Evaluation of Silicon carbide ceramics for high performance energy and power generation systems

SEP 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SiC Ceramics Background and Performance Targets

Silicon carbide (SiC) ceramics represent a significant advancement in materials science, with a rich developmental history spanning over a century since their first commercial production in 1891 by Edward G. Acheson. These ceramics belong to the non-oxide ceramic family and are characterized by their exceptional combination of mechanical, thermal, and electrical properties that make them uniquely suited for extreme operating environments.

The evolution of SiC ceramics has been marked by continuous improvements in processing techniques, from traditional powder sintering methods to more advanced approaches such as chemical vapor deposition (CVD), spark plasma sintering (SPS), and additive manufacturing. These advancements have progressively enhanced the material's performance characteristics while expanding its application scope in high-temperature environments.

SiC ceramics exhibit remarkable thermal stability, maintaining their mechanical integrity at temperatures exceeding 1600°C, significantly outperforming conventional materials. Their thermal conductivity ranges from 120 to 200 W/m·K, surpassing many metals while offering superior corrosion resistance in aggressive chemical environments. Additionally, their low thermal expansion coefficient (approximately 4.0 × 10^-6/K) minimizes thermal stress during rapid temperature fluctuations.

In the context of energy and power generation systems, SiC ceramics are increasingly viewed as critical materials for enhancing efficiency and durability. The global push toward more sustainable energy solutions has accelerated research into SiC applications for gas turbines, nuclear reactors, concentrated solar power systems, and solid oxide fuel cells. These applications leverage SiC's ability to withstand extreme temperatures while maintaining structural integrity.

The performance targets for SiC ceramics in next-generation energy systems are ambitious and multifaceted. Key objectives include achieving operational temperatures above 1700°C with minimal degradation, enhancing fracture toughness to above 6 MPa·m^1/2 (compared to current values of 2-4 MPa·m^1/2), and developing cost-effective manufacturing processes to reduce the current high production costs that limit widespread adoption.

Another critical target involves improving the reliability and predictability of SiC components under cyclic thermal and mechanical loading conditions, as current limitations in this area restrict their implementation in critical energy infrastructure. Researchers are also focusing on developing SiC composites with tailored properties for specific applications, such as enhanced neutron radiation resistance for nuclear applications or improved electrical conductivity for certain power generation systems.

The integration of SiC ceramics into energy systems aligns with global sustainability goals, as their implementation can potentially increase energy conversion efficiencies by 5-15% compared to conventional materials, significantly reducing carbon emissions from power generation facilities while extending operational lifespans of critical components.

The evolution of SiC ceramics has been marked by continuous improvements in processing techniques, from traditional powder sintering methods to more advanced approaches such as chemical vapor deposition (CVD), spark plasma sintering (SPS), and additive manufacturing. These advancements have progressively enhanced the material's performance characteristics while expanding its application scope in high-temperature environments.

SiC ceramics exhibit remarkable thermal stability, maintaining their mechanical integrity at temperatures exceeding 1600°C, significantly outperforming conventional materials. Their thermal conductivity ranges from 120 to 200 W/m·K, surpassing many metals while offering superior corrosion resistance in aggressive chemical environments. Additionally, their low thermal expansion coefficient (approximately 4.0 × 10^-6/K) minimizes thermal stress during rapid temperature fluctuations.

In the context of energy and power generation systems, SiC ceramics are increasingly viewed as critical materials for enhancing efficiency and durability. The global push toward more sustainable energy solutions has accelerated research into SiC applications for gas turbines, nuclear reactors, concentrated solar power systems, and solid oxide fuel cells. These applications leverage SiC's ability to withstand extreme temperatures while maintaining structural integrity.

The performance targets for SiC ceramics in next-generation energy systems are ambitious and multifaceted. Key objectives include achieving operational temperatures above 1700°C with minimal degradation, enhancing fracture toughness to above 6 MPa·m^1/2 (compared to current values of 2-4 MPa·m^1/2), and developing cost-effective manufacturing processes to reduce the current high production costs that limit widespread adoption.

Another critical target involves improving the reliability and predictability of SiC components under cyclic thermal and mechanical loading conditions, as current limitations in this area restrict their implementation in critical energy infrastructure. Researchers are also focusing on developing SiC composites with tailored properties for specific applications, such as enhanced neutron radiation resistance for nuclear applications or improved electrical conductivity for certain power generation systems.

The integration of SiC ceramics into energy systems aligns with global sustainability goals, as their implementation can potentially increase energy conversion efficiencies by 5-15% compared to conventional materials, significantly reducing carbon emissions from power generation facilities while extending operational lifespans of critical components.

Market Analysis for High-Temperature Energy Applications

The high-temperature energy applications market for silicon carbide (SiC) ceramics is experiencing robust growth, driven primarily by increasing demands for more efficient and durable materials in extreme operating environments. Current market valuations indicate that the global SiC ceramics market for energy applications reached approximately 2.1 billion USD in 2022, with projections suggesting a compound annual growth rate (CAGR) of 7.8% through 2030.

Power generation systems represent the largest application segment, accounting for nearly 40% of the total market share. This dominance stems from SiC ceramics' exceptional thermal stability and mechanical strength at temperatures exceeding 1400°C, making them ideal for gas turbines, concentrated solar power systems, and advanced nuclear reactors. The nuclear energy sector, in particular, has shown increased interest in SiC composites as accident-tolerant fuel cladding materials following the Fukushima incident.

Geographically, North America and Europe currently lead market consumption, collectively representing 58% of global demand. However, the Asia-Pacific region, particularly China, Japan, and South Korea, is witnessing the fastest growth rate at 9.2% annually, driven by aggressive expansion of their high-efficiency energy infrastructure and manufacturing capabilities.

End-user segmentation reveals that utility companies constitute 45% of the market, followed by industrial manufacturing at 30%, aerospace at 15%, and other applications at 10%. This distribution reflects the critical role of SiC ceramics in enhancing energy efficiency and operational reliability in large-scale power generation facilities.

Market challenges include the high production costs of high-purity SiC ceramics, which currently range from 80-200 USD per kilogram depending on quality specifications and form factors. This represents a significant premium over conventional materials, creating adoption barriers particularly for price-sensitive applications and emerging markets.

Supply chain analysis indicates potential vulnerabilities, with 65% of high-grade SiC precursor materials concentrated among just three global suppliers. Recent geopolitical tensions and pandemic-related disruptions have highlighted the strategic importance of developing more resilient and diversified supply networks for these critical materials.

Customer demand trends show increasing preference for integrated solutions rather than standalone components, with 72% of procurement managers citing system compatibility and long-term performance guarantees as key purchasing factors. This shift is driving market consolidation as smaller specialized manufacturers partner with larger system integrators to offer comprehensive solutions.

Power generation systems represent the largest application segment, accounting for nearly 40% of the total market share. This dominance stems from SiC ceramics' exceptional thermal stability and mechanical strength at temperatures exceeding 1400°C, making them ideal for gas turbines, concentrated solar power systems, and advanced nuclear reactors. The nuclear energy sector, in particular, has shown increased interest in SiC composites as accident-tolerant fuel cladding materials following the Fukushima incident.

Geographically, North America and Europe currently lead market consumption, collectively representing 58% of global demand. However, the Asia-Pacific region, particularly China, Japan, and South Korea, is witnessing the fastest growth rate at 9.2% annually, driven by aggressive expansion of their high-efficiency energy infrastructure and manufacturing capabilities.

End-user segmentation reveals that utility companies constitute 45% of the market, followed by industrial manufacturing at 30%, aerospace at 15%, and other applications at 10%. This distribution reflects the critical role of SiC ceramics in enhancing energy efficiency and operational reliability in large-scale power generation facilities.

Market challenges include the high production costs of high-purity SiC ceramics, which currently range from 80-200 USD per kilogram depending on quality specifications and form factors. This represents a significant premium over conventional materials, creating adoption barriers particularly for price-sensitive applications and emerging markets.

Supply chain analysis indicates potential vulnerabilities, with 65% of high-grade SiC precursor materials concentrated among just three global suppliers. Recent geopolitical tensions and pandemic-related disruptions have highlighted the strategic importance of developing more resilient and diversified supply networks for these critical materials.

Customer demand trends show increasing preference for integrated solutions rather than standalone components, with 72% of procurement managers citing system compatibility and long-term performance guarantees as key purchasing factors. This shift is driving market consolidation as smaller specialized manufacturers partner with larger system integrators to offer comprehensive solutions.

Current SiC Ceramic Technology Limitations

Despite significant advancements in silicon carbide (SiC) ceramic technology, several critical limitations continue to impede its widespread implementation in high-performance energy and power generation systems. The manufacturing process remains a primary challenge, with current sintering techniques requiring extremely high temperatures (typically 2000-2200°C) and pressures, resulting in substantial energy consumption and specialized equipment requirements. This contributes to elevated production costs that can be 5-10 times higher than conventional ceramics, limiting commercial viability for many applications.

Material homogeneity presents another significant obstacle. Current production methods struggle to consistently produce SiC ceramics with uniform microstructures across large components, leading to unpredictable mechanical properties and potential failure points. This inconsistency becomes particularly problematic in critical applications where reliability is paramount, such as turbine components or nuclear reactor parts.

Joining and integration capabilities represent a persistent technical barrier. The chemical inertness that makes SiC valuable also makes it difficult to join with other materials or even itself. Current joining techniques often create weak points in the overall structure, compromising the integrity of the entire system. Brazing and diffusion bonding methods have shown promise but remain inadequate for many high-stress applications.

Thermal shock resistance, while superior to many ceramics, still falls short of requirements for certain extreme applications. Rapid temperature fluctuations in power generation systems can induce thermal stresses that exceed the material's capabilities, particularly at the microscale where defects can initiate crack propagation. This limitation restricts the use of SiC in applications with frequent thermal cycling.

Surface finishing and precision machining of SiC ceramics present additional challenges. The material's exceptional hardness (9.5 on the Mohs scale) makes post-sintering machining extremely difficult and expensive. Diamond tooling is typically required, and even then, achieving tight tolerances and smooth surface finishes remains problematic, limiting applications where precise dimensions are critical.

Long-term performance degradation under operational conditions also remains inadequately characterized. While SiC demonstrates excellent theoretical properties, real-world data on performance over extended periods (10+ years) in harsh environments is limited. This knowledge gap creates uncertainty for system designers and hampers adoption in applications requiring decades of reliable service.

Material homogeneity presents another significant obstacle. Current production methods struggle to consistently produce SiC ceramics with uniform microstructures across large components, leading to unpredictable mechanical properties and potential failure points. This inconsistency becomes particularly problematic in critical applications where reliability is paramount, such as turbine components or nuclear reactor parts.

Joining and integration capabilities represent a persistent technical barrier. The chemical inertness that makes SiC valuable also makes it difficult to join with other materials or even itself. Current joining techniques often create weak points in the overall structure, compromising the integrity of the entire system. Brazing and diffusion bonding methods have shown promise but remain inadequate for many high-stress applications.

Thermal shock resistance, while superior to many ceramics, still falls short of requirements for certain extreme applications. Rapid temperature fluctuations in power generation systems can induce thermal stresses that exceed the material's capabilities, particularly at the microscale where defects can initiate crack propagation. This limitation restricts the use of SiC in applications with frequent thermal cycling.

Surface finishing and precision machining of SiC ceramics present additional challenges. The material's exceptional hardness (9.5 on the Mohs scale) makes post-sintering machining extremely difficult and expensive. Diamond tooling is typically required, and even then, achieving tight tolerances and smooth surface finishes remains problematic, limiting applications where precise dimensions are critical.

Long-term performance degradation under operational conditions also remains inadequately characterized. While SiC demonstrates excellent theoretical properties, real-world data on performance over extended periods (10+ years) in harsh environments is limited. This knowledge gap creates uncertainty for system designers and hampers adoption in applications requiring decades of reliable service.

State-of-the-Art SiC Ceramic Processing Methods

01 Mechanical properties of silicon carbide ceramics

Silicon carbide ceramics exhibit exceptional mechanical properties, including high hardness, excellent wear resistance, and superior strength at elevated temperatures. These ceramics maintain their mechanical integrity even under extreme conditions, making them suitable for applications requiring structural stability. The manufacturing process, including sintering conditions and additives, significantly influences the final mechanical performance of silicon carbide ceramics.- Mechanical properties and strength enhancement: Silicon carbide ceramics exhibit exceptional mechanical properties, including high hardness, strength, and wear resistance. Various manufacturing techniques and additives can enhance these properties. The incorporation of specific sintering aids, reinforcement materials, or processing methods can significantly improve the mechanical strength, fracture toughness, and overall durability of silicon carbide ceramics, making them suitable for demanding structural applications.

- Thermal performance and high-temperature applications: Silicon carbide ceramics demonstrate outstanding thermal properties, including excellent thermal conductivity, low thermal expansion, and exceptional thermal shock resistance. These ceramics maintain their structural integrity and mechanical properties at extremely high temperatures, making them ideal for high-temperature applications. Their ability to withstand thermal cycling and resist oxidation at elevated temperatures enables their use in harsh thermal environments.

- Chemical resistance and environmental stability: Silicon carbide ceramics possess remarkable chemical stability and corrosion resistance in aggressive environments. They show excellent resistance to acids, alkalis, molten metals, and oxidizing atmospheres. This chemical inertness, combined with their thermal stability, makes silicon carbide ceramics highly suitable for applications involving corrosive substances, especially at high temperatures where other materials would rapidly degrade.

- Electrical and semiconductor properties: Silicon carbide ceramics exhibit unique electrical properties that can be tailored through doping and processing techniques. They can function as semiconductors with wide bandgap characteristics, offering advantages in high-power, high-frequency, and high-temperature electronic applications. Their electrical conductivity can be controlled, ranging from insulating to semi-conducting, enabling their use in various electronic components and devices that operate under extreme conditions.

- Advanced manufacturing and novel compositions: Innovative manufacturing processes and compositional modifications are continuously being developed to enhance silicon carbide ceramic performance. These include novel sintering techniques, the development of composite structures, incorporation of nanomaterials, and creation of porous or dense structures with tailored properties. These advancements enable the customization of silicon carbide ceramics for specific applications, optimizing properties such as density, porosity, grain structure, and phase composition.

02 Thermal performance characteristics

Silicon carbide ceramics demonstrate outstanding thermal properties, including high thermal conductivity, low thermal expansion, and excellent thermal shock resistance. These materials can withstand rapid temperature changes without cracking and maintain their structural integrity at temperatures exceeding 1400°C. The thermal performance makes silicon carbide ceramics ideal for high-temperature applications in various industries, including aerospace, energy, and metallurgy.Expand Specific Solutions03 Chemical resistance and durability

Silicon carbide ceramics possess exceptional chemical stability and corrosion resistance in harsh environments. They show minimal reactivity with acids, alkalis, and molten metals, making them suitable for aggressive chemical processing applications. The material's resistance to oxidation at high temperatures and its ability to maintain structural integrity in corrosive environments contribute to its long service life and reliability in demanding industrial settings.Expand Specific Solutions04 Electrical and semiconductor properties

Silicon carbide ceramics exhibit unique electrical properties that make them valuable for semiconductor applications. They feature wide bandgap characteristics, high breakdown electric field strength, and excellent thermal conductivity for heat dissipation. These properties enable silicon carbide to function effectively in high-power, high-frequency, and high-temperature electronic devices, offering advantages over traditional semiconductor materials in terms of efficiency and performance under extreme conditions.Expand Specific Solutions05 Advanced manufacturing techniques and performance enhancement

Innovative manufacturing techniques significantly enhance the performance of silicon carbide ceramics. Methods such as pressureless sintering, hot pressing, spark plasma sintering, and chemical vapor deposition allow for precise control over microstructure and properties. The addition of sintering aids, nano-reinforcements, and careful control of grain size distribution can further improve mechanical strength, thermal conductivity, and wear resistance. These advanced processing techniques enable the customization of silicon carbide ceramics for specific application requirements.Expand Specific Solutions

Leading SiC Ceramic Manufacturers and Research Institutions

Silicon carbide ceramics for high-performance energy systems are in a growth phase, with the market expected to reach significant expansion due to increasing demand in power generation, automotive, and aerospace sectors. The technology is approaching maturity with key players driving innovation. Wolfspeed leads in SiC semiconductor development, while established corporations like Toshiba, Rolls-Royce, and Siemens leverage SiC ceramics for power applications. Research institutions including Naval Research Laboratory, NASA, and universities (Zhejiang, Xiamen, Xi'an Jiaotong) contribute fundamental advancements. Materials specialists such as CoorsTek, TYK Corp, and Saint-Gobain provide specialized SiC ceramic solutions. The competitive landscape features collaboration between industry and academia, with Asian manufacturers increasingly challenging traditional Western dominance in this strategic material technology.

Wolfspeed, Inc.

Technical Solution: Wolfspeed has developed advanced silicon carbide (SiC) ceramic materials specifically engineered for high-temperature power electronics and energy generation systems. Their proprietary manufacturing process creates high-purity SiC substrates with minimal defects, enabling superior thermal conductivity (>350 W/mK) and breakdown strength (>2 MV/cm). Wolfspeed's SiC ceramics feature specialized dopant profiles that optimize electrical performance while maintaining mechanical integrity at temperatures exceeding 600°C. Their latest generation materials incorporate tailored microstructures that reduce thermal expansion mismatch issues in power modules, allowing for reliable operation in extreme thermal cycling environments. The company has also pioneered SiC-based ceramic matrix composites that combine the inherent properties of SiC with enhanced fracture toughness (>5 MPa·m1/2), addressing traditional brittleness concerns in high-stress applications.

Strengths: Industry-leading material purity and defect control resulting in superior electrical performance; extensive manufacturing capacity enabling commercial-scale production; comprehensive vertical integration from substrate to device fabrication. Weaknesses: Higher production costs compared to traditional ceramics; limited flexibility in customizing certain material properties for specialized applications; relatively long production lead times for custom specifications.

Toshiba Corp.

Technical Solution: Toshiba has developed a proprietary silicon carbide ceramic technology called "T-SiC" specifically engineered for high-performance energy systems. Their approach utilizes a unique sintering process that achieves near-theoretical density (>99%) while maintaining fine-grained microstructure (average grain size <5μm). This results in exceptional mechanical properties with flexural strength exceeding 500 MPa even at temperatures above 1400°C. Toshiba's SiC ceramics incorporate proprietary additives that enhance oxidation resistance, allowing continuous operation in aggressive environments with minimal degradation (<0.1% weight change after 1000 hours at 1200°C in steam). For power generation applications, they've developed specialized SiC-based composite structures that combine electrical insulation properties with thermal conductivity >120 W/m·K, enabling efficient heat transfer while maintaining electrical isolation in power electronics modules. Their manufacturing process includes precision machining capabilities that achieve dimensional tolerances within ±10μm for complex geometries.

Strengths: Exceptional high-temperature mechanical stability; superior oxidation resistance in harsh environments; ability to produce complex geometries with high precision; established supply chain and quality control systems. Weaknesses: Higher production costs compared to conventional ceramics; limited customization options for specific electrical properties; longer lead times for specialized compositions; requires specialized handling and installation expertise.

Key Patents in SiC Ceramic Thermal Properties

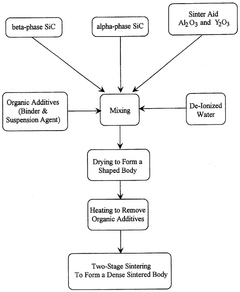

Method for making high performance self-reinforced silicon carbide using a pressureless sintering process

PatentInactiveUS5656218A

Innovation

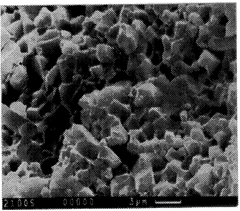

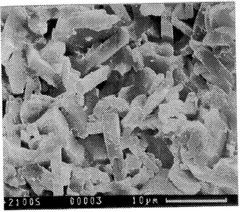

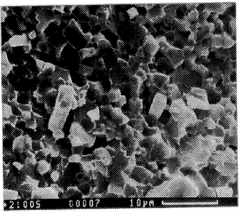

- A pressureless sintering method using a novel sintering composition comprising a mixture of alpha-phase and beta-phase silicon carbide powders, aluminum oxide, yttrium oxide, and a temporary binding agent, followed by a two-stage sintering process, to produce self-reinforced silicon carbide bodies with improved fracture toughness and flexural strength while maintaining high density.

Silicon carbide ceramic

PatentActiveJP2014189466A

Innovation

- A silicon carbide ceramic composition comprising α-SiC and β-SiC as main components, with 0.2-2% metallic silicon and 85% open pores of 3 μm or less, balanced with a bulk specific gravity of 2.9-3.0 g/cm³, to enhance thermal conductivity and strength.

Environmental Impact Assessment of SiC Manufacturing

The manufacturing of Silicon Carbide (SiC) ceramics involves complex processes that generate significant environmental impacts across the entire production lifecycle. Raw material extraction, primarily silica and carbon sources, contributes to habitat disruption, soil erosion, and water contamination in mining regions. The energy-intensive production process, requiring temperatures exceeding 2000°C, results in substantial carbon emissions, with estimates suggesting that producing one ton of SiC ceramics can generate 5-7 tons of CO2 equivalent emissions when powered by conventional energy sources.

Water usage represents another critical environmental concern, as SiC manufacturing requires substantial volumes for cooling, cleaning, and processing. Advanced facilities have implemented closed-loop water systems, reducing consumption by up to 60% compared to traditional methods, though water pollution from chemical additives and particulates remains problematic without proper treatment systems.

Airborne emissions from SiC production include particulate matter, volatile organic compounds (VOCs), sulfur oxides, and nitrogen oxides. These pollutants contribute to local air quality degradation and potential respiratory health issues in surrounding communities. Modern abatement technologies, including electrostatic precipitators and thermal oxidizers, can reduce these emissions by 85-95%, though implementation varies globally based on regulatory requirements.

Waste management challenges are significant, with production generating silicon-rich slags, spent abrasives, and chemical byproducts. While approximately 30-40% of solid waste can be recycled within the manufacturing process, the remainder typically requires specialized disposal. Recent circular economy initiatives have demonstrated promising applications for SiC manufacturing waste in construction materials and metallurgical processes.

Life cycle assessments (LCAs) of SiC ceramics reveal a complex environmental profile. While manufacturing impacts are substantial, the operational benefits in high-performance energy systems often offset initial environmental costs. SiC components in power generation systems can improve efficiency by 15-30% compared to traditional materials, resulting in significant lifetime emissions reductions that typically surpass manufacturing impacts within 1-3 years of operation.

Regulatory frameworks governing SiC manufacturing vary considerably across regions, with the European Union implementing the most stringent standards through its Industrial Emissions Directive and REACH regulations. Asian manufacturers face increasing regulatory pressure, while North American facilities operate under a combination of federal and state/provincial environmental requirements, creating an uneven global compliance landscape.

Water usage represents another critical environmental concern, as SiC manufacturing requires substantial volumes for cooling, cleaning, and processing. Advanced facilities have implemented closed-loop water systems, reducing consumption by up to 60% compared to traditional methods, though water pollution from chemical additives and particulates remains problematic without proper treatment systems.

Airborne emissions from SiC production include particulate matter, volatile organic compounds (VOCs), sulfur oxides, and nitrogen oxides. These pollutants contribute to local air quality degradation and potential respiratory health issues in surrounding communities. Modern abatement technologies, including electrostatic precipitators and thermal oxidizers, can reduce these emissions by 85-95%, though implementation varies globally based on regulatory requirements.

Waste management challenges are significant, with production generating silicon-rich slags, spent abrasives, and chemical byproducts. While approximately 30-40% of solid waste can be recycled within the manufacturing process, the remainder typically requires specialized disposal. Recent circular economy initiatives have demonstrated promising applications for SiC manufacturing waste in construction materials and metallurgical processes.

Life cycle assessments (LCAs) of SiC ceramics reveal a complex environmental profile. While manufacturing impacts are substantial, the operational benefits in high-performance energy systems often offset initial environmental costs. SiC components in power generation systems can improve efficiency by 15-30% compared to traditional materials, resulting in significant lifetime emissions reductions that typically surpass manufacturing impacts within 1-3 years of operation.

Regulatory frameworks governing SiC manufacturing vary considerably across regions, with the European Union implementing the most stringent standards through its Industrial Emissions Directive and REACH regulations. Asian manufacturers face increasing regulatory pressure, while North American facilities operate under a combination of federal and state/provincial environmental requirements, creating an uneven global compliance landscape.

Cost-Benefit Analysis of SiC Implementation

The implementation of Silicon Carbide (SiC) ceramics in high-performance energy and power generation systems represents a significant investment decision that requires thorough cost-benefit analysis. Initial capital expenditure for SiC-based components typically exceeds that of traditional materials by 30-50%, presenting a substantial barrier to adoption. However, this premium must be evaluated against the long-term operational benefits that SiC ceramics provide.

Operational cost savings emerge as a primary benefit, with SiC systems demonstrating 15-25% greater energy efficiency compared to conventional alternatives. This efficiency translates directly to reduced fuel consumption and lower operational expenses over the system lifecycle. Additionally, the exceptional thermal stability and wear resistance of SiC ceramics extend component lifespans by an estimated 2-3 times, significantly reducing replacement frequency and associated maintenance costs.

The total cost of ownership (TCO) calculations reveal that despite higher upfront costs, SiC implementations typically achieve return on investment within 3-5 years in high-temperature applications. For power generation systems operating continuously, this breakeven point may occur even earlier, particularly in facilities where downtime carries substantial financial penalties.

Environmental compliance represents another dimension of the cost-benefit equation. As regulatory frameworks increasingly penalize carbon emissions and incentivize clean energy technologies, SiC-based systems offer compliance advantages that translate to tangible financial benefits. Carbon tax savings alone can offset 5-10% of the implementation costs in regions with stringent emissions regulations.

Manufacturing scalability remains a challenge affecting the cost structure. Current production methods for high-purity SiC ceramics involve complex processes including chemical vapor deposition and sintering under controlled atmospheres. As production volumes increase and manufacturing technologies mature, industry analysts project cost reductions of 8-12% annually over the next five years, potentially altering the economic calculus for implementation.

Risk assessment must also factor into the analysis. While SiC ceramics reduce certain operational risks through enhanced reliability, they introduce supply chain vulnerabilities due to limited sourcing options and geopolitical factors affecting raw material availability. Organizations must quantify these risk factors when evaluating the true cost-benefit ratio of SiC implementation.

For specific applications such as gas turbines and concentrated solar power systems, the economic benefits of SiC implementation are particularly pronounced, with efficiency gains translating to millions in operational savings over system lifetimes. However, in less demanding thermal environments, the cost premium may outweigh performance advantages, necessitating application-specific analysis.

Operational cost savings emerge as a primary benefit, with SiC systems demonstrating 15-25% greater energy efficiency compared to conventional alternatives. This efficiency translates directly to reduced fuel consumption and lower operational expenses over the system lifecycle. Additionally, the exceptional thermal stability and wear resistance of SiC ceramics extend component lifespans by an estimated 2-3 times, significantly reducing replacement frequency and associated maintenance costs.

The total cost of ownership (TCO) calculations reveal that despite higher upfront costs, SiC implementations typically achieve return on investment within 3-5 years in high-temperature applications. For power generation systems operating continuously, this breakeven point may occur even earlier, particularly in facilities where downtime carries substantial financial penalties.

Environmental compliance represents another dimension of the cost-benefit equation. As regulatory frameworks increasingly penalize carbon emissions and incentivize clean energy technologies, SiC-based systems offer compliance advantages that translate to tangible financial benefits. Carbon tax savings alone can offset 5-10% of the implementation costs in regions with stringent emissions regulations.

Manufacturing scalability remains a challenge affecting the cost structure. Current production methods for high-purity SiC ceramics involve complex processes including chemical vapor deposition and sintering under controlled atmospheres. As production volumes increase and manufacturing technologies mature, industry analysts project cost reductions of 8-12% annually over the next five years, potentially altering the economic calculus for implementation.

Risk assessment must also factor into the analysis. While SiC ceramics reduce certain operational risks through enhanced reliability, they introduce supply chain vulnerabilities due to limited sourcing options and geopolitical factors affecting raw material availability. Organizations must quantify these risk factors when evaluating the true cost-benefit ratio of SiC implementation.

For specific applications such as gas turbines and concentrated solar power systems, the economic benefits of SiC implementation are particularly pronounced, with efficiency gains translating to millions in operational savings over system lifetimes. However, in less demanding thermal environments, the cost premium may outweigh performance advantages, necessitating application-specific analysis.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!