Energy autonomy enhancements with next-gen KERS

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

KERS Evolution & Goals

Kinetic Energy Recovery Systems (KERS) have undergone significant evolution since their inception in the automotive industry, particularly in motorsports. Initially developed to harness and reuse energy that would otherwise be lost during braking, KERS has become a cornerstone of energy efficiency in high-performance vehicles.

The early iterations of KERS focused primarily on mechanical systems, utilizing flywheels to store and release energy. These systems, while innovative, were limited in their capacity and efficiency. As technology progressed, electrical KERS emerged, employing motor-generator units and batteries to capture and deploy energy more effectively.

The goals of KERS have expanded beyond mere energy recovery. Modern systems aim to enhance overall vehicle performance, improve fuel efficiency, and reduce emissions. In motorsports, KERS has become a crucial element in strategy, allowing drivers to deploy additional power for overtaking or defending positions.

Next-generation KERS seeks to push the boundaries of energy autonomy even further. The primary objective is to maximize the amount of energy that can be recovered and stored, while minimizing system weight and complexity. This involves developing more efficient energy conversion methods, improving energy storage technologies, and optimizing power management systems.

One key goal is to increase the power density of KERS, allowing for greater energy storage and deployment capabilities without significantly impacting vehicle weight or design. This is particularly crucial in motorsports, where every gram matters, but also has implications for road-going vehicles in terms of improved fuel economy and performance.

Another important aim is to enhance the integration of KERS with other vehicle systems. This includes seamless coordination with traditional powertrains, as well as emerging technologies such as regenerative braking systems and advanced traction control. The ultimate goal is to create a holistic energy management ecosystem within the vehicle.

Durability and reliability remain critical objectives for next-gen KERS. As these systems become more complex and integral to vehicle performance, ensuring their longevity and consistent operation under extreme conditions becomes paramount. This is especially true in motorsports, where system failures can have significant competitive and safety implications.

Looking ahead, the evolution of KERS is closely tied to the broader trends in vehicle electrification and autonomy. Future systems may incorporate artificial intelligence to predict and optimize energy recovery and deployment based on driving conditions, route information, and even driver behavior. The long-term vision is for KERS to play a central role in achieving near-total energy autonomy in vehicles, significantly reducing reliance on external energy sources and pushing the boundaries of sustainable transportation.

The early iterations of KERS focused primarily on mechanical systems, utilizing flywheels to store and release energy. These systems, while innovative, were limited in their capacity and efficiency. As technology progressed, electrical KERS emerged, employing motor-generator units and batteries to capture and deploy energy more effectively.

The goals of KERS have expanded beyond mere energy recovery. Modern systems aim to enhance overall vehicle performance, improve fuel efficiency, and reduce emissions. In motorsports, KERS has become a crucial element in strategy, allowing drivers to deploy additional power for overtaking or defending positions.

Next-generation KERS seeks to push the boundaries of energy autonomy even further. The primary objective is to maximize the amount of energy that can be recovered and stored, while minimizing system weight and complexity. This involves developing more efficient energy conversion methods, improving energy storage technologies, and optimizing power management systems.

One key goal is to increase the power density of KERS, allowing for greater energy storage and deployment capabilities without significantly impacting vehicle weight or design. This is particularly crucial in motorsports, where every gram matters, but also has implications for road-going vehicles in terms of improved fuel economy and performance.

Another important aim is to enhance the integration of KERS with other vehicle systems. This includes seamless coordination with traditional powertrains, as well as emerging technologies such as regenerative braking systems and advanced traction control. The ultimate goal is to create a holistic energy management ecosystem within the vehicle.

Durability and reliability remain critical objectives for next-gen KERS. As these systems become more complex and integral to vehicle performance, ensuring their longevity and consistent operation under extreme conditions becomes paramount. This is especially true in motorsports, where system failures can have significant competitive and safety implications.

Looking ahead, the evolution of KERS is closely tied to the broader trends in vehicle electrification and autonomy. Future systems may incorporate artificial intelligence to predict and optimize energy recovery and deployment based on driving conditions, route information, and even driver behavior. The long-term vision is for KERS to play a central role in achieving near-total energy autonomy in vehicles, significantly reducing reliance on external energy sources and pushing the boundaries of sustainable transportation.

Market Demand Analysis

The market demand for next-generation Kinetic Energy Recovery Systems (KERS) is experiencing significant growth, driven by the increasing focus on energy efficiency and sustainability across various industries. The automotive sector, in particular, shows a strong appetite for advanced KERS technologies as manufacturers strive to meet stringent emissions regulations and improve fuel economy.

In the passenger vehicle market, the demand for KERS is primarily fueled by the growing popularity of hybrid and electric vehicles. Consumers are increasingly seeking vehicles with improved fuel efficiency and reduced environmental impact, creating a favorable market environment for KERS-equipped vehicles. This trend is particularly pronounced in urban areas where stop-and-start driving conditions are common, allowing KERS to maximize its energy recovery potential.

The commercial vehicle sector also presents a substantial market opportunity for next-gen KERS. Fleet operators are under pressure to reduce operating costs and minimize their carbon footprint, making KERS an attractive solution for improving fuel efficiency in trucks, buses, and delivery vehicles. The potential for significant fuel savings in heavy-duty vehicles with frequent braking cycles has led to increased interest from logistics companies and public transportation authorities.

In the motorsports industry, KERS has already established itself as a crucial technology for enhancing performance and efficiency. The demand for more advanced KERS solutions continues to grow as racing teams seek to gain competitive advantages while complying with energy usage regulations. This sector serves as a proving ground for cutting-edge KERS technologies, which often trickle down to consumer vehicles.

The industrial and manufacturing sectors are emerging as new markets for KERS applications. Energy-intensive industries are exploring ways to capture and reuse kinetic energy from machinery and processes to reduce overall energy consumption and operating costs. This trend is expected to drive demand for specialized KERS solutions tailored to industrial applications.

The global market for KERS is projected to expand significantly in the coming years, with Asia-Pacific region showing the highest growth potential. This is attributed to the rapid industrialization, increasing vehicle production, and stringent government regulations promoting energy-efficient technologies in countries like China and India.

However, the market demand for next-gen KERS is not without challenges. The high initial cost of advanced KERS technologies remains a barrier to widespread adoption, particularly in price-sensitive markets. Additionally, the complexity of integrating KERS into existing vehicle architectures and industrial systems poses technical challenges that need to be addressed to fully realize market potential.

Despite these challenges, the overall market outlook for next-gen KERS remains positive. As technology advances and production scales up, costs are expected to decrease, making KERS more accessible across various applications. The growing emphasis on sustainability and energy efficiency across industries is likely to sustain long-term demand for innovative KERS solutions, driving further research and development in this field.

In the passenger vehicle market, the demand for KERS is primarily fueled by the growing popularity of hybrid and electric vehicles. Consumers are increasingly seeking vehicles with improved fuel efficiency and reduced environmental impact, creating a favorable market environment for KERS-equipped vehicles. This trend is particularly pronounced in urban areas where stop-and-start driving conditions are common, allowing KERS to maximize its energy recovery potential.

The commercial vehicle sector also presents a substantial market opportunity for next-gen KERS. Fleet operators are under pressure to reduce operating costs and minimize their carbon footprint, making KERS an attractive solution for improving fuel efficiency in trucks, buses, and delivery vehicles. The potential for significant fuel savings in heavy-duty vehicles with frequent braking cycles has led to increased interest from logistics companies and public transportation authorities.

In the motorsports industry, KERS has already established itself as a crucial technology for enhancing performance and efficiency. The demand for more advanced KERS solutions continues to grow as racing teams seek to gain competitive advantages while complying with energy usage regulations. This sector serves as a proving ground for cutting-edge KERS technologies, which often trickle down to consumer vehicles.

The industrial and manufacturing sectors are emerging as new markets for KERS applications. Energy-intensive industries are exploring ways to capture and reuse kinetic energy from machinery and processes to reduce overall energy consumption and operating costs. This trend is expected to drive demand for specialized KERS solutions tailored to industrial applications.

The global market for KERS is projected to expand significantly in the coming years, with Asia-Pacific region showing the highest growth potential. This is attributed to the rapid industrialization, increasing vehicle production, and stringent government regulations promoting energy-efficient technologies in countries like China and India.

However, the market demand for next-gen KERS is not without challenges. The high initial cost of advanced KERS technologies remains a barrier to widespread adoption, particularly in price-sensitive markets. Additionally, the complexity of integrating KERS into existing vehicle architectures and industrial systems poses technical challenges that need to be addressed to fully realize market potential.

Despite these challenges, the overall market outlook for next-gen KERS remains positive. As technology advances and production scales up, costs are expected to decrease, making KERS more accessible across various applications. The growing emphasis on sustainability and energy efficiency across industries is likely to sustain long-term demand for innovative KERS solutions, driving further research and development in this field.

KERS Tech Challenges

Kinetic Energy Recovery Systems (KERS) have made significant strides in enhancing energy efficiency in various applications, particularly in automotive and motorsport industries. However, as we push towards greater energy autonomy, several technical challenges persist in the development of next-generation KERS.

One of the primary challenges is the optimization of energy storage capacity. Current KERS technologies often struggle to store large amounts of energy efficiently, limiting their overall effectiveness. This challenge is compounded by the need for compact and lightweight storage solutions, especially in applications where space and weight are at a premium, such as in racing vehicles or urban electric cars.

Another significant hurdle is the improvement of energy conversion efficiency. While KERS has shown promise in capturing and reusing kinetic energy, there are still considerable losses during the conversion process. Minimizing these losses and maximizing the amount of usable energy recovered remains a key area of focus for researchers and engineers.

The integration of KERS with other vehicle systems presents another set of challenges. Seamless coordination between KERS and traditional powertrains, as well as other advanced systems like regenerative braking, requires sophisticated control algorithms and hardware interfaces. Achieving this integration without compromising vehicle performance or driver experience is a complex task that demands innovative solutions.

Durability and reliability of KERS components under high-stress conditions continue to be areas of concern. The frequent charge-discharge cycles and exposure to varying environmental conditions can lead to degradation of system components, potentially affecting long-term performance and safety.

Cost-effectiveness remains a significant barrier to widespread adoption of advanced KERS technologies. The complex nature of these systems, coupled with the use of specialized materials and components, often results in high production costs. Reducing these costs while maintaining or improving performance is crucial for broader implementation across various vehicle segments.

Thermal management is another critical challenge, particularly in high-performance applications. The rapid energy transfers involved in KERS operation can generate substantial heat, which needs to be efficiently dissipated to prevent system degradation and ensure optimal performance.

Lastly, the development of more advanced control strategies and predictive algorithms presents an ongoing challenge. These are essential for optimizing energy recovery and deployment based on various driving conditions and user behaviors, ultimately maximizing the energy autonomy benefits of next-generation KERS.

One of the primary challenges is the optimization of energy storage capacity. Current KERS technologies often struggle to store large amounts of energy efficiently, limiting their overall effectiveness. This challenge is compounded by the need for compact and lightweight storage solutions, especially in applications where space and weight are at a premium, such as in racing vehicles or urban electric cars.

Another significant hurdle is the improvement of energy conversion efficiency. While KERS has shown promise in capturing and reusing kinetic energy, there are still considerable losses during the conversion process. Minimizing these losses and maximizing the amount of usable energy recovered remains a key area of focus for researchers and engineers.

The integration of KERS with other vehicle systems presents another set of challenges. Seamless coordination between KERS and traditional powertrains, as well as other advanced systems like regenerative braking, requires sophisticated control algorithms and hardware interfaces. Achieving this integration without compromising vehicle performance or driver experience is a complex task that demands innovative solutions.

Durability and reliability of KERS components under high-stress conditions continue to be areas of concern. The frequent charge-discharge cycles and exposure to varying environmental conditions can lead to degradation of system components, potentially affecting long-term performance and safety.

Cost-effectiveness remains a significant barrier to widespread adoption of advanced KERS technologies. The complex nature of these systems, coupled with the use of specialized materials and components, often results in high production costs. Reducing these costs while maintaining or improving performance is crucial for broader implementation across various vehicle segments.

Thermal management is another critical challenge, particularly in high-performance applications. The rapid energy transfers involved in KERS operation can generate substantial heat, which needs to be efficiently dissipated to prevent system degradation and ensure optimal performance.

Lastly, the development of more advanced control strategies and predictive algorithms presents an ongoing challenge. These are essential for optimizing energy recovery and deployment based on various driving conditions and user behaviors, ultimately maximizing the energy autonomy benefits of next-generation KERS.

Current KERS Solutions

01 Energy recovery and storage in vehicles

KERS technology is used in vehicles to recover kinetic energy during braking and store it for later use. This system enhances energy efficiency by converting the vehicle's kinetic energy into electrical or mechanical energy, which can be used to provide additional power during acceleration or to reduce fuel consumption.- Energy recovery and storage systems in vehicles: KERS technology is implemented in vehicles to recover and store kinetic energy during braking, which can then be used to provide additional power during acceleration. This system enhances energy efficiency and reduces fuel consumption in various types of vehicles, including cars, trucks, and racing vehicles.

- Integration of KERS with hybrid powertrains: KERS is integrated with hybrid powertrains to maximize energy recovery and utilization. This combination allows for improved energy management, increased power output, and enhanced fuel efficiency in hybrid vehicles. The system can work in conjunction with electric motors and internal combustion engines to optimize overall vehicle performance.

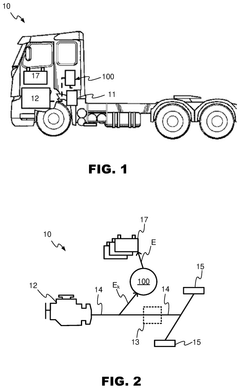

- KERS applications in heavy-duty vehicles: KERS technology is adapted for use in heavy-duty vehicles such as trucks, buses, and construction equipment. These systems are designed to recover and store larger amounts of energy, providing significant fuel savings and emissions reductions in vehicles that frequently start and stop or operate in urban environments.

- Advanced control strategies for KERS: Sophisticated control strategies are developed to optimize the operation of KERS. These include predictive algorithms, adaptive control systems, and integration with vehicle dynamics management. Advanced control strategies ensure efficient energy recovery, storage, and deployment, maximizing the benefits of KERS across various driving conditions.

- Novel energy storage technologies for KERS: Innovative energy storage technologies are explored to enhance the performance and efficiency of KERS. These include advanced battery systems, high-power capacitors, and mechanical energy storage solutions such as flywheels. Novel storage technologies aim to improve energy density, power density, and cycle life, contributing to increased energy autonomy in KERS-equipped vehicles.

02 Hybrid powertrains with KERS integration

Integration of KERS into hybrid powertrains allows for improved energy management and increased overall efficiency. These systems combine traditional internal combustion engines with electric motors and energy recovery systems to optimize power distribution and reduce emissions.Expand Specific Solutions03 KERS applications in renewable energy systems

KERS technology is being adapted for use in renewable energy systems, such as wind turbines and solar panels. By incorporating energy recovery and storage mechanisms, these systems can improve their overall efficiency and provide more consistent power output despite fluctuations in environmental conditions.Expand Specific Solutions04 Advanced control systems for KERS optimization

Development of sophisticated control systems and algorithms to optimize KERS performance. These systems manage energy flow, predict energy demands, and coordinate between various vehicle subsystems to maximize energy recovery and utilization, thereby enhancing overall energy autonomy.Expand Specific Solutions05 Novel energy storage technologies for KERS

Exploration of new energy storage technologies to improve KERS efficiency and capacity. This includes advancements in high-power density batteries, supercapacitors, and mechanical storage systems like flywheels, which can rapidly absorb and release energy to support KERS operations.Expand Specific Solutions

Key KERS Players

The energy autonomy enhancement market utilizing next-generation Kinetic Energy Recovery Systems (KERS) is in a growth phase, with increasing adoption across automotive and industrial sectors. The market size is expanding rapidly, driven by the global push for energy efficiency and sustainability. Technologically, KERS is maturing, with companies like Volvo Lastvagnar AB, Marelli Europe SpA, and Punch Flybrid Ltd leading innovation. Academic institutions such as Zhejiang University and Taiyuan University of Technology are contributing to research advancements. The competitive landscape is diverse, including established automotive players, specialized KERS developers, and new entrants from adjacent industries, indicating a dynamic and evolving market with significant potential for further technological breakthroughs and market expansion.

Volvo Lastvagnar AB

Technical Solution: Volvo Trucks has developed a KERS solution specifically tailored for heavy-duty trucks. Their system, known as I-See, combines kinetic energy recovery with predictive cruise control. It uses GPS and cloud-based map data to anticipate road topography, optimizing gear changes and speed to maximize energy recovery on downhill sections. The recovered energy is then used to power the truck on uphill climbs or during acceleration. Volvo claims fuel savings of up to 5% on undulating routes[5]. Additionally, Volvo has been experimenting with a mechanical KERS that uses a carbon fiber flywheel, capable of reducing fuel consumption by up to 25% for vehicles that frequently start and stop[6].

Strengths: Integration with existing truck systems, minimal additional components required, and continuous improvement through cloud-based data. Weaknesses: Effectiveness heavily dependent on route topography and driving conditions.

Perkins Engines Co. Ltd.

Technical Solution: Perkins Engines has focused on integrating KERS technology into their diesel engine systems for off-highway applications. Their approach combines electric hybrid technology with advanced engine control systems. The KERS captures braking energy and stores it in high-capacity ultracapacitors, which can rapidly discharge to assist the engine during high-load conditions. This system is particularly effective in applications with frequent load changes, such as material handling equipment and construction machinery. Perkins reports fuel savings of up to 15% in typical operating cycles, with additional benefits in reduced engine wear and emissions[7]. The company has also developed a modular KERS design that can be scaled and adapted to various engine sizes and application requirements[8].

Strengths: Seamless integration with existing diesel engine technology, scalability across different applications, and significant fuel savings. Weaknesses: Additional complexity in engine systems and potential high costs for ultracapacitor technology.

KERS Core Innovations

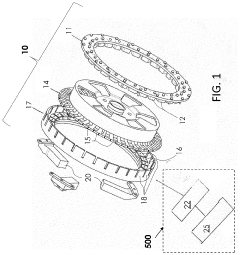

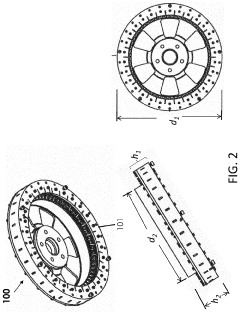

Powering and recharging long range electric vehicles

PatentInactiveUS20230336054A1

Innovation

- The Grayson Kinetic Recharger (GKR) system employs Advanced Kinetic Energy Recovery Systems (AKERS) with modular, scalable designs, including Center Hub, Rear Hub, and Hubless Tire kinetic rechargers, generating electricity from kinetic energy to extend range and reduce recharging needs, using redundant systems for safety and efficiency.

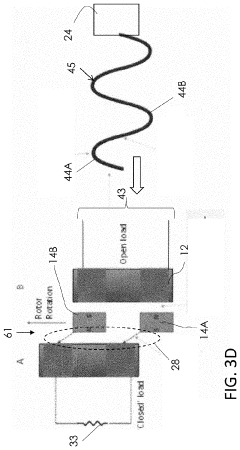

Kinetic energy recovery system

PatentPendingUS20240326574A1

Innovation

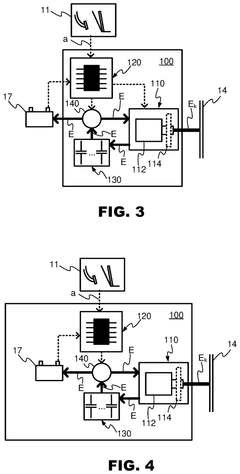

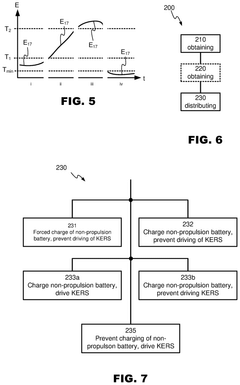

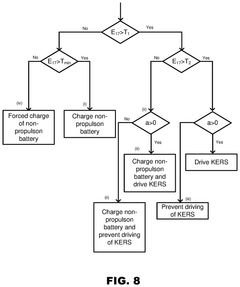

- A Kinetic Energy Recovery System (KERS) connected to the propulsion shaft, utilizing an internal energy storage device and processing circuitry to distribute energy to both propulsion and non-propulsion batteries based on energy levels, reducing the need for generators and enhancing energy efficiency.

Energy Efficiency Regs

Energy efficiency regulations play a crucial role in shaping the development and implementation of next-generation Kinetic Energy Recovery Systems (KERS) for enhancing energy autonomy. These regulations are designed to promote the efficient use of energy resources and reduce environmental impact across various sectors, including transportation and industrial applications.

In the context of KERS, energy efficiency regulations typically focus on improving the overall energy performance of vehicles and machinery. They set standards for energy recovery, storage, and utilization, pushing manufacturers to innovate and develop more advanced KERS technologies. These regulations often establish minimum efficiency requirements for energy recovery systems, ensuring that a significant portion of kinetic energy is captured and reused effectively.

Many countries and regions have implemented specific energy efficiency regulations that directly impact KERS development. For instance, the European Union's CO2 emission standards for new passenger cars and light commercial vehicles have indirectly encouraged the adoption of more efficient KERS technologies. Similarly, regulations in the United States, such as the Corporate Average Fuel Economy (CAFE) standards, have driven automotive manufacturers to explore advanced energy recovery solutions.

The regulatory landscape also extends to industrial applications, where energy efficiency standards for machinery and equipment are becoming increasingly stringent. These regulations often require the integration of energy recovery systems in high-energy-consuming processes, creating opportunities for next-generation KERS technologies to be applied beyond the automotive sector.

As energy efficiency regulations continue to evolve, they are likely to become more comprehensive and demanding. Future regulations may set higher benchmarks for energy recovery rates, expand the scope of applications where KERS is required, and potentially introduce specific standards for KERS performance and reliability. This regulatory pressure is expected to drive further innovation in KERS technology, leading to more efficient and versatile systems.

The impact of these regulations extends beyond technical requirements. They also influence market dynamics by creating incentives for early adopters of advanced KERS technologies. Tax benefits, subsidies, and other financial incentives tied to energy efficiency performance can accelerate the development and deployment of next-generation KERS solutions.

Furthermore, energy efficiency regulations often mandate reporting and monitoring of energy consumption and recovery rates. This requirement has led to the development of sophisticated energy management systems that can integrate with KERS to optimize overall energy efficiency. As a result, next-generation KERS are increasingly being designed with advanced monitoring and control capabilities to ensure compliance with regulatory standards and maximize energy autonomy.

In the context of KERS, energy efficiency regulations typically focus on improving the overall energy performance of vehicles and machinery. They set standards for energy recovery, storage, and utilization, pushing manufacturers to innovate and develop more advanced KERS technologies. These regulations often establish minimum efficiency requirements for energy recovery systems, ensuring that a significant portion of kinetic energy is captured and reused effectively.

Many countries and regions have implemented specific energy efficiency regulations that directly impact KERS development. For instance, the European Union's CO2 emission standards for new passenger cars and light commercial vehicles have indirectly encouraged the adoption of more efficient KERS technologies. Similarly, regulations in the United States, such as the Corporate Average Fuel Economy (CAFE) standards, have driven automotive manufacturers to explore advanced energy recovery solutions.

The regulatory landscape also extends to industrial applications, where energy efficiency standards for machinery and equipment are becoming increasingly stringent. These regulations often require the integration of energy recovery systems in high-energy-consuming processes, creating opportunities for next-generation KERS technologies to be applied beyond the automotive sector.

As energy efficiency regulations continue to evolve, they are likely to become more comprehensive and demanding. Future regulations may set higher benchmarks for energy recovery rates, expand the scope of applications where KERS is required, and potentially introduce specific standards for KERS performance and reliability. This regulatory pressure is expected to drive further innovation in KERS technology, leading to more efficient and versatile systems.

The impact of these regulations extends beyond technical requirements. They also influence market dynamics by creating incentives for early adopters of advanced KERS technologies. Tax benefits, subsidies, and other financial incentives tied to energy efficiency performance can accelerate the development and deployment of next-generation KERS solutions.

Furthermore, energy efficiency regulations often mandate reporting and monitoring of energy consumption and recovery rates. This requirement has led to the development of sophisticated energy management systems that can integrate with KERS to optimize overall energy efficiency. As a result, next-generation KERS are increasingly being designed with advanced monitoring and control capabilities to ensure compliance with regulatory standards and maximize energy autonomy.

KERS Integration Issues

The integration of Kinetic Energy Recovery Systems (KERS) into next-generation vehicles presents several challenges that need to be addressed for optimal performance and energy autonomy enhancement. One of the primary issues is the seamless integration of KERS with existing powertrain components. The system must be designed to work in harmony with the engine, transmission, and other drivetrain elements without causing interference or reducing overall efficiency.

Weight distribution is another critical factor in KERS integration. The addition of KERS components, such as the flywheel or electric motor-generator, can significantly impact the vehicle's center of gravity and weight balance. Engineers must carefully consider the placement of these components to maintain proper handling characteristics and vehicle dynamics.

Thermal management poses a significant challenge in KERS integration. The energy recovery and storage processes generate heat, which must be effectively dissipated to prevent system overheating and maintain optimal performance. This requires the development of advanced cooling systems that can handle the additional thermal load without compromising the vehicle's overall efficiency.

Space constraints within the vehicle present another hurdle for KERS integration. Modern vehicles are already packed with numerous systems and components, leaving limited room for additional hardware. Designers must find innovative ways to incorporate KERS components without sacrificing interior space or compromising other vehicle functions.

The control strategy for KERS integration is crucial for maximizing energy recovery and utilization. Developing sophisticated algorithms that can seamlessly manage the flow of energy between the KERS, engine, and other powertrain components is essential for achieving optimal efficiency and performance. This includes determining when to recover energy, when to deploy it, and how to balance power distribution among various systems.

Durability and reliability are key concerns in KERS integration. The system must be designed to withstand the rigors of daily use, including frequent charging and discharging cycles, vibrations, and varying environmental conditions. Ensuring long-term reliability is crucial for consumer acceptance and widespread adoption of KERS technology.

Cost considerations also play a significant role in KERS integration. While the technology offers potential fuel savings and performance benefits, the additional components and complexity can increase the overall vehicle cost. Manufacturers must strike a balance between the added value of KERS and its impact on the final price point to ensure market competitiveness.

Weight distribution is another critical factor in KERS integration. The addition of KERS components, such as the flywheel or electric motor-generator, can significantly impact the vehicle's center of gravity and weight balance. Engineers must carefully consider the placement of these components to maintain proper handling characteristics and vehicle dynamics.

Thermal management poses a significant challenge in KERS integration. The energy recovery and storage processes generate heat, which must be effectively dissipated to prevent system overheating and maintain optimal performance. This requires the development of advanced cooling systems that can handle the additional thermal load without compromising the vehicle's overall efficiency.

Space constraints within the vehicle present another hurdle for KERS integration. Modern vehicles are already packed with numerous systems and components, leaving limited room for additional hardware. Designers must find innovative ways to incorporate KERS components without sacrificing interior space or compromising other vehicle functions.

The control strategy for KERS integration is crucial for maximizing energy recovery and utilization. Developing sophisticated algorithms that can seamlessly manage the flow of energy between the KERS, engine, and other powertrain components is essential for achieving optimal efficiency and performance. This includes determining when to recover energy, when to deploy it, and how to balance power distribution among various systems.

Durability and reliability are key concerns in KERS integration. The system must be designed to withstand the rigors of daily use, including frequent charging and discharging cycles, vibrations, and varying environmental conditions. Ensuring long-term reliability is crucial for consumer acceptance and widespread adoption of KERS technology.

Cost considerations also play a significant role in KERS integration. While the technology offers potential fuel savings and performance benefits, the additional components and complexity can increase the overall vehicle cost. Manufacturers must strike a balance between the added value of KERS and its impact on the final price point to ensure market competitiveness.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!