Future of PVDF in Emerging IoT Devices

PVDF in IoT: Background and Objectives

Polyvinylidene fluoride (PVDF) has emerged as a promising material in the rapidly evolving landscape of Internet of Things (IoT) devices. This piezoelectric polymer has garnered significant attention due to its unique properties that align well with the demands of next-generation IoT applications. The development of PVDF technology can be traced back to the 1960s when its piezoelectric properties were first discovered. Since then, it has undergone substantial advancements, particularly in the last decade, as researchers and engineers have recognized its potential in sensing and energy harvesting applications.

The primary objective of exploring PVDF in IoT devices is to leverage its piezoelectric, pyroelectric, and ferroelectric properties to create more efficient, responsive, and self-powered smart devices. These properties allow PVDF to convert mechanical stress or temperature changes into electrical signals, making it ideal for various sensing applications. Additionally, its flexibility and durability make it suitable for integration into wearable technologies and other IoT devices that require adaptable form factors.

As IoT continues to expand, there is a growing need for materials that can support the development of smaller, more energy-efficient devices with enhanced sensing capabilities. PVDF addresses these requirements by offering a solution that can potentially reduce power consumption, increase sensitivity, and enable new functionalities in IoT devices. The material's ability to generate electricity from ambient vibrations or temperature fluctuations aligns perfectly with the IoT paradigm of creating self-sustaining, interconnected devices.

The technological evolution of PVDF in IoT is closely tied to advancements in materials science, nanotechnology, and manufacturing processes. Recent research has focused on improving the piezoelectric response of PVDF through various methods, including the development of nanocomposites and the optimization of polymer chain alignment. These efforts aim to enhance the material's sensitivity and broaden its application range in IoT devices.

Looking ahead, the future of PVDF in emerging IoT devices holds significant promise. The technology is expected to play a crucial role in the development of smart textiles, structural health monitoring systems, and energy harvesting devices for autonomous sensors. As IoT applications continue to diversify and penetrate various industries, PVDF is poised to become an integral component in creating more responsive, efficient, and sustainable smart ecosystems.

IoT Market Demand for PVDF Applications

The Internet of Things (IoT) market is experiencing rapid growth, and with it comes an increasing demand for advanced materials like Polyvinylidene Fluoride (PVDF) in various applications. PVDF's unique properties make it particularly suitable for emerging IoT devices, driving a significant market demand across multiple sectors.

In the smart home and building automation segment, PVDF is gaining traction due to its excellent piezoelectric properties. These properties allow PVDF to be used in sensors for motion detection, occupancy monitoring, and energy management systems. As the smart home market continues to expand, the demand for PVDF in these applications is expected to grow substantially.

The wearable technology sector is another area where PVDF is seeing increased demand. Its flexibility and biocompatibility make it an ideal material for sensors in fitness trackers, smartwatches, and medical monitoring devices. The ability of PVDF to detect minute changes in pressure and temperature enables more accurate health and activity tracking, driving its adoption in this rapidly growing market.

In the industrial IoT space, PVDF is finding applications in predictive maintenance systems and process control. Its resistance to harsh chemicals and high temperatures makes it suitable for sensors in manufacturing environments, oil and gas facilities, and chemical plants. The push towards Industry 4.0 and smart factories is expected to further boost the demand for PVDF-based sensors and actuators.

The automotive sector is also contributing to the growing demand for PVDF in IoT applications. As vehicles become more connected and autonomous, there is an increasing need for reliable sensors for various functions, including tire pressure monitoring, engine performance optimization, and advanced driver assistance systems. PVDF's durability and sensitivity make it an excellent choice for these automotive IoT applications.

Environmental monitoring is another area where PVDF is seeing increased adoption. Its resistance to UV radiation and weathering makes it suitable for outdoor sensors used in smart city applications, agriculture, and climate monitoring. As governments and organizations focus more on sustainability and environmental protection, the demand for PVDF in these IoT devices is expected to rise.

The healthcare sector is also driving demand for PVDF in IoT devices. Its biocompatibility and ability to be sterilized make it suitable for medical implants and wearable health monitoring devices. As remote patient monitoring and personalized healthcare gain prominence, the market for PVDF in medical IoT applications is projected to expand significantly.

Overall, the diverse properties of PVDF, including its piezoelectric characteristics, chemical resistance, and durability, position it as a key material in the evolving IoT landscape. As IoT technologies continue to penetrate various industries and aspects of daily life, the demand for PVDF is expected to grow across multiple application areas, driving innovation and market expansion in the coming years.

PVDF Technology: Current State and Challenges

Polyvinylidene fluoride (PVDF) technology has made significant strides in recent years, particularly in its application to emerging Internet of Things (IoT) devices. The current state of PVDF technology is characterized by its versatility and unique properties, making it a material of great interest for various IoT applications.

PVDF's piezoelectric and pyroelectric properties have positioned it as a key material for sensor technologies in IoT devices. Its ability to generate an electrical charge in response to mechanical stress or temperature changes has led to its widespread use in pressure sensors, motion detectors, and temperature monitoring systems. These applications are crucial for the development of smart homes, wearable devices, and industrial IoT solutions.

In the realm of energy harvesting, PVDF has shown promise as a flexible and efficient material for converting mechanical energy into electrical energy. This capability is particularly valuable for self-powered IoT devices, potentially eliminating the need for traditional batteries in certain applications. However, the efficiency of energy conversion in PVDF-based harvesters remains a challenge that researchers are actively addressing.

The flexibility and durability of PVDF have also made it an attractive option for IoT devices that require conformable or stretchable components. This has led to its incorporation in flexible electronics and smart textiles, opening up new possibilities for wearable IoT devices and human-machine interfaces.

Despite these advancements, PVDF technology faces several challenges in its integration into IoT devices. One significant hurdle is the scalability of PVDF production for large-scale IoT applications. Current manufacturing processes for high-quality PVDF films and nanofibers are often complex and costly, limiting their widespread adoption in consumer-grade IoT products.

Another challenge lies in optimizing the performance of PVDF in diverse environmental conditions. IoT devices are often deployed in varying temperatures, humidity levels, and mechanical stress situations. Ensuring consistent and reliable performance of PVDF-based components across these conditions remains an area of ongoing research and development.

The integration of PVDF with other materials and electronic components in IoT devices also presents technical challenges. Achieving seamless interfaces between PVDF and other device elements, such as electrodes and signal processing units, is crucial for maximizing the material's potential in IoT applications.

Furthermore, the long-term stability and degradation of PVDF in IoT devices are areas that require further investigation. As IoT devices are expected to operate for extended periods, understanding and mitigating any potential degradation of PVDF's properties over time is essential for ensuring the longevity and reliability of these devices.

Existing PVDF Solutions for IoT Devices

01 PVDF membrane fabrication and modification

Various techniques for fabricating and modifying PVDF membranes to enhance their properties and performance in applications such as filtration, separation, and energy storage. This includes methods for improving membrane porosity, hydrophilicity, and mechanical strength through surface treatments, blending with other polymers, or incorporating nanoparticles.- PVDF membrane fabrication and modification: Various techniques for fabricating and modifying PVDF membranes are explored, including the use of additives, surface treatments, and blending with other polymers. These methods aim to enhance the membrane's properties such as hydrophilicity, fouling resistance, and mechanical strength for applications in water treatment and filtration.

- PVDF in energy storage applications: PVDF is utilized in energy storage devices, particularly in lithium-ion batteries and supercapacitors. Its high dielectric constant and electrochemical stability make it suitable for use as a binder material in electrodes and as a separator membrane, contributing to improved battery performance and safety.

- PVDF-based piezoelectric materials: The piezoelectric properties of PVDF are exploited in various applications, including sensors, actuators, and energy harvesting devices. Research focuses on enhancing the piezoelectric response through methods such as stretching, poling, and incorporation of nanofillers.

- PVDF composites and nanocomposites: PVDF is combined with various materials to create composites and nanocomposites with enhanced properties. These include improved mechanical strength, thermal stability, and electrical conductivity. Applications range from coatings and films to advanced functional materials.

- PVDF in coating and surface treatment: PVDF-based coatings and surface treatments are developed for various substrates to impart properties such as corrosion resistance, weatherability, and self-cleaning capabilities. These coatings find applications in architecture, automotive, and industrial sectors.

02 PVDF-based piezoelectric and energy harvesting devices

Development of piezoelectric devices and energy harvesters using PVDF and its copolymers. These materials are utilized for their excellent piezoelectric properties to convert mechanical energy into electrical energy, with applications in sensors, actuators, and small-scale power generation systems.Expand Specific Solutions03 PVDF in battery and supercapacitor applications

Utilization of PVDF as a binder material in lithium-ion batteries and supercapacitors. PVDF's chemical stability, adhesion properties, and ability to form porous structures make it suitable for improving electrode performance and overall energy storage device efficiency.Expand Specific Solutions04 PVDF-based coatings and surface treatments

Development of PVDF-based coatings and surface treatments for various substrates to impart properties such as chemical resistance, weatherability, and self-cleaning capabilities. These coatings find applications in architecture, automotive, and industrial sectors.Expand Specific Solutions05 PVDF in composite materials and blends

Incorporation of PVDF into composite materials and polymer blends to create materials with enhanced properties such as improved mechanical strength, thermal stability, and chemical resistance. These composites find applications in aerospace, automotive, and industrial sectors.Expand Specific Solutions

Key Players in PVDF and IoT Industries

The future of PVDF in emerging IoT devices is characterized by a rapidly evolving competitive landscape. The industry is in a growth phase, with increasing market size driven by the expanding IoT sector. The technology maturity varies among key players, with companies like Intel Corp., Huawei Technologies Co., Ltd., and IBM leading in innovation. Established chemical manufacturers such as Arkema, Inc. are advancing PVDF applications, while research institutions like King Abdullah University of Science & Technology and SRI International contribute to fundamental breakthroughs. The market is seeing a blend of traditional electronics giants and specialized materials companies, indicating a diverse and dynamic competitive environment poised for significant developments in PVDF integration within IoT devices.

Intel Corp.

Huawei Technologies Co., Ltd.

Innovative PVDF Developments for IoT

- A Self-Sustainable Energy-Harvesting Integrated Circuit (EHIC) combining solar cells, kinetic energy harvesters, and ambient RF energy scavenging modules, with an advanced power management system to regulate and store energy for continuous and stable power supply.

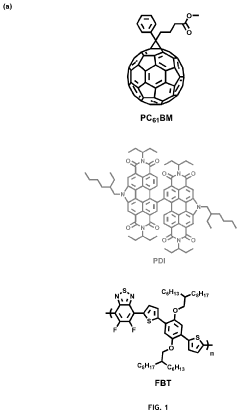

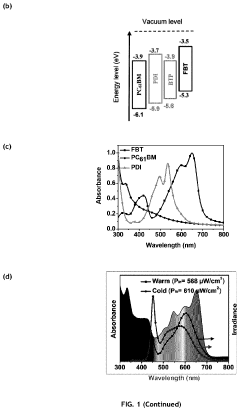

- The development of ternary blends comprising an electron donor material and two electron acceptor materials, specifically N-annulated perylene diimide-based and alkyl-12,13-dihydro[1,2,5]thiadiazolo[3,4e]thieno[2″,3″:4′,5′] thieno[2′,3′:4,5]pyrrolo[3,2-g] thieno[2′,3′:4,5]thieno[3,2-b]indole-2,10-diyl-based electron acceptor materials, which are slot-die coated from environmentally friendly solvents to enhance indoor light harvesting.

Environmental Impact of PVDF in IoT

The environmental impact of PVDF (Polyvinylidene Fluoride) in IoT devices is a critical consideration as these technologies become increasingly prevalent. PVDF, known for its excellent piezoelectric properties and chemical resistance, plays a significant role in various IoT applications, including sensors, actuators, and energy harvesting devices.

One of the primary environmental concerns associated with PVDF in IoT devices is its end-of-life disposal. As IoT devices proliferate, the potential for electronic waste accumulation increases. PVDF, being a fluoropolymer, presents challenges in recycling and biodegradation. Unlike some other plastics, PVDF does not readily decompose in natural environments, potentially contributing to long-term pollution if not properly managed.

However, the durability and longevity of PVDF can also be viewed as an environmental advantage. IoT devices incorporating PVDF components often have extended lifespans due to the material's resistance to wear, chemicals, and environmental factors. This longevity can reduce the frequency of device replacement, potentially mitigating overall electronic waste generation.

The production process of PVDF also warrants environmental scrutiny. The synthesis of PVDF involves the use of fluorine-containing compounds, which can have significant environmental impacts if not properly controlled. Emissions from PVDF manufacturing processes may contribute to air and water pollution if stringent environmental controls are not implemented.

On the positive side, PVDF's application in IoT devices can indirectly contribute to environmental benefits. IoT systems utilizing PVDF sensors and actuators often enhance energy efficiency in various applications, such as smart buildings and industrial processes. This improved efficiency can lead to reduced energy consumption and, consequently, lower greenhouse gas emissions.

Furthermore, PVDF's role in energy harvesting technologies within IoT devices presents an opportunity for sustainable energy generation. Piezoelectric PVDF films can convert mechanical energy from vibrations or movement into electrical energy, potentially reducing the reliance on battery power and associated environmental impacts.

As the IoT landscape evolves, there is a growing emphasis on developing more environmentally friendly alternatives to traditional PVDF. Research into bio-based and biodegradable piezoelectric materials is gaining traction, aiming to address the end-of-life concerns associated with PVDF while maintaining its desirable properties for IoT applications.

In conclusion, while PVDF offers significant benefits in IoT devices, its environmental impact remains a complex issue. Balancing the material's performance advantages with its environmental challenges will be crucial as the IoT industry continues to expand and evolve.

Standardization of PVDF in IoT Devices

The standardization of PVDF (Polyvinylidene Fluoride) in IoT devices is a critical step towards ensuring consistency, reliability, and interoperability across the rapidly expanding Internet of Things ecosystem. As PVDF continues to gain prominence in emerging IoT applications, establishing industry-wide standards becomes increasingly important for manufacturers, developers, and end-users alike.

One of the primary areas requiring standardization is the composition and quality of PVDF materials used in IoT devices. This includes defining acceptable ranges for molecular weight, crystallinity, and purity levels to ensure consistent performance across different applications. Standardized testing methods for evaluating PVDF properties, such as piezoelectric coefficients and dielectric strength, are essential for quality control and device characterization.

Another crucial aspect of PVDF standardization in IoT devices is the development of uniform fabrication processes. This encompasses guidelines for film deposition, poling techniques, and electrode application to achieve consistent piezoelectric properties. Standardized manufacturing protocols will facilitate scalability and reproducibility, enabling more efficient production of PVDF-based IoT components.

Interfacing standards for PVDF sensors and actuators in IoT devices are also necessary to ensure seamless integration with various hardware and software platforms. This includes defining standard signal conditioning circuits, data acquisition protocols, and communication interfaces to enable plug-and-play functionality across different IoT ecosystems.

Reliability and durability standards for PVDF components in IoT devices must be established to address the diverse environmental conditions these devices may encounter. This involves developing standardized testing procedures for temperature cycling, humidity resistance, and mechanical stress to ensure long-term performance and reliability in real-world applications.

Energy harvesting applications of PVDF in IoT devices require standardization of power output metrics and energy conversion efficiencies. This will enable fair comparisons between different PVDF-based energy harvesting solutions and help developers optimize their designs for specific IoT use cases.

As IoT devices increasingly incorporate PVDF for sensing and actuation, standardization of calibration procedures becomes crucial. This includes defining reference materials, calibration methods, and traceability standards to ensure accurate and consistent measurements across different devices and applications.

Lastly, the development of safety standards for PVDF in IoT devices is essential, particularly for applications in wearable technology and medical devices. This encompasses guidelines for biocompatibility, toxicity testing, and electrical safety to ensure that PVDF-based IoT devices meet regulatory requirements and pose no risk to users.