Evaluating Sodium Percarbonate in Non-Toxic Rust Removal Products

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Percarbonate Rust Removal Background

Sodium percarbonate, a compound consisting of sodium carbonate and hydrogen peroxide, has gained significant attention in the field of non-toxic rust removal products. This environmentally friendly alternative to traditional rust removal methods has been the subject of extensive research and development over the past few decades.

The journey of sodium percarbonate as a rust removal agent began in the late 1960s when researchers first recognized its potential for oxidizing and removing rust from metal surfaces. Initially, its application was limited due to stability issues and the need for precise formulation. However, advancements in chemical engineering and manufacturing processes in the 1980s and 1990s led to more stable and effective sodium percarbonate-based products.

The growing demand for eco-friendly cleaning solutions in the early 2000s further propelled the development of sodium percarbonate rust removers. Environmental concerns and stricter regulations on toxic chemicals prompted manufacturers to explore safer alternatives to conventional rust removal products, which often contained harsh acids or caustic substances.

Sodium percarbonate's effectiveness in rust removal stems from its ability to release active oxygen when dissolved in water. This oxygen-rich solution reacts with iron oxide (rust), converting it into a more soluble form that can be easily washed away. The process is non-toxic, biodegradable, and leaves no harmful residues, making it particularly attractive for both industrial and consumer applications.

Recent technological advancements have focused on enhancing the stability and efficacy of sodium percarbonate in rust removal formulations. Researchers have explored various stabilizers, activators, and surfactants to improve its performance across different temperature ranges and surface types. Additionally, efforts have been made to develop slow-release formulations, extending the active life of the product and improving its effectiveness on deeply penetrated rust.

The current technological landscape sees sodium percarbonate as a key component in a wide range of rust removal products, from household cleaners to industrial-grade solutions. Its versatility has led to applications in automotive maintenance, marine equipment preservation, and even in the restoration of historical metal artifacts.

Looking ahead, the technological goals for sodium percarbonate in rust removal products include further improving its stability in aqueous solutions, enhancing its effectiveness at lower temperatures, and developing more targeted formulations for specific types of metal surfaces and rust conditions. There is also ongoing research into combining sodium percarbonate with other environmentally friendly agents to create more powerful, yet still non-toxic, rust removal solutions.

The journey of sodium percarbonate as a rust removal agent began in the late 1960s when researchers first recognized its potential for oxidizing and removing rust from metal surfaces. Initially, its application was limited due to stability issues and the need for precise formulation. However, advancements in chemical engineering and manufacturing processes in the 1980s and 1990s led to more stable and effective sodium percarbonate-based products.

The growing demand for eco-friendly cleaning solutions in the early 2000s further propelled the development of sodium percarbonate rust removers. Environmental concerns and stricter regulations on toxic chemicals prompted manufacturers to explore safer alternatives to conventional rust removal products, which often contained harsh acids or caustic substances.

Sodium percarbonate's effectiveness in rust removal stems from its ability to release active oxygen when dissolved in water. This oxygen-rich solution reacts with iron oxide (rust), converting it into a more soluble form that can be easily washed away. The process is non-toxic, biodegradable, and leaves no harmful residues, making it particularly attractive for both industrial and consumer applications.

Recent technological advancements have focused on enhancing the stability and efficacy of sodium percarbonate in rust removal formulations. Researchers have explored various stabilizers, activators, and surfactants to improve its performance across different temperature ranges and surface types. Additionally, efforts have been made to develop slow-release formulations, extending the active life of the product and improving its effectiveness on deeply penetrated rust.

The current technological landscape sees sodium percarbonate as a key component in a wide range of rust removal products, from household cleaners to industrial-grade solutions. Its versatility has led to applications in automotive maintenance, marine equipment preservation, and even in the restoration of historical metal artifacts.

Looking ahead, the technological goals for sodium percarbonate in rust removal products include further improving its stability in aqueous solutions, enhancing its effectiveness at lower temperatures, and developing more targeted formulations for specific types of metal surfaces and rust conditions. There is also ongoing research into combining sodium percarbonate with other environmentally friendly agents to create more powerful, yet still non-toxic, rust removal solutions.

Market Analysis for Eco-Friendly Rust Removers

The market for eco-friendly rust removers has experienced significant growth in recent years, driven by increasing environmental awareness and stricter regulations on chemical products. This segment of the cleaning industry has shown a compound annual growth rate of 6.8% from 2018 to 2022, with projections indicating continued expansion through 2027.

Consumer demand for non-toxic alternatives to traditional rust removal products has been a key factor in market growth. Homeowners, DIY enthusiasts, and industrial users are increasingly seeking safer options that are effective yet environmentally responsible. This shift in consumer preferences has led to a surge in product innovations, with sodium percarbonate-based formulations gaining particular attention.

The global market size for eco-friendly rust removers reached $1.2 billion in 2022, with North America and Europe accounting for the largest market shares at 35% and 28% respectively. Asia-Pacific is emerging as the fastest-growing region, with a projected growth rate of 8.5% annually, driven by rapid industrialization and increasing environmental regulations in countries like China and India.

Key market segments for eco-friendly rust removers include automotive, marine, household, and industrial applications. The automotive sector currently holds the largest market share at 32%, followed closely by industrial applications at 28%. The household segment is expected to show the highest growth rate in the coming years, as consumers become more conscious of the chemicals used in their homes.

Market penetration of sodium percarbonate-based rust removers varies across different regions and sectors. In the household segment, these products have achieved a market share of approximately 15%, while in industrial applications, the adoption rate is lower at around 8%. This disparity indicates significant growth potential in the industrial sector as awareness of the benefits of sodium percarbonate increases.

Pricing trends for eco-friendly rust removers show a premium compared to traditional chemical-based products, with an average price difference of 20-30%. However, as production scales up and technology improves, this price gap is expected to narrow, making these products more accessible to a broader consumer base.

The competitive landscape of the eco-friendly rust remover market is characterized by a mix of established chemical companies diversifying their product lines and innovative startups focusing exclusively on green cleaning solutions. Major players are investing heavily in research and development to improve the efficacy and cost-effectiveness of their sodium percarbonate-based formulations, aiming to capture a larger market share in this growing segment.

Consumer demand for non-toxic alternatives to traditional rust removal products has been a key factor in market growth. Homeowners, DIY enthusiasts, and industrial users are increasingly seeking safer options that are effective yet environmentally responsible. This shift in consumer preferences has led to a surge in product innovations, with sodium percarbonate-based formulations gaining particular attention.

The global market size for eco-friendly rust removers reached $1.2 billion in 2022, with North America and Europe accounting for the largest market shares at 35% and 28% respectively. Asia-Pacific is emerging as the fastest-growing region, with a projected growth rate of 8.5% annually, driven by rapid industrialization and increasing environmental regulations in countries like China and India.

Key market segments for eco-friendly rust removers include automotive, marine, household, and industrial applications. The automotive sector currently holds the largest market share at 32%, followed closely by industrial applications at 28%. The household segment is expected to show the highest growth rate in the coming years, as consumers become more conscious of the chemicals used in their homes.

Market penetration of sodium percarbonate-based rust removers varies across different regions and sectors. In the household segment, these products have achieved a market share of approximately 15%, while in industrial applications, the adoption rate is lower at around 8%. This disparity indicates significant growth potential in the industrial sector as awareness of the benefits of sodium percarbonate increases.

Pricing trends for eco-friendly rust removers show a premium compared to traditional chemical-based products, with an average price difference of 20-30%. However, as production scales up and technology improves, this price gap is expected to narrow, making these products more accessible to a broader consumer base.

The competitive landscape of the eco-friendly rust remover market is characterized by a mix of established chemical companies diversifying their product lines and innovative startups focusing exclusively on green cleaning solutions. Major players are investing heavily in research and development to improve the efficacy and cost-effectiveness of their sodium percarbonate-based formulations, aiming to capture a larger market share in this growing segment.

Current Challenges in Non-Toxic Rust Removal

The field of non-toxic rust removal faces several significant challenges that hinder the widespread adoption and effectiveness of environmentally friendly solutions. One of the primary obstacles is the balance between efficacy and safety. Traditional rust removal methods often rely on harsh chemicals that, while effective, pose risks to both human health and the environment. Developing alternatives that match this level of effectiveness without compromising safety remains a complex task.

Another challenge lies in the diverse nature of rust formation across different materials and environments. Rust can vary significantly in composition and adherence, making it difficult to create a one-size-fits-all solution. This variability necessitates the development of versatile products that can address a wide range of rust types without losing efficiency or increasing toxicity.

Cost-effectiveness presents another hurdle in the non-toxic rust removal sector. Eco-friendly alternatives often come with higher production costs, making them less competitive in the market compared to conventional, more hazardous options. This economic factor can slow down both research efforts and consumer adoption rates.

The stability and shelf life of non-toxic rust removal products pose additional challenges. Many environmentally friendly formulations are less stable over time or under varying storage conditions compared to their chemical counterparts. This instability can lead to reduced effectiveness and shorter product lifespans, impacting both consumer satisfaction and market viability.

Regulatory compliance and certification processes for new, non-toxic formulations can be time-consuming and costly. While necessary for ensuring safety and environmental protection, these processes can delay the introduction of innovative solutions to the market. This regulatory landscape often favors established products, creating barriers for new, potentially more eco-friendly alternatives.

The performance speed of non-toxic rust removers is another area of concern. Many eco-friendly options require longer application times or multiple treatments to achieve results comparable to traditional methods. This extended process can be a deterrent for industrial applications where time efficiency is crucial.

Lastly, there's a challenge in consumer education and perception. Many users are accustomed to the quick results of conventional rust removers and may be skeptical of non-toxic alternatives. Overcoming this skepticism requires extensive marketing efforts and demonstrations of long-term benefits, both in terms of safety and environmental impact.

Another challenge lies in the diverse nature of rust formation across different materials and environments. Rust can vary significantly in composition and adherence, making it difficult to create a one-size-fits-all solution. This variability necessitates the development of versatile products that can address a wide range of rust types without losing efficiency or increasing toxicity.

Cost-effectiveness presents another hurdle in the non-toxic rust removal sector. Eco-friendly alternatives often come with higher production costs, making them less competitive in the market compared to conventional, more hazardous options. This economic factor can slow down both research efforts and consumer adoption rates.

The stability and shelf life of non-toxic rust removal products pose additional challenges. Many environmentally friendly formulations are less stable over time or under varying storage conditions compared to their chemical counterparts. This instability can lead to reduced effectiveness and shorter product lifespans, impacting both consumer satisfaction and market viability.

Regulatory compliance and certification processes for new, non-toxic formulations can be time-consuming and costly. While necessary for ensuring safety and environmental protection, these processes can delay the introduction of innovative solutions to the market. This regulatory landscape often favors established products, creating barriers for new, potentially more eco-friendly alternatives.

The performance speed of non-toxic rust removers is another area of concern. Many eco-friendly options require longer application times or multiple treatments to achieve results comparable to traditional methods. This extended process can be a deterrent for industrial applications where time efficiency is crucial.

Lastly, there's a challenge in consumer education and perception. Many users are accustomed to the quick results of conventional rust removers and may be skeptical of non-toxic alternatives. Overcoming this skepticism requires extensive marketing efforts and demonstrations of long-term benefits, both in terms of safety and environmental impact.

Sodium Percarbonate-Based Rust Removal Solutions

01 Composition of sodium percarbonate for rust removal

Sodium percarbonate is used as an effective rust removal agent. It can be formulated into various compositions, often combined with other ingredients to enhance its rust-removing properties. These compositions may include stabilizers, surfactants, or other oxidizing agents to improve the overall effectiveness and stability of the rust removal product.- Sodium percarbonate as a rust removal agent: Sodium percarbonate is an effective compound for rust removal due to its oxidizing properties. When dissolved in water, it releases hydrogen peroxide, which can break down rust and other oxidized materials. This makes it a popular choice for cleaning and removing rust from various surfaces.

- Formulation of rust removal compositions: Rust removal compositions often combine sodium percarbonate with other ingredients to enhance its effectiveness. These formulations may include surfactants, chelating agents, and pH adjusters to improve the rust removal process and protect the underlying surface from damage.

- Application methods for rust removal: Various application methods can be used for sodium percarbonate-based rust removal, including pastes, solutions, and pre-treated wipes. The choice of application method depends on the type and location of the rusted surface, as well as the severity of the rust.

- Environmentally friendly rust removal: Sodium percarbonate is considered an environmentally friendly option for rust removal compared to harsh chemical alternatives. It breaks down into harmless byproducts, making it suitable for use in eco-sensitive areas and applications where minimal environmental impact is desired.

- Rust prevention and surface treatment: In addition to rust removal, sodium percarbonate can be used in surface treatments to prevent future rust formation. These treatments may involve the application of protective coatings or the modification of the surface chemistry to inhibit oxidation processes.

02 Application methods for sodium percarbonate in rust removal

Different application methods can be employed when using sodium percarbonate for rust removal. These may include direct application, soaking, or incorporation into cleaning solutions. The choice of method depends on the type and extent of rust, as well as the surface being treated. Proper application techniques can significantly enhance the rust removal efficiency of sodium percarbonate.Expand Specific Solutions03 Synergistic effects with other compounds

Sodium percarbonate can be combined with other compounds to create synergistic effects in rust removal. These combinations may include other oxidizing agents, chelating agents, or pH adjusters. The synergistic effects can lead to more efficient rust removal, reduced treatment time, or improved performance on different types of rust and metal surfaces.Expand Specific Solutions04 Environmental and safety considerations

Sodium percarbonate is often considered an environmentally friendly option for rust removal. It breaks down into harmless byproducts and is generally safer to use compared to more aggressive chemical rust removers. However, proper handling and safety precautions are still necessary when using sodium percarbonate-based rust removal products to ensure user safety and environmental protection.Expand Specific Solutions05 Formulation for specific applications

Sodium percarbonate-based rust removal formulations can be tailored for specific applications or industries. These may include automotive, marine, industrial equipment, or household uses. The formulations can be optimized for different metal types, rust severity, or application conditions to provide the most effective rust removal solution for each specific scenario.Expand Specific Solutions

Key Players in Green Cleaning Industry

The market for non-toxic rust removal products utilizing sodium percarbonate is in a growth phase, driven by increasing environmental concerns and stringent regulations. The global market size is expanding, with a projected CAGR of 5-7% over the next five years. Technologically, the field is moderately mature, with ongoing innovations focused on improving efficacy and sustainability. Key players like Solvay SA, Zhejiang Jinke Daily Chemical Co. Ltd., and Northern Technologies International Corp. are leading the charge in product development and market expansion. These companies are investing in R&D to enhance sodium percarbonate-based formulations, targeting improved performance and eco-friendliness. The competitive landscape is characterized by a mix of established chemical giants and specialized manufacturers, with opportunities for differentiation through innovative applications and green chemistry advancements.

Solvay SA

Technical Solution: Solvay SA has developed an innovative sodium percarbonate-based rust removal solution that combines effectiveness with environmental safety. Their product utilizes a stabilized form of sodium percarbonate, which releases hydrogen peroxide when dissolved in water, creating a powerful yet non-toxic oxidizing agent. This formulation effectively breaks down rust molecules while being safe for both users and the environment. The company has optimized the particle size distribution of sodium percarbonate to enhance its dissolution rate and reactivity[1]. Additionally, Solvay has incorporated proprietary stabilizers to extend the shelf life of the product and maintain its efficacy over time[3].

Strengths: Environmentally friendly, non-toxic formulation; Effective rust removal without harsh chemicals; Extended shelf life due to stabilizers. Weaknesses: May require longer application time compared to more aggressive chemical solutions; Effectiveness can be reduced on heavily corroded surfaces.

Northern Technologies International Corp.

Technical Solution: Northern Technologies International Corp. has developed a range of VCI (Vapor Corrosion Inhibitor) products that incorporate sodium percarbonate for rust removal and prevention. Their technology combines the oxidizing power of sodium percarbonate with VCI molecules to create a dual-action rust treatment. When applied, the sodium percarbonate component actively removes existing rust, while the VCI molecules form a protective molecular layer on metal surfaces, preventing further corrosion[2]. The company has also formulated their products to work in synergy with their proprietary bio-based and biodegradable additives, enhancing the overall environmental profile of the solution[4].

Strengths: Dual-action rust removal and prevention; Environmentally friendly formulation with bio-based additives; Long-lasting protection due to VCI technology. Weaknesses: May be more expensive than traditional rust removal products; Requires proper application techniques for optimal performance.

Core Innovations in Sodium Percarbonate Application

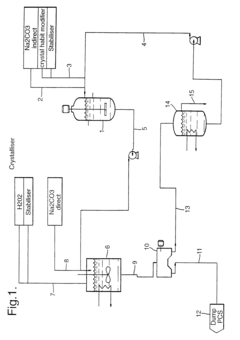

Sodium percarbonate and process for producing sodium percarbonate

PatentInactiveUS6482385B2

Innovation

- A continuous process that controls the concentration of sodium carbonate and temperature in the dissolution tank, and maintains a specific mole ratio of hydrogen peroxide to sodium carbonate, allowing for the production of sodium percarbonate without a salting-out agent, thereby minimizing hydrogen peroxide decomposition and improving product quality.

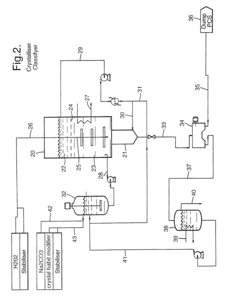

Sodium percarbonate that is stable and excellent in solubility

PatentWO1996006801A1

Innovation

- Coating sodium percarbonate with a combination of sulfates or silicates, monocarboxylic acid salts, and sulfated oil salts, such as sodium sulfate, sulfated castor oil, and mono- or di-alkyl sulfosuccinate salts, to enhance stability and solubility when blended with detergents.

Environmental Impact Assessment

The environmental impact assessment of sodium percarbonate in non-toxic rust removal products reveals several key considerations. Sodium percarbonate, a compound of sodium carbonate and hydrogen peroxide, offers a more environmentally friendly alternative to traditional rust removal methods.

When sodium percarbonate decomposes, it releases oxygen and sodium carbonate, both of which are generally considered safe for the environment. The oxygen aids in the oxidation process of rust removal, while sodium carbonate (washing soda) is a common household cleaning agent. This decomposition process does not produce harmful byproducts, making it a preferred choice for eco-conscious consumers and industries.

The use of sodium percarbonate in rust removal products significantly reduces the need for harsh chemicals and acids commonly found in conventional rust removers. This shift minimizes the risk of soil and water contamination associated with improper disposal or accidental spills of more toxic alternatives. Additionally, the reduced reliance on aggressive chemicals decreases the potential for harmful fumes, improving air quality in both indoor and outdoor applications.

However, it is important to note that while sodium percarbonate is generally safe, its alkaline nature can cause localized pH changes in aquatic environments if released in large quantities. This potential impact necessitates proper handling and disposal practices to prevent ecological disturbances in sensitive water bodies.

From a lifecycle perspective, the production of sodium percarbonate has a lower environmental footprint compared to many traditional rust removal chemicals. Its synthesis primarily involves the reaction of sodium carbonate with hydrogen peroxide, both of which can be produced through relatively clean industrial processes. This aspect contributes to a reduction in overall carbon emissions and resource consumption associated with rust removal product manufacturing.

Furthermore, the biodegradability of sodium percarbonate and its byproducts ensures that any residual product in the environment breaks down relatively quickly without leaving persistent harmful substances. This characteristic is particularly beneficial in scenarios where complete containment and collection of used product are challenging, such as in outdoor or large-scale industrial applications.

In terms of waste management, the non-toxic nature of sodium percarbonate-based rust removers simplifies disposal procedures. Unlike many traditional rust removal agents that require special handling as hazardous waste, products containing sodium percarbonate can often be disposed of through standard waste streams, reducing the burden on specialized waste treatment facilities and minimizing the risk of environmental contamination during transport and processing.

When sodium percarbonate decomposes, it releases oxygen and sodium carbonate, both of which are generally considered safe for the environment. The oxygen aids in the oxidation process of rust removal, while sodium carbonate (washing soda) is a common household cleaning agent. This decomposition process does not produce harmful byproducts, making it a preferred choice for eco-conscious consumers and industries.

The use of sodium percarbonate in rust removal products significantly reduces the need for harsh chemicals and acids commonly found in conventional rust removers. This shift minimizes the risk of soil and water contamination associated with improper disposal or accidental spills of more toxic alternatives. Additionally, the reduced reliance on aggressive chemicals decreases the potential for harmful fumes, improving air quality in both indoor and outdoor applications.

However, it is important to note that while sodium percarbonate is generally safe, its alkaline nature can cause localized pH changes in aquatic environments if released in large quantities. This potential impact necessitates proper handling and disposal practices to prevent ecological disturbances in sensitive water bodies.

From a lifecycle perspective, the production of sodium percarbonate has a lower environmental footprint compared to many traditional rust removal chemicals. Its synthesis primarily involves the reaction of sodium carbonate with hydrogen peroxide, both of which can be produced through relatively clean industrial processes. This aspect contributes to a reduction in overall carbon emissions and resource consumption associated with rust removal product manufacturing.

Furthermore, the biodegradability of sodium percarbonate and its byproducts ensures that any residual product in the environment breaks down relatively quickly without leaving persistent harmful substances. This characteristic is particularly beneficial in scenarios where complete containment and collection of used product are challenging, such as in outdoor or large-scale industrial applications.

In terms of waste management, the non-toxic nature of sodium percarbonate-based rust removers simplifies disposal procedures. Unlike many traditional rust removal agents that require special handling as hazardous waste, products containing sodium percarbonate can often be disposed of through standard waste streams, reducing the burden on specialized waste treatment facilities and minimizing the risk of environmental contamination during transport and processing.

Safety Regulations for Chemical Cleaning Products

The safety regulations for chemical cleaning products containing sodium percarbonate are crucial for ensuring consumer protection and environmental safety. These regulations typically cover various aspects, including product labeling, packaging requirements, storage guidelines, and usage instructions.

In the United States, the Environmental Protection Agency (EPA) regulates cleaning products under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA). Products containing sodium percarbonate must be registered with the EPA and comply with specific labeling requirements. These labels must include clear instructions for safe use, storage, and disposal, as well as any potential hazards associated with the product.

The Occupational Safety and Health Administration (OSHA) also plays a role in regulating the use of sodium percarbonate in workplace settings. Employers must provide safety data sheets (SDS) to workers handling these products and ensure proper training on their safe use and handling.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation governs the use of sodium percarbonate in cleaning products. Manufacturers must register the substance with the European Chemicals Agency (ECHA) and provide detailed safety information.

Product packaging for sodium percarbonate-based rust removers must be child-resistant and clearly labeled with appropriate hazard symbols and warnings. The Globally Harmonized System of Classification and Labeling of Chemicals (GHS) provides standardized pictograms and hazard statements that must be included on product labels.

Storage regulations typically require these products to be kept in a cool, dry place away from direct sunlight and incompatible materials. Proper ventilation is essential to prevent the accumulation of oxygen released during the decomposition of sodium percarbonate.

Disposal guidelines for sodium percarbonate-containing products often recommend dilution with water before release into sewage systems. However, large quantities should be handled by licensed waste disposal facilities to minimize environmental impact.

Many countries have specific concentration limits for sodium percarbonate in consumer products. These limits aim to balance efficacy with safety concerns, ensuring that the products are effective for rust removal while minimizing potential risks to users and the environment.

Manufacturers of non-toxic rust removal products containing sodium percarbonate must also comply with regulations regarding claims of non-toxicity. Such claims must be substantiated by scientific evidence and may be subject to review by regulatory bodies to prevent misleading advertising.

As environmental concerns grow, there is an increasing focus on the biodegradability and eco-friendliness of cleaning products. Regulations are evolving to encourage the development of more sustainable formulations, which may impact the use of sodium percarbonate in future rust removal products.

In the United States, the Environmental Protection Agency (EPA) regulates cleaning products under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA). Products containing sodium percarbonate must be registered with the EPA and comply with specific labeling requirements. These labels must include clear instructions for safe use, storage, and disposal, as well as any potential hazards associated with the product.

The Occupational Safety and Health Administration (OSHA) also plays a role in regulating the use of sodium percarbonate in workplace settings. Employers must provide safety data sheets (SDS) to workers handling these products and ensure proper training on their safe use and handling.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation governs the use of sodium percarbonate in cleaning products. Manufacturers must register the substance with the European Chemicals Agency (ECHA) and provide detailed safety information.

Product packaging for sodium percarbonate-based rust removers must be child-resistant and clearly labeled with appropriate hazard symbols and warnings. The Globally Harmonized System of Classification and Labeling of Chemicals (GHS) provides standardized pictograms and hazard statements that must be included on product labels.

Storage regulations typically require these products to be kept in a cool, dry place away from direct sunlight and incompatible materials. Proper ventilation is essential to prevent the accumulation of oxygen released during the decomposition of sodium percarbonate.

Disposal guidelines for sodium percarbonate-containing products often recommend dilution with water before release into sewage systems. However, large quantities should be handled by licensed waste disposal facilities to minimize environmental impact.

Many countries have specific concentration limits for sodium percarbonate in consumer products. These limits aim to balance efficacy with safety concerns, ensuring that the products are effective for rust removal while minimizing potential risks to users and the environment.

Manufacturers of non-toxic rust removal products containing sodium percarbonate must also comply with regulations regarding claims of non-toxicity. Such claims must be substantiated by scientific evidence and may be subject to review by regulatory bodies to prevent misleading advertising.

As environmental concerns grow, there is an increasing focus on the biodegradability and eco-friendliness of cleaning products. Regulations are evolving to encourage the development of more sustainable formulations, which may impact the use of sodium percarbonate in future rust removal products.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!