implemented to enhance heat dissipation in compact inverter designs. These innovations allow for more efficient cooling in smaller form factors, addressing the growing demand for residential and commercial rooftop solar installations where space is at a premium.

Predictive maintenance strategies, enabled by IoT and AI technologies, are now being employed to monitor inverter health and thermal performance in real-time. By analyzing temperature data and other operational parameters, these systems can predict potential failures before they occur, allowing for proactive maintenance and minimizing downtime.

The development of modular inverter designs has also contributed to improved reliability and easier maintenance. In these systems, critical components can be quickly replaced without the need for extensive downtime, reducing the overall impact of individual component failures on system performance.

As the solar industry continues to grow, the focus on inverter reliability and lifespan remains paramount. Ongoing research in nanotechnology and advanced materials promises further improvements in heat dissipation efficiency. These developments are expected to lead to solar inverters with longer operational lifespans, reduced maintenance requirements, and improved overall system performance, ultimately contributing to the increased adoption and cost-effectiveness of solar energy solutions.

Recent advancements in heat dissipation technologies have significantly improved the reliability of solar inverters. Traditional cooling methods, such as forced air cooling and liquid cooling, have been enhanced with innovative materials and designs. For instance, the integration of phase-change materials (PCMs) into inverter cooling systems has shown promising results in maintaining stable operating temperatures, thereby reducing thermal stress on components.

The use of wide-bandgap semiconductors, particularly silicon carbide (SiC) and gallium nitride (GaN), has revolutionized inverter design. These materials can operate at higher temperatures and switching frequencies compared to traditional silicon-based semiconductors. This capability not only improves efficiency but also reduces the overall thermal load, extending the lifespan of the inverter.

Advanced thermal management techniques, such as heat pipe technology and micro-channel cooling, have been implemented to enhance heat dissipation in compact inverter designs. These innovations allow for more efficient cooling in smaller form factors, addressing the growing demand for residential and commercial rooftop solar installations where space is at a premium.

Predictive maintenance strategies, enabled by IoT and AI technologies, are now being employed to monitor inverter health and thermal performance in real-time. By analyzing temperature data and other operational parameters, these systems can predict potential failures before they occur, allowing for proactive maintenance and minimizing downtime.

The development of modular inverter designs has also contributed to improved reliability and easier maintenance. In these systems, critical components can be quickly replaced without the need for extensive downtime, reducing the overall impact of individual component failures on system performance.

As the solar industry continues to grow, the focus on inverter reliability and lifespan remains paramount. Ongoing research in nanotechnology and advanced materials promises further improvements in heat dissipation efficiency. These developments are expected to lead to solar inverters with longer operational lifespans, reduced maintenance requirements, and improved overall system performance, ultimately contributing to the increased adoption and cost-effectiveness of solar energy solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!