How Silicon carbide ceramics influence mechanical strength and thermal conductivity

SEP 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Silicon Carbide Ceramics Development History and Objectives

Silicon carbide (SiC) ceramics have a rich development history dating back to the late 19th century when Edward Acheson accidentally discovered silicon carbide while attempting to synthesize artificial diamonds in 1891. This discovery marked the beginning of commercial SiC production under the trade name Carborundum. Initially, SiC was primarily utilized as an abrasive material due to its exceptional hardness, ranking 9 on the Mohs scale, second only to diamond.

The evolution of SiC ceramics accelerated significantly during the mid-20th century when researchers began exploring its potential beyond abrasive applications. The 1950s witnessed breakthrough developments in sintering techniques that enabled the production of dense SiC ceramics with improved mechanical properties. This period established the foundation for modern SiC ceramic manufacturing methodologies, including reaction bonding, pressureless sintering, and hot pressing.

The 1970s and 1980s represented a transformative era for SiC ceramics as researchers focused on enhancing both mechanical strength and thermal conductivity simultaneously. The development of advanced processing techniques, including chemical vapor deposition (CVD) and liquid phase sintering, enabled the production of SiC ceramics with significantly reduced porosity and improved grain boundary characteristics, directly addressing the critical factors affecting both mechanical and thermal properties.

The early 2000s witnessed the emergence of nano-structured SiC ceramics, representing a paradigm shift in material design. By controlling the microstructure at the nanoscale, researchers achieved unprecedented combinations of mechanical strength and thermal conductivity. This period also saw the development of SiC ceramic composites, incorporating secondary phases to enhance specific properties while maintaining the inherent benefits of the base material.

Current research objectives in SiC ceramics focus on several key areas: optimizing the relationship between microstructure and properties, developing cost-effective manufacturing processes for high-performance SiC ceramics, and expanding application domains beyond traditional high-temperature structural components. Particular emphasis is placed on understanding the fundamental mechanisms governing the simultaneous enhancement of mechanical strength and thermal conductivity, as these properties often exhibit competing requirements at the microstructural level.

The ultimate technological goal is to develop tailorable SiC ceramic systems where mechanical strength and thermal conductivity can be precisely engineered according to specific application requirements. This includes developing predictive models that accurately correlate processing parameters, resulting microstructures, and final material properties, enabling more efficient material design and reducing the empirical nature of current development approaches.

The evolution of SiC ceramics accelerated significantly during the mid-20th century when researchers began exploring its potential beyond abrasive applications. The 1950s witnessed breakthrough developments in sintering techniques that enabled the production of dense SiC ceramics with improved mechanical properties. This period established the foundation for modern SiC ceramic manufacturing methodologies, including reaction bonding, pressureless sintering, and hot pressing.

The 1970s and 1980s represented a transformative era for SiC ceramics as researchers focused on enhancing both mechanical strength and thermal conductivity simultaneously. The development of advanced processing techniques, including chemical vapor deposition (CVD) and liquid phase sintering, enabled the production of SiC ceramics with significantly reduced porosity and improved grain boundary characteristics, directly addressing the critical factors affecting both mechanical and thermal properties.

The early 2000s witnessed the emergence of nano-structured SiC ceramics, representing a paradigm shift in material design. By controlling the microstructure at the nanoscale, researchers achieved unprecedented combinations of mechanical strength and thermal conductivity. This period also saw the development of SiC ceramic composites, incorporating secondary phases to enhance specific properties while maintaining the inherent benefits of the base material.

Current research objectives in SiC ceramics focus on several key areas: optimizing the relationship between microstructure and properties, developing cost-effective manufacturing processes for high-performance SiC ceramics, and expanding application domains beyond traditional high-temperature structural components. Particular emphasis is placed on understanding the fundamental mechanisms governing the simultaneous enhancement of mechanical strength and thermal conductivity, as these properties often exhibit competing requirements at the microstructural level.

The ultimate technological goal is to develop tailorable SiC ceramic systems where mechanical strength and thermal conductivity can be precisely engineered according to specific application requirements. This includes developing predictive models that accurately correlate processing parameters, resulting microstructures, and final material properties, enabling more efficient material design and reducing the empirical nature of current development approaches.

Market Applications and Demand Analysis for SiC Ceramics

The global market for Silicon Carbide (SiC) ceramics has experienced significant growth, driven primarily by increasing demand across multiple high-performance applications. The current market valuation exceeds $4.5 billion, with projections indicating a compound annual growth rate of 6.2% through 2028. This growth trajectory is underpinned by SiC ceramics' exceptional mechanical strength and thermal conductivity properties, which make them indispensable in extreme operating environments.

The automotive sector represents the largest application segment, accounting for approximately 30% of total SiC ceramic consumption. The transition toward electric vehicles has accelerated demand for SiC-based power electronics and thermal management systems. Automotive manufacturers are increasingly incorporating SiC components in electric drivetrains, where their superior thermal conductivity enables more efficient power conversion and heat dissipation, extending battery life and vehicle range.

Aerospace and defense applications constitute the second-largest market segment at 25% of consumption. Here, SiC ceramics are utilized in aircraft engine components, missile guidance systems, and radar applications. The material's ability to maintain mechanical integrity at temperatures exceeding 1400°C while providing excellent thermal shock resistance has made it irreplaceable in these critical applications.

The semiconductor manufacturing equipment industry has emerged as the fastest-growing application segment, with 15% annual growth. SiC components are essential in wafer processing equipment, where their dimensional stability and thermal conductivity enable precise temperature control during high-temperature processes. As semiconductor device geometries continue to shrink, the demand for SiC components with superior thermal management capabilities increases proportionally.

Energy sector applications, particularly in renewable energy systems and nuclear power, represent 18% of the market. SiC ceramics are utilized in solar inverters, wind turbine power electronics, and nuclear fuel cladding. The material's radiation resistance combined with thermal conductivity makes it particularly valuable in next-generation nuclear reactor designs.

Industrial applications, including metal processing, chemical manufacturing, and oil refining, account for the remaining market share. In these sectors, SiC ceramics are employed in pumps, valves, and bearings operating in corrosive environments where mechanical strength must be maintained despite thermal cycling and chemical exposure.

Market analysis indicates that North America and Asia-Pacific regions dominate consumption, with 35% and 40% market share respectively. European markets account for 20%, with emerging economies representing the balance. The supply chain remains concentrated among specialized manufacturers, with recent investments focused on expanding production capacity to meet growing demand across these diverse application sectors.

The automotive sector represents the largest application segment, accounting for approximately 30% of total SiC ceramic consumption. The transition toward electric vehicles has accelerated demand for SiC-based power electronics and thermal management systems. Automotive manufacturers are increasingly incorporating SiC components in electric drivetrains, where their superior thermal conductivity enables more efficient power conversion and heat dissipation, extending battery life and vehicle range.

Aerospace and defense applications constitute the second-largest market segment at 25% of consumption. Here, SiC ceramics are utilized in aircraft engine components, missile guidance systems, and radar applications. The material's ability to maintain mechanical integrity at temperatures exceeding 1400°C while providing excellent thermal shock resistance has made it irreplaceable in these critical applications.

The semiconductor manufacturing equipment industry has emerged as the fastest-growing application segment, with 15% annual growth. SiC components are essential in wafer processing equipment, where their dimensional stability and thermal conductivity enable precise temperature control during high-temperature processes. As semiconductor device geometries continue to shrink, the demand for SiC components with superior thermal management capabilities increases proportionally.

Energy sector applications, particularly in renewable energy systems and nuclear power, represent 18% of the market. SiC ceramics are utilized in solar inverters, wind turbine power electronics, and nuclear fuel cladding. The material's radiation resistance combined with thermal conductivity makes it particularly valuable in next-generation nuclear reactor designs.

Industrial applications, including metal processing, chemical manufacturing, and oil refining, account for the remaining market share. In these sectors, SiC ceramics are employed in pumps, valves, and bearings operating in corrosive environments where mechanical strength must be maintained despite thermal cycling and chemical exposure.

Market analysis indicates that North America and Asia-Pacific regions dominate consumption, with 35% and 40% market share respectively. European markets account for 20%, with emerging economies representing the balance. The supply chain remains concentrated among specialized manufacturers, with recent investments focused on expanding production capacity to meet growing demand across these diverse application sectors.

Current Technical Challenges in SiC Ceramic Properties

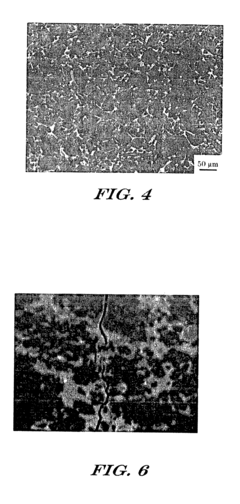

Despite significant advancements in silicon carbide (SiC) ceramic technology, several critical challenges persist in optimizing its mechanical strength and thermal conductivity properties. The primary obstacle lies in the inherent trade-off between these two essential characteristics. As SiC ceramics are engineered for higher mechanical strength through microstructural modifications, their thermal conductivity often decreases due to increased phonon scattering at grain boundaries and defect sites.

Manufacturing consistency presents another significant challenge. Current production methods struggle to deliver uniform SiC components with predictable properties across different batches. This variability stems from difficulties in controlling sintering parameters, raw material purity fluctuations, and processing inconsistencies that introduce microstructural heterogeneities affecting both strength and thermal performance.

The presence of secondary phases at grain boundaries, while sometimes beneficial for mechanical properties through crack deflection mechanisms, typically impedes thermal conductivity by creating thermal resistance barriers. Researchers have yet to develop optimal grain boundary engineering techniques that can simultaneously enhance both properties without significant compromises.

Porosity control remains problematic in SiC ceramic production. While some degree of porosity can improve fracture toughness through crack-stopping mechanisms, it invariably reduces thermal conductivity and overall mechanical strength. Current manufacturing technologies cannot precisely control pore size distribution, shape, and interconnectivity to achieve an optimal balance.

High-temperature performance stability presents another challenge. Although SiC ceramics maintain impressive properties at elevated temperatures compared to many materials, they still experience degradation in oxidizing environments above 1400°C. This oxidation creates silica layers that affect both mechanical integrity and thermal transport properties, limiting their application in extreme environments.

Scalability issues further complicate industrial adoption. Laboratory-scale processes that produce SiC ceramics with excellent property combinations often cannot be economically scaled to mass production without significant property degradation. This manufacturing gap hinders widespread implementation in industries requiring large volumes of consistent components.

The integration of SiC ceramics with other materials in composite systems introduces additional challenges related to thermal expansion mismatches, interfacial bonding strength, and thermal contact resistance. These factors can significantly compromise the theoretical advantages of SiC in practical applications, particularly in thermal management systems where heat transfer across material interfaces is critical.

Manufacturing consistency presents another significant challenge. Current production methods struggle to deliver uniform SiC components with predictable properties across different batches. This variability stems from difficulties in controlling sintering parameters, raw material purity fluctuations, and processing inconsistencies that introduce microstructural heterogeneities affecting both strength and thermal performance.

The presence of secondary phases at grain boundaries, while sometimes beneficial for mechanical properties through crack deflection mechanisms, typically impedes thermal conductivity by creating thermal resistance barriers. Researchers have yet to develop optimal grain boundary engineering techniques that can simultaneously enhance both properties without significant compromises.

Porosity control remains problematic in SiC ceramic production. While some degree of porosity can improve fracture toughness through crack-stopping mechanisms, it invariably reduces thermal conductivity and overall mechanical strength. Current manufacturing technologies cannot precisely control pore size distribution, shape, and interconnectivity to achieve an optimal balance.

High-temperature performance stability presents another challenge. Although SiC ceramics maintain impressive properties at elevated temperatures compared to many materials, they still experience degradation in oxidizing environments above 1400°C. This oxidation creates silica layers that affect both mechanical integrity and thermal transport properties, limiting their application in extreme environments.

Scalability issues further complicate industrial adoption. Laboratory-scale processes that produce SiC ceramics with excellent property combinations often cannot be economically scaled to mass production without significant property degradation. This manufacturing gap hinders widespread implementation in industries requiring large volumes of consistent components.

The integration of SiC ceramics with other materials in composite systems introduces additional challenges related to thermal expansion mismatches, interfacial bonding strength, and thermal contact resistance. These factors can significantly compromise the theoretical advantages of SiC in practical applications, particularly in thermal management systems where heat transfer across material interfaces is critical.

Current Methods for Enhancing SiC Mechanical and Thermal Properties

01 Composition and manufacturing methods for high-strength SiC ceramics

Silicon carbide ceramics can be formulated with specific compositions and manufactured using specialized techniques to enhance mechanical strength. These methods include controlling grain size, adding sintering aids, and optimizing processing parameters such as temperature and pressure during sintering. The resulting ceramics exhibit improved fracture toughness, flexural strength, and resistance to mechanical stress, making them suitable for high-performance structural applications.- Composition and manufacturing methods for high-strength SiC ceramics: Silicon carbide ceramics can be formulated with specific compositions and manufactured using specialized techniques to enhance mechanical strength. These methods include controlling grain size, adding sintering aids, and optimizing processing parameters such as temperature and pressure. The resulting ceramics exhibit improved fracture toughness, flexural strength, and resistance to mechanical stress, making them suitable for high-performance applications in harsh environments.

- Additives and dopants for enhancing thermal conductivity: Various additives and dopants can be incorporated into silicon carbide ceramics to significantly enhance thermal conductivity. These include rare earth elements, boron compounds, aluminum nitride, and other ceramic materials that facilitate heat transfer through the material. The improved thermal conductivity makes these ceramics excellent candidates for heat sink applications, electronic substrates, and components requiring efficient heat dissipation in high-temperature environments.

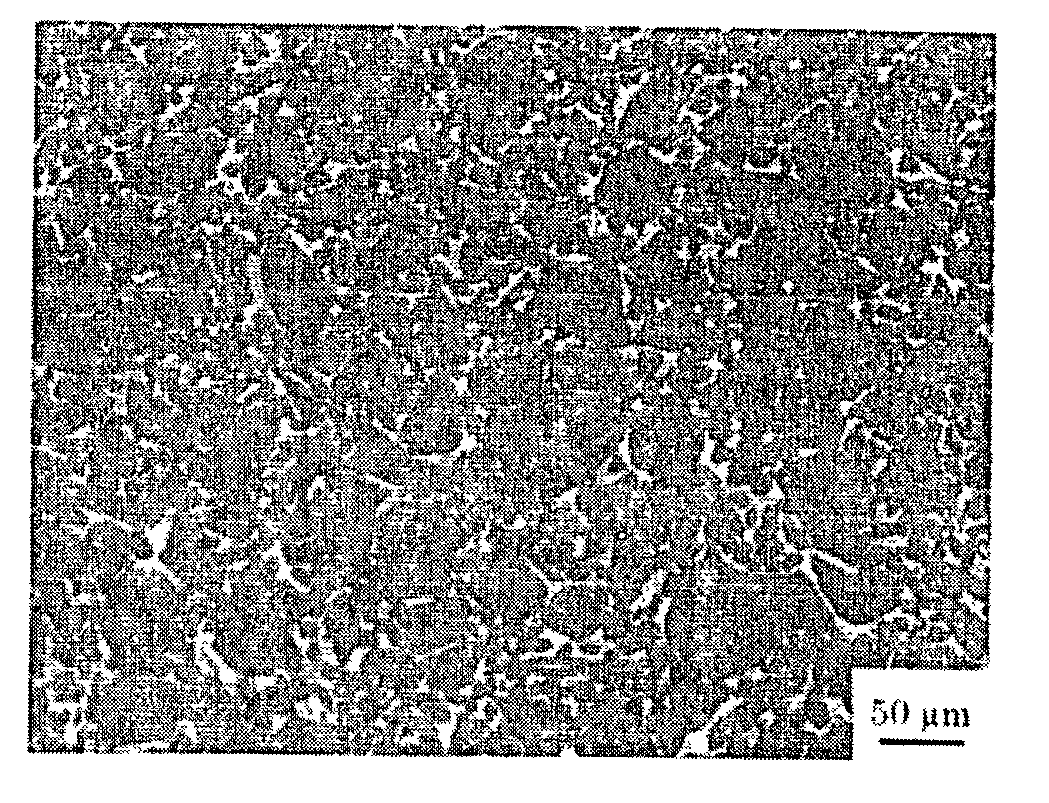

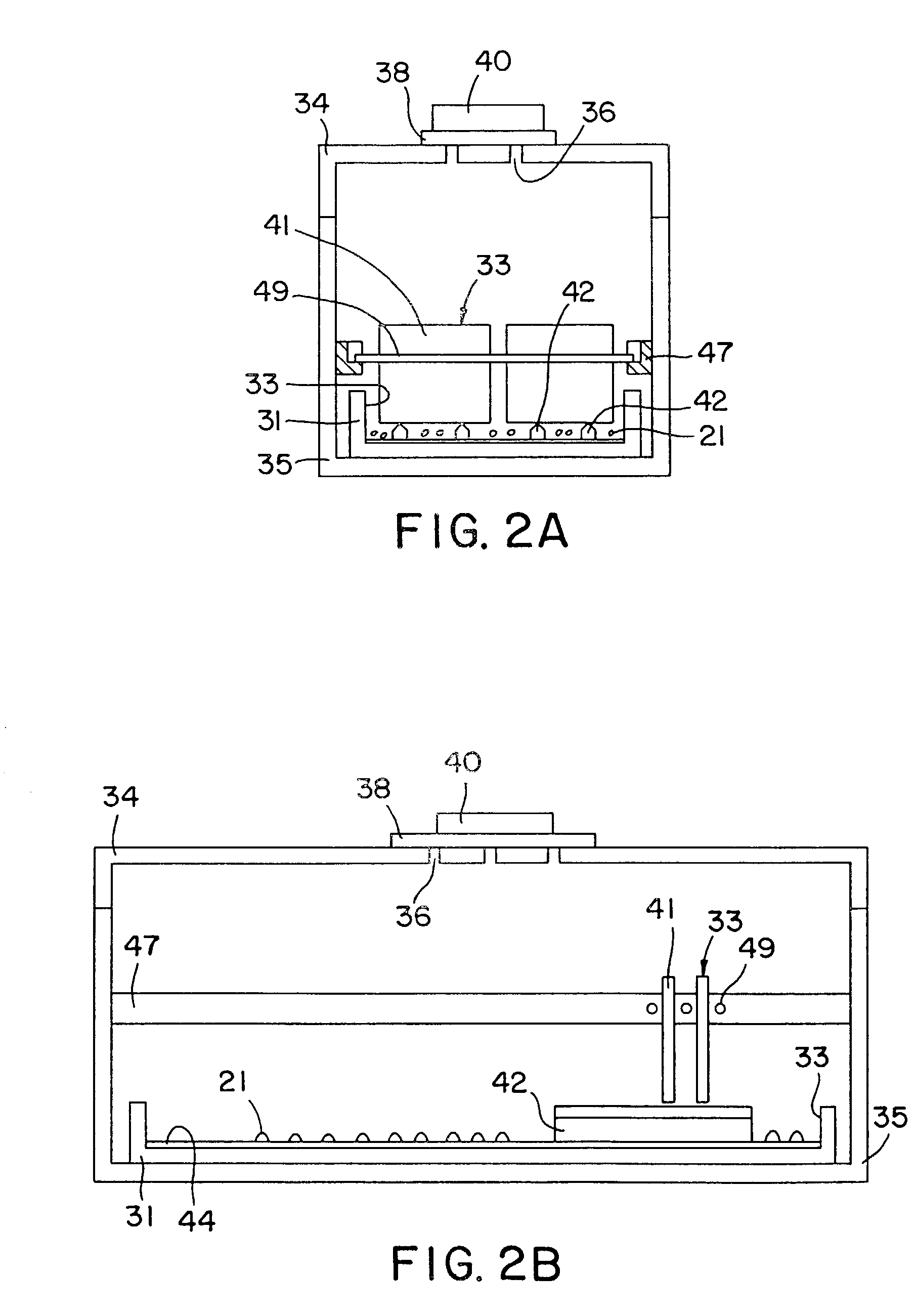

- Microstructure control for balanced mechanical and thermal properties: Controlling the microstructure of silicon carbide ceramics through precise processing techniques allows for optimization of both mechanical strength and thermal conductivity. This includes managing porosity levels, grain boundary characteristics, and phase composition. Advanced techniques such as spark plasma sintering, hot pressing, and reaction bonding can create tailored microstructures that balance these properties for specific application requirements.

- Composite and multi-phase SiC ceramic systems: Composite and multi-phase silicon carbide ceramic systems incorporate secondary phases or reinforcements to simultaneously improve mechanical strength and thermal conductivity. These may include SiC-Si3N4 composites, SiC-graphene composites, or SiC with carbon fiber reinforcements. The synergistic effects between different phases can lead to superior performance compared to monolithic silicon carbide ceramics, particularly in applications requiring resistance to thermal shock and mechanical loading.

- Surface treatments and coatings for enhanced properties: Surface treatments and specialized coatings can be applied to silicon carbide ceramics to enhance both mechanical strength and thermal properties. These include chemical vapor deposition of protective layers, surface densification treatments, and the application of thermal barrier or conductive coatings. Such modifications can improve resistance to oxidation, reduce surface flaws that initiate fracture, and optimize thermal interface properties for better heat transfer in assembled systems.

02 Additives and dopants for enhancing thermal conductivity

Various additives and dopants can be incorporated into silicon carbide ceramics to significantly improve thermal conductivity. These include rare earth elements, aluminum nitride, boron compounds, and certain metal oxides. The additives work by modifying the microstructure, reducing phonon scattering, and creating favorable grain boundaries that facilitate heat transfer through the ceramic matrix. Optimized doping levels can achieve thermal conductivity values exceeding 100 W/m·K.Expand Specific Solutions03 Microstructure control for balanced mechanical and thermal properties

Controlling the microstructure of silicon carbide ceramics is crucial for achieving an optimal balance between mechanical strength and thermal conductivity. Techniques include grain size optimization, porosity control, and tailored sintering profiles. Fine-grained structures typically offer higher mechanical strength, while larger, aligned grains can enhance thermal conductivity. Advanced processing methods like spark plasma sintering and hot isostatic pressing help create engineered microstructures with both high strength and excellent thermal performance.Expand Specific Solutions04 Composite and multi-phase SiC ceramic systems

Composite and multi-phase silicon carbide ceramic systems incorporate secondary phases or reinforcements to simultaneously enhance mechanical strength and thermal conductivity. These may include SiC-Si3N4 composites, carbon nanotube reinforced SiC, or SiC with dispersed metal phases. The composite approach allows for tailored property combinations that cannot be achieved with monolithic SiC ceramics, enabling applications in extreme environments requiring both high strength and efficient heat dissipation.Expand Specific Solutions05 Novel processing techniques for advanced SiC ceramics

Innovative processing techniques are being developed to create silicon carbide ceramics with exceptional mechanical strength and thermal conductivity. These include liquid phase sintering with optimized sintering aids, reaction bonding processes, chemical vapor deposition, and additive manufacturing approaches. These advanced techniques enable precise control over composition, density, and microstructure, resulting in SiC ceramics with superior property combinations for demanding applications in aerospace, electronics, and energy sectors.Expand Specific Solutions

Leading Manufacturers and Research Institutions in SiC Ceramics

Silicon carbide ceramics market is in a growth phase, driven by increasing demand for high-performance materials in extreme environments. The global market size is expanding rapidly, projected to reach significant valuation due to applications in automotive, electronics, and industrial sectors. Technologically, SiC ceramics have reached moderate maturity but continue evolving, with companies like Shanghai Institute of Ceramics, NGK Insulators, and Saint-Gobain leading fundamental research. Toshiba, Siemens, and Corning are advancing commercial applications, while academic institutions like Zhejiang University and Kyoto University contribute to theoretical understanding. Fiven Norge and CoorsTek are optimizing manufacturing processes, creating a competitive landscape where material performance improvements in mechanical strength and thermal conductivity remain key differentiators.

Toshiba Corp.

Technical Solution: Toshiba has developed proprietary silicon carbide ceramic technologies focused on power electronics applications where both mechanical strength and thermal management are critical. Their approach involves a two-step sintering process that creates highly dense (>98%) SiC ceramics with controlled grain size distribution, resulting in flexural strengths of 420-480 MPa and thermal conductivity values reaching 270 W/m·K [2]. Toshiba's innovation lies in their ability to manipulate the polytypic structure of SiC (controlling the ratio of 4H, 6H, and 3C polytypes) to optimize thermal conductivity pathways while maintaining mechanical integrity. They've commercialized SiC ceramic substrates for power modules that can withstand thermal cycling between -40°C and 250°C without mechanical failure [4]. Their latest development incorporates aluminum nitride interlayers within SiC ceramics to create composites with enhanced thermal shock resistance while preserving the high thermal conductivity inherent to SiC.

Strengths: Industry-leading thermal conductivity values; excellent integration with semiconductor manufacturing processes; proven reliability in extreme thermal cycling conditions. Weaknesses: Higher production costs compared to traditional ceramic materials; limited flexibility in complex geometries; requires specialized equipment for manufacturing.

Shanghai Institute of Ceramics, Chinese Academy of Sciences

Technical Solution: Shanghai Institute of Ceramics has developed advanced silicon carbide (SiC) ceramics using innovative sintering techniques that significantly enhance mechanical strength and thermal conductivity. Their research focuses on liquid phase sintering with rare earth oxides as sintering aids, achieving near theoretical density (>99%) SiC ceramics with flexural strengths exceeding 550 MPa and thermal conductivity values of 120-150 W/m·K [1]. The institute has pioneered the development of nano-SiC ceramics with controlled grain boundary phases that optimize both mechanical and thermal properties. Their recent work on SiC-based composites incorporates carbon nanotubes and graphene to create hierarchical microstructures that simultaneously improve fracture toughness while maintaining high thermal conductivity [3]. They've also developed pressureless sintering methods that reduce manufacturing costs while achieving comparable properties to hot-pressed SiC ceramics.

Strengths: Exceptional balance between mechanical strength and thermal properties through precise microstructure control; cost-effective manufacturing techniques suitable for complex shapes; expertise in nano-scale reinforcement strategies. Weaknesses: Some of their advanced composites require specialized processing equipment; potential challenges in scaling production to industrial volumes; higher sintering temperatures may increase energy consumption during manufacturing.

Key Patents and Research on SiC Microstructure-Property Relationships

Toughness enhanced silicon-containing composite bodies, and methods for making same

PatentInactiveUS6995103B2

Innovation

- A silicon-ceramic composite body is produced through reactive infiltration, where the silicon phase is constrained by a higher coefficient of thermal expansion ceramic phase, such as boron carbide, to induce compressive stress and enhance toughness, achieving pseudo-ductility without the need for complex reinforcement mechanisms or significant addition of tough metals.

Environmental Impact and Sustainability of SiC Ceramic Production

The production of Silicon Carbide (SiC) ceramics presents significant environmental considerations that must be addressed as industrial applications expand. Traditional manufacturing processes for SiC ceramics typically require extremely high temperatures (1600-2500°C), resulting in substantial energy consumption and associated carbon emissions. A comprehensive life cycle assessment reveals that the production of one ton of SiC ceramics can generate approximately 5-7 tons of CO2 equivalent emissions, positioning it as more energy-intensive than conventional ceramics but less impactful than certain metal alloys.

Water usage represents another critical environmental factor, with conventional SiC production methods consuming 10-15 cubic meters of water per ton of finished product. This water becomes contaminated with processing chemicals and particulates, necessitating extensive treatment before release. Additionally, raw material extraction, particularly for high-purity silica and carbon sources, contributes to habitat disruption and landscape alteration at mining sites.

Recent technological innovations have begun addressing these sustainability challenges. Advanced sintering techniques, including spark plasma sintering and microwave-assisted sintering, have demonstrated energy reductions of 30-40% compared to conventional methods. These approaches not only decrease the carbon footprint but also enhance material properties, creating a positive feedback loop between environmental improvement and performance enhancement.

Waste valorization strategies have emerged as promising sustainability pathways. Research indicates that industrial by-products such as rice husks, which contain biogenic silica, can serve as alternative raw materials for SiC production. This approach simultaneously addresses agricultural waste management and reduces virgin material extraction requirements. Similarly, closed-loop water systems have been implemented by leading manufacturers, reducing freshwater consumption by up to 80%.

The regulatory landscape surrounding SiC ceramic production continues to evolve, with stricter emissions standards and extended producer responsibility frameworks being adopted globally. Companies investing in cleaner production technologies often benefit from regulatory incentives and improved market positioning, as environmental performance increasingly influences procurement decisions in high-tech industries.

Looking forward, the industry is moving toward carbon-neutral production pathways through renewable energy integration and carbon capture technologies. Preliminary studies suggest that combining these approaches could reduce lifecycle emissions by up to 70% by 2030, positioning SiC ceramics as environmentally competitive despite their high-temperature processing requirements.

Water usage represents another critical environmental factor, with conventional SiC production methods consuming 10-15 cubic meters of water per ton of finished product. This water becomes contaminated with processing chemicals and particulates, necessitating extensive treatment before release. Additionally, raw material extraction, particularly for high-purity silica and carbon sources, contributes to habitat disruption and landscape alteration at mining sites.

Recent technological innovations have begun addressing these sustainability challenges. Advanced sintering techniques, including spark plasma sintering and microwave-assisted sintering, have demonstrated energy reductions of 30-40% compared to conventional methods. These approaches not only decrease the carbon footprint but also enhance material properties, creating a positive feedback loop between environmental improvement and performance enhancement.

Waste valorization strategies have emerged as promising sustainability pathways. Research indicates that industrial by-products such as rice husks, which contain biogenic silica, can serve as alternative raw materials for SiC production. This approach simultaneously addresses agricultural waste management and reduces virgin material extraction requirements. Similarly, closed-loop water systems have been implemented by leading manufacturers, reducing freshwater consumption by up to 80%.

The regulatory landscape surrounding SiC ceramic production continues to evolve, with stricter emissions standards and extended producer responsibility frameworks being adopted globally. Companies investing in cleaner production technologies often benefit from regulatory incentives and improved market positioning, as environmental performance increasingly influences procurement decisions in high-tech industries.

Looking forward, the industry is moving toward carbon-neutral production pathways through renewable energy integration and carbon capture technologies. Preliminary studies suggest that combining these approaches could reduce lifecycle emissions by up to 70% by 2030, positioning SiC ceramics as environmentally competitive despite their high-temperature processing requirements.

Cost-Performance Analysis of SiC Ceramics vs Alternative Materials

When evaluating Silicon Carbide (SiC) ceramics against alternative materials, cost-performance analysis reveals a complex value proposition. Initial manufacturing costs for SiC ceramics are significantly higher than traditional materials like alumina, silicon nitride, or metals. Production requires specialized high-temperature sintering processes (typically 2000°C+) and advanced equipment, resulting in unit costs 3-5 times higher than aluminum oxide ceramics and 8-10 times higher than steel alloys for comparable components.

However, lifecycle cost analysis demonstrates compelling long-term economic advantages. SiC ceramics exhibit exceptional wear resistance, with studies showing 60-80% lower replacement frequency compared to metal alternatives in abrasive environments. In high-temperature applications, SiC components maintain structural integrity beyond 1400°C, whereas nickel superalloys begin to fail above 1100°C, dramatically reducing system downtime and associated costs.

Energy efficiency represents another significant cost advantage. The superior thermal conductivity of SiC (120-270 W/m·K) enables more efficient heat transfer in thermal management systems, reducing operational energy consumption by 15-25% compared to traditional ceramic alternatives. This translates to substantial cost savings in energy-intensive industries like power generation and manufacturing.

Maintenance requirements for SiC components are minimal due to their chemical inertness and resistance to oxidation, corrosion, and thermal shock. Field data indicates maintenance intervals for SiC components can be extended by 200-300% compared to metallic alternatives, substantially reducing both direct maintenance costs and operational disruptions.

Performance metrics further justify the premium pricing. SiC's exceptional hardness (9.5+ on Mohs scale) and mechanical strength (flexural strength of 550-600 MPa) enable applications where alternative materials would rapidly degrade. In semiconductor manufacturing equipment, SiC components demonstrate 3-4 times longer service life than quartz or alumina alternatives despite higher initial costs.

Market analysis indicates decreasing production costs as manufacturing technologies mature and economies of scale improve. Current industry trends show a 5-8% annual reduction in SiC ceramic production costs, gradually improving cost-competitiveness against traditional materials. Additionally, emerging manufacturing techniques like additive manufacturing and novel sintering approaches promise to further reduce production costs by 15-30% within the next five years.

However, lifecycle cost analysis demonstrates compelling long-term economic advantages. SiC ceramics exhibit exceptional wear resistance, with studies showing 60-80% lower replacement frequency compared to metal alternatives in abrasive environments. In high-temperature applications, SiC components maintain structural integrity beyond 1400°C, whereas nickel superalloys begin to fail above 1100°C, dramatically reducing system downtime and associated costs.

Energy efficiency represents another significant cost advantage. The superior thermal conductivity of SiC (120-270 W/m·K) enables more efficient heat transfer in thermal management systems, reducing operational energy consumption by 15-25% compared to traditional ceramic alternatives. This translates to substantial cost savings in energy-intensive industries like power generation and manufacturing.

Maintenance requirements for SiC components are minimal due to their chemical inertness and resistance to oxidation, corrosion, and thermal shock. Field data indicates maintenance intervals for SiC components can be extended by 200-300% compared to metallic alternatives, substantially reducing both direct maintenance costs and operational disruptions.

Performance metrics further justify the premium pricing. SiC's exceptional hardness (9.5+ on Mohs scale) and mechanical strength (flexural strength of 550-600 MPa) enable applications where alternative materials would rapidly degrade. In semiconductor manufacturing equipment, SiC components demonstrate 3-4 times longer service life than quartz or alumina alternatives despite higher initial costs.

Market analysis indicates decreasing production costs as manufacturing technologies mature and economies of scale improve. Current industry trends show a 5-8% annual reduction in SiC ceramic production costs, gradually improving cost-competitiveness against traditional materials. Additionally, emerging manufacturing techniques like additive manufacturing and novel sintering approaches promise to further reduce production costs by 15-30% within the next five years.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!