Silicon carbide ceramics for high temperature aerospace and industrial applications

SEP 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SiC Ceramics Evolution and Research Objectives

Silicon carbide (SiC) ceramics have evolved significantly since their initial discovery in 1891 by Edward G. Acheson. The development trajectory of these advanced materials has been characterized by continuous improvements in processing techniques, property enhancement, and application expansion. Initially utilized primarily as abrasives due to their exceptional hardness, SiC ceramics have progressively transitioned into high-performance structural materials for extreme environments.

The evolution of SiC ceramics can be traced through several distinct technological generations. First-generation SiC materials were predominantly reaction-bonded variants with limited mechanical properties. Second-generation developments introduced pressureless sintering and hot pressing techniques, significantly improving density and performance characteristics. Current third-generation SiC ceramics feature advanced processing methods including chemical vapor deposition (CVD), spark plasma sintering (SPS), and additive manufacturing approaches, enabling unprecedented control over microstructure and properties.

Recent technological breakthroughs have focused on nano-structured SiC ceramics, which demonstrate superior mechanical properties and thermal shock resistance compared to their conventional counterparts. Additionally, composite systems incorporating SiC fibers, whiskers, or particles have emerged as promising materials for aerospace applications, offering tailored property combinations not achievable with monolithic ceramics.

The global research landscape for SiC ceramics has expanded dramatically, with significant contributions from research institutions in the United States, Japan, Germany, China, and France. This international effort has accelerated the pace of innovation, particularly in addressing key challenges such as improving fracture toughness, reducing processing temperatures, and enhancing oxidation resistance at ultra-high temperatures exceeding 1600°C.

The primary research objectives for SiC ceramics in aerospace and industrial applications center on several critical areas. First, developing cost-effective manufacturing processes to reduce the prohibitively high production costs that currently limit widespread adoption. Second, enhancing reliability through improved understanding of failure mechanisms and development of non-destructive evaluation techniques. Third, extending service temperature capabilities beyond current limits to meet the demands of hypersonic flight and advanced energy systems.

Additional research priorities include improving integration with metallic and composite structures through novel joining techniques, developing self-healing capabilities to mitigate damage accumulation during service, and establishing comprehensive material property databases to facilitate design and qualification processes. These objectives collectively aim to position SiC ceramics as enabling materials for next-generation aerospace propulsion systems, thermal protection structures, and industrial components operating in extreme environments.

The evolution of SiC ceramics can be traced through several distinct technological generations. First-generation SiC materials were predominantly reaction-bonded variants with limited mechanical properties. Second-generation developments introduced pressureless sintering and hot pressing techniques, significantly improving density and performance characteristics. Current third-generation SiC ceramics feature advanced processing methods including chemical vapor deposition (CVD), spark plasma sintering (SPS), and additive manufacturing approaches, enabling unprecedented control over microstructure and properties.

Recent technological breakthroughs have focused on nano-structured SiC ceramics, which demonstrate superior mechanical properties and thermal shock resistance compared to their conventional counterparts. Additionally, composite systems incorporating SiC fibers, whiskers, or particles have emerged as promising materials for aerospace applications, offering tailored property combinations not achievable with monolithic ceramics.

The global research landscape for SiC ceramics has expanded dramatically, with significant contributions from research institutions in the United States, Japan, Germany, China, and France. This international effort has accelerated the pace of innovation, particularly in addressing key challenges such as improving fracture toughness, reducing processing temperatures, and enhancing oxidation resistance at ultra-high temperatures exceeding 1600°C.

The primary research objectives for SiC ceramics in aerospace and industrial applications center on several critical areas. First, developing cost-effective manufacturing processes to reduce the prohibitively high production costs that currently limit widespread adoption. Second, enhancing reliability through improved understanding of failure mechanisms and development of non-destructive evaluation techniques. Third, extending service temperature capabilities beyond current limits to meet the demands of hypersonic flight and advanced energy systems.

Additional research priorities include improving integration with metallic and composite structures through novel joining techniques, developing self-healing capabilities to mitigate damage accumulation during service, and establishing comprehensive material property databases to facilitate design and qualification processes. These objectives collectively aim to position SiC ceramics as enabling materials for next-generation aerospace propulsion systems, thermal protection structures, and industrial components operating in extreme environments.

Aerospace and Industrial Market Demand Analysis

The aerospace and industrial sectors are experiencing a significant surge in demand for advanced materials capable of withstanding extreme operating conditions. Silicon carbide (SiC) ceramics have emerged as a critical material solution due to their exceptional thermal stability, mechanical strength, and chemical resistance at elevated temperatures. Market analysis indicates that the global SiC ceramics market for high-temperature applications is projected to grow at a compound annual growth rate of 7.2% through 2028, driven primarily by aerospace and industrial applications.

In the aerospace sector, the demand for SiC ceramics is being fueled by the development of next-generation aircraft engines and hypersonic vehicles. Engine manufacturers are seeking materials that can operate efficiently at temperatures exceeding 1400°C, significantly higher than the capabilities of traditional superalloys. This push toward higher operating temperatures is driven by the industry's goal to improve fuel efficiency by 25% and reduce emissions by 20% by 2030. SiC ceramic components in turbine engines, combustion chambers, and thermal protection systems enable these performance improvements while reducing overall weight.

The space exploration segment presents another substantial market opportunity, with requirements for thermal protection systems that can withstand atmospheric re-entry temperatures above 1600°C. As commercial space activities expand with an expected market value reaching $1.4 trillion by 2030, the demand for reliable high-temperature materials continues to grow exponentially.

In industrial applications, the power generation sector is increasingly adopting SiC ceramics for gas turbines, where efficiency improvements of 2-3% can translate to millions in operational cost savings. The chemical processing industry requires materials resistant to corrosive environments at high temperatures, with SiC ceramics offering superior performance compared to conventional materials, extending equipment lifespan by up to 300%.

The metal processing industry represents another significant market, with foundries and steel mills requiring crucibles and other components capable of withstanding molten metal environments. This sector alone accounts for approximately 18% of the current SiC ceramics market for high-temperature applications.

Regional analysis reveals that North America and Europe currently dominate the aerospace applications market for SiC ceramics, while Asia-Pacific leads in industrial applications with rapid growth driven by expanding manufacturing sectors in China, Japan, and South Korea. The market distribution reflects the global aerospace and industrial manufacturing footprint, with specialized applications creating niche markets in regions with concentrated high-tech manufacturing capabilities.

Customer requirements across these markets consistently emphasize reliability, consistency in material properties, and cost-effectiveness, with aerospace applications placing additional emphasis on certification and traceability throughout the supply chain. As manufacturing processes improve and economies of scale are realized, the adoption rate of SiC ceramics is expected to accelerate across both sectors.

In the aerospace sector, the demand for SiC ceramics is being fueled by the development of next-generation aircraft engines and hypersonic vehicles. Engine manufacturers are seeking materials that can operate efficiently at temperatures exceeding 1400°C, significantly higher than the capabilities of traditional superalloys. This push toward higher operating temperatures is driven by the industry's goal to improve fuel efficiency by 25% and reduce emissions by 20% by 2030. SiC ceramic components in turbine engines, combustion chambers, and thermal protection systems enable these performance improvements while reducing overall weight.

The space exploration segment presents another substantial market opportunity, with requirements for thermal protection systems that can withstand atmospheric re-entry temperatures above 1600°C. As commercial space activities expand with an expected market value reaching $1.4 trillion by 2030, the demand for reliable high-temperature materials continues to grow exponentially.

In industrial applications, the power generation sector is increasingly adopting SiC ceramics for gas turbines, where efficiency improvements of 2-3% can translate to millions in operational cost savings. The chemical processing industry requires materials resistant to corrosive environments at high temperatures, with SiC ceramics offering superior performance compared to conventional materials, extending equipment lifespan by up to 300%.

The metal processing industry represents another significant market, with foundries and steel mills requiring crucibles and other components capable of withstanding molten metal environments. This sector alone accounts for approximately 18% of the current SiC ceramics market for high-temperature applications.

Regional analysis reveals that North America and Europe currently dominate the aerospace applications market for SiC ceramics, while Asia-Pacific leads in industrial applications with rapid growth driven by expanding manufacturing sectors in China, Japan, and South Korea. The market distribution reflects the global aerospace and industrial manufacturing footprint, with specialized applications creating niche markets in regions with concentrated high-tech manufacturing capabilities.

Customer requirements across these markets consistently emphasize reliability, consistency in material properties, and cost-effectiveness, with aerospace applications placing additional emphasis on certification and traceability throughout the supply chain. As manufacturing processes improve and economies of scale are realized, the adoption rate of SiC ceramics is expected to accelerate across both sectors.

Global SiC Ceramics Development Status and Barriers

Silicon carbide (SiC) ceramics have emerged as critical materials for extreme environment applications, yet their global development faces significant disparities and technical barriers. Currently, the United States, Japan, and Germany lead in SiC ceramic technology, with China rapidly advancing its capabilities through substantial research investments. These regional differences create an uneven landscape in terms of material quality, manufacturing capabilities, and application readiness.

The primary technical barriers limiting widespread SiC ceramic adoption include high production costs, which remain 5-10 times higher than conventional ceramics due to complex processing requirements and expensive raw materials. Manufacturing challenges persist in achieving consistent quality across large-scale production, particularly in maintaining uniform microstructures and minimizing defects that can compromise performance in critical applications.

Processing limitations represent another significant hurdle, as the extreme hardness and chemical stability of SiC make traditional machining and shaping processes inefficient or ineffective. Advanced techniques like hot isostatic pressing and spark plasma sintering show promise but require further refinement for complex geometries needed in aerospace components.

Material performance barriers also exist, particularly in achieving optimal combinations of thermal shock resistance, mechanical strength, and oxidation resistance at ultra-high temperatures exceeding 1600°C. Current SiC ceramics often exhibit trade-offs between these properties, limiting their application range in the most extreme environments.

Joining and integration challenges further complicate implementation, as creating reliable connections between SiC components and dissimilar materials remains problematic due to coefficient of thermal expansion mismatches and chemical compatibility issues. This significantly impacts system-level design and reliability in aerospace applications.

Standardization represents another global barrier, with inconsistent testing methodologies and performance metrics across different regions creating obstacles for international collaboration and technology transfer. The lack of unified standards slows adoption in regulated industries like aerospace and nuclear power.

Intellectual property landscapes vary considerably across regions, with fragmented patent portfolios creating complex licensing requirements for global manufacturers. This situation has led to technology silos that impede knowledge sharing and collaborative innovation in addressing fundamental material challenges.

Environmental and sustainability concerns are emerging as additional barriers, with energy-intensive production processes and limited recycling pathways raising questions about the long-term viability of SiC ceramics in increasingly carbon-conscious industrial sectors. Developing greener manufacturing routes remains a significant challenge for the global research community.

The primary technical barriers limiting widespread SiC ceramic adoption include high production costs, which remain 5-10 times higher than conventional ceramics due to complex processing requirements and expensive raw materials. Manufacturing challenges persist in achieving consistent quality across large-scale production, particularly in maintaining uniform microstructures and minimizing defects that can compromise performance in critical applications.

Processing limitations represent another significant hurdle, as the extreme hardness and chemical stability of SiC make traditional machining and shaping processes inefficient or ineffective. Advanced techniques like hot isostatic pressing and spark plasma sintering show promise but require further refinement for complex geometries needed in aerospace components.

Material performance barriers also exist, particularly in achieving optimal combinations of thermal shock resistance, mechanical strength, and oxidation resistance at ultra-high temperatures exceeding 1600°C. Current SiC ceramics often exhibit trade-offs between these properties, limiting their application range in the most extreme environments.

Joining and integration challenges further complicate implementation, as creating reliable connections between SiC components and dissimilar materials remains problematic due to coefficient of thermal expansion mismatches and chemical compatibility issues. This significantly impacts system-level design and reliability in aerospace applications.

Standardization represents another global barrier, with inconsistent testing methodologies and performance metrics across different regions creating obstacles for international collaboration and technology transfer. The lack of unified standards slows adoption in regulated industries like aerospace and nuclear power.

Intellectual property landscapes vary considerably across regions, with fragmented patent portfolios creating complex licensing requirements for global manufacturers. This situation has led to technology silos that impede knowledge sharing and collaborative innovation in addressing fundamental material challenges.

Environmental and sustainability concerns are emerging as additional barriers, with energy-intensive production processes and limited recycling pathways raising questions about the long-term viability of SiC ceramics in increasingly carbon-conscious industrial sectors. Developing greener manufacturing routes remains a significant challenge for the global research community.

Current SiC Ceramic Processing and Manufacturing Methods

01 Manufacturing methods for silicon carbide ceramics

Various manufacturing processes are employed to produce silicon carbide ceramics with desired properties. These methods include sintering, hot pressing, and reaction bonding techniques that control the microstructure and density of the final ceramic product. The manufacturing processes often involve specific temperature profiles, pressure conditions, and the use of sintering aids to achieve optimal mechanical and thermal properties in the resulting silicon carbide ceramics.- Manufacturing methods for silicon carbide ceramics: Various manufacturing methods are employed to produce silicon carbide ceramics with enhanced properties. These methods include sintering processes, hot pressing techniques, and reaction bonding approaches. The manufacturing processes can be optimized to control grain size, density, and microstructure, which directly influence the mechanical and thermal properties of the final ceramic product. Advanced processing techniques help to minimize defects and improve the overall quality of silicon carbide ceramics.

- Composition and additives for silicon carbide ceramics: The composition of silicon carbide ceramics can be modified with various additives to enhance specific properties. Sintering aids such as aluminum oxide, yttrium oxide, and rare earth elements are commonly used to promote densification at lower temperatures. Other additives may include boron compounds, carbon sources, and metal oxides that influence grain growth, phase formation, and mechanical properties. The precise control of these additives is crucial for tailoring the ceramic properties for specific applications.

- High-temperature applications of silicon carbide ceramics: Silicon carbide ceramics exhibit exceptional thermal stability and mechanical strength at elevated temperatures, making them ideal for high-temperature applications. These ceramics maintain their structural integrity in extreme environments, including furnaces, combustion chambers, and heat exchangers. Their resistance to thermal shock, oxidation, and creep at high temperatures enables their use in aerospace components, gas turbine parts, and industrial processing equipment where conventional materials would fail.

- Structural and mechanical properties of silicon carbide ceramics: Silicon carbide ceramics possess outstanding mechanical properties including high hardness, excellent wear resistance, and good fracture toughness. The structural characteristics of these ceramics, such as grain size, porosity, and phase composition, significantly influence their mechanical behavior. Various techniques can be employed to enhance these properties, including microstructure control, reinforcement with fibers or whiskers, and development of composite structures. These improvements make silicon carbide ceramics suitable for demanding structural applications.

- Novel silicon carbide ceramic composites: Advanced silicon carbide ceramic composites incorporate additional phases or materials to achieve enhanced performance characteristics. These may include silicon carbide-metal composites, silicon carbide-carbon composites, or silicon carbide reinforced with other ceramic phases. The development of these composite materials aims to overcome the inherent brittleness of monolithic ceramics while maintaining their high-temperature capabilities. These composites find applications in cutting tools, armor systems, semiconductor processing equipment, and other demanding environments.

02 Composition and additives for enhanced properties

Silicon carbide ceramics can be enhanced through the addition of various compounds and elements that improve their mechanical, thermal, and electrical properties. These additives include sintering aids, binders, and reinforcement materials that contribute to increased strength, toughness, and thermal conductivity. The specific composition formulations are designed to optimize performance characteristics for particular applications while maintaining the inherent properties of silicon carbide.Expand Specific Solutions03 Advanced processing techniques for silicon carbide ceramics

Advanced processing techniques are employed to create silicon carbide ceramics with specialized properties. These include methods such as chemical vapor deposition, spark plasma sintering, and additive manufacturing approaches that allow for precise control over the microstructure and properties of the ceramic. These techniques enable the production of complex shapes, gradient structures, and tailored porosity that would be difficult to achieve using conventional processing methods.Expand Specific Solutions04 High-temperature applications and thermal properties

Silicon carbide ceramics exhibit exceptional thermal properties that make them suitable for high-temperature applications. These materials demonstrate high thermal conductivity, low thermal expansion, and excellent thermal shock resistance. The thermal stability of silicon carbide ceramics at elevated temperatures makes them ideal for use in harsh environments such as furnace components, heat exchangers, and thermal protection systems where other materials would fail.Expand Specific Solutions05 Structural and mechanical properties optimization

The structural and mechanical properties of silicon carbide ceramics can be optimized through careful control of processing parameters and composition. Techniques to enhance hardness, fracture toughness, and wear resistance include grain size control, reinforcement with secondary phases, and surface treatments. These optimizations result in silicon carbide ceramics with superior mechanical performance for applications requiring high strength, wear resistance, and dimensional stability under mechanical loads.Expand Specific Solutions

Leading Manufacturers and Research Institutions Analysis

Silicon carbide ceramics for high-temperature aerospace and industrial applications are experiencing rapid market growth due to increasing demand in extreme environment operations. The market is currently in a growth phase, with projections indicating expansion from approximately $4.5 billion to $7.2 billion by 2027, driven by aerospace, power generation, and industrial sectors. Leading players include established corporations like Rolls-Royce, Toshiba, and Honeywell International Technologies, alongside specialized manufacturers such as Saint-Gobain Ceramics & Plastics. Research institutions including National Institute for Materials Science, Kyoto University, and Zhejiang University are advancing material properties and manufacturing techniques. The technology is approaching maturity for standard applications, while next-generation composites and coatings remain in development phases, with companies like Shin-Etsu Chemical and UBE Corp focusing on innovative formulations for enhanced performance.

Toshiba Corp.

Technical Solution: Toshiba has developed advanced silicon carbide (SiC) ceramic components specifically engineered for extreme aerospace and industrial environments. Their proprietary manufacturing process involves high-pressure sintering of ultra-fine SiC powders with carefully selected sintering aids to achieve near-theoretical density ceramics. Toshiba's SiC ceramics demonstrate exceptional thermal stability at temperatures exceeding 1600°C while maintaining structural integrity[1]. Their technology incorporates a unique grain boundary engineering approach that minimizes oxygen diffusion at high temperatures, resulting in superior creep resistance compared to conventional ceramics[3]. For aerospace applications, Toshiba has developed specialized SiC ceramic matrix composites (CMCs) that incorporate carbon fiber reinforcement to enhance fracture toughness while preserving the inherent thermal properties of SiC. These materials are particularly targeted for use in next-generation aircraft engine components and thermal protection systems for spacecraft[5].

Strengths: Superior thermal shock resistance and exceptional mechanical stability at extreme temperatures make these materials ideal for aerospace applications. The proprietary sintering process results in near-perfect densification, minimizing porosity-related failures. Weaknesses: Higher manufacturing costs compared to traditional ceramics and limited flexibility in complex geometries due to the challenging machining requirements of fully-densified SiC.

Rolls-Royce Corp.

Technical Solution: Rolls-Royce has pioneered the development of silicon carbide ceramic components for their advanced aerospace engines, focusing on high-temperature applications that can withstand the extreme conditions of modern turbine systems. Their proprietary SiC ceramic technology utilizes a chemical vapor infiltration (CVI) process combined with melt infiltration techniques to create complex-shaped components with exceptional thermal and mechanical properties[2]. The company has successfully implemented SiC ceramic matrix composites in turbine shrouds and combustor liners, allowing engines to operate at temperatures up to 1400°C - significantly higher than traditional superalloy components[4]. Rolls-Royce's SiC ceramics feature a specialized environmental barrier coating (EBC) system that provides protection against water vapor and other combustion byproducts, extending component life in harsh operating environments. Their latest generation of SiC ceramics incorporates nano-scale additives that enhance fracture toughness while maintaining the material's inherent high-temperature capabilities, addressing one of the traditional limitations of ceramic materials in dynamic applications[7].

Strengths: Exceptional high-temperature performance enabling more efficient engine designs with higher operating temperatures and reduced cooling requirements. Their integrated manufacturing approach allows for complex component geometries necessary for advanced engine designs. Weaknesses: High production costs and lengthy qualification processes for aerospace certification limit widespread adoption. The specialized manufacturing techniques require significant capital investment.

Key Patents and Innovations in High-Temperature SiC Applications

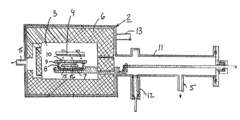

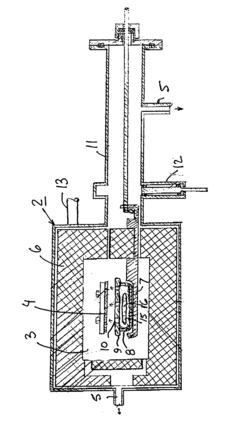

High temperature sensors utilizing doping controlled, dielectrically isolated beta silicon carbide (SiC) sensing elements on a specifically selected high temperature force collecting membrane

PatentInactiveUS6900108B2

Innovation

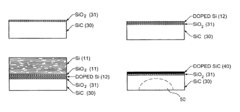

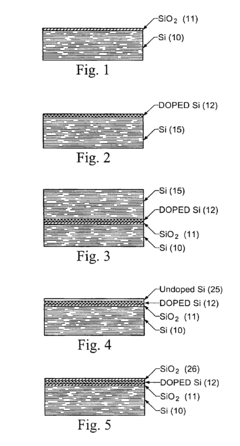

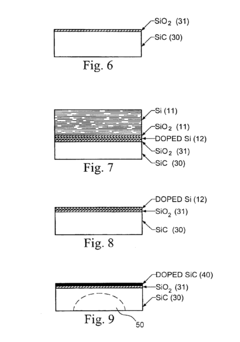

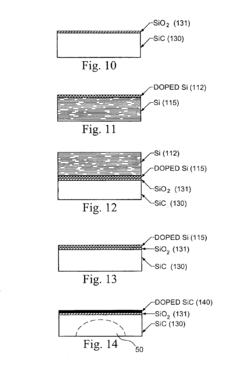

- A 3C—SiC layer is fabricated on a dielectrically isolated 6H—SiC or other SiC substrate, using a process involving bonding, selective oxidation, and conversion of doped silicon to crystalline silicon carbide, enabling the creation of a piezoresistive sensor structure with excellent single-crystal properties and an independently selected substrate for high-temperature applications.

Method of producing silicon carbide: high temperature sensor elements

PatentInactiveUS20020071804A1

Innovation

- A method involving mixing finely-divided carbon particles with a binder and elemental silicon, heating them in a vacuum to vaporize silicon and react it with carbon, producing silicon carbide without the need for high temperatures or long heating times, allowing for the creation of high-internal-resistance silicon carbide high-temperature sensor elements.

Material Sustainability and Environmental Impact Assessment

Silicon carbide ceramics production and application present significant environmental considerations that must be evaluated through comprehensive lifecycle assessment. The manufacturing process requires substantial energy inputs, particularly during sintering which occurs at temperatures exceeding 2000°C. This energy-intensive production contributes to considerable carbon emissions, estimated at 10-15 kg CO2 equivalent per kilogram of SiC ceramic produced, significantly higher than conventional ceramics.

Raw material extraction presents another sustainability challenge. Silicon carbide production requires high-purity silica and carbon sources, often obtained through mining operations that can lead to habitat disruption, soil erosion, and water contamination. The mining footprint extends beyond immediate extraction sites, affecting surrounding ecosystems and communities.

However, SiC ceramics offer compelling sustainability advantages during their operational lifecycle. Their exceptional durability and resistance to extreme environments result in service lifespans often exceeding 20 years in aerospace applications and 15+ years in industrial settings. This extended operational life significantly reduces replacement frequency and associated environmental impacts compared to alternative materials requiring more frequent substitution.

The material's thermal efficiency provides additional environmental benefits. In high-temperature applications, SiC components improve system efficiency by 15-30% through superior heat transfer and thermal management capabilities. This efficiency gain translates to reduced fuel consumption and lower emissions across the operational lifecycle of aerospace and industrial systems.

End-of-life considerations reveal both challenges and opportunities. Silicon carbide ceramics are chemically stable and non-biodegradable, potentially persisting in landfills indefinitely. However, recent recycling innovations demonstrate promising recovery rates of 60-75% of SiC from end-of-life components, which can be reprocessed into secondary applications or reintroduced into manufacturing streams.

Emerging manufacturing techniques are progressively reducing the environmental footprint of SiC production. Advanced sintering methods utilizing microwave or spark plasma technologies have demonstrated energy requirement reductions of 30-40% compared to conventional processes. Additionally, research into bio-based carbon sources and cleaner silicon extraction methods suggests potential for further sustainability improvements in the supply chain.

The aerospace industry's increasing focus on lifecycle environmental impact has accelerated development of more sustainable SiC ceramic production pathways, with several major manufacturers implementing closed-loop water systems and energy recovery technologies that reduce overall environmental impact by 20-25% compared to previous generation manufacturing processes.

Raw material extraction presents another sustainability challenge. Silicon carbide production requires high-purity silica and carbon sources, often obtained through mining operations that can lead to habitat disruption, soil erosion, and water contamination. The mining footprint extends beyond immediate extraction sites, affecting surrounding ecosystems and communities.

However, SiC ceramics offer compelling sustainability advantages during their operational lifecycle. Their exceptional durability and resistance to extreme environments result in service lifespans often exceeding 20 years in aerospace applications and 15+ years in industrial settings. This extended operational life significantly reduces replacement frequency and associated environmental impacts compared to alternative materials requiring more frequent substitution.

The material's thermal efficiency provides additional environmental benefits. In high-temperature applications, SiC components improve system efficiency by 15-30% through superior heat transfer and thermal management capabilities. This efficiency gain translates to reduced fuel consumption and lower emissions across the operational lifecycle of aerospace and industrial systems.

End-of-life considerations reveal both challenges and opportunities. Silicon carbide ceramics are chemically stable and non-biodegradable, potentially persisting in landfills indefinitely. However, recent recycling innovations demonstrate promising recovery rates of 60-75% of SiC from end-of-life components, which can be reprocessed into secondary applications or reintroduced into manufacturing streams.

Emerging manufacturing techniques are progressively reducing the environmental footprint of SiC production. Advanced sintering methods utilizing microwave or spark plasma technologies have demonstrated energy requirement reductions of 30-40% compared to conventional processes. Additionally, research into bio-based carbon sources and cleaner silicon extraction methods suggests potential for further sustainability improvements in the supply chain.

The aerospace industry's increasing focus on lifecycle environmental impact has accelerated development of more sustainable SiC ceramic production pathways, with several major manufacturers implementing closed-loop water systems and energy recovery technologies that reduce overall environmental impact by 20-25% compared to previous generation manufacturing processes.

Cost-Performance Analysis and Economic Feasibility

The economic viability of silicon carbide (SiC) ceramics remains a critical factor in their widespread adoption across aerospace and industrial applications. Current production costs for high-quality SiC ceramics range from $500 to $2,000 per kilogram, significantly higher than conventional materials like steel ($1-5/kg) or aluminum ($2-20/kg). This substantial cost differential primarily stems from complex manufacturing processes, high-temperature sintering requirements, and specialized equipment needs.

When evaluating cost-performance metrics, SiC ceramics demonstrate exceptional value in high-temperature environments where traditional materials fail. The extended service life of SiC components—often 3-5 times longer than metallic alternatives—creates compelling long-term economic benefits despite higher initial investments. For instance, in gas turbine applications, SiC components reduce maintenance frequency by approximately 40%, translating to significant operational cost savings.

Manufacturing scale presents a notable economic challenge, with current production volumes insufficient to achieve economies of scale. Analysis indicates that a 10-fold increase in production volume could potentially reduce unit costs by 30-45%, making SiC ceramics more competitive across broader application spaces. Recent advancements in additive manufacturing techniques for SiC show promise for reducing production costs by 15-25% compared to traditional methods.

The economic feasibility varies considerably across application sectors. In aerospace, where performance and weight savings are paramount, the cost premium of SiC ceramics is more readily justified. Each kilogram of weight reduction in aircraft components can save approximately $1,000-$3,000 in fuel costs over the vehicle's lifetime. Conversely, industrial applications face more stringent cost constraints, requiring clearer ROI demonstrations.

Market analysis projects that continued technological improvements and increasing production volumes will drive a 5-8% annual reduction in SiC ceramic costs over the next decade. This trajectory suggests that economic barriers will gradually diminish, particularly for high-value applications where performance advantages are most pronounced. The development of hybrid material systems that strategically incorporate SiC ceramics only where critically needed represents another promising approach to optimize cost-performance ratios.

When evaluating cost-performance metrics, SiC ceramics demonstrate exceptional value in high-temperature environments where traditional materials fail. The extended service life of SiC components—often 3-5 times longer than metallic alternatives—creates compelling long-term economic benefits despite higher initial investments. For instance, in gas turbine applications, SiC components reduce maintenance frequency by approximately 40%, translating to significant operational cost savings.

Manufacturing scale presents a notable economic challenge, with current production volumes insufficient to achieve economies of scale. Analysis indicates that a 10-fold increase in production volume could potentially reduce unit costs by 30-45%, making SiC ceramics more competitive across broader application spaces. Recent advancements in additive manufacturing techniques for SiC show promise for reducing production costs by 15-25% compared to traditional methods.

The economic feasibility varies considerably across application sectors. In aerospace, where performance and weight savings are paramount, the cost premium of SiC ceramics is more readily justified. Each kilogram of weight reduction in aircraft components can save approximately $1,000-$3,000 in fuel costs over the vehicle's lifetime. Conversely, industrial applications face more stringent cost constraints, requiring clearer ROI demonstrations.

Market analysis projects that continued technological improvements and increasing production volumes will drive a 5-8% annual reduction in SiC ceramic costs over the next decade. This trajectory suggests that economic barriers will gradually diminish, particularly for high-value applications where performance advantages are most pronounced. The development of hybrid material systems that strategically incorporate SiC ceramics only where critically needed represents another promising approach to optimize cost-performance ratios.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!