Environmental Risks Associated with Isopentane Emissions

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isopentane Emissions: Background and Objectives

Isopentane, a volatile organic compound (VOC) and hydrocarbon, has gained significant attention in recent years due to its widespread use in various industries and the associated environmental risks of its emissions. This technical report aims to provide a comprehensive overview of the background and objectives related to isopentane emissions, setting the stage for a deeper exploration of their environmental impact and potential mitigation strategies.

Isopentane, also known as 2-methylbutane, is a branched-chain alkane with the molecular formula C5H12. It is a colorless, highly flammable liquid at room temperature, with a low boiling point of approximately 28°C (82°F). This property makes it particularly prone to evaporation and, consequently, atmospheric emissions. Isopentane occurs naturally in small quantities in petroleum and natural gas but is primarily produced through the distillation and isomerization of light hydrocarbons.

The industrial applications of isopentane have expanded significantly over the past few decades. It is commonly used as a blowing agent in the production of polystyrene foam, a refrigerant in air conditioning systems, and a component in the manufacturing of aerosols and adhesives. Additionally, isopentane plays a crucial role in the petrochemical industry as a feedstock for various chemical processes and as an octane-enhancing additive in gasoline formulations.

As the global demand for isopentane continues to rise, driven by industrial growth and technological advancements, so does the concern over its environmental impact. Isopentane emissions primarily occur during production, storage, transportation, and end-use applications. These emissions contribute to the formation of ground-level ozone, a key component of photochemical smog, which can have detrimental effects on human health and ecosystems.

The primary objective of this technical research is to assess the environmental risks associated with isopentane emissions comprehensively. This includes identifying the major sources of emissions, quantifying their impact on air quality and climate change, and evaluating the potential health effects on human populations and wildlife. Furthermore, the research aims to explore the regulatory landscape surrounding isopentane emissions, examining existing policies and guidelines at both national and international levels.

Another critical objective is to investigate the current state of emission control technologies and practices. This involves analyzing the effectiveness of various containment, recovery, and treatment methods employed across different industries to minimize isopentane releases into the atmosphere. The research will also seek to identify emerging technologies and innovative approaches that show promise in reducing emissions more efficiently and cost-effectively.

Lastly, this technical exploration aims to provide a forward-looking perspective on the future of isopentane use and emission management. This includes assessing potential alternatives to isopentane in various applications, evaluating their feasibility and environmental impact, and projecting future trends in isopentane consumption and emission patterns based on technological advancements and evolving regulatory frameworks.

Isopentane, also known as 2-methylbutane, is a branched-chain alkane with the molecular formula C5H12. It is a colorless, highly flammable liquid at room temperature, with a low boiling point of approximately 28°C (82°F). This property makes it particularly prone to evaporation and, consequently, atmospheric emissions. Isopentane occurs naturally in small quantities in petroleum and natural gas but is primarily produced through the distillation and isomerization of light hydrocarbons.

The industrial applications of isopentane have expanded significantly over the past few decades. It is commonly used as a blowing agent in the production of polystyrene foam, a refrigerant in air conditioning systems, and a component in the manufacturing of aerosols and adhesives. Additionally, isopentane plays a crucial role in the petrochemical industry as a feedstock for various chemical processes and as an octane-enhancing additive in gasoline formulations.

As the global demand for isopentane continues to rise, driven by industrial growth and technological advancements, so does the concern over its environmental impact. Isopentane emissions primarily occur during production, storage, transportation, and end-use applications. These emissions contribute to the formation of ground-level ozone, a key component of photochemical smog, which can have detrimental effects on human health and ecosystems.

The primary objective of this technical research is to assess the environmental risks associated with isopentane emissions comprehensively. This includes identifying the major sources of emissions, quantifying their impact on air quality and climate change, and evaluating the potential health effects on human populations and wildlife. Furthermore, the research aims to explore the regulatory landscape surrounding isopentane emissions, examining existing policies and guidelines at both national and international levels.

Another critical objective is to investigate the current state of emission control technologies and practices. This involves analyzing the effectiveness of various containment, recovery, and treatment methods employed across different industries to minimize isopentane releases into the atmosphere. The research will also seek to identify emerging technologies and innovative approaches that show promise in reducing emissions more efficiently and cost-effectively.

Lastly, this technical exploration aims to provide a forward-looking perspective on the future of isopentane use and emission management. This includes assessing potential alternatives to isopentane in various applications, evaluating their feasibility and environmental impact, and projecting future trends in isopentane consumption and emission patterns based on technological advancements and evolving regulatory frameworks.

Market Analysis of Isopentane-Using Industries

The isopentane market is experiencing significant growth driven by its widespread applications across various industries. The refrigeration and air conditioning sector represents a major consumer of isopentane, utilizing it as a replacement for ozone-depleting substances in cooling systems. This shift is propelled by environmental regulations and the push for more sustainable refrigerants. The automotive industry also contributes substantially to isopentane demand, incorporating it in the production of foam insulation for vehicle interiors and as a blowing agent in the manufacturing of lightweight components.

In the petrochemical industry, isopentane serves as a crucial feedstock for the production of various chemicals and solvents. Its use in the synthesis of high-octane gasoline components has seen an uptick due to stringent fuel efficiency standards and the growing demand for premium fuels. The electronics sector utilizes isopentane in the production of circuit boards and as a cleaning agent for sensitive electronic components, further diversifying its market reach.

The personal care and cosmetics industry has embraced isopentane as a propellant in aerosol products, replacing chlorofluorocarbons (CFCs) and other environmentally harmful propellants. This transition aligns with the industry's move towards more eco-friendly formulations while maintaining product performance.

Geographically, Asia-Pacific leads the isopentane market, with China and India being major consumers due to their rapidly expanding industrial sectors and increasing urbanization. North America and Europe follow, driven by stringent environmental regulations and the adoption of energy-efficient technologies. The Middle East is emerging as a significant player, leveraging its petrochemical infrastructure to increase isopentane production capacity.

Market analysts project a compound annual growth rate (CAGR) for the global isopentane market in the mid-single digits over the next five years. This growth is attributed to the increasing adoption of energy-efficient appliances, the expansion of the automotive sector in developing economies, and the ongoing substitution of environmentally harmful substances across industries.

However, the market faces challenges related to the environmental risks associated with isopentane emissions. As awareness of these risks grows, industries are under pressure to develop and implement more effective containment and emission reduction strategies. This dynamic is likely to shape future market trends, potentially driving innovation in emission control technologies and the development of alternative substances with lower environmental impact.

In the petrochemical industry, isopentane serves as a crucial feedstock for the production of various chemicals and solvents. Its use in the synthesis of high-octane gasoline components has seen an uptick due to stringent fuel efficiency standards and the growing demand for premium fuels. The electronics sector utilizes isopentane in the production of circuit boards and as a cleaning agent for sensitive electronic components, further diversifying its market reach.

The personal care and cosmetics industry has embraced isopentane as a propellant in aerosol products, replacing chlorofluorocarbons (CFCs) and other environmentally harmful propellants. This transition aligns with the industry's move towards more eco-friendly formulations while maintaining product performance.

Geographically, Asia-Pacific leads the isopentane market, with China and India being major consumers due to their rapidly expanding industrial sectors and increasing urbanization. North America and Europe follow, driven by stringent environmental regulations and the adoption of energy-efficient technologies. The Middle East is emerging as a significant player, leveraging its petrochemical infrastructure to increase isopentane production capacity.

Market analysts project a compound annual growth rate (CAGR) for the global isopentane market in the mid-single digits over the next five years. This growth is attributed to the increasing adoption of energy-efficient appliances, the expansion of the automotive sector in developing economies, and the ongoing substitution of environmentally harmful substances across industries.

However, the market faces challenges related to the environmental risks associated with isopentane emissions. As awareness of these risks grows, industries are under pressure to develop and implement more effective containment and emission reduction strategies. This dynamic is likely to shape future market trends, potentially driving innovation in emission control technologies and the development of alternative substances with lower environmental impact.

Current Challenges in Isopentane Emission Control

Isopentane emissions pose significant environmental challenges, particularly in the context of industrial processes and consumer products. The current state of isopentane emission control faces several critical obstacles that demand immediate attention and innovative solutions.

One of the primary challenges is the lack of comprehensive regulatory frameworks specifically targeting isopentane emissions. While many countries have general volatile organic compound (VOC) regulations, isopentane-specific guidelines are often absent or inadequate. This regulatory gap hampers the implementation of effective control measures and creates inconsistencies in emission standards across different regions and industries.

The detection and quantification of isopentane emissions present another significant hurdle. Current monitoring technologies often struggle to accurately measure low-concentration isopentane emissions, especially in complex industrial environments. This limitation impedes the development of precise emission inventories and hinders the assessment of control measure effectiveness.

The cost-effectiveness of existing emission control technologies remains a major concern for many industries. While several abatement techniques, such as thermal oxidation and carbon adsorption, have proven effective, their high operational costs and energy requirements often deter widespread adoption, particularly among smaller enterprises.

Another challenge lies in the diverse sources of isopentane emissions, ranging from industrial processes to consumer products. This diversity complicates the development of universally applicable control strategies and necessitates tailored approaches for different emission sources.

The potential for fugitive emissions during the storage, handling, and transportation of isopentane-containing materials presents ongoing difficulties. Leaks from valves, flanges, and storage tanks can contribute significantly to overall emissions, yet they are often challenging to detect and control effectively.

Furthermore, the environmental impact of some emission control technologies themselves raises concerns. For instance, certain abatement methods may lead to secondary pollutants or increased energy consumption, potentially offsetting their environmental benefits.

The lack of public awareness about the environmental risks associated with isopentane emissions hinders the implementation of control measures and the development of more environmentally friendly alternatives. This knowledge gap extends to some industry stakeholders, impeding the adoption of best practices and innovative solutions.

Lastly, the global nature of isopentane production and use necessitates international cooperation in emission control efforts. However, disparities in regulatory approaches, technological capabilities, and economic priorities among countries pose significant challenges to achieving harmonized global standards and practices for isopentane emission control.

One of the primary challenges is the lack of comprehensive regulatory frameworks specifically targeting isopentane emissions. While many countries have general volatile organic compound (VOC) regulations, isopentane-specific guidelines are often absent or inadequate. This regulatory gap hampers the implementation of effective control measures and creates inconsistencies in emission standards across different regions and industries.

The detection and quantification of isopentane emissions present another significant hurdle. Current monitoring technologies often struggle to accurately measure low-concentration isopentane emissions, especially in complex industrial environments. This limitation impedes the development of precise emission inventories and hinders the assessment of control measure effectiveness.

The cost-effectiveness of existing emission control technologies remains a major concern for many industries. While several abatement techniques, such as thermal oxidation and carbon adsorption, have proven effective, their high operational costs and energy requirements often deter widespread adoption, particularly among smaller enterprises.

Another challenge lies in the diverse sources of isopentane emissions, ranging from industrial processes to consumer products. This diversity complicates the development of universally applicable control strategies and necessitates tailored approaches for different emission sources.

The potential for fugitive emissions during the storage, handling, and transportation of isopentane-containing materials presents ongoing difficulties. Leaks from valves, flanges, and storage tanks can contribute significantly to overall emissions, yet they are often challenging to detect and control effectively.

Furthermore, the environmental impact of some emission control technologies themselves raises concerns. For instance, certain abatement methods may lead to secondary pollutants or increased energy consumption, potentially offsetting their environmental benefits.

The lack of public awareness about the environmental risks associated with isopentane emissions hinders the implementation of control measures and the development of more environmentally friendly alternatives. This knowledge gap extends to some industry stakeholders, impeding the adoption of best practices and innovative solutions.

Lastly, the global nature of isopentane production and use necessitates international cooperation in emission control efforts. However, disparities in regulatory approaches, technological capabilities, and economic priorities among countries pose significant challenges to achieving harmonized global standards and practices for isopentane emission control.

Existing Isopentane Emission Mitigation Strategies

01 Isopentane emission reduction in industrial processes

Various industrial processes involve the use of isopentane, which can lead to emissions. Techniques have been developed to reduce these emissions, including improved sealing systems, vapor recovery units, and process optimization. These methods aim to capture and recycle isopentane vapors, minimizing their release into the environment.- Isopentane emission reduction in industrial processes: Various industrial processes involve the use of isopentane, which can lead to emissions. Techniques have been developed to reduce these emissions, including improved sealing systems, vapor recovery units, and process optimization. These methods aim to capture and recycle isopentane vapors, minimizing their release into the environment.

- Isopentane as a blowing agent in foam production: Isopentane is used as a blowing agent in the production of foams, particularly in the manufacture of insulation materials. Efforts have been made to develop processes that minimize isopentane emissions during foam production and use. This includes improved encapsulation techniques and the development of alternative blowing agents with lower emission profiles.

- Isopentane in refrigeration and air conditioning systems: Isopentane is used as a refrigerant in some cooling systems. Research has focused on developing more efficient systems that reduce isopentane leakage and emissions. This includes improved system designs, better sealing technologies, and the use of alternative refrigerants with similar properties but lower environmental impact.

- Isopentane emissions in fuel systems: Isopentane is a component of some fuels and can contribute to evaporative emissions from fuel systems. Technologies have been developed to reduce these emissions, including improved fuel tank designs, vapor recovery systems, and the use of low-permeation materials in fuel system components.

- Monitoring and control of isopentane emissions: Advanced monitoring and control systems have been developed to detect and manage isopentane emissions in various industrial settings. These systems employ sensors, real-time data analysis, and automated control mechanisms to identify leaks, optimize processes, and ensure compliance with environmental regulations regarding isopentane emissions.

02 Isopentane as a blowing agent alternative

Isopentane is used as an alternative blowing agent in foam production, replacing ozone-depleting substances. While it offers environmental benefits, its volatile nature requires careful handling to prevent emissions. Techniques have been developed to encapsulate isopentane within the foam structure, reducing potential releases during manufacturing and product use.Expand Specific Solutions03 Isopentane in refrigeration and air conditioning systems

Isopentane is employed in certain refrigeration and air conditioning systems as a more environmentally friendly alternative to traditional refrigerants. However, its flammability and potential for leakage necessitate the development of specialized containment and safety systems to minimize emissions and ensure safe operation.Expand Specific Solutions04 Isopentane emissions in fuel systems

Isopentane is a component in some fuel blends, particularly for high-performance applications. Emissions can occur during fuel storage, transfer, and vehicle operation. Technologies have been developed to reduce these emissions, including improved fuel system designs, vapor recovery systems, and advanced engine management techniques.Expand Specific Solutions05 Analytical methods for isopentane emission detection

To effectively manage isopentane emissions, accurate detection and measurement techniques are crucial. Advanced analytical methods have been developed, including gas chromatography, mass spectrometry, and real-time monitoring systems. These technologies enable precise quantification of isopentane emissions, facilitating better control and regulatory compliance.Expand Specific Solutions

Key Stakeholders in Isopentane Emission Management

The environmental risks associated with isopentane emissions are part of an evolving technological landscape. The industry is in a growth phase, driven by increasing awareness of environmental concerns and stricter regulations. The market size is expanding as more companies invest in research and mitigation strategies. Technologically, the field is advancing rapidly, with varying levels of maturity among key players. Companies like Gevo, Inc. and Phillips 66 are at the forefront, developing innovative solutions for reducing isopentane emissions. Academic institutions such as the University of California and East China Normal University are contributing valuable research. Collaboration between industry leaders and research institutions is accelerating progress in addressing these environmental challenges.

Gevo, Inc.

Technical Solution: Gevo, Inc. has focused on developing alternatives to petroleum-based hydrocarbons, including isopentane, to address environmental concerns. Their approach centers on the production of renewable isobutanol, which can be further processed into renewable hydrocarbons, including isopentane[10]. Gevo's fermentation and separation technologies allow for the production of these renewable alternatives with significantly lower lifecycle greenhouse gas emissions compared to petroleum-based counterparts[11]. They have also developed advanced catalytic processes to convert isobutanol into various hydrocarbons, potentially offering a more environmentally friendly source of isopentane for applications where its use is necessary[12].

Strengths: Addresses the root cause by providing renewable alternatives. Potential for significant reduction in lifecycle emissions. Weaknesses: Currently limited production scale. May require modifications to existing infrastructure for adoption.

Phillips 66

Technical Solution: Phillips 66 has developed advanced emission control technologies for isopentane, focusing on vapor recovery systems and leak detection and repair (LDAR) programs. Their approach includes the implementation of floating roof tanks with advanced seals to minimize evaporative losses[1]. They have also invested in regenerative thermal oxidizers (RTOs) to destroy volatile organic compounds (VOCs) including isopentane, achieving destruction efficiencies of up to 99%[2]. Additionally, Phillips 66 has implemented advanced monitoring systems using optical gas imaging cameras and continuous emissions monitoring systems (CEMS) to detect and quantify isopentane emissions in real-time, allowing for rapid response to potential leaks[3].

Strengths: Comprehensive approach combining prevention, control, and monitoring. High efficiency in VOC destruction. Weaknesses: High initial investment costs for advanced technologies. Potential for increased energy consumption in emission control processes.

Innovative Approaches to Isopentane Emission Reduction

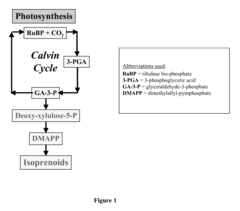

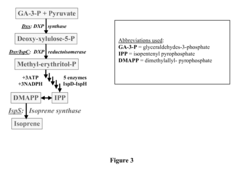

Short chain volatile hydrocarbon production using genetically engineered microalgae, cyanobacteria or bacteria

PatentActiveUS7947478B2

Innovation

- Genetically modified microalgae, cyanobacteria, and photosynthetic bacteria are used to produce 5-carbon isoprenoids like isoprene and methyl-butenol through the DXP-MEP pathway, enabling the generation of renewable fuel sources in enclosed systems, improving fuel production and storage efficiency, and reducing environmental impact.

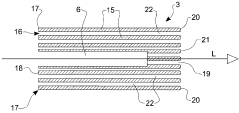

Air treatment unit

PatentPendingGB2600935A

Innovation

- A component for air treatment units featuring a solid body with multiple sets of longitudinal channels and perimeter walls, designed to maximize surface area and facilitate efficient light transmission, supporting photocatalytic materials like zirconium and cerium oxides, and incorporating a recess for a UV light source to enhance light-catalyzed conversion of pollutants.

Environmental Impact Assessment of Isopentane

The environmental impact assessment of isopentane emissions is a critical component in evaluating the overall environmental risks associated with its use. Isopentane, a volatile organic compound (VOC), is widely used in various industrial applications, including as a blowing agent in foam production and as a refrigerant in heat pumps and air conditioning systems. However, its release into the atmosphere can have significant environmental consequences.

One of the primary concerns regarding isopentane emissions is their contribution to ground-level ozone formation. When exposed to sunlight and nitrogen oxides, isopentane can undergo photochemical reactions, leading to the production of tropospheric ozone. This secondary pollutant is a key component of smog and can have detrimental effects on human health, vegetation, and ecosystems. Prolonged exposure to elevated ozone levels can cause respiratory issues in humans and damage to plant tissues, potentially impacting agricultural productivity.

Furthermore, isopentane emissions contribute to the overall burden of VOCs in the atmosphere. VOCs are known to play a role in the formation of secondary organic aerosols (SOA), which are a significant component of particulate matter pollution. These fine particles can have adverse effects on air quality and human health, particularly in urban areas where isopentane emissions may be more concentrated due to industrial activities.

From a climate perspective, while isopentane itself has a relatively low global warming potential compared to some other refrigerants, its indirect effects on climate change should not be overlooked. The formation of tropospheric ozone resulting from isopentane emissions can contribute to short-term climate forcing, as ozone is a potent greenhouse gas in the lower atmosphere.

In aquatic environments, the release of isopentane can lead to water pollution. Although isopentane has low water solubility, it can still impact aquatic ecosystems if released in significant quantities. The compound may accumulate in sediments and potentially affect benthic organisms. Moreover, its volatility means that it can easily evaporate from water surfaces, leading to air pollution concerns even from water-based sources.

The assessment of isopentane's environmental impact also extends to its potential for soil contamination. Spills or leaks of isopentane can result in soil pollution, affecting soil microorganisms and potentially entering the food chain through plant uptake. This highlights the importance of proper handling and storage practices in industrial settings to minimize the risk of environmental contamination.

To comprehensively evaluate the environmental impact of isopentane emissions, it is crucial to consider both direct and indirect effects across various environmental compartments. This includes assessing its role in atmospheric chemistry, its potential for bioaccumulation, and its interactions with different ecosystems. Such a holistic approach enables a more accurate understanding of the compound's overall environmental footprint and informs the development of appropriate mitigation strategies and regulatory frameworks.

One of the primary concerns regarding isopentane emissions is their contribution to ground-level ozone formation. When exposed to sunlight and nitrogen oxides, isopentane can undergo photochemical reactions, leading to the production of tropospheric ozone. This secondary pollutant is a key component of smog and can have detrimental effects on human health, vegetation, and ecosystems. Prolonged exposure to elevated ozone levels can cause respiratory issues in humans and damage to plant tissues, potentially impacting agricultural productivity.

Furthermore, isopentane emissions contribute to the overall burden of VOCs in the atmosphere. VOCs are known to play a role in the formation of secondary organic aerosols (SOA), which are a significant component of particulate matter pollution. These fine particles can have adverse effects on air quality and human health, particularly in urban areas where isopentane emissions may be more concentrated due to industrial activities.

From a climate perspective, while isopentane itself has a relatively low global warming potential compared to some other refrigerants, its indirect effects on climate change should not be overlooked. The formation of tropospheric ozone resulting from isopentane emissions can contribute to short-term climate forcing, as ozone is a potent greenhouse gas in the lower atmosphere.

In aquatic environments, the release of isopentane can lead to water pollution. Although isopentane has low water solubility, it can still impact aquatic ecosystems if released in significant quantities. The compound may accumulate in sediments and potentially affect benthic organisms. Moreover, its volatility means that it can easily evaporate from water surfaces, leading to air pollution concerns even from water-based sources.

The assessment of isopentane's environmental impact also extends to its potential for soil contamination. Spills or leaks of isopentane can result in soil pollution, affecting soil microorganisms and potentially entering the food chain through plant uptake. This highlights the importance of proper handling and storage practices in industrial settings to minimize the risk of environmental contamination.

To comprehensively evaluate the environmental impact of isopentane emissions, it is crucial to consider both direct and indirect effects across various environmental compartments. This includes assessing its role in atmospheric chemistry, its potential for bioaccumulation, and its interactions with different ecosystems. Such a holistic approach enables a more accurate understanding of the compound's overall environmental footprint and informs the development of appropriate mitigation strategies and regulatory frameworks.

Regulatory Framework for Volatile Organic Compounds

The regulatory framework for volatile organic compounds (VOCs) plays a crucial role in addressing the environmental risks associated with isopentane emissions. Isopentane, a highly volatile organic compound, falls under the broader category of VOCs regulated by various environmental agencies worldwide.

In the United States, the Environmental Protection Agency (EPA) is the primary regulatory body responsible for controlling VOC emissions. The Clean Air Act provides the legal foundation for regulating these compounds, with the National Ambient Air Quality Standards (NAAQS) setting limits on ground-level ozone, a secondary pollutant formed by VOCs and nitrogen oxides. The EPA's New Source Performance Standards (NSPS) and National Emission Standards for Hazardous Air Pollutants (NESHAP) specifically target VOC emissions from industrial sources.

At the state level, many jurisdictions have implemented their own VOC regulations, often more stringent than federal standards. For instance, California's Air Resources Board (CARB) has established strict VOC limits for consumer products and industrial processes, which have been adopted by other states as well.

In the European Union, the Directive on Industrial Emissions (IED) sets the framework for regulating VOC emissions from industrial activities. The Solvent Emissions Directive (SED) specifically addresses VOC emissions from the use of organic solvents in certain activities and installations. Additionally, the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation requires manufacturers and importers to assess and manage the risks associated with substances they produce or import, including VOCs like isopentane.

Many countries have adopted similar regulatory approaches, often modeled after the US or EU frameworks. For example, China's Air Pollution Prevention and Control Law includes provisions for VOC control, with specific emission standards set for various industries.

International agreements also play a role in shaping VOC regulations. The Gothenburg Protocol, part of the Convention on Long-range Transboundary Air Pollution, sets emission ceilings for VOCs among other pollutants for its signatories.

Compliance with these regulations often requires industries to implement best available techniques (BAT) for VOC emission control. These may include process modifications, end-of-pipe technologies such as thermal oxidizers or carbon adsorption systems, and leak detection and repair (LDAR) programs.

As scientific understanding of the environmental impacts of VOCs evolves, regulatory frameworks continue to adapt. Recent trends include the development of more targeted regulations for specific VOCs, increased focus on indoor air quality, and the integration of VOC control strategies with broader climate change mitigation efforts.

In the United States, the Environmental Protection Agency (EPA) is the primary regulatory body responsible for controlling VOC emissions. The Clean Air Act provides the legal foundation for regulating these compounds, with the National Ambient Air Quality Standards (NAAQS) setting limits on ground-level ozone, a secondary pollutant formed by VOCs and nitrogen oxides. The EPA's New Source Performance Standards (NSPS) and National Emission Standards for Hazardous Air Pollutants (NESHAP) specifically target VOC emissions from industrial sources.

At the state level, many jurisdictions have implemented their own VOC regulations, often more stringent than federal standards. For instance, California's Air Resources Board (CARB) has established strict VOC limits for consumer products and industrial processes, which have been adopted by other states as well.

In the European Union, the Directive on Industrial Emissions (IED) sets the framework for regulating VOC emissions from industrial activities. The Solvent Emissions Directive (SED) specifically addresses VOC emissions from the use of organic solvents in certain activities and installations. Additionally, the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation requires manufacturers and importers to assess and manage the risks associated with substances they produce or import, including VOCs like isopentane.

Many countries have adopted similar regulatory approaches, often modeled after the US or EU frameworks. For example, China's Air Pollution Prevention and Control Law includes provisions for VOC control, with specific emission standards set for various industries.

International agreements also play a role in shaping VOC regulations. The Gothenburg Protocol, part of the Convention on Long-range Transboundary Air Pollution, sets emission ceilings for VOCs among other pollutants for its signatories.

Compliance with these regulations often requires industries to implement best available techniques (BAT) for VOC emission control. These may include process modifications, end-of-pipe technologies such as thermal oxidizers or carbon adsorption systems, and leak detection and repair (LDAR) programs.

As scientific understanding of the environmental impacts of VOCs evolves, regulatory frameworks continue to adapt. Recent trends include the development of more targeted regulations for specific VOCs, increased focus on indoor air quality, and the integration of VOC control strategies with broader climate change mitigation efforts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!