How to Optimize Solar Inverter Lifecycles?

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solar Inverter Evolution and Optimization Goals

Solar inverter technology has undergone significant evolution since its inception in the 1990s. Initially designed for simple DC to AC conversion, modern solar inverters have become sophisticated devices capable of grid integration, power optimization, and advanced monitoring. The primary goal in optimizing solar inverter lifecycles is to enhance their efficiency, reliability, and longevity while reducing costs and environmental impact.

The evolution of solar inverters has been driven by the rapid growth of the solar energy sector and the increasing demand for more efficient and intelligent power conversion systems. Early inverters were bulky, less efficient, and had limited functionality. Over time, technological advancements have led to the development of more compact, efficient, and feature-rich inverters.

One of the key optimization goals is to improve the overall efficiency of solar inverters. This involves reducing energy losses during the conversion process, which directly impacts the amount of usable electricity generated from solar panels. Modern inverters aim to achieve efficiency ratings of 98% or higher, significantly improving the return on investment for solar installations.

Another crucial objective is to extend the operational lifespan of solar inverters. Typically, inverters have a shorter lifespan compared to solar panels, often requiring replacement after 10-15 years. Enhancing the durability and reliability of inverters can significantly reduce maintenance costs and improve the long-term economics of solar energy systems.

Integrating smart technologies and advanced monitoring capabilities is also a key focus in solar inverter optimization. This includes features such as remote diagnostics, predictive maintenance, and real-time performance tracking. These capabilities not only improve the overall system efficiency but also enable proactive maintenance, reducing downtime and extending the inverter's operational life.

Adapting to evolving grid requirements is another critical aspect of solar inverter evolution. As power grids become more complex and decentralized, inverters must be capable of providing grid support functions, such as voltage regulation and reactive power control. This adaptability ensures that solar systems can continue to operate effectively within changing regulatory environments.

Reducing the environmental impact of solar inverters throughout their lifecycle is an increasingly important goal. This involves using more sustainable materials in manufacturing, improving energy efficiency during operation, and enhancing recyclability at the end of the inverter's life. Manufacturers are exploring ways to minimize the use of rare earth elements and develop more eco-friendly production processes.

As the solar industry continues to grow, optimizing inverter costs while maintaining high performance remains a crucial objective. This includes streamlining manufacturing processes, leveraging economies of scale, and exploring innovative designs that reduce material costs without compromising functionality or reliability.

The evolution of solar inverters has been driven by the rapid growth of the solar energy sector and the increasing demand for more efficient and intelligent power conversion systems. Early inverters were bulky, less efficient, and had limited functionality. Over time, technological advancements have led to the development of more compact, efficient, and feature-rich inverters.

One of the key optimization goals is to improve the overall efficiency of solar inverters. This involves reducing energy losses during the conversion process, which directly impacts the amount of usable electricity generated from solar panels. Modern inverters aim to achieve efficiency ratings of 98% or higher, significantly improving the return on investment for solar installations.

Another crucial objective is to extend the operational lifespan of solar inverters. Typically, inverters have a shorter lifespan compared to solar panels, often requiring replacement after 10-15 years. Enhancing the durability and reliability of inverters can significantly reduce maintenance costs and improve the long-term economics of solar energy systems.

Integrating smart technologies and advanced monitoring capabilities is also a key focus in solar inverter optimization. This includes features such as remote diagnostics, predictive maintenance, and real-time performance tracking. These capabilities not only improve the overall system efficiency but also enable proactive maintenance, reducing downtime and extending the inverter's operational life.

Adapting to evolving grid requirements is another critical aspect of solar inverter evolution. As power grids become more complex and decentralized, inverters must be capable of providing grid support functions, such as voltage regulation and reactive power control. This adaptability ensures that solar systems can continue to operate effectively within changing regulatory environments.

Reducing the environmental impact of solar inverters throughout their lifecycle is an increasingly important goal. This involves using more sustainable materials in manufacturing, improving energy efficiency during operation, and enhancing recyclability at the end of the inverter's life. Manufacturers are exploring ways to minimize the use of rare earth elements and develop more eco-friendly production processes.

As the solar industry continues to grow, optimizing inverter costs while maintaining high performance remains a crucial objective. This includes streamlining manufacturing processes, leveraging economies of scale, and exploring innovative designs that reduce material costs without compromising functionality or reliability.

Market Demand for Long-Lasting Solar Inverters

The market demand for long-lasting solar inverters has been steadily increasing in recent years, driven by the growing adoption of solar energy systems worldwide. As solar installations become more prevalent, both residential and commercial customers are seeking inverters that can withstand the test of time, reducing the need for frequent replacements and minimizing system downtime.

One of the primary factors fueling this demand is the desire for improved return on investment (ROI) in solar energy systems. Long-lasting inverters contribute significantly to the overall cost-effectiveness of solar installations by reducing maintenance and replacement expenses over the system's lifetime. This is particularly crucial for large-scale commercial and utility-scale solar projects, where the financial impact of inverter failures can be substantial.

The push for sustainability and environmental responsibility also plays a role in driving the demand for durable solar inverters. By extending the lifespan of these critical components, the overall environmental footprint of solar energy systems is reduced, aligning with the broader goals of renewable energy adoption and carbon footprint reduction.

In the residential sector, homeowners are increasingly aware of the importance of inverter longevity in maintaining the efficiency and reliability of their solar systems. This awareness has led to a shift in consumer preferences towards higher-quality, longer-lasting inverters, even if they come at a premium initial cost.

The commercial and industrial sectors have shown a particularly strong interest in long-lasting solar inverters. For businesses, the reliability and longevity of solar equipment directly impact operational costs and energy security. Extended inverter lifecycles translate to reduced downtime, lower maintenance costs, and more predictable long-term energy expenses.

Utility-scale solar projects have also been a significant driver of demand for durable inverters. These large-scale installations require inverters that can operate consistently under challenging conditions for extended periods. The financial implications of inverter failures in utility-scale projects are substantial, making the longevity of these components a critical factor in project planning and execution.

Geographically, mature solar markets such as Europe and North America have shown a strong preference for high-quality, long-lasting inverters. In these regions, the focus has shifted from rapid expansion to optimizing existing installations and ensuring long-term performance. Emerging markets, while still price-sensitive, are increasingly recognizing the value of investing in durable inverter technology to support the sustainable growth of their solar energy sectors.

The market trend towards long-lasting solar inverters has prompted manufacturers to innovate and improve their product offerings. This has led to the development of advanced inverter technologies with enhanced durability, improved thermal management, and more robust components. As a result, the market is seeing a gradual shift towards inverters with longer warranty periods and higher reliability ratings, reflecting the industry's response to consumer demands for extended lifecycle products.

One of the primary factors fueling this demand is the desire for improved return on investment (ROI) in solar energy systems. Long-lasting inverters contribute significantly to the overall cost-effectiveness of solar installations by reducing maintenance and replacement expenses over the system's lifetime. This is particularly crucial for large-scale commercial and utility-scale solar projects, where the financial impact of inverter failures can be substantial.

The push for sustainability and environmental responsibility also plays a role in driving the demand for durable solar inverters. By extending the lifespan of these critical components, the overall environmental footprint of solar energy systems is reduced, aligning with the broader goals of renewable energy adoption and carbon footprint reduction.

In the residential sector, homeowners are increasingly aware of the importance of inverter longevity in maintaining the efficiency and reliability of their solar systems. This awareness has led to a shift in consumer preferences towards higher-quality, longer-lasting inverters, even if they come at a premium initial cost.

The commercial and industrial sectors have shown a particularly strong interest in long-lasting solar inverters. For businesses, the reliability and longevity of solar equipment directly impact operational costs and energy security. Extended inverter lifecycles translate to reduced downtime, lower maintenance costs, and more predictable long-term energy expenses.

Utility-scale solar projects have also been a significant driver of demand for durable inverters. These large-scale installations require inverters that can operate consistently under challenging conditions for extended periods. The financial implications of inverter failures in utility-scale projects are substantial, making the longevity of these components a critical factor in project planning and execution.

Geographically, mature solar markets such as Europe and North America have shown a strong preference for high-quality, long-lasting inverters. In these regions, the focus has shifted from rapid expansion to optimizing existing installations and ensuring long-term performance. Emerging markets, while still price-sensitive, are increasingly recognizing the value of investing in durable inverter technology to support the sustainable growth of their solar energy sectors.

The market trend towards long-lasting solar inverters has prompted manufacturers to innovate and improve their product offerings. This has led to the development of advanced inverter technologies with enhanced durability, improved thermal management, and more robust components. As a result, the market is seeing a gradual shift towards inverters with longer warranty periods and higher reliability ratings, reflecting the industry's response to consumer demands for extended lifecycle products.

Current Challenges in Solar Inverter Longevity

Solar inverter longevity faces several significant challenges in the current technological landscape. One of the primary issues is the degradation of components over time, particularly capacitors and power semiconductors. These components are subjected to high temperatures and electrical stress, leading to reduced efficiency and potential failure.

Environmental factors also play a crucial role in inverter lifespan. Exposure to extreme temperatures, humidity, and dust can accelerate wear and tear on internal components. This is especially problematic in regions with harsh climates, where solar installations are often deployed.

Another challenge is the mismatch between inverter lifespans and solar panel longevity. While solar panels typically last 25-30 years, inverters often require replacement after 10-15 years. This discrepancy creates maintenance issues and increases the overall cost of solar energy systems over their operational lifetime.

The rapid evolution of solar technology presents an additional hurdle. As new, more efficient solar panels are developed, older inverters may struggle to optimize power conversion, leading to reduced system performance. This technological gap can necessitate premature inverter replacements to maintain optimal system efficiency.

Reliability and performance consistency over time are ongoing concerns. Inverters may experience gradual declines in efficiency or sudden failures, both of which can significantly impact energy production and system reliability. Detecting and predicting these issues before they cause substantial power losses remains a challenge.

Grid integration and compliance with evolving regulatory standards also pose difficulties for inverter longevity. As grid requirements change, older inverters may become non-compliant, necessitating upgrades or replacements to meet new standards for grid stability and power quality.

Lastly, the balance between cost and quality in inverter manufacturing presents a persistent challenge. While higher-quality components and robust designs can extend inverter lifespan, they also increase initial costs. Finding the optimal balance between longevity and affordability is crucial for widespread solar adoption.

Environmental factors also play a crucial role in inverter lifespan. Exposure to extreme temperatures, humidity, and dust can accelerate wear and tear on internal components. This is especially problematic in regions with harsh climates, where solar installations are often deployed.

Another challenge is the mismatch between inverter lifespans and solar panel longevity. While solar panels typically last 25-30 years, inverters often require replacement after 10-15 years. This discrepancy creates maintenance issues and increases the overall cost of solar energy systems over their operational lifetime.

The rapid evolution of solar technology presents an additional hurdle. As new, more efficient solar panels are developed, older inverters may struggle to optimize power conversion, leading to reduced system performance. This technological gap can necessitate premature inverter replacements to maintain optimal system efficiency.

Reliability and performance consistency over time are ongoing concerns. Inverters may experience gradual declines in efficiency or sudden failures, both of which can significantly impact energy production and system reliability. Detecting and predicting these issues before they cause substantial power losses remains a challenge.

Grid integration and compliance with evolving regulatory standards also pose difficulties for inverter longevity. As grid requirements change, older inverters may become non-compliant, necessitating upgrades or replacements to meet new standards for grid stability and power quality.

Lastly, the balance between cost and quality in inverter manufacturing presents a persistent challenge. While higher-quality components and robust designs can extend inverter lifespan, they also increase initial costs. Finding the optimal balance between longevity and affordability is crucial for widespread solar adoption.

Existing Lifecycle Extension Strategies

01 Lifecycle management and monitoring of solar inverters

This involves systems and methods for managing and monitoring the lifecycle of solar inverters, including performance tracking, maintenance scheduling, and end-of-life predictions. These solutions help optimize the operation and longevity of solar inverter systems.- Lifecycle management and monitoring of solar inverters: This involves systems and methods for managing and monitoring the lifecycle of solar inverters, including performance tracking, maintenance scheduling, and predictive analytics to optimize their operation and longevity.

- Efficiency improvement and power optimization: Techniques for enhancing the efficiency and power output of solar inverters throughout their lifecycle, including advanced control algorithms, maximum power point tracking, and adaptive power management strategies.

- Thermal management and cooling systems: Innovations in thermal management and cooling systems for solar inverters to extend their lifespan, improve reliability, and maintain optimal performance under various environmental conditions.

- Grid integration and smart inverter functionalities: Advanced features for seamless grid integration of solar inverters, including smart grid compatibility, voltage and frequency regulation, and reactive power control to enhance grid stability and inverter longevity.

- Fault detection and diagnostics: Systems and methods for early fault detection, diagnostics, and prognostics in solar inverters, enabling proactive maintenance and reducing downtime throughout the inverter's lifecycle.

02 Efficiency improvement and power optimization

Techniques for enhancing the efficiency and power output of solar inverters throughout their lifecycle. This includes advanced control algorithms, power point tracking, and adaptive systems to maximize energy conversion and minimize losses.Expand Specific Solutions03 Thermal management and cooling systems

Innovations in thermal management and cooling systems for solar inverters to extend their operational life and maintain performance. These solutions address heat dissipation challenges and help prevent premature component failure due to thermal stress.Expand Specific Solutions04 Fault detection and diagnostics

Advanced fault detection and diagnostic systems for solar inverters, enabling early identification of potential issues and predictive maintenance. These technologies help prevent unexpected failures and extend the overall lifecycle of the inverters.Expand Specific Solutions05 Grid integration and smart inverter functionalities

Development of smart inverter functionalities and improved grid integration capabilities to enhance the adaptability and longevity of solar inverters. These features allow inverters to better respond to grid conditions and regulatory requirements throughout their lifecycle.Expand Specific Solutions

Key Players in Solar Inverter Manufacturing

The solar inverter lifecycle optimization market is in a growth phase, driven by increasing global solar energy adoption. The market size is expanding rapidly, with projections indicating significant growth in the coming years. Technologically, the field is advancing quickly, with major players like Huawei Digital Power, Enphase Energy, and SolarEdge Technologies leading innovation. These companies are developing more efficient, durable, and intelligent inverters, incorporating features such as AI-driven predictive maintenance and advanced power electronics. Other significant contributors include established industrial giants like Siemens and emerging specialists like Sungrow Power Supply, all competing to enhance inverter performance, longevity, and overall system efficiency in the evolving solar energy landscape.

Huawei Digital Power Technologies Co Ltd

Technical Solution: Huawei's approach to optimizing solar inverter lifecycles involves the use of advanced AI algorithms and big data analytics. Their smart inverters employ self-learning capabilities to adapt to environmental conditions, optimizing performance and extending lifespan. The company has developed a predictive maintenance system that uses real-time monitoring and fault prediction to reduce downtime and maintenance costs[1]. Huawei's FusionSolar Smart PV Solution integrates string inverters with optimizers, providing module-level power optimization and improving overall system efficiency by up to 30%[2]. Additionally, their inverters feature IP65 protection and natural cooling design, enhancing durability in harsh environments[3].

Strengths: Advanced AI integration, predictive maintenance, and high efficiency. Weaknesses: Potential high initial costs and reliance on proprietary technology.

Enphase Energy, Inc.

Technical Solution: Enphase Energy focuses on microinverter technology to optimize solar inverter lifecycles. Their IQ8 microinverters are designed with software-defined architecture, allowing for remote upgrades and adaptability to changing grid requirements[4]. The company employs a distributed architecture, where each solar panel has its own microinverter, reducing the impact of individual component failures on the overall system. Enphase's Envoy communication gateway provides continuous monitoring and diagnostics, enabling proactive maintenance and rapid issue resolution[5]. The microinverters are built with high-quality, long-life components and undergo rigorous testing, resulting in a reported 0.05% annual failure rate[6].

Strengths: Distributed architecture for enhanced reliability, remote upgrade capability, and low failure rates. Weaknesses: Higher per-watt cost compared to string inverters and potential complexity in large-scale installations.

Innovative Materials and Design Approaches

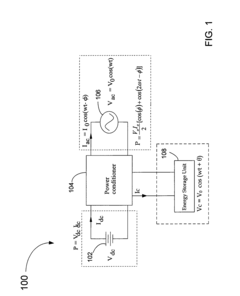

Methods for minimizing double-frequency ripple power in single-phase power conditioners

PatentActiveUS8004865B2

Innovation

- A method that senses the AC waveform at the output of the power conditioner and generates a second AC waveform with the same frequency but shifted by π/4 radians, which is applied to an energy storage device to minimize double-frequency ripple power, using a phase shift and appropriate amplitude to reduce the capacitance required, allowing for the use of more reliable film capacitors or inductors.

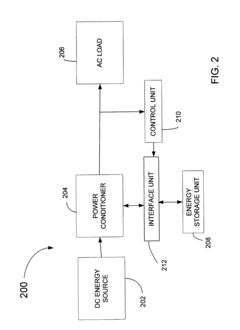

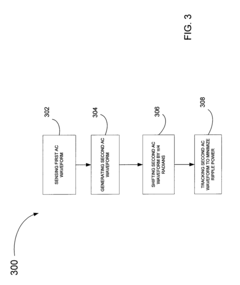

High reliability power systems and solar power converters

PatentWO2009055474A1

Innovation

- The use of switchmode power conversion technology with film capacitors that emulate high capacitance, allowing for energy storage over a large voltage range, thereby extending the lifespan of components like grid-tied PV converters to several decades.

Environmental Impact of Inverter Lifecycle Optimization

The optimization of solar inverter lifecycles has significant environmental implications that extend beyond the immediate benefits of renewable energy generation. As inverters play a crucial role in converting DC power from solar panels to AC power for grid use, their lifecycle management directly impacts the overall sustainability of solar energy systems.

Inverter lifecycle optimization contributes to reduced electronic waste, a growing concern in the renewable energy sector. By extending the operational lifespan of inverters through improved design, materials, and maintenance practices, the frequency of replacements decreases. This reduction in turnover leads to fewer discarded units, mitigating the environmental burden associated with electronic waste disposal and the extraction of raw materials for new inverters.

Energy efficiency improvements in inverter technology also play a vital role in environmental impact reduction. Optimized inverters with higher conversion efficiencies result in less energy loss during the DC to AC conversion process. This increased efficiency translates to more usable energy output from solar installations, effectively reducing the carbon footprint per unit of electricity generated and enhancing the overall environmental benefits of solar power systems.

The manufacturing process of solar inverters is another area where lifecycle optimization can yield significant environmental benefits. By focusing on sustainable production methods, such as using recycled materials, implementing energy-efficient manufacturing processes, and minimizing hazardous substances, the environmental impact of inverter production can be substantially reduced. This approach aligns with circular economy principles, promoting resource conservation and minimizing pollution throughout the inverter's lifecycle.

Lifecycle optimization also encompasses improved maintenance and repair strategies. Predictive maintenance techniques, enabled by advanced monitoring and diagnostics, can prevent premature failures and extend inverter lifespans. This proactive approach not only reduces waste but also ensures consistent performance, maximizing the environmental benefits of solar energy systems over time.

Furthermore, the end-of-life management of inverters is a critical aspect of lifecycle optimization with direct environmental implications. Developing effective recycling and refurbishment programs for decommissioned inverters can recover valuable materials, reduce landfill waste, and decrease the demand for virgin resources in new inverter production. This closed-loop approach significantly enhances the overall sustainability of solar energy infrastructure.

In conclusion, the environmental impact of inverter lifecycle optimization is multifaceted, encompassing waste reduction, energy efficiency improvements, sustainable manufacturing, enhanced maintenance practices, and responsible end-of-life management. These efforts collectively contribute to minimizing the ecological footprint of solar energy systems, reinforcing their position as a truly sustainable power generation solution.

Inverter lifecycle optimization contributes to reduced electronic waste, a growing concern in the renewable energy sector. By extending the operational lifespan of inverters through improved design, materials, and maintenance practices, the frequency of replacements decreases. This reduction in turnover leads to fewer discarded units, mitigating the environmental burden associated with electronic waste disposal and the extraction of raw materials for new inverters.

Energy efficiency improvements in inverter technology also play a vital role in environmental impact reduction. Optimized inverters with higher conversion efficiencies result in less energy loss during the DC to AC conversion process. This increased efficiency translates to more usable energy output from solar installations, effectively reducing the carbon footprint per unit of electricity generated and enhancing the overall environmental benefits of solar power systems.

The manufacturing process of solar inverters is another area where lifecycle optimization can yield significant environmental benefits. By focusing on sustainable production methods, such as using recycled materials, implementing energy-efficient manufacturing processes, and minimizing hazardous substances, the environmental impact of inverter production can be substantially reduced. This approach aligns with circular economy principles, promoting resource conservation and minimizing pollution throughout the inverter's lifecycle.

Lifecycle optimization also encompasses improved maintenance and repair strategies. Predictive maintenance techniques, enabled by advanced monitoring and diagnostics, can prevent premature failures and extend inverter lifespans. This proactive approach not only reduces waste but also ensures consistent performance, maximizing the environmental benefits of solar energy systems over time.

Furthermore, the end-of-life management of inverters is a critical aspect of lifecycle optimization with direct environmental implications. Developing effective recycling and refurbishment programs for decommissioned inverters can recover valuable materials, reduce landfill waste, and decrease the demand for virgin resources in new inverter production. This closed-loop approach significantly enhances the overall sustainability of solar energy infrastructure.

In conclusion, the environmental impact of inverter lifecycle optimization is multifaceted, encompassing waste reduction, energy efficiency improvements, sustainable manufacturing, enhanced maintenance practices, and responsible end-of-life management. These efforts collectively contribute to minimizing the ecological footprint of solar energy systems, reinforcing their position as a truly sustainable power generation solution.

Cost-Benefit Analysis of Extended Inverter Lifespans

Extending the lifespan of solar inverters presents a compelling cost-benefit proposition for solar energy system owners and operators. The initial investment in high-quality, durable inverters may be higher, but the long-term savings and benefits often outweigh these upfront costs. Improved reliability and reduced replacement frequency lead to lower maintenance expenses and minimized system downtime, enhancing overall energy production and revenue generation.

Advanced inverter technologies, such as those incorporating wide-bandgap semiconductors like silicon carbide, offer superior performance and longevity. While these components increase initial costs, they significantly reduce energy losses and thermal stress, extending the inverter's operational life. This translates to improved system efficiency and reduced cooling requirements, further lowering operational expenses.

The financial benefits of extended inverter lifespans become particularly evident when considering the total cost of ownership over the system's lifetime. Longer-lasting inverters reduce the number of replacements needed, cutting both equipment and labor costs associated with installations. This is especially crucial for large-scale solar installations where inverter replacement can be logistically challenging and expensive.

Moreover, extended inverter lifespans align with the increasing longevity of solar panels, which now often come with 25-30 year warranties. By matching inverter durability to panel lifespan, system owners can optimize their investment and reduce the likelihood of mismatched component replacements, which can lead to efficiency losses and increased costs.

From an environmental perspective, longer-lasting inverters contribute to sustainability efforts by reducing electronic waste and the carbon footprint associated with manufacturing and transporting replacement units. This aligns with the broader goals of renewable energy adoption and can enhance the overall environmental benefits of solar power systems.

However, it's essential to balance the pursuit of extended lifespans with technological advancements. As inverter technology evolves, newer models may offer significant efficiency improvements or additional features that could justify earlier replacement. A comprehensive cost-benefit analysis should consider not only the direct costs of replacement but also the potential gains from upgrading to more advanced technology.

Advanced inverter technologies, such as those incorporating wide-bandgap semiconductors like silicon carbide, offer superior performance and longevity. While these components increase initial costs, they significantly reduce energy losses and thermal stress, extending the inverter's operational life. This translates to improved system efficiency and reduced cooling requirements, further lowering operational expenses.

The financial benefits of extended inverter lifespans become particularly evident when considering the total cost of ownership over the system's lifetime. Longer-lasting inverters reduce the number of replacements needed, cutting both equipment and labor costs associated with installations. This is especially crucial for large-scale solar installations where inverter replacement can be logistically challenging and expensive.

Moreover, extended inverter lifespans align with the increasing longevity of solar panels, which now often come with 25-30 year warranties. By matching inverter durability to panel lifespan, system owners can optimize their investment and reduce the likelihood of mismatched component replacements, which can lead to efficiency losses and increased costs.

From an environmental perspective, longer-lasting inverters contribute to sustainability efforts by reducing electronic waste and the carbon footprint associated with manufacturing and transporting replacement units. This aligns with the broader goals of renewable energy adoption and can enhance the overall environmental benefits of solar power systems.

However, it's essential to balance the pursuit of extended lifespans with technological advancements. As inverter technology evolves, newer models may offer significant efficiency improvements or additional features that could justify earlier replacement. A comprehensive cost-benefit analysis should consider not only the direct costs of replacement but also the potential gains from upgrading to more advanced technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!