Solar Inverter Diagnostics: Tools and Methods

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solar Inverter Evolution

Solar inverter technology has undergone significant evolution since its inception, driven by the rapid growth of the solar energy industry and the increasing demand for more efficient and reliable power conversion systems. The journey of solar inverters began in the 1970s with simple, grid-tied devices that converted DC power from solar panels into AC power for home use. These early inverters were bulky, inefficient, and had limited functionality.

The 1990s saw a major leap forward with the introduction of string inverters, which allowed multiple solar panels to be connected in series. This innovation improved overall system efficiency and reduced installation costs. As the solar industry expanded in the early 2000s, manufacturers focused on enhancing inverter reliability, efficiency, and power density.

The mid-2000s marked the advent of transformerless inverters, which eliminated the need for heavy and costly transformers. This breakthrough significantly reduced inverter size and weight while improving efficiency. Concurrently, the development of maximum power point tracking (MPPT) technology enabled inverters to optimize power output under varying environmental conditions.

The late 2000s and early 2010s witnessed the rise of microinverters and power optimizers. These module-level power electronics (MLPE) solutions offered improved performance in shaded conditions and enhanced system monitoring capabilities. This period also saw the integration of advanced communication features, allowing for remote monitoring and control of solar systems.

In recent years, the focus has shifted towards smart inverters with grid support functions. These advanced inverters can actively participate in grid stability by providing reactive power support, voltage regulation, and frequency response. The integration of energy storage capabilities has also become a key trend, with hybrid inverters enabling seamless interaction between solar panels, batteries, and the grid.

The latest developments in solar inverter technology include the use of wide-bandgap semiconductors, such as silicon carbide (SiC) and gallium nitride (GaN), which offer higher efficiency and power density. Additionally, the incorporation of artificial intelligence and machine learning algorithms is enhancing inverter performance and predictive maintenance capabilities.

As the solar industry continues to grow and evolve, inverter technology is expected to play an increasingly critical role in grid integration, energy management, and overall system performance. Future innovations are likely to focus on further improving efficiency, reliability, and grid support functions, as well as enhancing compatibility with emerging smart grid technologies and energy storage systems.

The 1990s saw a major leap forward with the introduction of string inverters, which allowed multiple solar panels to be connected in series. This innovation improved overall system efficiency and reduced installation costs. As the solar industry expanded in the early 2000s, manufacturers focused on enhancing inverter reliability, efficiency, and power density.

The mid-2000s marked the advent of transformerless inverters, which eliminated the need for heavy and costly transformers. This breakthrough significantly reduced inverter size and weight while improving efficiency. Concurrently, the development of maximum power point tracking (MPPT) technology enabled inverters to optimize power output under varying environmental conditions.

The late 2000s and early 2010s witnessed the rise of microinverters and power optimizers. These module-level power electronics (MLPE) solutions offered improved performance in shaded conditions and enhanced system monitoring capabilities. This period also saw the integration of advanced communication features, allowing for remote monitoring and control of solar systems.

In recent years, the focus has shifted towards smart inverters with grid support functions. These advanced inverters can actively participate in grid stability by providing reactive power support, voltage regulation, and frequency response. The integration of energy storage capabilities has also become a key trend, with hybrid inverters enabling seamless interaction between solar panels, batteries, and the grid.

The latest developments in solar inverter technology include the use of wide-bandgap semiconductors, such as silicon carbide (SiC) and gallium nitride (GaN), which offer higher efficiency and power density. Additionally, the incorporation of artificial intelligence and machine learning algorithms is enhancing inverter performance and predictive maintenance capabilities.

As the solar industry continues to grow and evolve, inverter technology is expected to play an increasingly critical role in grid integration, energy management, and overall system performance. Future innovations are likely to focus on further improving efficiency, reliability, and grid support functions, as well as enhancing compatibility with emerging smart grid technologies and energy storage systems.

Market Demand Analysis

The market demand for solar inverter diagnostics tools and methods has been experiencing significant growth in recent years, driven by the rapid expansion of solar energy installations worldwide. As the global shift towards renewable energy sources continues, the solar power industry has seen substantial investments, leading to an increased need for efficient maintenance and monitoring solutions.

The solar inverter market itself is projected to grow at a robust rate, with estimates suggesting a compound annual growth rate (CAGR) of over 15% in the coming years. This growth directly correlates with the demand for diagnostic tools and methods, as inverters are critical components in solar power systems that require regular monitoring and maintenance to ensure optimal performance and longevity.

One of the key factors driving the demand for solar inverter diagnostics is the growing emphasis on maximizing the return on investment (ROI) for solar installations. As the initial costs of solar systems continue to decrease, operators are focusing more on optimizing system performance and reducing downtime. Advanced diagnostic tools and methods play a crucial role in achieving these objectives by enabling predictive maintenance, early fault detection, and efficient troubleshooting.

The increasing complexity of solar inverter systems, including the integration of smart grid technologies and energy storage solutions, has further amplified the need for sophisticated diagnostic capabilities. These advanced systems require more comprehensive monitoring and analysis tools to ensure seamless operation and integration with the broader energy infrastructure.

Another significant trend driving market demand is the shift towards remote monitoring and diagnostics. With the advent of Internet of Things (IoT) technologies and cloud-based platforms, solar plant operators are increasingly seeking solutions that allow for real-time monitoring and remote diagnostics of inverter performance. This trend has been accelerated by the global pandemic, which has highlighted the importance of remote management capabilities in maintaining critical infrastructure.

The market for solar inverter diagnostics is also being shaped by regulatory requirements and industry standards. As governments and regulatory bodies implement stricter guidelines for solar energy system performance and reliability, the demand for advanced diagnostic tools that can ensure compliance and optimize system efficiency is on the rise.

Geographically, the demand for solar inverter diagnostics tools and methods is particularly strong in regions with high solar energy adoption rates, such as Europe, North America, and parts of Asia. However, emerging markets in Africa, South America, and Southeast Asia are also showing increasing interest in these technologies as they expand their solar energy capacities.

In conclusion, the market demand for solar inverter diagnostics tools and methods is robust and growing, driven by the expansion of solar energy installations, the need for improved system performance and reliability, and the increasing complexity of solar power systems. As the industry continues to evolve, we can expect to see further innovations in diagnostic technologies to meet the changing needs of solar energy operators and stakeholders.

The solar inverter market itself is projected to grow at a robust rate, with estimates suggesting a compound annual growth rate (CAGR) of over 15% in the coming years. This growth directly correlates with the demand for diagnostic tools and methods, as inverters are critical components in solar power systems that require regular monitoring and maintenance to ensure optimal performance and longevity.

One of the key factors driving the demand for solar inverter diagnostics is the growing emphasis on maximizing the return on investment (ROI) for solar installations. As the initial costs of solar systems continue to decrease, operators are focusing more on optimizing system performance and reducing downtime. Advanced diagnostic tools and methods play a crucial role in achieving these objectives by enabling predictive maintenance, early fault detection, and efficient troubleshooting.

The increasing complexity of solar inverter systems, including the integration of smart grid technologies and energy storage solutions, has further amplified the need for sophisticated diagnostic capabilities. These advanced systems require more comprehensive monitoring and analysis tools to ensure seamless operation and integration with the broader energy infrastructure.

Another significant trend driving market demand is the shift towards remote monitoring and diagnostics. With the advent of Internet of Things (IoT) technologies and cloud-based platforms, solar plant operators are increasingly seeking solutions that allow for real-time monitoring and remote diagnostics of inverter performance. This trend has been accelerated by the global pandemic, which has highlighted the importance of remote management capabilities in maintaining critical infrastructure.

The market for solar inverter diagnostics is also being shaped by regulatory requirements and industry standards. As governments and regulatory bodies implement stricter guidelines for solar energy system performance and reliability, the demand for advanced diagnostic tools that can ensure compliance and optimize system efficiency is on the rise.

Geographically, the demand for solar inverter diagnostics tools and methods is particularly strong in regions with high solar energy adoption rates, such as Europe, North America, and parts of Asia. However, emerging markets in Africa, South America, and Southeast Asia are also showing increasing interest in these technologies as they expand their solar energy capacities.

In conclusion, the market demand for solar inverter diagnostics tools and methods is robust and growing, driven by the expansion of solar energy installations, the need for improved system performance and reliability, and the increasing complexity of solar power systems. As the industry continues to evolve, we can expect to see further innovations in diagnostic technologies to meet the changing needs of solar energy operators and stakeholders.

Diagnostic Challenges

Solar inverter diagnostics face several significant challenges that impact the efficiency and reliability of photovoltaic systems. One of the primary obstacles is the complexity of fault detection in large-scale solar installations. With numerous inverters operating simultaneously, identifying the source of a malfunction can be akin to finding a needle in a haystack. This complexity is further compounded by the dynamic nature of solar energy production, which fluctuates based on weather conditions, time of day, and seasonal variations.

Another critical challenge lies in the real-time monitoring and analysis of inverter performance. Traditional diagnostic methods often rely on periodic inspections or reactive maintenance, which can lead to prolonged downtime and reduced energy output. The sheer volume of data generated by modern solar inverters presents both an opportunity and a challenge. While this data can provide valuable insights, processing and interpreting it in a timely manner requires sophisticated algorithms and robust data management systems.

The diverse range of inverter technologies and manufacturers in the market also poses a significant hurdle for diagnostics. Each inverter type may have unique failure modes and diagnostic requirements, necessitating a flexible and adaptable approach to fault detection and analysis. This diversity complicates the development of universal diagnostic tools and standardized protocols, often resulting in a fragmented landscape of proprietary solutions.

Environmental factors present yet another layer of complexity in solar inverter diagnostics. Inverters are exposed to harsh conditions, including extreme temperatures, humidity, and dust, which can accelerate wear and tear. Distinguishing between environmentally induced degradation and actual component failures requires advanced diagnostic capabilities that can account for these external influences.

The integration of solar inverters with smart grids and energy storage systems introduces additional diagnostic challenges. These interconnected systems create more potential points of failure and increase the complexity of fault isolation. Diagnostics must not only identify issues within the inverter itself but also consider its interactions with other components of the broader energy ecosystem.

Lastly, the rapid evolution of solar technology presents an ongoing challenge for diagnostic tools and methods. As inverters become more sophisticated, incorporating features like advanced grid support functions and AI-driven optimization, diagnostic systems must keep pace. This requires continuous research and development to ensure that diagnostic capabilities remain aligned with the latest inverter technologies and performance standards.

Another critical challenge lies in the real-time monitoring and analysis of inverter performance. Traditional diagnostic methods often rely on periodic inspections or reactive maintenance, which can lead to prolonged downtime and reduced energy output. The sheer volume of data generated by modern solar inverters presents both an opportunity and a challenge. While this data can provide valuable insights, processing and interpreting it in a timely manner requires sophisticated algorithms and robust data management systems.

The diverse range of inverter technologies and manufacturers in the market also poses a significant hurdle for diagnostics. Each inverter type may have unique failure modes and diagnostic requirements, necessitating a flexible and adaptable approach to fault detection and analysis. This diversity complicates the development of universal diagnostic tools and standardized protocols, often resulting in a fragmented landscape of proprietary solutions.

Environmental factors present yet another layer of complexity in solar inverter diagnostics. Inverters are exposed to harsh conditions, including extreme temperatures, humidity, and dust, which can accelerate wear and tear. Distinguishing between environmentally induced degradation and actual component failures requires advanced diagnostic capabilities that can account for these external influences.

The integration of solar inverters with smart grids and energy storage systems introduces additional diagnostic challenges. These interconnected systems create more potential points of failure and increase the complexity of fault isolation. Diagnostics must not only identify issues within the inverter itself but also consider its interactions with other components of the broader energy ecosystem.

Lastly, the rapid evolution of solar technology presents an ongoing challenge for diagnostic tools and methods. As inverters become more sophisticated, incorporating features like advanced grid support functions and AI-driven optimization, diagnostic systems must keep pace. This requires continuous research and development to ensure that diagnostic capabilities remain aligned with the latest inverter technologies and performance standards.

Current Diagnostic Tools

01 Fault detection and diagnosis in solar inverters

Advanced fault detection and diagnosis systems for solar inverters use various sensors and algorithms to monitor performance, identify issues, and predict potential failures. These systems analyze data from multiple parameters such as voltage, current, and temperature to detect anomalies and provide early warnings, improving overall system reliability and efficiency.- Fault detection and diagnosis in solar inverters: Advanced fault detection and diagnosis systems for solar inverters use various sensors and algorithms to monitor performance, identify issues, and predict potential failures. These systems analyze data from multiple parameters such as voltage, current, and temperature to detect anomalies and provide early warnings, improving overall system reliability and efficiency.

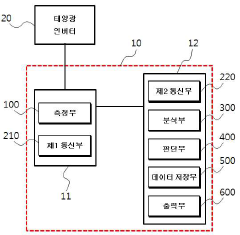

- Remote monitoring and control of solar inverters: Remote monitoring and control systems enable real-time observation and management of solar inverters from a distance. These systems utilize communication technologies to transmit data, allowing operators to assess performance, diagnose issues, and implement corrective actions without physical presence at the installation site.

- Predictive maintenance for solar inverters: Predictive maintenance techniques employ machine learning and data analytics to forecast potential failures in solar inverters. By analyzing historical data and current operating conditions, these systems can predict when maintenance is required, reducing downtime and optimizing performance.

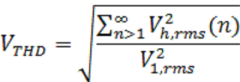

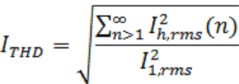

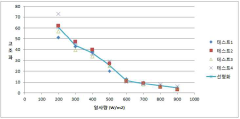

- Power quality analysis in solar inverter systems: Power quality analysis tools for solar inverters measure and evaluate various electrical parameters to ensure optimal performance and grid compatibility. These tools assess factors such as harmonic distortion, power factor, and voltage fluctuations to maintain high-quality power output and comply with grid standards.

- Thermal management diagnostics for solar inverters: Thermal management diagnostic systems monitor and analyze temperature-related parameters in solar inverters. These systems use temperature sensors and thermal imaging techniques to detect hotspots, assess cooling efficiency, and prevent overheating-related failures, ensuring optimal performance and longevity of the inverter.

02 Remote monitoring and control of solar inverters

Remote monitoring and control systems enable real-time observation and management of solar inverters from a distance. These systems utilize communication technologies to transmit data, allowing operators to assess performance, diagnose issues, and implement corrective actions without on-site visits, thereby reducing maintenance costs and improving response times.Expand Specific Solutions03 Predictive maintenance for solar inverters

Predictive maintenance techniques employ machine learning and data analytics to forecast potential failures in solar inverters. By analyzing historical data and current operating conditions, these systems can predict when maintenance is required, optimizing scheduling and reducing downtime while extending the lifespan of the equipment.Expand Specific Solutions04 Power quality analysis in solar inverter systems

Power quality analysis tools for solar inverters measure and evaluate various electrical parameters such as harmonics, power factor, and voltage fluctuations. These diagnostic tools help identify issues that may affect grid stability or inverter performance, ensuring compliance with grid codes and optimizing energy production.Expand Specific Solutions05 Thermal management diagnostics for solar inverters

Thermal management diagnostic systems monitor temperature-related parameters in solar inverters to prevent overheating and ensure optimal performance. These systems use temperature sensors and thermal imaging techniques to detect hotspots, assess cooling efficiency, and trigger protective measures when necessary, thereby enhancing the reliability and longevity of the inverters.Expand Specific Solutions

Key Industry Players

The solar inverter diagnostics market is in a growth phase, driven by increasing adoption of solar energy systems worldwide. The market size is expanding rapidly, with projections indicating significant growth in the coming years. Technologically, the field is advancing quickly, with major players like Fronius, Sungrow, and Huawei Digital Power leading innovation. These companies are developing sophisticated diagnostic tools and methods, integrating AI and IoT technologies for improved efficiency and reliability. Established industrial giants such as OMRON and Delta Electronics are also making significant contributions, leveraging their expertise in power electronics. Research institutions like the Korea Institute of Energy Research and the Indian Institute of Science are pushing the boundaries of solar inverter technology, focusing on next-generation diagnostics and predictive maintenance solutions.

Fronius International GmbH

Technical Solution: Fronius has developed advanced solar inverter diagnostics tools and methods, including their Solar.web online monitoring platform. This system provides real-time performance data, fault detection, and predictive maintenance capabilities for solar inverters[1]. Their inverters feature integrated self-diagnostic functions that continuously monitor critical components and operating parameters. Fronius also employs machine learning algorithms to analyze historical data and predict potential issues before they occur, enabling proactive maintenance[2]. Additionally, they have implemented remote firmware updates and configuration changes, allowing for efficient troubleshooting and optimization without on-site visits[3].

Strengths: Comprehensive online monitoring, predictive maintenance, and remote diagnostics capabilities. Weaknesses: May require consistent internet connectivity for full functionality, and the system's complexity could lead to higher initial costs.

Sungrow Power Supply Co., Ltd.

Technical Solution: Sungrow has developed a suite of advanced diagnostic tools for their solar inverters, including the iSolarCloud platform. This cloud-based system offers real-time monitoring, performance analysis, and fault diagnosis for solar inverters[4]. Sungrow's inverters are equipped with self-diagnostic capabilities that can detect and report issues such as grid instability, insulation faults, and component malfunctions. The company has also implemented AI-driven predictive maintenance algorithms that analyze operational data to forecast potential failures and optimize maintenance schedules[5]. Furthermore, Sungrow has developed mobile apps for on-site diagnostics, allowing technicians to quickly identify and resolve issues using their smartphones[6].

Strengths: Comprehensive cloud-based monitoring, AI-driven predictive maintenance, and user-friendly mobile diagnostics. Weaknesses: Potential dependency on cloud services and internet connectivity for full diagnostic capabilities.

Innovative Techniques

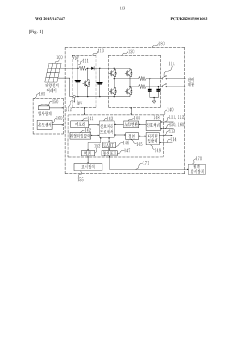

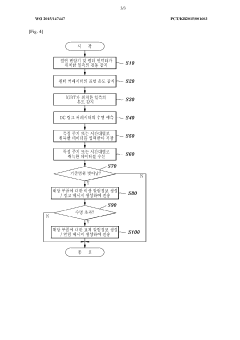

Solar inverter diagnostic system and method therefor

PatentWO2015147447A1

Innovation

- A solar inverter diagnostic system that converts DC power from a solar cell array to AC, includes vibration and temperature sensors, a life prediction unit for the DC link capacitor, and a management server that determines abnormal conditions and schedules maintenance based on acquired data, using a signal transceiver to notify administrators of potential issues before they become critical.

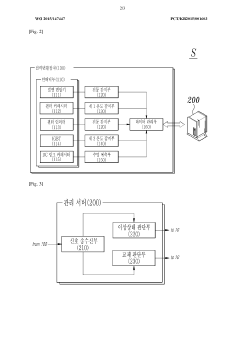

Diagnosis apparatus and method of photovoltaic inverter using analysis of power quality

PatentActiveKR1020200114282A

Innovation

- A diagnostic apparatus and method using power quality analysis, including a measurement unit, communication unit, analysis unit, determination unit, and output unit, perform real-time monitoring and statistical linear regression analysis of solar insolation and harmonic values to predict electrolytic capacitor degradation, enabling proactive maintenance.

Regulatory Compliance

Regulatory compliance is a critical aspect of solar inverter diagnostics, as it ensures that the tools and methods used for diagnostics meet the required standards and regulations. The solar energy industry is subject to various national and international regulations, which aim to maintain safety, reliability, and performance standards for solar inverter systems.

One of the primary regulatory bodies for solar inverter compliance is the International Electrotechnical Commission (IEC). The IEC has established several standards specifically for solar inverters, including IEC 62109 for safety and IEC 61727 for grid connection requirements. These standards outline the necessary safety features, performance criteria, and testing procedures that solar inverters must adhere to.

In the United States, the Underwriters Laboratories (UL) plays a significant role in setting standards for solar inverter safety and performance. UL 1741 is a widely recognized standard that covers inverters, converters, and interconnection system equipment for use with distributed energy resources. This standard ensures that solar inverters can safely disconnect from the grid during power outages and reconnect when power is restored.

The European Union has its own set of regulations, including the Low Voltage Directive (LVD) and the Electromagnetic Compatibility (EMC) Directive. These directives ensure that solar inverters operate safely and do not cause electromagnetic interference with other electronic devices.

When it comes to diagnostic tools and methods, compliance with these regulations is essential. Manufacturers and service providers must ensure that their diagnostic equipment and procedures do not compromise the safety features or performance characteristics required by these standards. This includes maintaining electrical isolation, adhering to voltage and current limits, and preserving the integrity of communication protocols.

Furthermore, diagnostic tools themselves must often meet specific safety and accuracy standards. For example, measurement instruments used in solar inverter diagnostics may need to comply with standards such as IEC 61010 for safety requirements and IEC 61326 for EMC requirements.

As the solar energy industry continues to evolve, regulatory compliance for diagnostics tools and methods must adapt to new technologies and challenges. This includes addressing cybersecurity concerns, as many modern solar inverters are connected to smart grids and remote monitoring systems. Regulations such as the IEC 62443 series for industrial communication networks are becoming increasingly relevant in this context.

In conclusion, regulatory compliance in solar inverter diagnostics is a multifaceted and dynamic field. It requires ongoing attention to evolving standards and regulations across different regions and jurisdictions. Manufacturers, service providers, and technicians must stay informed about these requirements to ensure that their diagnostic tools and methods not only effectively identify and resolve issues but also maintain the highest standards of safety and reliability in solar inverter systems.

One of the primary regulatory bodies for solar inverter compliance is the International Electrotechnical Commission (IEC). The IEC has established several standards specifically for solar inverters, including IEC 62109 for safety and IEC 61727 for grid connection requirements. These standards outline the necessary safety features, performance criteria, and testing procedures that solar inverters must adhere to.

In the United States, the Underwriters Laboratories (UL) plays a significant role in setting standards for solar inverter safety and performance. UL 1741 is a widely recognized standard that covers inverters, converters, and interconnection system equipment for use with distributed energy resources. This standard ensures that solar inverters can safely disconnect from the grid during power outages and reconnect when power is restored.

The European Union has its own set of regulations, including the Low Voltage Directive (LVD) and the Electromagnetic Compatibility (EMC) Directive. These directives ensure that solar inverters operate safely and do not cause electromagnetic interference with other electronic devices.

When it comes to diagnostic tools and methods, compliance with these regulations is essential. Manufacturers and service providers must ensure that their diagnostic equipment and procedures do not compromise the safety features or performance characteristics required by these standards. This includes maintaining electrical isolation, adhering to voltage and current limits, and preserving the integrity of communication protocols.

Furthermore, diagnostic tools themselves must often meet specific safety and accuracy standards. For example, measurement instruments used in solar inverter diagnostics may need to comply with standards such as IEC 61010 for safety requirements and IEC 61326 for EMC requirements.

As the solar energy industry continues to evolve, regulatory compliance for diagnostics tools and methods must adapt to new technologies and challenges. This includes addressing cybersecurity concerns, as many modern solar inverters are connected to smart grids and remote monitoring systems. Regulations such as the IEC 62443 series for industrial communication networks are becoming increasingly relevant in this context.

In conclusion, regulatory compliance in solar inverter diagnostics is a multifaceted and dynamic field. It requires ongoing attention to evolving standards and regulations across different regions and jurisdictions. Manufacturers, service providers, and technicians must stay informed about these requirements to ensure that their diagnostic tools and methods not only effectively identify and resolve issues but also maintain the highest standards of safety and reliability in solar inverter systems.

Environmental Impact

Solar inverter diagnostics tools and methods play a crucial role in ensuring the optimal performance and longevity of solar power systems. However, their environmental impact is an important consideration that must be addressed. The production, use, and disposal of diagnostic equipment can have significant environmental implications.

The manufacturing process of solar inverter diagnostic tools often involves the use of rare earth metals and other materials that require extensive mining and processing. These activities can lead to habitat destruction, soil erosion, and water pollution in the areas where these resources are extracted. Additionally, the production of electronic components generates greenhouse gas emissions and consumes substantial energy, contributing to climate change.

During the operational phase, diagnostic tools generally have a minimal direct environmental impact. They consume relatively little energy compared to the solar power systems they monitor. However, the indirect environmental benefits of these tools are substantial. By enabling early detection of inverter issues and optimizing system performance, they help maximize the energy output of solar installations. This increased efficiency reduces the need for additional fossil fuel-based energy generation, thereby lowering overall carbon emissions.

The disposal of outdated or malfunctioning diagnostic equipment presents another environmental challenge. Electronic waste contains hazardous materials that can leach into soil and water if not properly managed. Implementing effective e-waste recycling programs is essential to mitigate these risks and recover valuable materials for reuse.

On a positive note, advancements in diagnostic technology are leading to more compact, energy-efficient tools with longer lifespans. This trend helps reduce the environmental footprint of diagnostic equipment over time. Furthermore, the shift towards remote monitoring and cloud-based diagnostic solutions is decreasing the need for on-site visits, reducing transportation-related emissions.

The environmental impact of solar inverter diagnostics must be weighed against the significant benefits they provide in supporting renewable energy adoption. By ensuring the reliability and efficiency of solar power systems, these tools and methods contribute to the broader goal of transitioning to cleaner energy sources. This transition is crucial for combating climate change and reducing the overall environmental impact of global energy production.

The manufacturing process of solar inverter diagnostic tools often involves the use of rare earth metals and other materials that require extensive mining and processing. These activities can lead to habitat destruction, soil erosion, and water pollution in the areas where these resources are extracted. Additionally, the production of electronic components generates greenhouse gas emissions and consumes substantial energy, contributing to climate change.

During the operational phase, diagnostic tools generally have a minimal direct environmental impact. They consume relatively little energy compared to the solar power systems they monitor. However, the indirect environmental benefits of these tools are substantial. By enabling early detection of inverter issues and optimizing system performance, they help maximize the energy output of solar installations. This increased efficiency reduces the need for additional fossil fuel-based energy generation, thereby lowering overall carbon emissions.

The disposal of outdated or malfunctioning diagnostic equipment presents another environmental challenge. Electronic waste contains hazardous materials that can leach into soil and water if not properly managed. Implementing effective e-waste recycling programs is essential to mitigate these risks and recover valuable materials for reuse.

On a positive note, advancements in diagnostic technology are leading to more compact, energy-efficient tools with longer lifespans. This trend helps reduce the environmental footprint of diagnostic equipment over time. Furthermore, the shift towards remote monitoring and cloud-based diagnostic solutions is decreasing the need for on-site visits, reducing transportation-related emissions.

The environmental impact of solar inverter diagnostics must be weighed against the significant benefits they provide in supporting renewable energy adoption. By ensuring the reliability and efficiency of solar power systems, these tools and methods contribute to the broader goal of transitioning to cleaner energy sources. This transition is crucial for combating climate change and reducing the overall environmental impact of global energy production.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!