How to Predict Solar Inverter Failure Modes?

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solar Inverter Reliability Background and Objectives

Solar inverters play a crucial role in photovoltaic systems, converting direct current (DC) from solar panels into alternating current (AC) for use in electrical grids or local consumption. The reliability of these inverters is paramount to the overall performance and longevity of solar energy installations. Over the past decades, the solar industry has witnessed significant advancements in inverter technology, driven by the growing demand for renewable energy sources and the need for more efficient and reliable power conversion systems.

The primary objective of predicting solar inverter failure modes is to enhance the reliability and performance of photovoltaic systems. By accurately forecasting potential failures, operators can implement proactive maintenance strategies, minimize downtime, and optimize the overall system efficiency. This predictive approach aims to reduce operational costs, extend the lifespan of solar installations, and improve the return on investment for stakeholders in the renewable energy sector.

The evolution of solar inverter technology has been marked by several key milestones. Early inverters were primarily focused on basic power conversion, while modern inverters incorporate advanced features such as maximum power point tracking (MPPT), grid support functions, and smart monitoring capabilities. This technological progression has led to improved efficiency, reduced failure rates, and enhanced integration with smart grid systems.

Despite these advancements, solar inverters remain one of the most vulnerable components in photovoltaic systems. Common failure modes include thermal stress, component degradation, and environmental factors. The increasing complexity of inverter designs, coupled with the harsh operating conditions often encountered in solar installations, presents ongoing challenges for reliability prediction and maintenance.

Recent trends in solar inverter technology focus on improving reliability through innovative design approaches, advanced materials, and intelligent monitoring systems. Machine learning and artificial intelligence are being leveraged to analyze vast amounts of operational data, enabling more accurate prediction of failure modes and optimized maintenance schedules. Additionally, the integration of wide-bandgap semiconductors, such as silicon carbide (SiC) and gallium nitride (GaN), is enhancing the thermal performance and efficiency of inverters, potentially reducing failure rates.

The goal of predicting solar inverter failure modes extends beyond mere fault detection. It encompasses a comprehensive understanding of the underlying causes of failures, the development of robust predictive models, and the implementation of effective preventive measures. This holistic approach aims to create a more resilient and sustainable solar energy infrastructure, capable of meeting the growing global demand for clean, reliable power.

The primary objective of predicting solar inverter failure modes is to enhance the reliability and performance of photovoltaic systems. By accurately forecasting potential failures, operators can implement proactive maintenance strategies, minimize downtime, and optimize the overall system efficiency. This predictive approach aims to reduce operational costs, extend the lifespan of solar installations, and improve the return on investment for stakeholders in the renewable energy sector.

The evolution of solar inverter technology has been marked by several key milestones. Early inverters were primarily focused on basic power conversion, while modern inverters incorporate advanced features such as maximum power point tracking (MPPT), grid support functions, and smart monitoring capabilities. This technological progression has led to improved efficiency, reduced failure rates, and enhanced integration with smart grid systems.

Despite these advancements, solar inverters remain one of the most vulnerable components in photovoltaic systems. Common failure modes include thermal stress, component degradation, and environmental factors. The increasing complexity of inverter designs, coupled with the harsh operating conditions often encountered in solar installations, presents ongoing challenges for reliability prediction and maintenance.

Recent trends in solar inverter technology focus on improving reliability through innovative design approaches, advanced materials, and intelligent monitoring systems. Machine learning and artificial intelligence are being leveraged to analyze vast amounts of operational data, enabling more accurate prediction of failure modes and optimized maintenance schedules. Additionally, the integration of wide-bandgap semiconductors, such as silicon carbide (SiC) and gallium nitride (GaN), is enhancing the thermal performance and efficiency of inverters, potentially reducing failure rates.

The goal of predicting solar inverter failure modes extends beyond mere fault detection. It encompasses a comprehensive understanding of the underlying causes of failures, the development of robust predictive models, and the implementation of effective preventive measures. This holistic approach aims to create a more resilient and sustainable solar energy infrastructure, capable of meeting the growing global demand for clean, reliable power.

Market Demand for Predictive Maintenance in Solar Energy

The predictive maintenance market for solar energy systems, particularly for solar inverters, has been experiencing significant growth in recent years. This surge is driven by the increasing adoption of solar power globally and the critical role inverters play in the overall efficiency and reliability of solar energy systems. Solar inverters, being the heart of photovoltaic systems, are responsible for converting DC power generated by solar panels into AC power for use in homes, businesses, and the grid.

The demand for predictive maintenance solutions in the solar energy sector is primarily fueled by the need to minimize downtime, reduce operational costs, and extend the lifespan of solar installations. As solar farms and rooftop installations continue to proliferate, operators and owners are increasingly recognizing the value of proactive maintenance strategies. Predictive maintenance, powered by advanced analytics and machine learning algorithms, offers the ability to detect potential inverter failures before they occur, allowing for timely interventions and optimized maintenance schedules.

The market for solar inverter predictive maintenance is closely tied to the overall growth of the solar energy industry. With the global push towards renewable energy sources and the declining costs of solar technology, the installed capacity of solar power is projected to continue its upward trajectory. This expansion directly translates to a larger addressable market for predictive maintenance solutions, as more inverters are deployed and require monitoring and maintenance.

Furthermore, the increasing complexity and scale of solar installations are driving the need for more sophisticated maintenance approaches. Large-scale solar farms, in particular, stand to benefit significantly from predictive maintenance technologies, as the financial impact of inverter failures can be substantial. The ability to predict and prevent such failures can lead to considerable cost savings and improved return on investment for solar project developers and operators.

The market demand is also influenced by regulatory pressures and performance guarantees. Many regions have implemented strict reliability standards for renewable energy systems, incentivizing the adoption of advanced maintenance practices. Additionally, solar project developers often provide performance guarantees to investors and utility companies, making the ability to predict and prevent inverter failures a crucial factor in meeting these commitments.

As the solar energy industry matures, there is a growing emphasis on optimizing the performance and longevity of existing installations. This shift from a focus on rapid deployment to efficient operation and maintenance is further driving the demand for predictive maintenance solutions. The market is seeing increased interest in integrated monitoring systems that can provide real-time insights into inverter health and performance, enabling data-driven decision-making and proactive maintenance strategies.

The demand for predictive maintenance solutions in the solar energy sector is primarily fueled by the need to minimize downtime, reduce operational costs, and extend the lifespan of solar installations. As solar farms and rooftop installations continue to proliferate, operators and owners are increasingly recognizing the value of proactive maintenance strategies. Predictive maintenance, powered by advanced analytics and machine learning algorithms, offers the ability to detect potential inverter failures before they occur, allowing for timely interventions and optimized maintenance schedules.

The market for solar inverter predictive maintenance is closely tied to the overall growth of the solar energy industry. With the global push towards renewable energy sources and the declining costs of solar technology, the installed capacity of solar power is projected to continue its upward trajectory. This expansion directly translates to a larger addressable market for predictive maintenance solutions, as more inverters are deployed and require monitoring and maintenance.

Furthermore, the increasing complexity and scale of solar installations are driving the need for more sophisticated maintenance approaches. Large-scale solar farms, in particular, stand to benefit significantly from predictive maintenance technologies, as the financial impact of inverter failures can be substantial. The ability to predict and prevent such failures can lead to considerable cost savings and improved return on investment for solar project developers and operators.

The market demand is also influenced by regulatory pressures and performance guarantees. Many regions have implemented strict reliability standards for renewable energy systems, incentivizing the adoption of advanced maintenance practices. Additionally, solar project developers often provide performance guarantees to investors and utility companies, making the ability to predict and prevent inverter failures a crucial factor in meeting these commitments.

As the solar energy industry matures, there is a growing emphasis on optimizing the performance and longevity of existing installations. This shift from a focus on rapid deployment to efficient operation and maintenance is further driving the demand for predictive maintenance solutions. The market is seeing increased interest in integrated monitoring systems that can provide real-time insights into inverter health and performance, enabling data-driven decision-making and proactive maintenance strategies.

Current Challenges in Solar Inverter Failure Prediction

Predicting solar inverter failure modes presents several significant challenges in the current technological landscape. One of the primary obstacles is the complexity of inverter systems, which consist of multiple components interacting in intricate ways. This complexity makes it difficult to isolate and identify specific failure modes, as issues in one component can cascade and affect others.

Data availability and quality pose another major challenge. While modern inverters are equipped with sensors and monitoring systems, the data collected is often incomplete or inconsistent across different manufacturers and models. This lack of standardization hampers the development of universal prediction models and necessitates tailored approaches for different inverter types.

The dynamic nature of operating conditions further complicates failure prediction. Solar inverters are exposed to varying environmental factors such as temperature, humidity, and irradiance levels, which can significantly impact their performance and lifespan. Accounting for these fluctuating conditions in predictive models requires sophisticated algorithms and extensive historical data.

Aging and degradation patterns of inverter components add another layer of complexity. Different components may degrade at varying rates, and their interactions can lead to unexpected failure modes. Developing models that accurately capture these long-term degradation processes and their interdependencies remains a significant challenge.

The rapid evolution of inverter technology also presents obstacles for failure prediction. As new designs and materials are introduced, existing prediction models may become obsolete or require substantial modifications. This constant evolution necessitates ongoing research and model updates to maintain accuracy and relevance.

Furthermore, the integration of inverters with other smart grid components introduces new failure modes and interdependencies that are not yet fully understood. As inverters take on more advanced grid support functions, predicting failures in these complex, interconnected systems becomes increasingly challenging.

Lastly, balancing the trade-off between prediction accuracy and computational efficiency poses a significant challenge. While more complex models may offer higher accuracy, they often require substantial computational resources, making real-time monitoring and prediction difficult in large-scale solar installations.

Data availability and quality pose another major challenge. While modern inverters are equipped with sensors and monitoring systems, the data collected is often incomplete or inconsistent across different manufacturers and models. This lack of standardization hampers the development of universal prediction models and necessitates tailored approaches for different inverter types.

The dynamic nature of operating conditions further complicates failure prediction. Solar inverters are exposed to varying environmental factors such as temperature, humidity, and irradiance levels, which can significantly impact their performance and lifespan. Accounting for these fluctuating conditions in predictive models requires sophisticated algorithms and extensive historical data.

Aging and degradation patterns of inverter components add another layer of complexity. Different components may degrade at varying rates, and their interactions can lead to unexpected failure modes. Developing models that accurately capture these long-term degradation processes and their interdependencies remains a significant challenge.

The rapid evolution of inverter technology also presents obstacles for failure prediction. As new designs and materials are introduced, existing prediction models may become obsolete or require substantial modifications. This constant evolution necessitates ongoing research and model updates to maintain accuracy and relevance.

Furthermore, the integration of inverters with other smart grid components introduces new failure modes and interdependencies that are not yet fully understood. As inverters take on more advanced grid support functions, predicting failures in these complex, interconnected systems becomes increasingly challenging.

Lastly, balancing the trade-off between prediction accuracy and computational efficiency poses a significant challenge. While more complex models may offer higher accuracy, they often require substantial computational resources, making real-time monitoring and prediction difficult in large-scale solar installations.

Existing Failure Mode Prediction Techniques for Inverters

01 Thermal management failures

Solar inverters can experience failures due to thermal issues. Overheating of components can lead to reduced efficiency and premature failure. Proper cooling systems and thermal management strategies are crucial to prevent these failures and ensure optimal performance of the inverter.- Thermal management failures: Solar inverters can experience failures due to thermal management issues. Overheating of components can lead to reduced efficiency and potential system shutdown. Proper cooling mechanisms and temperature monitoring are crucial to prevent thermal-related failures in solar inverters.

- Grid-related failures: Grid-related issues can cause solar inverter failures. These may include voltage fluctuations, frequency variations, and grid instability. Advanced grid monitoring and protection features are essential to mitigate such failures and ensure proper operation of the solar inverter.

- Component degradation and wear: Solar inverters can fail due to the degradation and wear of critical components over time. This includes capacitors, switches, and other electronic parts. Regular maintenance and monitoring of component health can help prevent unexpected failures and extend the inverter's lifespan.

- Control system and firmware failures: Failures in the control system or firmware of solar inverters can lead to operational issues. These may include software bugs, communication errors, or improper system responses. Regular firmware updates and robust control algorithms are important to minimize such failures.

- Environmental and external factors: Solar inverters can fail due to environmental and external factors such as lightning strikes, humidity, dust, and extreme weather conditions. Proper protection measures, including surge protection devices and appropriate enclosures, are necessary to safeguard the inverter against these external threats.

02 Grid-related failures

Failures can occur due to grid instability or fluctuations. These may include voltage spikes, frequency variations, or power outages that can damage the inverter or cause it to shut down. Advanced grid monitoring and protection features are essential to mitigate these risks.Expand Specific Solutions03 Component degradation and wear

Over time, various components of solar inverters can degrade or wear out. This includes capacitors, switches, and other electronic components. Regular maintenance and monitoring can help identify and address these issues before they lead to complete failure.Expand Specific Solutions04 Software and control system failures

Inverters can experience failures due to software bugs, firmware issues, or control system malfunctions. These can lead to improper operation, reduced efficiency, or complete shutdown. Regular software updates and robust control algorithms are important to prevent such failures.Expand Specific Solutions05 Environmental stress-related failures

Solar inverters can fail due to environmental stresses such as humidity, dust, or extreme temperatures. These factors can cause corrosion, short circuits, or other damage to the inverter components. Proper enclosure design and environmental protection measures are crucial to prevent these failures.Expand Specific Solutions

Key Players in Solar Inverter Predictive Maintenance

The solar inverter failure prediction market is in a growth phase, driven by increasing adoption of solar energy systems worldwide. The market size is expanding rapidly, with projections indicating significant growth in the coming years. Technologically, predictive maintenance for solar inverters is advancing, but still maturing. Key players like SMA Solar Technology, Sungrow Power Supply, and Huawei are leading innovation in this space, leveraging AI and IoT technologies to enhance prediction accuracy. State Grid Corp. of China and Électricité de France are also investing in smart grid technologies that incorporate inverter health monitoring. While larger companies have more resources for R&D, smaller specialized firms like Solar Analytics are developing niche solutions, indicating a competitive and dynamic market landscape.

SMA Solar Technology AG

Technical Solution: SMA Solar Technology AG has developed an advanced predictive maintenance system for solar inverters. Their approach combines real-time monitoring, data analytics, and machine learning algorithms to predict potential failure modes before they occur. The system continuously collects performance data from inverters, including voltage, current, temperature, and efficiency metrics. This data is then analyzed using sophisticated algorithms that can identify patterns and anomalies indicative of impending failures[1]. SMA's system also incorporates environmental factors such as weather conditions and historical performance data to improve prediction accuracy. Additionally, they have implemented a cloud-based platform that allows for remote diagnostics and proactive maintenance scheduling, reducing downtime and improving overall system reliability[3].

Strengths: Comprehensive data collection and analysis, integration of environmental factors, remote diagnostics capabilities. Weaknesses: May require significant initial investment, potential for false positives in predictions.

Sungrow Power Supply Co., Ltd.

Technical Solution: Sungrow Power Supply Co., Ltd. has developed a multi-faceted approach to predicting solar inverter failure modes. Their system utilizes a combination of big data analytics, artificial intelligence, and Internet of Things (IoT) technologies. Sungrow's predictive maintenance platform collects vast amounts of operational data from their inverters deployed worldwide. This data is processed using advanced machine learning algorithms that can detect subtle changes in inverter performance that may indicate potential failures[2]. The company has also implemented a unique "digital twin" technology, creating virtual models of each inverter to simulate various operating conditions and predict potential failure scenarios[4]. Furthermore, Sungrow has integrated their predictive maintenance system with their customer service platform, enabling automated alerts and rapid response to potential issues.

Strengths: Utilization of cutting-edge technologies like AI and digital twins, global data collection for improved accuracy. Weaknesses: High complexity may require specialized expertise for maintenance and updates.

Core Innovations in Solar Inverter Diagnostics

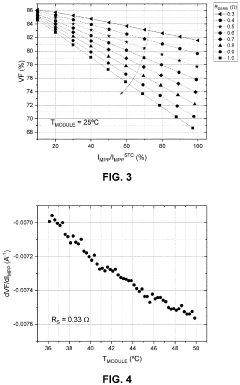

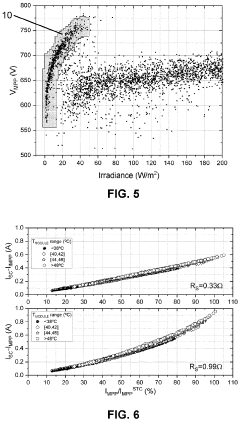

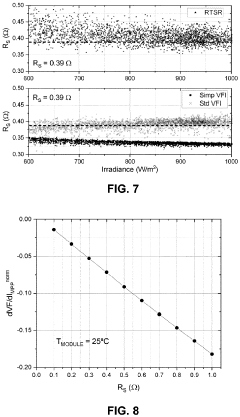

Determination and monitoring of series resistance of a photovoltaic device or system from voltage factor

PatentPendingEP4312035A1

Innovation

- A method that computes the series resistance of a photovoltaic device or system using a voltage factor ratio, partial derivatives, and thermal voltage, without requiring I-V curves, and utilizes multiparametric models to estimate open circuit voltage and short circuit current, improving reliability and robustness against measurement errors.

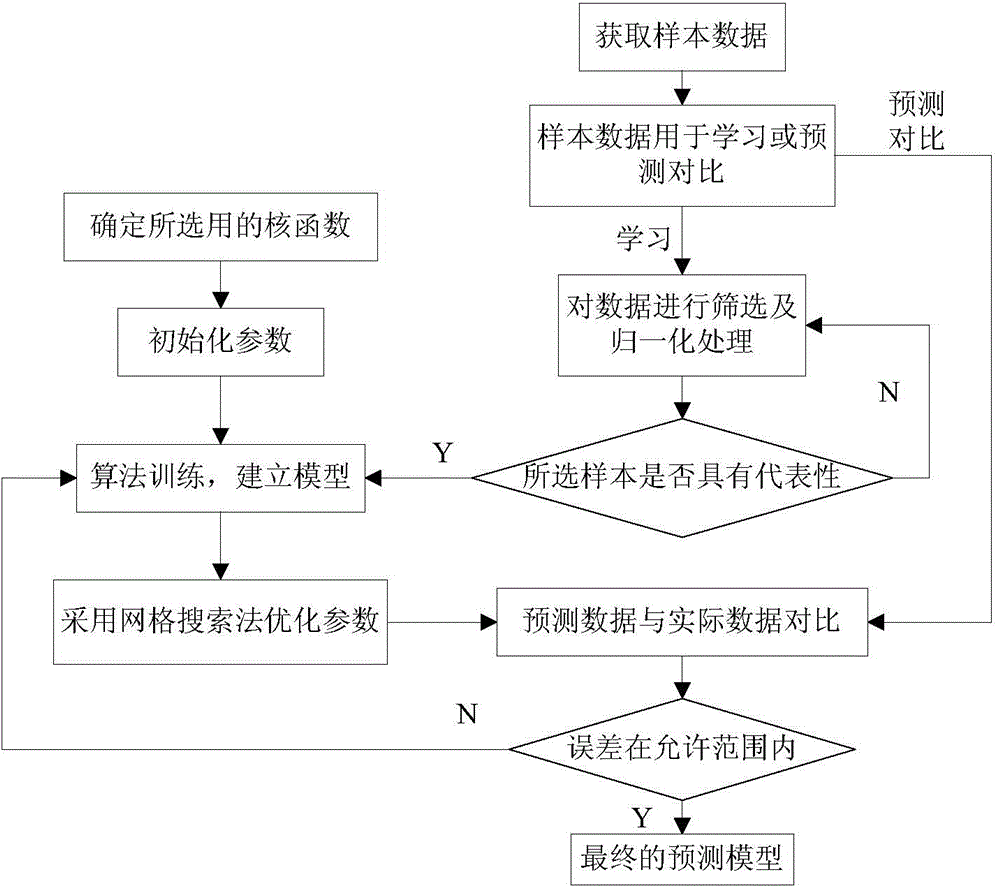

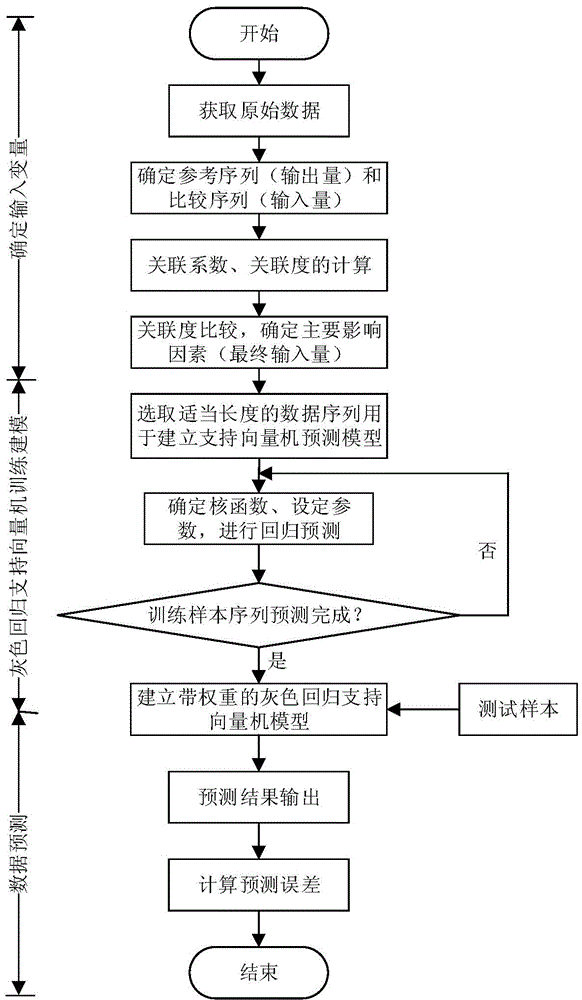

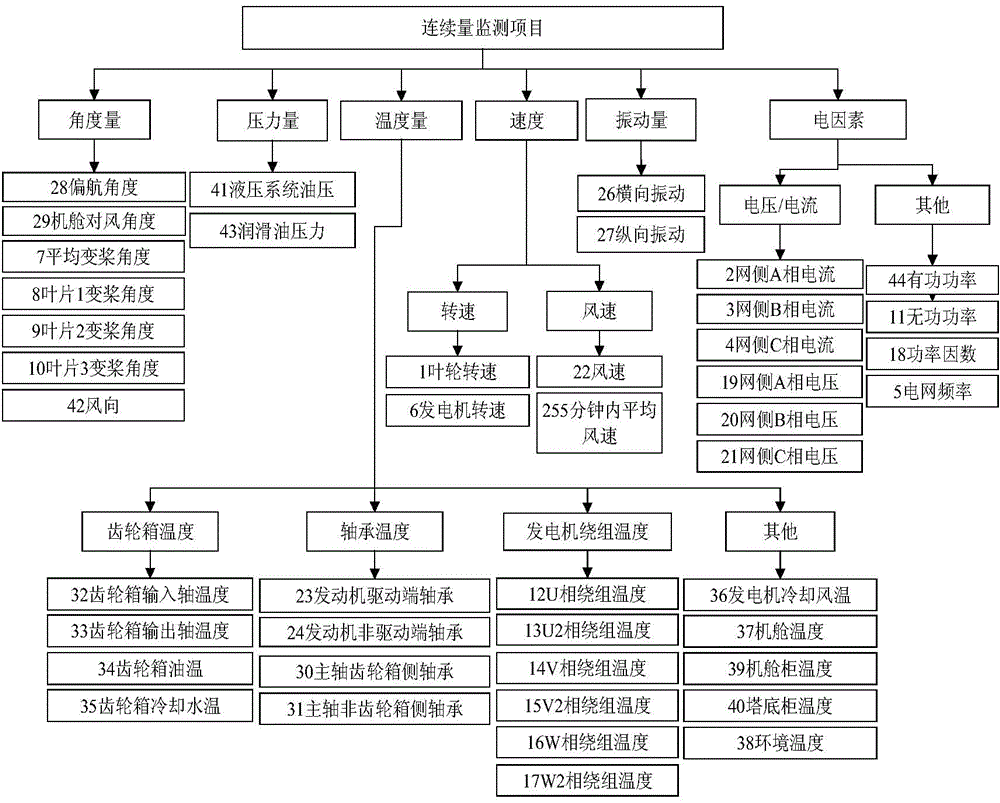

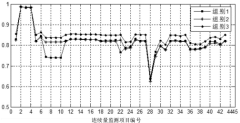

Wind turbine state prediction model establishing method based on grey relation-regression SVM (support vector machine)

PatentActiveCN104951851A

Innovation

- A method based on gray correlation-regression support vector machine is used to collect historical data through the SCADA system, calculate the correlation degree of monitoring items, screen out key input quantities, and establish a weighted gray regression support vector machine model to perform status prediction.

Economic Impact of Improved Solar Inverter Reliability

The economic impact of improved solar inverter reliability extends far beyond the immediate cost savings associated with reduced maintenance and replacement. As solar energy continues to play a crucial role in the global transition to renewable energy sources, the reliability of solar inverters becomes increasingly important in ensuring the overall efficiency and profitability of solar power systems.

Improved reliability in solar inverters leads to increased system uptime and energy production. This translates directly into higher revenue generation for solar farm operators and individual system owners. By minimizing unexpected downtime and maximizing energy output, reliable inverters contribute significantly to the overall return on investment for solar projects.

Furthermore, enhanced inverter reliability reduces operational and maintenance costs. With fewer failures and longer intervals between replacements, solar farm operators can allocate resources more efficiently, reducing the need for frequent site visits and emergency repairs. This cost reduction not only improves the bottom line for operators but also contributes to making solar energy more competitive with traditional energy sources.

The impact on insurance premiums and financing terms is another crucial economic consideration. As solar inverters become more reliable, the perceived risk associated with solar projects decreases. This can lead to more favorable insurance rates and better financing terms for new solar installations, further driving down the overall cost of solar energy production.

In the broader economic context, improved solar inverter reliability contributes to grid stability and resilience. By reducing the frequency of unexpected power fluctuations and outages, reliable inverters help maintain a stable power supply, which is critical for businesses and industries relying on consistent energy availability. This stability can have far-reaching economic benefits, supporting industrial productivity and economic growth.

The ripple effect of improved solar inverter reliability extends to the manufacturing and supply chain sectors as well. As demand for high-quality, reliable inverters increases, it stimulates innovation and competition among manufacturers. This can lead to job creation in the renewable energy sector and related industries, contributing to economic growth and technological advancement.

Lastly, the environmental and social benefits of reliable solar energy systems have indirect economic impacts. By ensuring more consistent and efficient clean energy production, reliable inverters contribute to reducing carbon emissions and mitigating climate change impacts. This can lead to long-term economic benefits through reduced healthcare costs associated with air pollution and mitigation of climate-related economic risks.

Improved reliability in solar inverters leads to increased system uptime and energy production. This translates directly into higher revenue generation for solar farm operators and individual system owners. By minimizing unexpected downtime and maximizing energy output, reliable inverters contribute significantly to the overall return on investment for solar projects.

Furthermore, enhanced inverter reliability reduces operational and maintenance costs. With fewer failures and longer intervals between replacements, solar farm operators can allocate resources more efficiently, reducing the need for frequent site visits and emergency repairs. This cost reduction not only improves the bottom line for operators but also contributes to making solar energy more competitive with traditional energy sources.

The impact on insurance premiums and financing terms is another crucial economic consideration. As solar inverters become more reliable, the perceived risk associated with solar projects decreases. This can lead to more favorable insurance rates and better financing terms for new solar installations, further driving down the overall cost of solar energy production.

In the broader economic context, improved solar inverter reliability contributes to grid stability and resilience. By reducing the frequency of unexpected power fluctuations and outages, reliable inverters help maintain a stable power supply, which is critical for businesses and industries relying on consistent energy availability. This stability can have far-reaching economic benefits, supporting industrial productivity and economic growth.

The ripple effect of improved solar inverter reliability extends to the manufacturing and supply chain sectors as well. As demand for high-quality, reliable inverters increases, it stimulates innovation and competition among manufacturers. This can lead to job creation in the renewable energy sector and related industries, contributing to economic growth and technological advancement.

Lastly, the environmental and social benefits of reliable solar energy systems have indirect economic impacts. By ensuring more consistent and efficient clean energy production, reliable inverters contribute to reducing carbon emissions and mitigating climate change impacts. This can lead to long-term economic benefits through reduced healthcare costs associated with air pollution and mitigation of climate-related economic risks.

Environmental Benefits of Extended Inverter Lifespan

The extension of solar inverter lifespan offers significant environmental benefits, contributing to the overall sustainability of solar energy systems. By prolonging the operational life of inverters, we can substantially reduce electronic waste and minimize the environmental impact associated with manufacturing and disposing of these critical components.

One of the primary environmental advantages of extended inverter lifespan is the reduction in raw material extraction and processing. Solar inverters contain various metals and rare earth elements, the mining and refining of which can have detrimental effects on ecosystems and contribute to greenhouse gas emissions. By increasing the longevity of inverters, we decrease the demand for these materials, thereby reducing the environmental footprint of the solar industry.

Furthermore, extended inverter lifespan leads to a decrease in energy consumption and carbon emissions associated with manufacturing new units. The production of solar inverters involves energy-intensive processes, including the fabrication of electronic components and assembly. By reducing the frequency of inverter replacements, we can significantly lower the cumulative energy requirements and carbon emissions over the lifetime of a solar installation.

Improved inverter durability also contributes to the reduction of electronic waste. As inverters typically have shorter lifespans compared to solar panels, they are a major source of e-waste in the solar industry. Extended lifespan means fewer inverters end up in landfills or require recycling, alleviating the burden on waste management systems and reducing the potential for harmful substances to leach into the environment.

Moreover, longer-lasting inverters enhance the overall efficiency and reliability of solar energy systems. This increased reliability translates to more consistent renewable energy generation, potentially offsetting a greater amount of fossil fuel-based electricity over time. The cumulative effect of this improved performance can lead to a more significant reduction in greenhouse gas emissions and other pollutants associated with conventional power generation.

From a lifecycle perspective, extended inverter lifespan improves the environmental payback time of solar installations. By spreading the initial environmental cost of manufacturing over a longer operational period, the net positive environmental impact of solar energy systems is realized more quickly. This accelerated payback enhances the overall sustainability credentials of solar power as a clean energy solution.

In conclusion, the environmental benefits of extended inverter lifespan are multifaceted and far-reaching. From reducing raw material extraction and manufacturing emissions to minimizing e-waste and improving the efficiency of solar energy systems, longer-lasting inverters play a crucial role in enhancing the environmental performance of solar power. As the industry continues to focus on sustainability, efforts to predict and prevent inverter failures will not only improve system reliability but also contribute significantly to the broader goals of environmental conservation and climate change mitigation.

One of the primary environmental advantages of extended inverter lifespan is the reduction in raw material extraction and processing. Solar inverters contain various metals and rare earth elements, the mining and refining of which can have detrimental effects on ecosystems and contribute to greenhouse gas emissions. By increasing the longevity of inverters, we decrease the demand for these materials, thereby reducing the environmental footprint of the solar industry.

Furthermore, extended inverter lifespan leads to a decrease in energy consumption and carbon emissions associated with manufacturing new units. The production of solar inverters involves energy-intensive processes, including the fabrication of electronic components and assembly. By reducing the frequency of inverter replacements, we can significantly lower the cumulative energy requirements and carbon emissions over the lifetime of a solar installation.

Improved inverter durability also contributes to the reduction of electronic waste. As inverters typically have shorter lifespans compared to solar panels, they are a major source of e-waste in the solar industry. Extended lifespan means fewer inverters end up in landfills or require recycling, alleviating the burden on waste management systems and reducing the potential for harmful substances to leach into the environment.

Moreover, longer-lasting inverters enhance the overall efficiency and reliability of solar energy systems. This increased reliability translates to more consistent renewable energy generation, potentially offsetting a greater amount of fossil fuel-based electricity over time. The cumulative effect of this improved performance can lead to a more significant reduction in greenhouse gas emissions and other pollutants associated with conventional power generation.

From a lifecycle perspective, extended inverter lifespan improves the environmental payback time of solar installations. By spreading the initial environmental cost of manufacturing over a longer operational period, the net positive environmental impact of solar energy systems is realized more quickly. This accelerated payback enhances the overall sustainability credentials of solar power as a clean energy solution.

In conclusion, the environmental benefits of extended inverter lifespan are multifaceted and far-reaching. From reducing raw material extraction and manufacturing emissions to minimizing e-waste and improving the efficiency of solar energy systems, longer-lasting inverters play a crucial role in enhancing the environmental performance of solar power. As the industry continues to focus on sustainability, efforts to predict and prevent inverter failures will not only improve system reliability but also contribute significantly to the broader goals of environmental conservation and climate change mitigation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!