PVDF in Construction: Advancements in Durability Solutions

PVDF in Construction: Evolution and Objectives

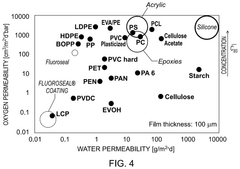

Polyvinylidene fluoride (PVDF) has emerged as a revolutionary material in the construction industry, offering exceptional durability and weather resistance. The evolution of PVDF in construction can be traced back to the 1960s when it was first synthesized and recognized for its unique properties. Initially used in industrial applications, PVDF's potential in construction was gradually realized due to its outstanding chemical stability and resistance to UV radiation.

The primary objective of incorporating PVDF in construction has been to enhance the longevity and performance of building materials, particularly in exterior applications. As urbanization accelerated and environmental concerns grew, the demand for sustainable and long-lasting construction solutions increased. PVDF coatings and membranes became pivotal in addressing these needs, offering superior protection against weathering, corrosion, and degradation.

Over the decades, PVDF technology has undergone significant advancements. Early applications were limited to simple protective coatings, but research and development efforts have expanded its use to more complex systems. The introduction of PVDF-based architectural coatings in the 1970s marked a significant milestone, providing buildings with extended color and gloss retention capabilities.

The 1990s and 2000s saw a surge in PVDF's application in membrane roofing systems, capitalizing on its excellent waterproofing properties and resistance to chemical pollutants. This period also witnessed the development of PVDF composites, combining the polymer with other materials to enhance its mechanical properties and expand its applicability in construction.

Recent technological objectives have focused on improving PVDF's environmental profile and performance in extreme conditions. Researchers are exploring ways to increase the material's recyclability and reduce its carbon footprint, aligning with global sustainability goals. Additionally, there's a growing emphasis on developing PVDF formulations that can withstand increasingly severe weather events due to climate change.

The current trajectory of PVDF in construction is geared towards smart and responsive building materials. Innovations in nanotechnology are being integrated with PVDF to create self-cleaning surfaces and materials with enhanced thermal management properties. These advancements aim to reduce maintenance costs and improve energy efficiency in buildings.

Looking ahead, the objectives for PVDF in construction are multifaceted. There's a push towards developing PVDF-based materials with improved fire resistance and structural integrity. Researchers are also exploring the potential of PVDF in 3D printing applications for construction, which could revolutionize building techniques and allow for more complex, customized architectural designs.

Market Demand Analysis for PVDF-based Construction Materials

The market demand for PVDF-based construction materials has been steadily increasing due to the growing emphasis on durability and sustainability in the construction industry. PVDF (Polyvinylidene Fluoride) coatings and membranes have gained significant traction in recent years, particularly in high-performance architectural applications.

The global PVDF market in construction is projected to experience substantial growth, driven by the material's exceptional weatherability, chemical resistance, and long-term performance. Key factors contributing to this demand include the rising need for corrosion-resistant materials in coastal and industrial environments, as well as the increasing focus on energy-efficient building solutions.

In the architectural coatings segment, PVDF-based products are witnessing strong demand for exterior cladding, roofing, and facade applications. The material's ability to maintain color stability and resist fading, chalking, and UV degradation makes it particularly attractive for high-end commercial and institutional buildings where aesthetic longevity is crucial.

The roofing sector represents another significant market for PVDF materials. Cool roof solutions utilizing PVDF coatings are gaining popularity due to their ability to reflect solar radiation and reduce building energy consumption. This aligns with the growing trend towards sustainable and energy-efficient construction practices.

Geographically, North America and Europe currently dominate the PVDF construction materials market, with Asia-Pacific emerging as the fastest-growing region. Rapid urbanization, infrastructure development, and increasing awareness of sustainable building practices in countries like China and India are driving the demand for high-performance construction materials.

The automotive and aerospace industries' adoption of PVDF-based materials for exterior applications has also indirectly boosted demand in the construction sector. Cross-industry technology transfer and material advancements have led to improved formulations and application techniques in construction-specific PVDF products.

Market analysts predict that the PVDF construction materials segment will continue to expand, with a particular focus on developing countries and regions prone to harsh environmental conditions. The increasing implementation of stringent building codes and sustainability regulations in various countries is expected to further propel the adoption of PVDF-based solutions in the construction industry.

Current PVDF Applications and Challenges in Construction

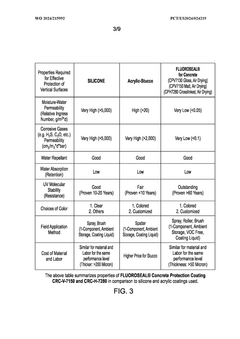

Polyvinylidene fluoride (PVDF) has emerged as a versatile material in the construction industry, offering exceptional durability and resistance to various environmental factors. Its current applications span across multiple areas of building construction and infrastructure development. In exterior architectural coatings, PVDF-based paints and finishes provide long-lasting protection against UV radiation, weathering, and chemical exposure, maintaining the aesthetic appeal of buildings for extended periods.

Roofing systems have also benefited from PVDF technology, with membranes and coatings that offer superior water resistance and thermal stability. These PVDF-based roofing solutions have shown remarkable longevity, often outlasting traditional materials in harsh climates. Additionally, PVDF has found its way into window systems, where it is used in frame coatings and sealants, enhancing the overall energy efficiency and durability of fenestration products.

In the realm of infrastructure, PVDF-based materials are increasingly utilized in bridge coatings, tunnel linings, and water management systems. The material's resistance to corrosion and chemical degradation makes it particularly suitable for these demanding applications, where long-term performance is critical.

Despite its widespread adoption, PVDF faces several challenges in the construction sector. One of the primary concerns is the relatively high cost of PVDF-based products compared to conventional alternatives. This cost factor often leads to hesitation among project developers and contractors, particularly in budget-sensitive projects. Additionally, the application of PVDF coatings and membranes requires specialized skills and equipment, which can limit its accessibility in some markets.

Another challenge lies in the environmental impact of PVDF production and disposal. While the material itself is inert and non-toxic, the manufacturing process involves fluorine-based chemicals, raising concerns about potential environmental effects. End-of-life considerations for PVDF products in construction also present challenges, as recycling options are currently limited.

The performance of PVDF in extreme conditions, while generally excellent, still presents areas for improvement. In regions with severe temperature fluctuations or exposure to specific chemical pollutants, some PVDF applications have shown signs of degradation over time. Research is ongoing to enhance the material's resilience in these extreme scenarios.

Lastly, the integration of PVDF with other construction materials and systems poses technical challenges. Ensuring compatibility and optimal performance when PVDF is used in conjunction with diverse substrates and building components requires continuous research and development efforts. As the construction industry moves towards more complex, multi-material solutions, addressing these integration challenges becomes increasingly important for the widespread adoption of PVDF in advanced building systems.

Existing PVDF-based Durability Enhancement Techniques

01 Chemical modification for enhanced durability

PVDF durability can be improved through chemical modification techniques. These methods involve altering the polymer structure to enhance its resistance to environmental factors, UV radiation, and chemical degradation. Modifications may include cross-linking, grafting, or the incorporation of stabilizing additives, resulting in a more robust and long-lasting PVDF material.- Chemical modification of PVDF: Chemical modification techniques can be applied to PVDF to enhance its durability. These methods may include grafting, crosslinking, or introducing functional groups to the polymer chain. Such modifications can improve the material's resistance to chemical degradation, thermal stability, and mechanical properties, thereby increasing its overall durability and lifespan.

- PVDF composite materials: Incorporating PVDF into composite materials can significantly enhance its durability. By combining PVDF with other materials such as nanoparticles, fibers, or other polymers, the resulting composites can exhibit improved mechanical strength, chemical resistance, and thermal stability. These composites often demonstrate superior durability compared to pure PVDF.

- Surface treatment of PVDF: Various surface treatment techniques can be applied to PVDF to enhance its durability. These may include plasma treatment, UV irradiation, or chemical etching. Such treatments can modify the surface properties of PVDF, improving its adhesion, wear resistance, and chemical resistance, thus contributing to increased durability in specific applications.

- PVDF blends and alloys: Blending PVDF with other polymers or creating polymer alloys can lead to materials with enhanced durability. These blends or alloys often combine the desirable properties of PVDF with complementary characteristics of other polymers, resulting in materials with improved mechanical properties, chemical resistance, and long-term stability.

- Processing techniques for improved PVDF durability: Specialized processing techniques can be employed to enhance the durability of PVDF products. These may include optimized extrusion or molding processes, heat treatment methods, or specific cooling regimes. Such techniques can influence the crystallinity, molecular orientation, and overall structure of PVDF, leading to improved mechanical properties and long-term durability.

02 Surface treatment for improved weatherability

Surface treatments can significantly enhance the durability of PVDF. These treatments may include plasma processing, corona discharge, or the application of protective coatings. Such methods improve the material's resistance to weathering, UV radiation, and chemical attack, thereby extending its lifespan and maintaining its properties over time.Expand Specific Solutions03 Composite formulations for increased strength

Incorporating PVDF into composite materials can enhance its durability. By combining PVDF with other polymers, fibers, or nanoparticles, the resulting composite can exhibit improved mechanical strength, thermal stability, and chemical resistance. This approach allows for the creation of materials with tailored properties suitable for specific high-durability applications.Expand Specific Solutions04 Optimized processing techniques

The durability of PVDF can be significantly influenced by the processing techniques used during manufacturing. Optimized methods such as controlled crystallization, orientation of polymer chains, and precise temperature management during molding or extrusion can lead to PVDF products with enhanced mechanical properties and improved resistance to environmental stressors.Expand Specific Solutions05 Additives for long-term stability

The incorporation of specific additives can greatly improve the long-term stability and durability of PVDF. These may include UV stabilizers, antioxidants, heat stabilizers, and other functional additives that protect the polymer from degradation caused by environmental factors, heat, and oxidation. The careful selection and optimal concentration of these additives can significantly extend the service life of PVDF materials.Expand Specific Solutions

Key Players in PVDF Construction Solutions

The PVDF market in construction is experiencing significant growth, driven by increasing demand for durable and weather-resistant materials. The industry is in a mature stage, with a global market size expected to reach $1.5 billion by 2027. Technological advancements are focused on enhancing PVDF's performance in harsh environments. Key players like Arkema, Solvay, and Kureha are leading innovation, developing high-performance PVDF formulations for construction applications. Emerging companies such as Zhejiang Green New Materials and Shandong Huaxia Shenzhou New Materials are also contributing to market expansion. The technology's maturity is evident in its widespread adoption, but ongoing research by companies like Asahi Kasei and LG Electronics continues to push the boundaries of PVDF's capabilities in construction durability solutions.

Arkema France SA

Solvay Specialty Polymers Italy SpA

Innovative PVDF Formulations for Construction Durability

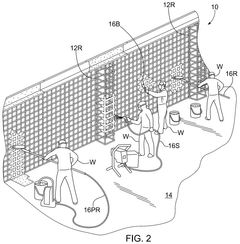

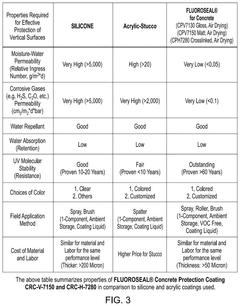

- A method involving the application of a liquidous coating of modified polyvinylidene fluoride (PVDF) or polyvinylidene difluoride (PVDF) material in an air dryable solution, which is highly fluorinated and has high polymer crystallinity, allowing it to be applied in the field without specialized equipment, effectively blocking moisture and corrosive gases, and providing long-term protection against corrosion.

- A method involving the application of a liquidous coating of modified polyvinylidene fluoride (PVDF) or polyvinylidene difluoride (PVDF) material in an air dryable solution, which forms a blend with compatible acrylic and/or other polymers, providing a robust barrier against moisture and corrosive gases, and can be applied in the field without controlled conditions.

Environmental Impact of PVDF in Construction

The environmental impact of PVDF (Polyvinylidene Fluoride) in construction is a critical consideration as the material gains prominence in durability solutions. PVDF's exceptional resistance to weathering, UV radiation, and chemical corrosion contributes to its longevity in building applications, potentially reducing the need for frequent replacements and renovations. This durability translates to reduced waste generation and resource consumption over the lifecycle of structures incorporating PVDF-based materials.

However, the production of PVDF involves energy-intensive processes and the use of fluorine-based compounds, which can have significant environmental implications. The manufacturing process may contribute to greenhouse gas emissions and the potential release of fluorinated compounds into the environment. These concerns necessitate a careful evaluation of the overall environmental footprint of PVDF production and its long-term benefits in construction applications.

PVDF's resistance to degradation also raises questions about its end-of-life management. While the material's durability extends the lifespan of building components, it presents challenges for recycling and disposal. The strong chemical bonds that provide PVDF with its desirable properties also make it difficult to break down or recycle using conventional methods. This persistence in the environment could lead to accumulation in landfills or ecosystems if not properly managed.

On the positive side, PVDF's reflective properties, when used in roofing and exterior cladding, can contribute to improved energy efficiency in buildings. By reflecting solar radiation, PVDF-coated surfaces can reduce heat absorption, potentially lowering cooling costs and mitigating urban heat island effects. This energy-saving aspect partially offsets the environmental impact of its production.

Recent advancements in PVDF technology have focused on enhancing its eco-friendly attributes. Researchers are exploring bio-based alternatives and developing more sustainable production methods to reduce the environmental footprint of PVDF manufacturing. Additionally, efforts are underway to improve the recyclability of PVDF-containing construction materials, aiming to create closed-loop systems that minimize waste and maximize resource efficiency.

The use of PVDF in construction also intersects with broader sustainability goals in the building sector. Its durability and performance characteristics align with the principles of sustainable construction by promoting longer-lasting structures and reducing the frequency of maintenance and replacement. This longevity can lead to overall reductions in material consumption and construction-related emissions over time.

As the construction industry continues to prioritize sustainability, the environmental impact of PVDF remains a subject of ongoing research and development. Balancing its beneficial properties with environmental considerations will be crucial in determining its role in future sustainable building practices.

Regulatory Framework for PVDF Use in Building Materials

The regulatory framework for PVDF use in building materials has evolved significantly in recent years, reflecting the growing recognition of its durability and performance benefits in construction applications. In the United States, the International Building Code (IBC) and the American Society for Testing and Materials (ASTM) have established specific standards for PVDF-based coatings and materials used in construction. These standards outline requirements for fire resistance, weatherability, and chemical resistance, ensuring that PVDF products meet stringent safety and performance criteria.

The European Union has implemented the Construction Products Regulation (CPR), which includes provisions for PVDF materials used in building facades and roofing systems. This regulation mandates CE marking for PVDF products, indicating compliance with harmonized technical specifications. Additionally, the European Committee for Standardization (CEN) has developed specific standards for PVDF coatings, addressing aspects such as color retention, chalking resistance, and long-term durability.

In Asia, countries like Japan and China have incorporated PVDF-specific regulations into their building codes. The Japanese Industrial Standards (JIS) include guidelines for PVDF coatings in architectural applications, focusing on weathering resistance and color stability. China's GB standards have also been updated to include specifications for PVDF materials, particularly in the context of high-rise building exteriors and corrosion-resistant infrastructure.

Environmental regulations have played a crucial role in shaping the use of PVDF in construction. Many jurisdictions now require low-VOC (volatile organic compound) formulations, prompting manufacturers to develop water-based PVDF coatings that comply with stricter emissions standards. The REACH regulation in Europe and similar initiatives in other regions have also influenced the composition of PVDF products, ensuring they meet increasingly stringent environmental and health safety requirements.

The regulatory landscape for PVDF in construction continues to evolve, with a growing emphasis on sustainability and life-cycle assessment. Some jurisdictions are beginning to incorporate criteria for recyclability and end-of-life management of PVDF materials into their building regulations. This trend is likely to accelerate as circular economy principles gain traction in the construction industry, potentially leading to new standards for the recovery and reuse of PVDF components in buildings.

As PVDF technology advances, regulatory bodies are also adapting their frameworks to address emerging applications. For instance, the integration of PVDF in smart building materials and energy-efficient designs has prompted discussions on updating existing standards to encompass these innovative uses. This ongoing dialogue between industry, research institutions, and regulatory authorities ensures that the regulatory framework remains responsive to technological advancements while maintaining a focus on safety, performance, and sustainability in the built environment.