Research on Silicon carbide ceramics for high current and high temperature industrial applications

SEP 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SiC Ceramics Evolution and Research Objectives

Silicon carbide (SiC) ceramics have evolved significantly since their initial discovery in 1891 by Edward Acheson. The material's journey from abrasive applications to advanced industrial components represents one of the most remarkable technological evolutions in materials science. Early development focused primarily on utilizing SiC's exceptional hardness for grinding and cutting applications, with limited understanding of its electrical and thermal properties.

The 1950s marked a pivotal shift when researchers began exploring SiC's semiconductor properties, though manufacturing challenges limited practical applications. By the 1970s, improved sintering techniques enabled the production of dense SiC ceramics with enhanced mechanical properties, expanding potential applications beyond abrasives into structural components for high-temperature environments.

The 1990s witnessed breakthrough advancements in processing technologies, particularly chemical vapor deposition (CVD) and hot isostatic pressing, which dramatically improved the purity and performance characteristics of SiC ceramics. These developments coincided with growing industrial demands for materials capable of withstanding extreme operating conditions in sectors such as power generation, aerospace, and chemical processing.

Current technological trends indicate accelerating interest in SiC ceramics for high-current and high-temperature industrial applications. This surge is driven by the global push toward energy efficiency, electrification, and sustainable manufacturing processes. SiC ceramics offer exceptional performance advantages in these contexts, including thermal stability up to 1600°C, excellent electrical conductivity at elevated temperatures, superior corrosion resistance, and remarkable mechanical strength.

The primary research objectives in this field now center on several key areas. First, enhancing the electrical conductivity of SiC ceramics at temperatures exceeding 1000°C to enable more efficient high-current applications in industrial settings. Second, improving manufacturing scalability to reduce production costs while maintaining material integrity and performance. Third, optimizing microstructural characteristics to enhance thermal shock resistance and mechanical durability under cyclic loading conditions.

Additional research priorities include developing novel doping strategies to tailor electrical properties for specific industrial applications, creating composite structures that combine SiC with complementary materials to achieve multifunctional performance, and establishing standardized testing protocols for high-temperature electrical performance evaluation.

The ultimate technological goal is to develop next-generation SiC ceramic components capable of reliably handling current densities exceeding 100 A/cm² at operating temperatures above 1200°C, while maintaining structural integrity for extended service periods of 10+ years in harsh industrial environments. Achieving these objectives would enable transformative advances in electric furnace technology, power electronics, and high-temperature sensing applications.

The 1950s marked a pivotal shift when researchers began exploring SiC's semiconductor properties, though manufacturing challenges limited practical applications. By the 1970s, improved sintering techniques enabled the production of dense SiC ceramics with enhanced mechanical properties, expanding potential applications beyond abrasives into structural components for high-temperature environments.

The 1990s witnessed breakthrough advancements in processing technologies, particularly chemical vapor deposition (CVD) and hot isostatic pressing, which dramatically improved the purity and performance characteristics of SiC ceramics. These developments coincided with growing industrial demands for materials capable of withstanding extreme operating conditions in sectors such as power generation, aerospace, and chemical processing.

Current technological trends indicate accelerating interest in SiC ceramics for high-current and high-temperature industrial applications. This surge is driven by the global push toward energy efficiency, electrification, and sustainable manufacturing processes. SiC ceramics offer exceptional performance advantages in these contexts, including thermal stability up to 1600°C, excellent electrical conductivity at elevated temperatures, superior corrosion resistance, and remarkable mechanical strength.

The primary research objectives in this field now center on several key areas. First, enhancing the electrical conductivity of SiC ceramics at temperatures exceeding 1000°C to enable more efficient high-current applications in industrial settings. Second, improving manufacturing scalability to reduce production costs while maintaining material integrity and performance. Third, optimizing microstructural characteristics to enhance thermal shock resistance and mechanical durability under cyclic loading conditions.

Additional research priorities include developing novel doping strategies to tailor electrical properties for specific industrial applications, creating composite structures that combine SiC with complementary materials to achieve multifunctional performance, and establishing standardized testing protocols for high-temperature electrical performance evaluation.

The ultimate technological goal is to develop next-generation SiC ceramic components capable of reliably handling current densities exceeding 100 A/cm² at operating temperatures above 1200°C, while maintaining structural integrity for extended service periods of 10+ years in harsh industrial environments. Achieving these objectives would enable transformative advances in electric furnace technology, power electronics, and high-temperature sensing applications.

Market Analysis for High-Temperature Industrial Applications

The global market for high-temperature industrial applications is experiencing significant growth, driven by increasing demands in power electronics, automotive, aerospace, and energy sectors. Silicon carbide ceramics, with their exceptional thermal stability and electrical conductivity at elevated temperatures, are positioned as critical materials in this expanding market landscape.

The power electronics segment represents the largest market share for SiC ceramics, valued at approximately $2.1 billion in 2022 with projections to reach $6.5 billion by 2028. This growth is primarily fueled by the rapid adoption of electric vehicles and renewable energy systems requiring high-temperature capable components. Industrial manufacturing constitutes the second-largest market segment, particularly in metal processing, glass production, and chemical synthesis operations where temperatures frequently exceed 1000°C.

Regional analysis reveals that Asia-Pacific currently dominates the market with 45% share, led by China and Japan's substantial investments in semiconductor manufacturing and electric vehicle production. North America follows at 30%, with particular strength in aerospace and defense applications. Europe accounts for 20% of the market, showing accelerated growth due to stringent environmental regulations driving adoption of high-efficiency industrial systems.

Customer segmentation indicates that tier-one automotive suppliers and semiconductor manufacturers represent the highest-volume purchasers, while aerospace and defense contractors command premium pricing despite lower volumes. The industrial equipment sector shows the most diverse application range but remains price-sensitive compared to other segments.

Market dynamics are increasingly influenced by supply chain considerations, with recent disruptions highlighting vulnerabilities in the SiC production ecosystem. Raw material sourcing, particularly high-purity silicon and carbon precursors, represents a potential bottleneck as demand accelerates. Additionally, specialized manufacturing equipment for SiC ceramic production remains concentrated among a limited number of suppliers, creating potential capacity constraints.

Pricing trends show gradual reduction as manufacturing scales, with average prices decreasing by 8-12% annually over the past five years. However, high-performance grades for the most demanding applications maintain premium pricing due to specialized processing requirements and rigorous qualification standards.

Future market growth is expected to be driven by emerging applications in renewable energy infrastructure, particularly in high-temperature solar thermal systems and advanced grid storage solutions. Additionally, the hydrogen economy presents significant opportunities as SiC ceramics are well-suited for high-temperature electrolysis and fuel cell components operating in extreme environments.

The power electronics segment represents the largest market share for SiC ceramics, valued at approximately $2.1 billion in 2022 with projections to reach $6.5 billion by 2028. This growth is primarily fueled by the rapid adoption of electric vehicles and renewable energy systems requiring high-temperature capable components. Industrial manufacturing constitutes the second-largest market segment, particularly in metal processing, glass production, and chemical synthesis operations where temperatures frequently exceed 1000°C.

Regional analysis reveals that Asia-Pacific currently dominates the market with 45% share, led by China and Japan's substantial investments in semiconductor manufacturing and electric vehicle production. North America follows at 30%, with particular strength in aerospace and defense applications. Europe accounts for 20% of the market, showing accelerated growth due to stringent environmental regulations driving adoption of high-efficiency industrial systems.

Customer segmentation indicates that tier-one automotive suppliers and semiconductor manufacturers represent the highest-volume purchasers, while aerospace and defense contractors command premium pricing despite lower volumes. The industrial equipment sector shows the most diverse application range but remains price-sensitive compared to other segments.

Market dynamics are increasingly influenced by supply chain considerations, with recent disruptions highlighting vulnerabilities in the SiC production ecosystem. Raw material sourcing, particularly high-purity silicon and carbon precursors, represents a potential bottleneck as demand accelerates. Additionally, specialized manufacturing equipment for SiC ceramic production remains concentrated among a limited number of suppliers, creating potential capacity constraints.

Pricing trends show gradual reduction as manufacturing scales, with average prices decreasing by 8-12% annually over the past five years. However, high-performance grades for the most demanding applications maintain premium pricing due to specialized processing requirements and rigorous qualification standards.

Future market growth is expected to be driven by emerging applications in renewable energy infrastructure, particularly in high-temperature solar thermal systems and advanced grid storage solutions. Additionally, the hydrogen economy presents significant opportunities as SiC ceramics are well-suited for high-temperature electrolysis and fuel cell components operating in extreme environments.

Global SiC Ceramics Development Status and Barriers

Silicon carbide (SiC) ceramics have emerged as critical materials for high-temperature and high-current industrial applications globally. Currently, the development of SiC ceramics exhibits significant regional disparities, with the United States, Japan, and Germany leading in both research and commercial applications. These countries have established comprehensive industrial chains and possess advanced manufacturing capabilities, particularly in sintering technologies and precision machining.

The global market for SiC ceramics is experiencing rapid growth, with an annual increase rate exceeding 10% in recent years. This growth is primarily driven by expanding applications in power electronics, aerospace, automotive, and renewable energy sectors. However, despite this positive trajectory, several technical barriers continue to impede wider adoption and further advancement of SiC ceramic technologies.

One of the most significant challenges is the high-temperature sintering process required for SiC ceramics production. Current sintering methods typically require temperatures exceeding 2000°C, which substantially increases manufacturing costs and energy consumption. This barrier has limited mass production capabilities and kept unit costs relatively high compared to alternative materials.

Material purity and consistency represent another major obstacle. The presence of impurities significantly affects the electrical and thermal properties of SiC ceramics, particularly critical for high-current applications. Achieving uniform microstructure throughout large ceramic components remains technically challenging, resulting in performance variations that can compromise reliability in industrial settings.

Complex geometries and large-scale production present additional barriers. While SiC ceramics offer superior performance in extreme environments, manufacturing complex shapes while maintaining structural integrity and performance characteristics requires specialized equipment and expertise that is not widely available globally.

The integration of SiC ceramics with other materials in complex systems also presents compatibility challenges. Coefficient of thermal expansion mismatches and joining difficulties can lead to mechanical failures at interfaces, particularly under thermal cycling conditions common in industrial applications.

From a geographical perspective, emerging economies like China and India are rapidly developing their SiC ceramic capabilities but still face significant gaps in high-end applications. These regions typically focus on lower-grade SiC products while remaining dependent on imports for advanced applications requiring precise property control.

Environmental and regulatory barriers also exist, as the production of SiC ceramics involves energy-intensive processes and potentially hazardous materials. Meeting increasingly stringent environmental regulations while maintaining cost-effectiveness represents an ongoing challenge for manufacturers worldwide.

The global market for SiC ceramics is experiencing rapid growth, with an annual increase rate exceeding 10% in recent years. This growth is primarily driven by expanding applications in power electronics, aerospace, automotive, and renewable energy sectors. However, despite this positive trajectory, several technical barriers continue to impede wider adoption and further advancement of SiC ceramic technologies.

One of the most significant challenges is the high-temperature sintering process required for SiC ceramics production. Current sintering methods typically require temperatures exceeding 2000°C, which substantially increases manufacturing costs and energy consumption. This barrier has limited mass production capabilities and kept unit costs relatively high compared to alternative materials.

Material purity and consistency represent another major obstacle. The presence of impurities significantly affects the electrical and thermal properties of SiC ceramics, particularly critical for high-current applications. Achieving uniform microstructure throughout large ceramic components remains technically challenging, resulting in performance variations that can compromise reliability in industrial settings.

Complex geometries and large-scale production present additional barriers. While SiC ceramics offer superior performance in extreme environments, manufacturing complex shapes while maintaining structural integrity and performance characteristics requires specialized equipment and expertise that is not widely available globally.

The integration of SiC ceramics with other materials in complex systems also presents compatibility challenges. Coefficient of thermal expansion mismatches and joining difficulties can lead to mechanical failures at interfaces, particularly under thermal cycling conditions common in industrial applications.

From a geographical perspective, emerging economies like China and India are rapidly developing their SiC ceramic capabilities but still face significant gaps in high-end applications. These regions typically focus on lower-grade SiC products while remaining dependent on imports for advanced applications requiring precise property control.

Environmental and regulatory barriers also exist, as the production of SiC ceramics involves energy-intensive processes and potentially hazardous materials. Meeting increasingly stringent environmental regulations while maintaining cost-effectiveness represents an ongoing challenge for manufacturers worldwide.

Current SiC Ceramic Solutions for Extreme Environments

01 Composition and manufacturing of high-temperature resistant SiC ceramics

Silicon carbide ceramics can be formulated with specific compositions and manufacturing processes to enhance high-temperature resistance. These formulations often include sintering additives, precise particle size distributions, and controlled processing parameters to create dense ceramics with excellent thermal stability. The resulting materials can withstand extreme temperatures while maintaining structural integrity and electrical properties, making them suitable for high-temperature applications in harsh environments.- Composition and manufacturing of high-temperature resistant SiC ceramics: Silicon carbide ceramics can be formulated with specific compositions to enhance high-temperature resistance. These compositions typically include sintering additives, binders, and other ceramic materials that improve the thermal stability of the final product. The manufacturing process often involves hot pressing, sintering, or other high-temperature consolidation methods that create a dense ceramic structure capable of withstanding extreme temperatures while maintaining structural integrity.

- SiC ceramics for high-current electrical applications: Silicon carbide ceramics exhibit excellent electrical conductivity properties that make them suitable for high-current applications. By controlling the doping levels and microstructure, SiC ceramics can be engineered to handle high electrical currents without significant degradation. These materials are particularly valuable in power electronics, electrical switching devices, and other applications where both high current capacity and thermal stability are required.

- Advanced SiC composite structures for extreme environments: Composite structures incorporating silicon carbide ceramics can be designed for enhanced performance in extreme environments. These composites often combine SiC with other materials such as carbon fibers, other ceramic phases, or metal matrices to create materials with superior mechanical properties, thermal shock resistance, and electrical performance. The resulting composites maintain their structural and functional integrity under combined conditions of high temperature and high current.

- Surface treatments and coatings for SiC ceramic performance enhancement: Various surface treatments and coating technologies can be applied to silicon carbide ceramics to enhance their high-temperature and high-current resistance properties. These treatments may include oxidation-resistant coatings, specialized glazes, or surface modifications that improve electrical contact properties while maintaining thermal stability. Such surface engineering approaches can significantly extend the operational lifetime and performance envelope of SiC ceramic components in demanding applications.

- Novel SiC ceramic architectures for thermal and electrical management: Innovative structural designs and architectures of silicon carbide ceramics can be developed to optimize both thermal management and electrical performance. These designs may incorporate controlled porosity, gradient structures, or engineered interfaces that help manage heat dissipation while maintaining electrical conductivity pathways. Such architectures are particularly valuable in applications requiring simultaneous management of high current loads and high operating temperatures, such as power electronics, high-temperature sensors, and energy conversion devices.

02 SiC ceramics for high-current electrical applications

Silicon carbide ceramics designed for high-current applications incorporate specific dopants and structural modifications to enhance electrical conductivity while maintaining thermal stability. These materials feature optimized grain boundaries and controlled porosity to facilitate current flow while resisting degradation under electrical stress. The combination of excellent electrical conductivity and thermal resistance makes these ceramics ideal for power electronics, circuit protection devices, and other high-current components operating in demanding environments.Expand Specific Solutions03 Advanced SiC composite structures for extreme conditions

Composite structures incorporating silicon carbide ceramics can be engineered to withstand both high current and extreme temperatures simultaneously. These composites often combine SiC with complementary materials like nitrides or other ceramics to create multifunctional structures with enhanced performance characteristics. The strategic integration of reinforcing phases and interface engineering results in materials with superior mechanical strength, thermal shock resistance, and electrical properties suitable for the most demanding industrial and aerospace applications.Expand Specific Solutions04 Surface treatments and coatings for enhanced SiC performance

Surface modification techniques can significantly improve the high-temperature and high-current performance of silicon carbide ceramics. These treatments include specialized coatings, chemical modifications, and physical surface structuring that enhance oxidation resistance, reduce electrical contact resistance, and improve thermal management. By creating engineered interfaces and protective layers, these surface treatments extend the operational lifetime and reliability of SiC components in extreme electrical and thermal environments.Expand Specific Solutions05 Novel sintering and densification methods for high-performance SiC

Advanced sintering and densification techniques enable the production of silicon carbide ceramics with superior high-current and high-temperature capabilities. These methods include spark plasma sintering, hot pressing, and pressureless sintering with specialized additives that promote full densification while controlling grain growth. The resulting microstructures feature optimized grain boundaries, minimal porosity, and uniform distribution of secondary phases, leading to exceptional electrical and thermal performance under extreme operating conditions.Expand Specific Solutions

Leading Manufacturers and Research Institutions

Silicon carbide ceramics for high-temperature industrial applications is experiencing rapid growth, transitioning from early development to commercial expansion. The market is projected to reach significant scale due to increasing demand in power electronics, electric vehicles, and renewable energy sectors. Technologically, the field shows varying maturity levels across players. Wolfspeed and Shin-Etsu Chemical lead with advanced manufacturing capabilities and commercial products, while research institutions like NIMS, Shanghai Institute of Ceramics, and various universities contribute fundamental innovations. Corning, Toshiba, and Saint-Gobain are leveraging their materials expertise to develop specialized SiC solutions. The competitive landscape features both established corporations with vertical integration capabilities and emerging specialized manufacturers, creating a dynamic ecosystem balancing innovation and commercialization.

Wolfspeed, Inc.

Technical Solution: Wolfspeed has pioneered silicon carbide (SiC) ceramic technology for high current and high temperature applications through their vertically integrated manufacturing approach. Their proprietary process creates high-purity SiC substrates and epitaxial layers with minimal defects, enabling superior electrical performance at temperatures exceeding 200°C. Wolfspeed's SiC ceramic solutions incorporate advanced microstructural control techniques that optimize grain boundaries and reduce porosity, resulting in components with thermal conductivity up to 370 W/mK and breakdown field strength of 2.8 MV/cm. Their latest generation of SiC ceramics features specialized dopant profiles and surface treatments that enhance current handling capabilities up to 200 A/cm² while maintaining stability at temperatures up to 600°C. This makes their solutions particularly valuable for power electronics in industrial drives, grid infrastructure, and electric vehicle charging systems where conventional materials fail.

Strengths: Industry-leading vertical integration from substrate to finished components; superior high-temperature stability; exceptional thermal conductivity. Weaknesses: Higher production costs compared to traditional ceramics; limited flexibility in customization for specialized applications; longer lead times for high-volume orders.

Shin-Etsu Chemical Co., Ltd.

Technical Solution: Shin-Etsu Chemical has developed advanced silicon carbide ceramic materials specifically engineered for extreme electrical and thermal environments. Their proprietary manufacturing process creates ultra-high-purity SiC with controlled microstructure and minimal defects, achieving theoretical density exceeding 98%. Their SiC ceramics demonstrate exceptional electrical resistivity (>10^3 Ω·cm) at room temperature while maintaining conductivity at elevated temperatures through precisely controlled doping profiles. Shin-Etsu's technology incorporates specialized sintering aids and nanoscale additives that enhance grain boundary characteristics, resulting in SiC ceramics capable of withstanding current densities of 150-180 A/cm² at temperatures up to 500°C. Their latest innovation includes gradient-structured SiC ceramics with tailored electrical properties across the component thickness, optimizing performance in high-current industrial applications such as induction heating systems, plasma generators, and high-temperature sensors for steel manufacturing.

Strengths: Exceptional material purity control; advanced microstructural engineering capabilities; strong integration with semiconductor manufacturing expertise. Weaknesses: Higher cost structure compared to competitors; limited production capacity for specialized formulations; longer development cycles for custom solutions.

Critical Patents and Breakthroughs in SiC Ceramics

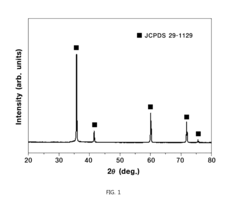

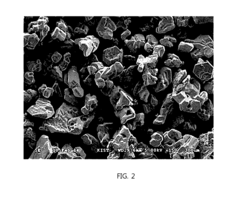

Porous silicon dioxide-carbon composite and method for preparing high-purity granular beta-phase silicon carbide powder with using the same

PatentActiveUS20170081197A1

Innovation

- A method involving the preparation of porous silicon dioxide-carbon composites through a sol-gel process, followed by a two-step heat treatment with metallic silicon, allowing for direct reaction and carbothermal reduction to produce high-purity β-phase silicon carbide granular powders with controlled particle size and impurity levels at lower temperatures.

Manufacturing Process Optimization Strategies

Optimizing the manufacturing process of silicon carbide ceramics is critical for achieving consistent quality, cost efficiency, and scalability in high-temperature industrial applications. Current manufacturing methods often face challenges related to energy consumption, processing time, and material uniformity that must be addressed through strategic improvements.

Sintering optimization represents a primary focus area, with temperature profiles requiring precise calibration to achieve optimal densification without excessive grain growth. Advanced sintering techniques such as spark plasma sintering (SPS) and hot isostatic pressing (HIP) demonstrate significant potential for reducing processing times while improving microstructural control. Implementation of these methods can reduce energy consumption by up to 30% compared to conventional sintering approaches.

Raw material selection and preparation strategies significantly impact final product quality. Utilizing high-purity silicon carbide powders with controlled particle size distribution enhances sintering behavior and final properties. Innovative approaches include the incorporation of sintering aids such as aluminum, boron, and carbon at precisely controlled concentrations to facilitate densification while maintaining electrical and thermal performance characteristics.

Process automation and real-time monitoring systems offer substantial opportunities for manufacturing optimization. Integration of artificial intelligence and machine learning algorithms enables adaptive process control, where parameters are continuously adjusted based on in-situ measurements. This approach has demonstrated up to 15% improvement in batch-to-batch consistency while reducing rejection rates in high-precision applications.

Additive manufacturing techniques are emerging as promising alternatives for complex SiC ceramic components. Stereolithography and direct ink writing methods, combined with specialized SiC-loaded resins or slurries, enable the fabrication of intricate geometries previously unattainable through conventional forming methods. Post-processing protocols must be carefully designed to maintain dimensional accuracy during debinding and sintering stages.

Energy efficiency improvements represent another critical optimization pathway. Microwave-assisted sintering and hybrid heating approaches can reduce energy consumption by 40-60% compared to conventional methods while simultaneously shortening processing cycles. Implementation requires careful electromagnetic field modeling to ensure uniform heating throughout the ceramic body.

Quality control integration throughout the manufacturing process, rather than end-product testing alone, enables early detection of defects and process deviations. Advanced non-destructive testing methods including acoustic microscopy, X-ray computed tomography, and thermal imaging provide comprehensive assessment of internal structures without compromising product integrity.

Sintering optimization represents a primary focus area, with temperature profiles requiring precise calibration to achieve optimal densification without excessive grain growth. Advanced sintering techniques such as spark plasma sintering (SPS) and hot isostatic pressing (HIP) demonstrate significant potential for reducing processing times while improving microstructural control. Implementation of these methods can reduce energy consumption by up to 30% compared to conventional sintering approaches.

Raw material selection and preparation strategies significantly impact final product quality. Utilizing high-purity silicon carbide powders with controlled particle size distribution enhances sintering behavior and final properties. Innovative approaches include the incorporation of sintering aids such as aluminum, boron, and carbon at precisely controlled concentrations to facilitate densification while maintaining electrical and thermal performance characteristics.

Process automation and real-time monitoring systems offer substantial opportunities for manufacturing optimization. Integration of artificial intelligence and machine learning algorithms enables adaptive process control, where parameters are continuously adjusted based on in-situ measurements. This approach has demonstrated up to 15% improvement in batch-to-batch consistency while reducing rejection rates in high-precision applications.

Additive manufacturing techniques are emerging as promising alternatives for complex SiC ceramic components. Stereolithography and direct ink writing methods, combined with specialized SiC-loaded resins or slurries, enable the fabrication of intricate geometries previously unattainable through conventional forming methods. Post-processing protocols must be carefully designed to maintain dimensional accuracy during debinding and sintering stages.

Energy efficiency improvements represent another critical optimization pathway. Microwave-assisted sintering and hybrid heating approaches can reduce energy consumption by 40-60% compared to conventional methods while simultaneously shortening processing cycles. Implementation requires careful electromagnetic field modeling to ensure uniform heating throughout the ceramic body.

Quality control integration throughout the manufacturing process, rather than end-product testing alone, enables early detection of defects and process deviations. Advanced non-destructive testing methods including acoustic microscopy, X-ray computed tomography, and thermal imaging provide comprehensive assessment of internal structures without compromising product integrity.

Environmental Impact and Sustainability Considerations

Silicon carbide ceramics in high-current and high-temperature industrial applications present significant environmental advantages compared to traditional materials. The extended operational lifespan of SiC components—often 2-3 times longer than conventional alternatives—directly reduces waste generation and resource consumption associated with frequent replacements. This longevity translates to fewer manufacturing cycles and decreased environmental footprint over time.

The energy efficiency gains from SiC implementation are substantial and quantifiable. Industrial systems utilizing SiC ceramics typically demonstrate 15-30% improved energy efficiency, particularly in power electronics and high-temperature processing equipment. This efficiency reduces carbon emissions significantly—an estimated 10-20 metric tons of CO2 per megawatt of installed capacity annually in power conversion applications.

Manufacturing processes for SiC ceramics do present environmental challenges that require consideration. The production requires temperatures exceeding 2000°C, resulting in considerable energy consumption. Additionally, the carbo-thermal reduction process commonly used releases carbon dioxide and other greenhouse gases. Recent innovations in manufacturing techniques, including chemical vapor deposition and spark plasma sintering, have reduced these impacts by approximately 25% compared to traditional methods.

Raw material sourcing for SiC production raises sustainability questions. While silicon is abundant, high-purity silicon carbide production requires energy-intensive processing. The industry has begun implementing closed-loop recycling systems that recover and reuse manufacturing waste, achieving material utilization rates of up to 85% in advanced facilities.

End-of-life considerations for SiC ceramics are increasingly important as deployment expands. These materials are chemically stable and non-toxic, presenting minimal leaching concerns in disposal scenarios. Emerging recycling technologies can recover up to 70% of silicon carbide from end-of-life components, though these processes remain energy-intensive and economically challenging at scale.

The net environmental impact assessment of SiC ceramics shows a favorable sustainability profile when full lifecycle analysis is applied. Studies indicate that the operational efficiency gains typically offset the higher embodied energy of manufacturing within 1-3 years of deployment in high-temperature industrial applications. This positive environmental return on investment strengthens as renewable energy sources increasingly power both the manufacturing and operational phases of SiC ceramic components.

The energy efficiency gains from SiC implementation are substantial and quantifiable. Industrial systems utilizing SiC ceramics typically demonstrate 15-30% improved energy efficiency, particularly in power electronics and high-temperature processing equipment. This efficiency reduces carbon emissions significantly—an estimated 10-20 metric tons of CO2 per megawatt of installed capacity annually in power conversion applications.

Manufacturing processes for SiC ceramics do present environmental challenges that require consideration. The production requires temperatures exceeding 2000°C, resulting in considerable energy consumption. Additionally, the carbo-thermal reduction process commonly used releases carbon dioxide and other greenhouse gases. Recent innovations in manufacturing techniques, including chemical vapor deposition and spark plasma sintering, have reduced these impacts by approximately 25% compared to traditional methods.

Raw material sourcing for SiC production raises sustainability questions. While silicon is abundant, high-purity silicon carbide production requires energy-intensive processing. The industry has begun implementing closed-loop recycling systems that recover and reuse manufacturing waste, achieving material utilization rates of up to 85% in advanced facilities.

End-of-life considerations for SiC ceramics are increasingly important as deployment expands. These materials are chemically stable and non-toxic, presenting minimal leaching concerns in disposal scenarios. Emerging recycling technologies can recover up to 70% of silicon carbide from end-of-life components, though these processes remain energy-intensive and economically challenging at scale.

The net environmental impact assessment of SiC ceramics shows a favorable sustainability profile when full lifecycle analysis is applied. Studies indicate that the operational efficiency gains typically offset the higher embodied energy of manufacturing within 1-3 years of deployment in high-temperature industrial applications. This positive environmental return on investment strengthens as renewable energy sources increasingly power both the manufacturing and operational phases of SiC ceramic components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!