How to Advance PVDF Integration in Wireless Communication?

PVDF in Wireless Comm: Background and Objectives

Polyvinylidene fluoride (PVDF) has emerged as a promising material in the field of wireless communication, offering unique properties that can potentially revolutionize the industry. The integration of PVDF in wireless communication systems has gained significant attention due to its piezoelectric, pyroelectric, and ferroelectric characteristics. These properties make PVDF an ideal candidate for various applications in wireless communication, including sensors, actuators, and energy harvesting devices.

The evolution of wireless communication technology has been marked by continuous advancements in materials and components. PVDF, with its exceptional flexibility and adaptability, presents an opportunity to address some of the challenges faced by current wireless communication systems. The primary objective of integrating PVDF into wireless communication is to enhance the overall performance, efficiency, and functionality of communication devices and infrastructure.

One of the key areas where PVDF shows promise is in the development of flexible and wearable antennas. As the demand for compact and conformable communication devices grows, PVDF's ability to be molded into various shapes while maintaining its electrical properties makes it an attractive option for antenna design. This flexibility allows for the creation of antennas that can be seamlessly integrated into clothing, accessories, or other everyday objects, potentially expanding the reach and capabilities of wireless communication.

Another significant application of PVDF in wireless communication lies in its potential for energy harvesting. The piezoelectric properties of PVDF enable it to convert mechanical energy into electrical energy. This characteristic can be harnessed to develop self-powered wireless sensors and devices, reducing the reliance on traditional power sources and extending the operational life of communication systems in remote or hard-to-reach locations.

The integration of PVDF in wireless communication also aims to address the growing need for improved signal processing and filtering. PVDF-based acoustic wave devices can be utilized for frequency filtering and signal processing in wireless communication systems, potentially leading to enhanced signal quality and reduced interference. This application is particularly relevant in the context of 5G and future generations of wireless networks, where high-frequency operations and complex signal processing are crucial.

As research in this field progresses, the goal is to develop innovative PVDF-based solutions that can overcome current limitations in wireless communication technology. This includes exploring ways to enhance the material's properties, optimize its integration with existing communication systems, and identify novel applications that leverage its unique characteristics. The ultimate objective is to create more efficient, reliable, and versatile wireless communication systems that can meet the evolving demands of our increasingly connected world.

Market Demand Analysis for PVDF-Enhanced Wireless Systems

The integration of Polyvinylidene Fluoride (PVDF) in wireless communication systems has garnered significant attention due to its potential to enhance performance and efficiency. Market demand for PVDF-enhanced wireless systems is driven by the increasing need for high-speed, reliable, and energy-efficient communication technologies across various sectors.

In the telecommunications industry, the rollout of 5G networks has created a substantial demand for advanced materials like PVDF. These materials can improve antenna performance, reduce signal loss, and enhance overall system efficiency. As 5G deployment continues to accelerate globally, the market for PVDF-enhanced components is expected to grow significantly in the coming years.

The consumer electronics sector represents another major market for PVDF-enhanced wireless systems. With the proliferation of smartphones, tablets, and wearable devices, there is a growing demand for compact, high-performance antennas and RF components. PVDF's unique properties make it an attractive option for manufacturers looking to improve device performance while maintaining or reducing form factors.

In the automotive industry, the trend towards connected and autonomous vehicles is driving demand for advanced wireless communication systems. PVDF-enhanced components can help improve in-vehicle connectivity, support vehicle-to-everything (V2X) communication, and enhance the reliability of safety-critical systems. As the automotive sector continues its digital transformation, the market for PVDF-based solutions is expected to expand.

The industrial Internet of Things (IIoT) sector presents another significant opportunity for PVDF-enhanced wireless systems. In smart factories and industrial environments, reliable wireless communication is crucial for monitoring, control, and automation systems. PVDF's resistance to harsh environments and its ability to improve signal quality make it well-suited for these applications.

The aerospace and defense sectors also show promising demand for PVDF-enhanced wireless systems. In these industries, the need for high-performance, lightweight, and durable communication equipment is paramount. PVDF's unique properties can contribute to the development of advanced radar systems, satellite communications, and other mission-critical applications.

As the global focus on sustainability and energy efficiency intensifies, there is growing interest in materials that can improve the energy efficiency of wireless systems. PVDF's potential to reduce power consumption in RF components aligns well with this trend, potentially driving further market demand across various sectors.

While the market potential for PVDF-enhanced wireless systems is significant, it's important to note that adoption may face challenges such as cost considerations, integration complexities, and competition from alternative materials. However, as research and development efforts continue to advance PVDF technology, these barriers are likely to diminish, paving the way for broader market acceptance and implementation.

Current PVDF Integration Challenges in Wireless Communication

The integration of Polyvinylidene Fluoride (PVDF) in wireless communication systems presents several significant challenges that hinder its widespread adoption and optimal performance. One of the primary obstacles is the complex manufacturing process required to produce PVDF-based components suitable for wireless applications. The precise control of crystallinity, orientation, and thickness of PVDF films is crucial for achieving desired piezoelectric properties, yet maintaining consistency across large-scale production remains difficult.

Another major challenge lies in the frequency response limitations of PVDF materials. While PVDF exhibits excellent piezoelectric properties at lower frequencies, its performance tends to degrade at higher frequencies commonly used in modern wireless communication systems. This frequency-dependent behavior restricts the potential applications of PVDF in high-frequency domains, such as 5G and beyond.

The integration of PVDF with existing wireless communication infrastructure also poses significant challenges. Compatibility issues arise when attempting to incorporate PVDF-based components into conventional circuit designs and antenna structures. Engineers must develop novel approaches to seamlessly integrate PVDF elements without compromising the overall system performance or introducing unwanted interference.

Temperature sensitivity is another critical concern in PVDF integration. The piezoelectric properties of PVDF can vary significantly with temperature fluctuations, potentially leading to inconsistent performance in diverse environmental conditions. This sensitivity necessitates the development of robust temperature compensation techniques or the exploration of more stable PVDF copolymers and composites.

The long-term reliability and durability of PVDF-based components in wireless communication systems remain uncertain. Factors such as mechanical stress, environmental exposure, and electrical fatigue can potentially degrade the performance of PVDF over time. Extensive testing and validation procedures are required to ensure the longevity and consistent operation of PVDF-integrated devices in real-world scenarios.

Cost considerations also present a significant barrier to widespread PVDF integration. The specialized manufacturing processes and materials required for high-quality PVDF components can lead to increased production costs compared to conventional alternatives. Striking a balance between performance improvements and economic viability is crucial for the commercial success of PVDF-based wireless communication solutions.

Lastly, the lack of standardization in PVDF integration techniques and performance metrics poses challenges for industry-wide adoption. The absence of unified guidelines and benchmarks makes it difficult for manufacturers and system designers to evaluate and compare different PVDF-based solutions effectively. Establishing industry standards and best practices for PVDF integration in wireless communication will be essential for fostering innovation and accelerating market acceptance.

Existing PVDF Integration Solutions for Wireless Systems

01 PVDF membrane fabrication and modification

Various techniques for fabricating and modifying PVDF membranes to enhance their properties and performance in different applications. This includes methods for improving membrane porosity, hydrophilicity, and mechanical strength through processes such as blending, surface modification, and incorporation of additives.- PVDF membrane fabrication and modification: Various techniques for fabricating and modifying PVDF membranes to enhance their properties and performance in different applications. This includes methods for improving membrane porosity, hydrophilicity, and mechanical strength through processes such as blending, surface modification, and incorporation of additives.

- PVDF-based composites and nanocomposites: Development of PVDF-based composite and nanocomposite materials by incorporating various fillers, nanoparticles, or other polymers. These composites often exhibit enhanced mechanical, thermal, and electrical properties, making them suitable for a wide range of applications in electronics, energy storage, and sensors.

- PVDF in energy storage and conversion devices: Integration of PVDF in energy storage and conversion devices, such as batteries, supercapacitors, and fuel cells. PVDF is used as a binder, separator, or electrolyte material, contributing to improved device performance, stability, and longevity.

- PVDF in sensor and actuator applications: Utilization of PVDF's piezoelectric and pyroelectric properties in various sensor and actuator applications. This includes the development of pressure sensors, motion detectors, and energy harvesting devices that leverage PVDF's ability to generate electrical signals in response to mechanical stress or temperature changes.

- PVDF in water treatment and filtration: Application of PVDF membranes and materials in water treatment and filtration processes. This includes the development of PVDF-based ultrafiltration and microfiltration membranes for water purification, desalination, and wastewater treatment, as well as methods to improve membrane fouling resistance and flux performance.

02 PVDF-based composite materials

Development of composite materials incorporating PVDF for enhanced functionality. These composites often combine PVDF with other polymers, nanoparticles, or functional materials to create hybrid structures with improved mechanical, electrical, or thermal properties for use in various applications such as energy storage, sensors, and filtration systems.Expand Specific Solutions03 PVDF in energy storage and conversion devices

Integration of PVDF in energy-related applications, particularly in the development of batteries, supercapacitors, and piezoelectric devices. PVDF's unique properties, such as its high dielectric constant and ferroelectric behavior, make it valuable for improving the performance and efficiency of these energy storage and conversion systems.Expand Specific Solutions04 PVDF-based sensors and actuators

Utilization of PVDF's piezoelectric properties in the design and fabrication of sensors and actuators. This includes the development of flexible and wearable sensors, pressure sensors, and various types of actuators for applications in robotics, biomedical devices, and environmental monitoring.Expand Specific Solutions05 PVDF in water treatment and filtration

Application of PVDF membranes and materials in water treatment and filtration processes. This involves the development of PVDF-based ultrafiltration and microfiltration membranes, as well as techniques for improving their fouling resistance, flux, and selectivity for various water purification and desalination applications.Expand Specific Solutions

Key Players in PVDF and Wireless Communication Industries

The integration of PVDF in wireless communication is in its early development stage, with a growing market potential driven by the demand for advanced materials in 5G and future networks. The technology's maturity is still evolving, as evidenced by ongoing research and patent activities from key players. Companies like QUALCOMM, Huawei, and Nokia are at the forefront, leveraging their expertise in wireless technologies to explore PVDF applications. Universities and research institutions, such as The University of California and Georgia Tech Research Corp., are contributing significantly to fundamental research. The involvement of materials companies like Furukawa Electric and Corning indicates the cross-disciplinary nature of this field, suggesting a collaborative ecosystem forming around PVDF integration in wireless communication.

QUALCOMM, Inc.

Huawei Technologies Co., Ltd.

Core Innovations in PVDF for Wireless Communication

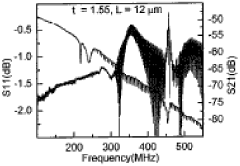

- A novel polymer-based SAW device design using Poly(vinylidenefluoride-trifluoroethylene) (P(VDF-TrFE)) as the piezoelectric layer, deposited on a glass substrate with lithographically patterned metal interdigitated electrodes, employing in-situ poling and a sandwich structure to achieve low insertion loss and high coupling, while maintaining ferroelectric properties through optimized processing.

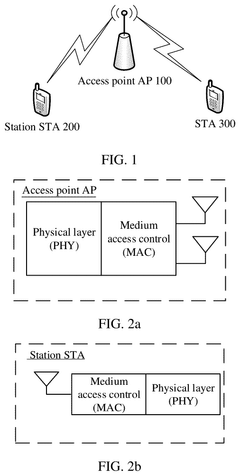

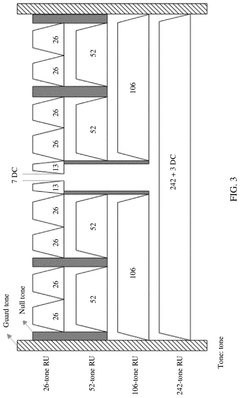

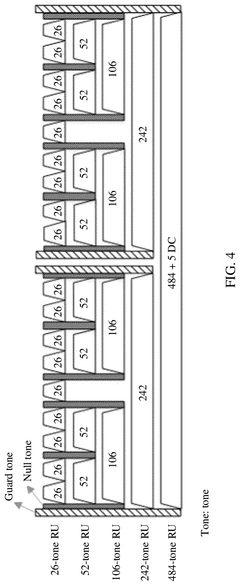

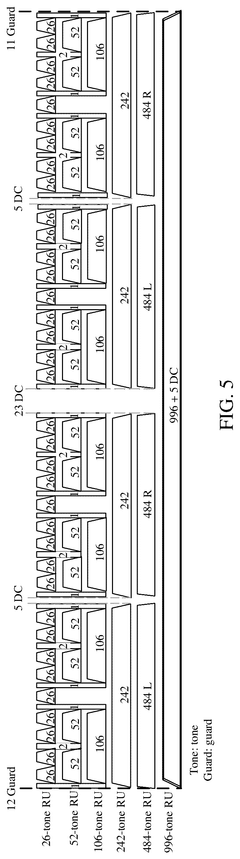

- The implementation of a communication method and apparatus that utilizes a distributed resource unit (DRU) transmission mode with a low peak-to-average ratio (PAPR) long training field (LTF) in trigger-based physical layer protocol data units (PPDU), allowing for improved transmission efficiency and system performance by optimizing tone distribution and resource allocation.

Regulatory Framework for PVDF in Wireless Devices

The regulatory framework for PVDF integration in wireless devices is a critical aspect that shapes the development and deployment of this technology. As PVDF (Polyvinylidene Fluoride) gains traction in wireless communication applications, regulatory bodies worldwide are adapting their guidelines to ensure safe and efficient implementation.

At the forefront of PVDF regulation in wireless devices is the Federal Communications Commission (FCC) in the United States. The FCC has established specific guidelines for the use of PVDF in wireless communication devices, focusing on electromagnetic compatibility and radiation safety. These regulations require manufacturers to demonstrate that PVDF-integrated devices comply with emission limits and do not cause harmful interference to other electronic equipment.

In the European Union, the European Telecommunications Standards Institute (ETSI) plays a crucial role in setting standards for PVDF use in wireless devices. ETSI has developed harmonized standards that align with the Radio Equipment Directive (RED), ensuring that PVDF-integrated devices meet essential requirements for safety, electromagnetic compatibility, and efficient use of the radio spectrum.

The International Telecommunication Union (ITU) has also recognized the potential of PVDF in wireless communication and is working on global recommendations for its integration. These recommendations aim to provide a framework for consistent implementation across different countries and regions, facilitating international trade and interoperability of PVDF-enabled devices.

In Asia, regulatory bodies such as Japan's Ministry of Internal Affairs and Communications (MIC) and China's Ministry of Industry and Information Technology (MIIT) have begun to incorporate PVDF-specific regulations into their existing frameworks for wireless devices. These regulations often focus on performance standards, energy efficiency, and environmental impact considerations.

As PVDF technology evolves, regulatory frameworks are expected to become more sophisticated. Future regulations may address specific aspects of PVDF integration, such as its use in 5G and beyond networks, IoT applications, and wearable devices. Regulatory bodies are likely to collaborate more closely with industry stakeholders to develop standards that balance innovation with safety and performance requirements.

The regulatory landscape for PVDF in wireless devices also encompasses environmental considerations. As sustainability becomes increasingly important, regulations may extend to cover the lifecycle management of PVDF-integrated devices, including recycling and disposal guidelines. This holistic approach aims to ensure that the benefits of PVDF technology are realized without compromising environmental objectives.

Environmental Impact of PVDF in Wireless Communication

The integration of Polyvinylidene Fluoride (PVDF) in wireless communication systems has raised important environmental considerations. PVDF, a fluoropolymer known for its piezoelectric properties, offers significant advantages in antenna design and signal processing. However, its production, use, and disposal present potential environmental challenges that must be carefully evaluated.

The manufacturing process of PVDF involves the use of fluorine-based compounds, which can contribute to greenhouse gas emissions if not properly managed. The production of PVDF monomers and subsequent polymerization require energy-intensive processes, potentially increasing the carbon footprint of wireless communication devices. Additionally, the use of solvents and other chemicals in PVDF production may lead to air and water pollution if strict environmental controls are not implemented.

During the operational phase of PVDF-integrated wireless communication systems, the environmental impact is generally minimal. PVDF components are known for their durability and long lifespan, which can reduce the need for frequent replacements and minimize electronic waste. The material's resistance to degradation also means that it does not release harmful substances into the environment under normal operating conditions.

However, the end-of-life management of PVDF-containing devices presents significant challenges. PVDF is not biodegradable and can persist in the environment for extended periods. Improper disposal of PVDF-integrated components may lead to the accumulation of fluoropolymers in landfills or natural ecosystems. Incineration of PVDF waste can result in the release of toxic gases, including hydrogen fluoride, necessitating specialized waste treatment facilities.

To mitigate these environmental concerns, several strategies can be employed. Developing more efficient PVDF production methods that reduce energy consumption and minimize the use of harmful chemicals is crucial. Implementing closed-loop manufacturing processes and exploring bio-based alternatives for certain PVDF applications could further reduce the environmental footprint.

Improving recycling technologies for PVDF-containing devices is essential for sustainable wireless communication. This includes developing methods for separating PVDF from other materials in electronic waste and exploring chemical recycling techniques to break down PVDF into reusable monomers. Encouraging manufacturers to design products with end-of-life considerations in mind can facilitate easier disassembly and recycling.

As the demand for wireless communication continues to grow, balancing the technological benefits of PVDF with environmental responsibility becomes increasingly important. Future research should focus on developing eco-friendly alternatives that maintain the desirable properties of PVDF while reducing its environmental impact. This may involve exploring hybrid materials or novel composites that combine the performance of PVDF with improved environmental characteristics.