How to Increase System Lifespan of Solar Inverters?

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solar Inverter Longevity Objectives

Solar inverter longevity is a critical factor in the overall efficiency and cost-effectiveness of solar energy systems. The primary objective in increasing the system lifespan of solar inverters is to maximize the return on investment for solar installations while ensuring consistent and reliable power generation over extended periods.

One key goal is to enhance the durability of inverter components to withstand environmental stresses. This includes improving resistance to temperature fluctuations, humidity, and dust, which are common challenges in outdoor installations. By developing more robust materials and protective enclosures, manufacturers aim to reduce the impact of these environmental factors on inverter performance and longevity.

Another important objective is to optimize the thermal management of solar inverters. Efficient heat dissipation is crucial for preventing premature component degradation and maintaining optimal operating conditions. This involves designing advanced cooling systems, implementing intelligent thermal monitoring, and utilizing high-performance thermal materials to ensure stable operation even under high-load conditions.

Improving the reliability of power electronic components is also a primary focus. This includes developing more durable capacitors, transistors, and other critical elements that are prone to wear and failure over time. By enhancing the quality and resilience of these components, manufacturers can significantly extend the operational life of solar inverters.

Implementing advanced monitoring and diagnostic systems is another key objective. These systems aim to detect potential issues before they lead to critical failures, allowing for proactive maintenance and reducing downtime. This includes the integration of smart sensors, real-time performance analysis, and predictive maintenance algorithms to optimize inverter operation and extend its lifespan.

Furthermore, there is a growing emphasis on modular design and easy serviceability. This approach allows for the replacement of individual components rather than entire units, reducing maintenance costs and extending the overall system lifespan. It also facilitates easier upgrades to keep pace with technological advancements without requiring a complete system overhaul.

Lastly, improving the efficiency of power conversion is a crucial objective. Higher efficiency not only increases energy yield but also reduces thermal stress on components, contributing to longer operational life. This involves refining inverter topologies, implementing advanced control algorithms, and utilizing high-performance semiconductor materials to minimize power losses and heat generation.

One key goal is to enhance the durability of inverter components to withstand environmental stresses. This includes improving resistance to temperature fluctuations, humidity, and dust, which are common challenges in outdoor installations. By developing more robust materials and protective enclosures, manufacturers aim to reduce the impact of these environmental factors on inverter performance and longevity.

Another important objective is to optimize the thermal management of solar inverters. Efficient heat dissipation is crucial for preventing premature component degradation and maintaining optimal operating conditions. This involves designing advanced cooling systems, implementing intelligent thermal monitoring, and utilizing high-performance thermal materials to ensure stable operation even under high-load conditions.

Improving the reliability of power electronic components is also a primary focus. This includes developing more durable capacitors, transistors, and other critical elements that are prone to wear and failure over time. By enhancing the quality and resilience of these components, manufacturers can significantly extend the operational life of solar inverters.

Implementing advanced monitoring and diagnostic systems is another key objective. These systems aim to detect potential issues before they lead to critical failures, allowing for proactive maintenance and reducing downtime. This includes the integration of smart sensors, real-time performance analysis, and predictive maintenance algorithms to optimize inverter operation and extend its lifespan.

Furthermore, there is a growing emphasis on modular design and easy serviceability. This approach allows for the replacement of individual components rather than entire units, reducing maintenance costs and extending the overall system lifespan. It also facilitates easier upgrades to keep pace with technological advancements without requiring a complete system overhaul.

Lastly, improving the efficiency of power conversion is a crucial objective. Higher efficiency not only increases energy yield but also reduces thermal stress on components, contributing to longer operational life. This involves refining inverter topologies, implementing advanced control algorithms, and utilizing high-performance semiconductor materials to minimize power losses and heat generation.

Market Demand Analysis

The market demand for solar inverters with increased system lifespan is experiencing significant growth, driven by the global shift towards renewable energy sources and the need for more efficient and durable solar power systems. As solar energy installations continue to expand worldwide, there is a growing emphasis on maximizing the return on investment for solar projects, which directly correlates with the longevity and reliability of key components such as inverters.

The solar inverter market is projected to witness substantial growth in the coming years, with a particular focus on technologies that extend operational lifespans. This demand is fueled by both residential and commercial sectors seeking to reduce long-term costs associated with solar power systems. Residential consumers are increasingly looking for inverters that can match or exceed the 25-30 year lifespan of solar panels, while commercial and utility-scale projects require even more robust solutions to ensure consistent power generation over extended periods.

Geographically, mature solar markets such as Europe and North America are showing a strong preference for high-quality, long-lasting inverters, as they move towards replacing and upgrading existing installations. Emerging markets in Asia-Pacific and Latin America are also recognizing the value of investing in durable inverter technologies as they rapidly expand their solar capacity.

The push for increased system lifespan is further supported by evolving industry standards and regulations that emphasize reliability and performance over time. This has led to a growing demand for inverters with advanced monitoring capabilities, predictive maintenance features, and modular designs that facilitate easier repairs and upgrades.

From an economic perspective, the market is seeing a shift in consumer behavior, with many buyers willing to pay a premium for inverters that offer extended warranties and demonstrated longevity. This trend is particularly pronounced in the commercial and industrial sectors, where downtime can result in significant financial losses.

The integration of energy storage systems with solar installations is also driving demand for inverters with longer lifespans. As battery technology improves and becomes more prevalent in solar setups, there is an increasing need for inverters that can maintain high efficiency and reliability over extended periods to match the longevity of these integrated systems.

In conclusion, the market demand for solar inverters with increased system lifespan is robust and growing. This trend is reshaping the competitive landscape of the solar industry, pushing manufacturers to innovate and develop more durable and efficient inverter technologies to meet the evolving needs of a maturing solar market.

The solar inverter market is projected to witness substantial growth in the coming years, with a particular focus on technologies that extend operational lifespans. This demand is fueled by both residential and commercial sectors seeking to reduce long-term costs associated with solar power systems. Residential consumers are increasingly looking for inverters that can match or exceed the 25-30 year lifespan of solar panels, while commercial and utility-scale projects require even more robust solutions to ensure consistent power generation over extended periods.

Geographically, mature solar markets such as Europe and North America are showing a strong preference for high-quality, long-lasting inverters, as they move towards replacing and upgrading existing installations. Emerging markets in Asia-Pacific and Latin America are also recognizing the value of investing in durable inverter technologies as they rapidly expand their solar capacity.

The push for increased system lifespan is further supported by evolving industry standards and regulations that emphasize reliability and performance over time. This has led to a growing demand for inverters with advanced monitoring capabilities, predictive maintenance features, and modular designs that facilitate easier repairs and upgrades.

From an economic perspective, the market is seeing a shift in consumer behavior, with many buyers willing to pay a premium for inverters that offer extended warranties and demonstrated longevity. This trend is particularly pronounced in the commercial and industrial sectors, where downtime can result in significant financial losses.

The integration of energy storage systems with solar installations is also driving demand for inverters with longer lifespans. As battery technology improves and becomes more prevalent in solar setups, there is an increasing need for inverters that can maintain high efficiency and reliability over extended periods to match the longevity of these integrated systems.

In conclusion, the market demand for solar inverters with increased system lifespan is robust and growing. This trend is reshaping the competitive landscape of the solar industry, pushing manufacturers to innovate and develop more durable and efficient inverter technologies to meet the evolving needs of a maturing solar market.

Current Challenges in Inverter Durability

Solar inverters face several critical challenges in terms of durability and longevity, which directly impact the overall system lifespan of solar power installations. One of the primary issues is thermal stress, as inverters are often exposed to extreme temperature fluctuations and high heat levels. This thermal cycling can lead to component fatigue, solder joint cracking, and premature failure of electronic components.

Another significant challenge is the degradation of power electronic components, particularly capacitors and semiconductors. Electrolytic capacitors, commonly used in inverters, are prone to drying out over time, especially in high-temperature environments. This degradation can result in reduced power output and eventual system failure. Similarly, semiconductor devices such as IGBTs and MOSFETs are susceptible to thermal runaway and voltage stress, which can lead to sudden failures or gradual performance decline.

Environmental factors also play a crucial role in inverter durability. Exposure to humidity, dust, and corrosive atmospheres can accelerate the deterioration of internal components and compromise the integrity of the inverter's enclosure. This is particularly problematic in coastal or industrial areas where salt spray or pollutants are present in the air.

Grid instability and power quality issues pose additional challenges to inverter longevity. Voltage spikes, frequency variations, and harmonic distortions from the grid can stress the inverter's components and control systems, potentially leading to premature wear or failure. The increasing integration of renewable energy sources into the grid exacerbates these issues, as it can lead to more frequent and severe grid fluctuations.

The rapid evolution of solar technology and grid requirements also presents a challenge for inverter durability. As new standards and regulations emerge, older inverters may become obsolete or require significant upgrades to remain compliant. This technological obsolescence can effectively shorten the useful lifespan of inverters, even if they are still functioning properly from a hardware perspective.

Maintenance and serviceability are additional factors affecting inverter durability. Many inverters are designed with sealed enclosures to protect against environmental factors, which can make routine maintenance and component replacement difficult. This design approach, while beneficial for short-term protection, can hinder long-term serviceability and potentially reduce the overall lifespan of the system.

Lastly, the challenge of balancing cost and quality in inverter manufacturing impacts durability. The pressure to reduce costs in the competitive solar market can lead to the use of lower-quality components or simplified designs that may compromise long-term reliability. Striking the right balance between affordability and durability remains an ongoing challenge for manufacturers and system integrators.

Another significant challenge is the degradation of power electronic components, particularly capacitors and semiconductors. Electrolytic capacitors, commonly used in inverters, are prone to drying out over time, especially in high-temperature environments. This degradation can result in reduced power output and eventual system failure. Similarly, semiconductor devices such as IGBTs and MOSFETs are susceptible to thermal runaway and voltage stress, which can lead to sudden failures or gradual performance decline.

Environmental factors also play a crucial role in inverter durability. Exposure to humidity, dust, and corrosive atmospheres can accelerate the deterioration of internal components and compromise the integrity of the inverter's enclosure. This is particularly problematic in coastal or industrial areas where salt spray or pollutants are present in the air.

Grid instability and power quality issues pose additional challenges to inverter longevity. Voltage spikes, frequency variations, and harmonic distortions from the grid can stress the inverter's components and control systems, potentially leading to premature wear or failure. The increasing integration of renewable energy sources into the grid exacerbates these issues, as it can lead to more frequent and severe grid fluctuations.

The rapid evolution of solar technology and grid requirements also presents a challenge for inverter durability. As new standards and regulations emerge, older inverters may become obsolete or require significant upgrades to remain compliant. This technological obsolescence can effectively shorten the useful lifespan of inverters, even if they are still functioning properly from a hardware perspective.

Maintenance and serviceability are additional factors affecting inverter durability. Many inverters are designed with sealed enclosures to protect against environmental factors, which can make routine maintenance and component replacement difficult. This design approach, while beneficial for short-term protection, can hinder long-term serviceability and potentially reduce the overall lifespan of the system.

Lastly, the challenge of balancing cost and quality in inverter manufacturing impacts durability. The pressure to reduce costs in the competitive solar market can lead to the use of lower-quality components or simplified designs that may compromise long-term reliability. Striking the right balance between affordability and durability remains an ongoing challenge for manufacturers and system integrators.

Existing Lifespan Extension Techniques

01 Lifespan extension through advanced cooling systems

Solar inverter systems can achieve extended lifespans through the implementation of advanced cooling systems. These systems help manage temperature-related stress on components, reducing wear and tear. Efficient cooling methods, such as liquid cooling or advanced heat sink designs, can significantly improve the longevity of inverter systems by maintaining optimal operating temperatures.- Lifespan extension through advanced cooling systems: Solar inverter systems can achieve extended lifespans through the implementation of advanced cooling systems. These systems help maintain optimal operating temperatures, reducing thermal stress on components and preventing premature failure. Efficient cooling methods may include liquid cooling, heat sinks, or advanced air circulation designs, which contribute to prolonging the overall system lifespan.

- Intelligent power management for longevity: Implementing intelligent power management techniques can significantly enhance the lifespan of solar inverter systems. These methods involve optimizing power flow, load balancing, and efficient energy distribution to reduce stress on individual components. Advanced algorithms and control systems can adapt to varying environmental conditions and energy demands, ensuring consistent performance and extended operational life.

- Modular design for easy maintenance and upgrades: Adopting a modular design approach in solar inverter systems can contribute to increased lifespan. This design philosophy allows for easier maintenance, component replacement, and system upgrades without the need for complete system overhauls. Modular systems enable targeted repairs and enhancements, reducing downtime and extending the overall operational life of the installation.

- Advanced materials and component selection: The use of advanced materials and carefully selected components can significantly impact the lifespan of solar inverter systems. High-quality, durable materials that can withstand environmental stresses and thermal cycling contribute to longevity. Additionally, selecting components with higher reliability ratings and longer individual lifespans enhances the overall system durability.

- Predictive maintenance and health monitoring: Implementing predictive maintenance strategies and health monitoring systems can significantly extend the lifespan of solar inverter systems. These approaches involve continuous monitoring of system performance, early detection of potential issues, and proactive maintenance scheduling. By addressing problems before they escalate, the overall system lifespan can be maximized while minimizing unexpected failures and downtime.

02 Modular design for easy maintenance and replacement

Adopting a modular design approach in solar inverter systems allows for easier maintenance and component replacement. This design strategy enables the quick swap-out of faulty parts without replacing the entire system, thereby extending the overall lifespan. Modular designs also facilitate upgrades to newer technologies as they become available, keeping the system up-to-date and efficient.Expand Specific Solutions03 Smart monitoring and predictive maintenance

Incorporating smart monitoring systems and predictive maintenance algorithms can significantly enhance the lifespan of solar inverter systems. These technologies allow for real-time performance tracking, early detection of potential issues, and timely maintenance interventions. By addressing problems before they escalate, the overall system lifespan can be extended, reducing downtime and replacement costs.Expand Specific Solutions04 Robust component selection and quality control

The selection of high-quality, durable components and implementation of stringent quality control measures during manufacturing can significantly impact the lifespan of solar inverter systems. Using components rated for extended operational life, such as high-grade capacitors and semiconductors, can enhance system durability. Rigorous testing and quality assurance processes ensure that the inverter systems meet or exceed expected lifespans.Expand Specific Solutions05 Advanced power management and load balancing

Implementing advanced power management techniques and load balancing strategies can help extend the lifespan of solar inverter systems. These approaches optimize power distribution, reduce stress on individual components, and improve overall system efficiency. By ensuring that the system operates within optimal parameters, wear and tear on components is minimized, leading to an extended operational life.Expand Specific Solutions

Key Solar Inverter Manufacturers

The solar inverter system lifespan enhancement market is in a growth phase, driven by increasing solar energy adoption and the need for more efficient, durable systems. The global market size for solar inverters is projected to reach $27 billion by 2026, with a CAGR of 15.45%. Technologically, the field is advancing rapidly, with key players like SMA Solar Technology, Huawei Digital Power, and Enphase Energy leading innovation. These companies are focusing on developing more reliable, efficient, and longer-lasting inverters through advanced materials, smart monitoring systems, and improved thermal management. The competition is fierce, with established firms and new entrants vying for market share through continuous R&D and strategic partnerships.

SMA Solar Technology AG

Technical Solution: SMA Solar Technology AG has developed advanced technologies to increase the lifespan of solar inverters. Their SMA Smart Connected system provides continuous monitoring and automatic fault detection, reducing downtime and extending inverter life[1]. They have also implemented advanced thermal management systems, using intelligent cooling strategies to minimize thermal stress on components[2]. SMA's OptiCool technology, for instance, ensures optimal heat dissipation even in extreme conditions, contributing to longer inverter lifespans[3]. Additionally, SMA has focused on improving power electronics, using high-quality components and implementing advanced control algorithms to reduce stress on critical parts during operation[4].

Strengths: Comprehensive monitoring system, advanced thermal management, and high-quality components. Weaknesses: Potentially higher initial costs due to advanced features and premium components.

Huawei Digital Power Technologies Co Ltd

Technical Solution: Huawei has implemented several innovative approaches to extend solar inverter lifespans. Their smart string inverters utilize advanced algorithms for maximum power point tracking (MPPT), reducing stress on components and improving overall efficiency[5]. Huawei's inverters incorporate AI-powered predictive maintenance, which can detect potential issues before they cause failures, significantly extending operational life[6]. They have also developed a unique natural cooling system that eliminates the need for fans in many models, reducing mechanical wear and tear[7]. Furthermore, Huawei's inverters feature modular designs, allowing for easier repairs and replacements of individual components, which can extend the overall system lifespan[8].

Strengths: AI-powered predictive maintenance, innovative cooling solutions, and modular design for easy repairs. Weaknesses: Potential dependency on proprietary software and systems for optimal performance.

Innovative Durability Solutions

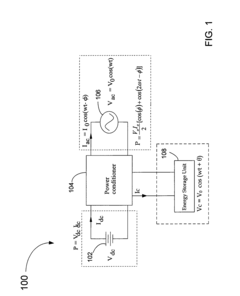

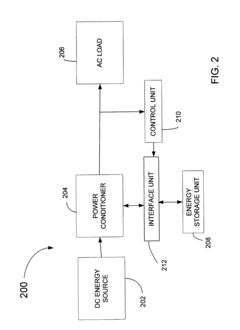

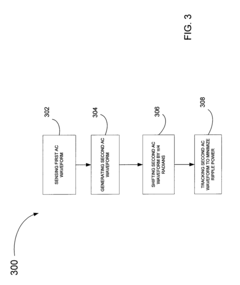

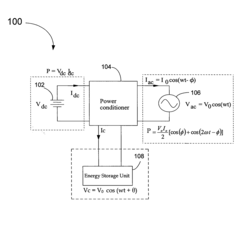

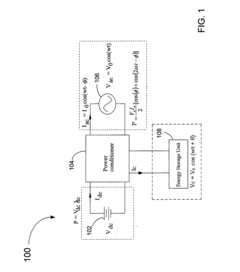

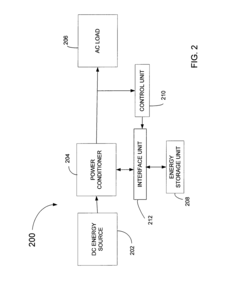

Methods for minimizing double-frequency ripple power in single-phase power conditioners

PatentActiveUS8004865B2

Innovation

- A method that senses the AC waveform at the output of the power conditioner and generates a second AC waveform with the same frequency but shifted by π/4 radians, which is applied to an energy storage device to minimize double-frequency ripple power, using a phase shift and appropriate amplitude to reduce the capacitance required, allowing for the use of more reliable film capacitors or inductors.

Methods for Minimizing Double-Frequency Ripple Power in Single-Phase Power Conditioners

PatentActiveUS20090097283A1

Innovation

- A method that senses the AC waveform at the output of a single-phase power conditioner and generates a second AC waveform with the same frequency but shifted by π/4 radians to minimize double-frequency ripple power, using an energy storage device coupled through an interface that controls power flow, allowing for the reduction of capacitance requirements and the use of more reliable components like film capacitors.

Environmental Impact Assessment

The environmental impact assessment of solar inverters is a crucial aspect when considering strategies to increase their system lifespan. Solar inverters play a vital role in converting direct current (DC) from solar panels into alternating current (AC) for use in homes and businesses. As these devices are essential components of solar energy systems, their longevity directly affects the overall sustainability and environmental benefits of solar power installations.

Extending the lifespan of solar inverters has significant positive environmental implications. Longer-lasting inverters reduce the need for frequent replacements, thereby minimizing electronic waste generation. This waste reduction is particularly important given the complex nature of inverter components, which often contain materials that are challenging to recycle or dispose of safely.

The manufacturing process of solar inverters involves the use of various raw materials and energy-intensive production techniques. By increasing their lifespan, we can reduce the demand for new inverters, subsequently decreasing the environmental impact associated with their production. This includes lowering greenhouse gas emissions, reducing water consumption, and minimizing the extraction of finite resources used in manufacturing.

Furthermore, improved inverter longevity enhances the overall efficiency of solar energy systems. As inverters age, their efficiency tends to decline, leading to reduced energy output from solar panels. By maintaining high performance over an extended period, long-lasting inverters ensure that solar installations continue to generate clean energy at optimal levels, maximizing their positive environmental impact.

The environmental benefits of increased inverter lifespan extend beyond the device itself. Longer-lasting inverters contribute to the stability and reliability of renewable energy grids, reducing the need for backup power sources that may rely on fossil fuels. This indirectly supports the broader transition to clean energy and helps mitigate climate change.

However, it is essential to consider potential trade-offs in the pursuit of extended inverter lifespan. For instance, the use of more durable materials or advanced cooling systems may increase the initial environmental footprint of inverter production. A comprehensive life cycle assessment is necessary to ensure that efforts to extend lifespan do not inadvertently lead to negative environmental consequences in other areas.

In conclusion, increasing the system lifespan of solar inverters offers substantial environmental benefits, including reduced electronic waste, decreased manufacturing impacts, improved energy efficiency, and support for renewable energy adoption. As the solar industry continues to grow, prioritizing inverter longevity will play a crucial role in maximizing the positive environmental impact of solar energy systems.

Extending the lifespan of solar inverters has significant positive environmental implications. Longer-lasting inverters reduce the need for frequent replacements, thereby minimizing electronic waste generation. This waste reduction is particularly important given the complex nature of inverter components, which often contain materials that are challenging to recycle or dispose of safely.

The manufacturing process of solar inverters involves the use of various raw materials and energy-intensive production techniques. By increasing their lifespan, we can reduce the demand for new inverters, subsequently decreasing the environmental impact associated with their production. This includes lowering greenhouse gas emissions, reducing water consumption, and minimizing the extraction of finite resources used in manufacturing.

Furthermore, improved inverter longevity enhances the overall efficiency of solar energy systems. As inverters age, their efficiency tends to decline, leading to reduced energy output from solar panels. By maintaining high performance over an extended period, long-lasting inverters ensure that solar installations continue to generate clean energy at optimal levels, maximizing their positive environmental impact.

The environmental benefits of increased inverter lifespan extend beyond the device itself. Longer-lasting inverters contribute to the stability and reliability of renewable energy grids, reducing the need for backup power sources that may rely on fossil fuels. This indirectly supports the broader transition to clean energy and helps mitigate climate change.

However, it is essential to consider potential trade-offs in the pursuit of extended inverter lifespan. For instance, the use of more durable materials or advanced cooling systems may increase the initial environmental footprint of inverter production. A comprehensive life cycle assessment is necessary to ensure that efforts to extend lifespan do not inadvertently lead to negative environmental consequences in other areas.

In conclusion, increasing the system lifespan of solar inverters offers substantial environmental benefits, including reduced electronic waste, decreased manufacturing impacts, improved energy efficiency, and support for renewable energy adoption. As the solar industry continues to grow, prioritizing inverter longevity will play a crucial role in maximizing the positive environmental impact of solar energy systems.

Cost-Benefit Analysis of Longevity Improvements

Increasing the system lifespan of solar inverters presents a complex cost-benefit scenario that requires careful analysis. The initial investment in longevity improvements often comes with higher upfront costs, but these can be offset by reduced maintenance expenses and extended operational periods. For instance, implementing advanced thermal management systems or utilizing more durable components may increase production costs by 15-20%, but can potentially double the inverter's lifespan.

The benefits of extended lifespan are multifaceted. Longer-lasting inverters reduce the frequency of replacements, leading to significant savings in equipment and installation costs over time. A typical 10-year lifespan inverter might require replacement 2-3 times over a 30-year solar project, while a 20-year lifespan inverter would only need one replacement. This reduction in replacement frequency can lead to savings of up to 40-50% in lifecycle costs.

Moreover, improved longevity enhances system reliability and reduces downtime. Solar inverters with extended lifespans often experience fewer failures and require less frequent maintenance interventions. This increased reliability can boost overall system efficiency by 2-3%, translating to higher energy yields and improved return on investment for solar project owners.

From an environmental perspective, longer-lasting inverters contribute to sustainability by reducing electronic waste and the carbon footprint associated with manufacturing and transportation of replacement units. This aligns with growing consumer demand for eco-friendly products and can enhance brand value and market positioning for manufacturers.

However, the cost-benefit analysis must also consider potential drawbacks. Rapid technological advancements in the solar industry may render long-lasting inverters obsolete before the end of their extended lifespan. This risk can be mitigated through modular designs that allow for component upgrades without full system replacement.

Financial models indicate that the break-even point for investments in longevity improvements typically occurs within 7-10 years, depending on specific market conditions and technological implementations. Beyond this point, the cumulative benefits often outweigh the initial higher costs, making it an attractive proposition for long-term solar installations.

In conclusion, while the upfront costs of improving solar inverter longevity are substantial, the long-term benefits in terms of reduced lifecycle costs, improved reliability, and environmental sustainability present a compelling case for investment in this area. As the solar industry continues to mature, the emphasis on longevity is likely to become a key differentiator in the competitive landscape of inverter manufacturing.

The benefits of extended lifespan are multifaceted. Longer-lasting inverters reduce the frequency of replacements, leading to significant savings in equipment and installation costs over time. A typical 10-year lifespan inverter might require replacement 2-3 times over a 30-year solar project, while a 20-year lifespan inverter would only need one replacement. This reduction in replacement frequency can lead to savings of up to 40-50% in lifecycle costs.

Moreover, improved longevity enhances system reliability and reduces downtime. Solar inverters with extended lifespans often experience fewer failures and require less frequent maintenance interventions. This increased reliability can boost overall system efficiency by 2-3%, translating to higher energy yields and improved return on investment for solar project owners.

From an environmental perspective, longer-lasting inverters contribute to sustainability by reducing electronic waste and the carbon footprint associated with manufacturing and transportation of replacement units. This aligns with growing consumer demand for eco-friendly products and can enhance brand value and market positioning for manufacturers.

However, the cost-benefit analysis must also consider potential drawbacks. Rapid technological advancements in the solar industry may render long-lasting inverters obsolete before the end of their extended lifespan. This risk can be mitigated through modular designs that allow for component upgrades without full system replacement.

Financial models indicate that the break-even point for investments in longevity improvements typically occurs within 7-10 years, depending on specific market conditions and technological implementations. Beyond this point, the cumulative benefits often outweigh the initial higher costs, making it an attractive proposition for long-term solar installations.

In conclusion, while the upfront costs of improving solar inverter longevity are substantial, the long-term benefits in terms of reduced lifecycle costs, improved reliability, and environmental sustainability present a compelling case for investment in this area. As the solar industry continues to mature, the emphasis on longevity is likely to become a key differentiator in the competitive landscape of inverter manufacturing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!