How to Apply PVDF in Advanced Multilayer Film Structures?

PVDF in Multilayer Films: Background and Objectives

Polyvinylidene fluoride (PVDF) has emerged as a crucial material in the development of advanced multilayer film structures, revolutionizing various industries due to its unique properties. The evolution of PVDF technology can be traced back to its discovery in 1948 by Dupont scientist Reginald Plunkett. Since then, PVDF has undergone significant advancements, particularly in its application within multilayer film structures.

The primary objective of incorporating PVDF in multilayer films is to enhance the overall performance and functionality of the final product. PVDF's exceptional chemical resistance, thermal stability, and mechanical strength make it an ideal candidate for use in demanding applications across diverse sectors, including aerospace, automotive, electronics, and renewable energy.

In recent years, the focus has shifted towards developing more sophisticated multilayer film structures that can meet the increasingly complex requirements of modern industries. This has led to a surge in research and development activities aimed at optimizing PVDF's properties and exploring novel ways to integrate it into multilayer systems.

One of the key trends driving the evolution of PVDF in multilayer films is the growing demand for lightweight, durable, and high-performance materials. As industries strive for greater efficiency and sustainability, PVDF-based multilayer films offer a promising solution by combining the benefits of multiple materials in a single, thin structure.

The technical landscape surrounding PVDF in multilayer films has been shaped by several significant milestones. These include the development of improved processing techniques, such as co-extrusion and lamination, which have enabled the creation of more complex and precisely engineered film structures. Additionally, advancements in polymer science have led to the formulation of specialized PVDF grades tailored for specific applications in multilayer systems.

Looking ahead, the future of PVDF in advanced multilayer film structures appears promising, with several emerging trends on the horizon. These include the integration of nanotechnology to further enhance PVDF's properties, the development of bio-based alternatives to traditional PVDF, and the exploration of smart, responsive multilayer films that can adapt to changing environmental conditions.

As we delve deeper into the application of PVDF in advanced multilayer film structures, it is essential to consider the broader context of materials science and engineering. The ongoing quest for innovative solutions that can address the challenges of the 21st century continues to drive research and development in this field, with PVDF playing a pivotal role in shaping the future of multilayer film technology.

Market Analysis for PVDF-based Multilayer Films

The global market for PVDF-based multilayer films is experiencing robust growth, driven by increasing demand across various industries such as automotive, construction, and electronics. These advanced film structures offer superior performance characteristics, including excellent chemical resistance, weatherability, and thermal stability, making them highly sought after in high-value applications.

In the automotive sector, PVDF-based multilayer films are gaining traction for exterior applications, particularly in paint protection films and decorative wraps. The automotive industry's shift towards electric vehicles and lightweight materials has further boosted the demand for these films, as they provide enhanced protection and aesthetics without adding significant weight to the vehicle.

The construction industry represents another significant market for PVDF-based multilayer films. These films are extensively used in architectural membranes, roofing systems, and facade cladding due to their exceptional durability and resistance to UV radiation, pollution, and extreme weather conditions. The growing trend towards sustainable and energy-efficient buildings has further propelled the adoption of PVDF-based films in this sector.

In the electronics industry, PVDF-based multilayer films find applications in flexible printed circuits, touchscreens, and protective coatings for electronic devices. The increasing miniaturization of electronic components and the rising demand for flexible and durable electronic products have created new opportunities for these advanced film structures.

The packaging industry is also emerging as a promising market for PVDF-based multilayer films. These films offer excellent barrier properties against moisture, gases, and chemicals, making them ideal for high-performance packaging solutions in the food, pharmaceutical, and industrial sectors.

Geographically, North America and Europe currently dominate the market for PVDF-based multilayer films, owing to the presence of established end-use industries and stringent regulations promoting the use of high-performance materials. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, urbanization, and increasing investments in infrastructure development.

Key market players in the PVDF-based multilayer film industry include Arkema, Solvay, Kureha Corporation, and 3M Company. These companies are focusing on research and development to enhance the performance characteristics of their products and expand their application scope. Additionally, strategic collaborations and partnerships are being formed to strengthen market presence and cater to evolving customer demands.

Current Challenges in PVDF Multilayer Film Fabrication

The fabrication of advanced multilayer film structures incorporating PVDF presents several significant challenges that researchers and manufacturers must address. One of the primary obstacles is achieving optimal adhesion between PVDF and other polymer layers. PVDF's low surface energy and chemical inertness make it inherently difficult to bond with other materials, often resulting in delamination or poor interfacial strength in multilayer structures.

Another critical challenge lies in controlling the crystallization behavior of PVDF during the film formation process. The polymorphism of PVDF, which can exist in multiple crystalline phases (α, β, γ, δ), significantly affects the film's properties. Achieving the desired crystal phase, particularly the electroactive β-phase, while maintaining film uniformity and structural integrity, remains a complex task in multilayer configurations.

The thermal processing of PVDF in multilayer structures also poses considerable difficulties. The high melting point of PVDF (around 170°C) compared to many other polymers used in multilayer films can lead to processing incompatibilities. This temperature mismatch may cause thermal degradation of less stable polymers or uneven layer formation during co-extrusion or lamination processes.

Furthermore, the dimensional stability of PVDF layers within multilayer structures is a persistent issue. PVDF's tendency to shrink or expand differently from adjacent layers due to thermal or mechanical stress can result in warping, curling, or internal stresses that compromise the film's performance and durability.

The incorporation of functional additives or nanofillers into PVDF layers while maintaining the desired multilayer structure presents another set of challenges. Ensuring uniform dispersion of additives without compromising the interfacial adhesion or altering the crystallization behavior of PVDF requires careful formulation and processing control.

Scaling up the production of PVDF-containing multilayer films from laboratory to industrial scale introduces additional complexities. Maintaining consistent film quality, thickness uniformity, and interlayer adhesion across large production runs demands sophisticated process control and equipment optimization.

Lastly, the environmental and regulatory challenges associated with PVDF processing cannot be overlooked. The potential emission of harmful fluorinated compounds during high-temperature processing and the end-of-life considerations for PVDF-containing multilayer films necessitate the development of more sustainable manufacturing practices and recycling strategies.

Existing PVDF Multilayer Film Structures

01 PVDF membrane fabrication and modification

Various techniques for fabricating and modifying PVDF membranes to enhance their properties and performance in applications such as filtration, separation, and energy storage. This includes methods for improving membrane porosity, hydrophilicity, and mechanical strength through surface treatments, blending with other polymers, or incorporating nanoparticles.- PVDF membrane fabrication and modification: Various techniques for fabricating and modifying PVDF membranes to enhance their properties and performance in applications such as filtration, separation, and energy storage. This includes methods for improving membrane porosity, hydrophilicity, and mechanical strength through surface treatments, blending with other polymers, or incorporating nanoparticles.

- PVDF-based piezoelectric and ferroelectric materials: Development of PVDF and its copolymers as piezoelectric and ferroelectric materials for sensors, actuators, and energy harvesting devices. This involves optimizing the crystalline structure, enhancing the piezoelectric response, and improving the overall performance of PVDF-based materials in various electronic and energy applications.

- PVDF composites and blends: Creation of PVDF-based composites and blends with other materials to achieve specific properties or functionalities. This includes combining PVDF with nanofillers, conductive materials, or other polymers to enhance mechanical, thermal, or electrical properties for applications in coatings, electronics, and energy storage.

- PVDF in energy storage applications: Utilization of PVDF as a binder or separator material in lithium-ion batteries and other energy storage devices. This involves optimizing PVDF formulations to improve electrode adhesion, enhance electrolyte uptake, and increase overall battery performance and safety.

- PVDF processing and manufacturing techniques: Advanced processing and manufacturing methods for PVDF materials, including extrusion, electrospinning, and solution casting. These techniques aim to control the morphology, crystallinity, and properties of PVDF products for various industrial applications, such as films, fibers, and coatings.

02 PVDF-based piezoelectric and ferroelectric materials

Development of PVDF and its copolymers as piezoelectric and ferroelectric materials for sensors, actuators, and energy harvesting devices. This includes methods for enhancing the piezoelectric properties through various processing techniques, such as stretching, poling, and the addition of fillers or nanoparticles.Expand Specific Solutions03 PVDF in battery and energy storage applications

Utilization of PVDF as a binder material in lithium-ion batteries and other energy storage devices. This includes methods for improving the adhesion between active materials and current collectors, enhancing the electrochemical stability, and increasing the overall performance and longevity of batteries.Expand Specific Solutions04 PVDF-based coatings and films

Development of PVDF-based coatings and films for various applications, including corrosion protection, weather resistance, and self-cleaning surfaces. This includes methods for improving the adhesion, durability, and functional properties of PVDF coatings through the incorporation of additives or surface treatments.Expand Specific Solutions05 PVDF in composite materials

Incorporation of PVDF into composite materials to enhance their properties, such as mechanical strength, thermal stability, and chemical resistance. This includes the development of PVDF-based nanocomposites, fiber-reinforced composites, and hybrid materials for various industrial and engineering applications.Expand Specific Solutions

Key Players in PVDF and Multilayer Film Industry

The application of PVDF in advanced multilayer film structures is in a growth phase, with increasing market size due to its unique properties and versatility. The global PVDF market is expected to expand significantly in the coming years, driven by demand in various industries. Technologically, PVDF application in multilayer films is moderately mature, with ongoing innovations. Companies like Arkema France SA, Asahi Kasei Corp., and Solvay Specialty Polymers Italy SpA are leading players, continuously advancing PVDF technology. Other notable contributors include Kureha Corp. and LG Chem Ltd., who are actively developing new applications and improving existing processes. The competitive landscape is characterized by a mix of established chemical companies and innovative materials science firms, all striving to enhance PVDF's performance in multilayer film structures.

Arkema France SA

Asahi Kasei Corp.

Innovative PVDF Multilayer Film Patents

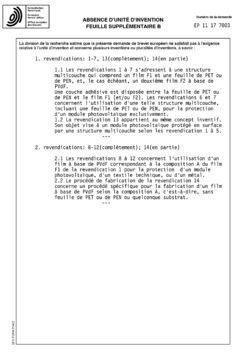

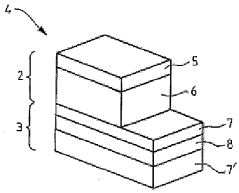

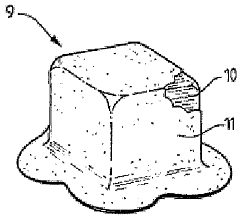

- A multilayer structure combining a PVDF-based film with a PET or PEN sheet, incorporating a flexible PVDF copolymer with high VDF content, a PMMA layer, and an adhesive layer, along with a mineral filler and UV absorber, to enhance adhesion, thermal resistance, and mechanical properties.

- A multilayer structure combining a PVDF-based film with a PET or PEN sheet, incorporating a flexible PVDF copolymer with high VDF content, a PMMA layer, and an adhesive layer, which can include a polyurethane glue, to enhance adhesion and mechanical properties, along with a mineral filler for additional protection.

Environmental Impact of PVDF Multilayer Films

The environmental impact of PVDF multilayer films is a critical consideration in their application and development. These advanced structures offer numerous benefits in terms of performance and durability, but their environmental footprint must be carefully evaluated.

PVDF, as a fluoropolymer, presents both advantages and challenges from an environmental perspective. On the positive side, PVDF's exceptional chemical resistance and longevity contribute to extended product lifecycles, potentially reducing waste generation and resource consumption over time. The material's stability also minimizes the risk of harmful chemical leaching into the environment during use.

However, the production of PVDF and its incorporation into multilayer film structures does raise environmental concerns. The manufacturing process of PVDF involves energy-intensive procedures and the use of fluorine-based compounds, which can have significant greenhouse gas emissions. Additionally, the complex nature of multilayer films, often combining PVDF with other polymers, can complicate recycling efforts and end-of-life management.

The disposal of PVDF multilayer films presents another environmental challenge. While PVDF itself is not biodegradable, proper waste management strategies can mitigate its environmental impact. Incineration of PVDF-containing products must be carried out under controlled conditions to prevent the release of harmful substances, such as hydrogen fluoride.

Recent advancements in recycling technologies offer promising solutions for reducing the environmental footprint of PVDF multilayer films. Mechanical recycling methods, such as delamination and separation of individual layers, are being explored to recover and reuse PVDF components. Chemical recycling techniques, including solvent-based processes, show potential for breaking down multilayer structures into their constituent materials for reprocessing.

The industry is also focusing on developing more environmentally friendly alternatives to traditional PVDF formulations. Bio-based or partially bio-based PVDF variants are being researched to reduce reliance on fossil fuel-derived raw materials. Furthermore, efforts are underway to optimize film structures, minimizing the use of PVDF while maintaining desired performance characteristics.

Life cycle assessments (LCAs) play a crucial role in evaluating the overall environmental impact of PVDF multilayer films. These comprehensive analyses consider factors such as raw material extraction, manufacturing processes, transportation, use phase, and end-of-life scenarios. LCAs help identify hotspots in the product lifecycle where environmental improvements can be made, guiding sustainable design and production practices.

As environmental regulations become more stringent, manufacturers are increasingly adopting eco-design principles in the development of PVDF multilayer films. This approach considers environmental factors from the earliest stages of product design, aiming to minimize resource consumption, reduce emissions, and improve recyclability without compromising performance.

Regulatory Landscape for PVDF in Food Packaging

The regulatory landscape for PVDF in food packaging is complex and evolving, reflecting the growing concern for food safety and environmental impact. In the United States, the Food and Drug Administration (FDA) regulates the use of PVDF in food contact materials under the Federal Food, Drug, and Cosmetic Act. PVDF is generally recognized as safe (GRAS) for use in food packaging, provided it meets specific purity and migration limits.

The European Union has established more stringent regulations through the European Food Safety Authority (EFSA). The EU Regulation No. 10/2011 on plastic materials and articles intended to come into contact with food sets specific migration limits (SMLs) for PVDF and its monomers. Manufacturers must ensure that PVDF-based packaging materials comply with these limits and do not transfer their constituents to food in quantities that could endanger human health.

In Asia, countries like Japan and China have their own regulatory frameworks. Japan's Ministry of Health, Labour and Welfare has established positive lists for food contact materials, including PVDF. China's GB 9685-2016 standard regulates the use of PVDF in food contact materials, setting specific migration limits and usage conditions.

Global harmonization efforts are underway to streamline regulations across different regions. The Global Food Contact Substances (FCS) Initiative, led by industry stakeholders and regulatory bodies, aims to develop a unified approach to food contact material regulations, including those for PVDF.

Environmental concerns have led to increased scrutiny of PVDF in food packaging. While PVDF is not biodegradable, its durability and chemical resistance make it a candidate for recycling programs. Regulatory bodies are considering lifecycle assessments and circular economy principles in their evaluation of PVDF and other polymers used in food packaging.

Emerging regulations are focusing on the potential presence of per- and polyfluoroalkyl substances (PFAS) in PVDF-based materials. Some jurisdictions are implementing bans or restrictions on PFAS in food packaging, which may indirectly affect PVDF usage if trace amounts of these substances are present.

As nanotechnology advances, regulatory bodies are also considering the potential use of PVDF nanocomposites in food packaging. The FDA and EFSA are developing guidelines for the safety assessment of nanomaterials in food contact applications, which may impact future PVDF formulations and applications.