How to Implement PVDF Technologies in Farmlands Automation?

PVDF in Agriculture: Background and Objectives

Polyvinylidene fluoride (PVDF) technology has emerged as a promising solution for advancing agricultural automation and precision farming. The integration of PVDF sensors and actuators in farmland management systems represents a significant leap forward in the quest for sustainable and efficient agricultural practices. This technology, originally developed for industrial applications, has found a new purpose in the agricultural sector due to its unique properties and versatility.

The evolution of PVDF technology in agriculture can be traced back to the early 2000s when researchers began exploring its potential for soil moisture sensing and crop monitoring. As the technology matured, its applications expanded to include irrigation control, pest detection, and even crop yield prediction. The primary objective of implementing PVDF technologies in farmland automation is to enhance resource utilization, minimize environmental impact, and optimize crop production through data-driven decision-making.

PVDF's piezoelectric properties make it an ideal candidate for developing highly sensitive and durable sensors capable of withstanding harsh agricultural environments. These sensors can detect minute changes in soil moisture, temperature, and nutrient levels, providing farmers with real-time data to make informed decisions about irrigation, fertilization, and pest control. Furthermore, PVDF-based actuators can be employed in precision agriculture systems for targeted application of water, fertilizers, and pesticides, significantly reducing waste and environmental impact.

The current technological landscape is characterized by a growing interest in integrating PVDF sensors with Internet of Things (IoT) platforms and artificial intelligence algorithms. This convergence of technologies aims to create smart farming systems that can autonomously monitor and manage agricultural operations, adapting to changing environmental conditions and crop requirements in real-time. The ultimate goal is to develop a fully automated farmland ecosystem that maximizes productivity while minimizing resource consumption and environmental footprint.

As we look towards the future, the implementation of PVDF technologies in farmland automation faces several challenges and opportunities. One of the primary challenges is the need for standardization and scalability of PVDF-based agricultural solutions. Researchers and industry players are working towards developing plug-and-play PVDF sensor networks that can be easily integrated into existing farm management systems. Additionally, efforts are being made to improve the energy efficiency and durability of PVDF devices to ensure long-term reliability in diverse agricultural settings.

The potential impact of PVDF technologies on global food security and sustainable agriculture cannot be overstated. By enabling precise control over agricultural inputs and outputs, these technologies have the potential to significantly increase crop yields while reducing the environmental impact of farming practices. As climate change continues to pose challenges to traditional agricultural methods, the adoption of PVDF-based smart farming solutions may prove crucial in ensuring food security for a growing global population.

Market Analysis for Smart Farming Solutions

The smart farming solutions market is experiencing significant growth, driven by the increasing demand for precision agriculture and the need to optimize farm productivity. As farmers seek to enhance efficiency and reduce costs, the adoption of advanced technologies like PVDF (Polyvinylidene Fluoride) in farmland automation is gaining traction.

The global smart farming market is projected to expand rapidly in the coming years, with a compound annual growth rate (CAGR) exceeding 10% through 2026. This growth is fueled by factors such as population growth, climate change, and the need for sustainable agricultural practices. The integration of PVDF technologies in farmland automation represents a promising segment within this market.

PVDF sensors and actuators offer unique advantages in agricultural applications due to their durability, flexibility, and resistance to harsh environmental conditions. These properties make them ideal for use in soil moisture monitoring, crop health assessment, and automated irrigation systems. The market for PVDF-based smart farming solutions is expected to grow as farmers recognize the benefits of these technologies in improving crop yields and resource management.

One of the key drivers for the adoption of PVDF technologies in farmland automation is the increasing focus on water conservation. With water scarcity becoming a critical issue in many agricultural regions, PVDF-based soil moisture sensors and smart irrigation systems are gaining popularity. These solutions enable precise water management, reducing waste and improving crop resilience to drought conditions.

Another significant market trend is the integration of PVDF sensors with IoT (Internet of Things) platforms and data analytics. This combination allows for real-time monitoring of field conditions and automated decision-making, enhancing overall farm management. The demand for such integrated solutions is expected to drive further growth in the PVDF-based smart farming market.

The market for PVDF technologies in farmland automation is not without challenges. High initial investment costs and the need for technical expertise can be barriers to adoption, particularly for small-scale farmers. However, as technology costs decrease and awareness of the long-term benefits increases, these obstacles are expected to diminish.

Geographically, North America and Europe are currently leading in the adoption of smart farming solutions, including PVDF-based technologies. However, rapid growth is anticipated in Asia-Pacific and Latin American markets as agricultural modernization efforts intensify in these regions. Government initiatives promoting sustainable agriculture and precision farming techniques are likely to further stimulate market growth in emerging economies.

In conclusion, the market analysis for smart farming solutions, particularly those incorporating PVDF technologies for farmland automation, indicates a robust growth trajectory. The increasing need for efficient resource management, coupled with advancements in sensor technologies and data analytics, positions PVDF-based solutions as a key component in the future of agriculture.

Current PVDF Applications and Challenges in Agriculture

Polyvinylidene fluoride (PVDF) technology has found increasing applications in agricultural automation, particularly in sensor systems for monitoring and controlling various environmental parameters. Currently, PVDF-based sensors are being utilized for soil moisture detection, crop health monitoring, and precision irrigation systems. These sensors leverage PVDF's piezoelectric properties to convert mechanical stress into electrical signals, enabling real-time data collection on soil conditions and plant health.

One of the primary applications of PVDF in agriculture is in soil moisture sensors. These sensors can accurately measure water content in the soil, allowing farmers to optimize irrigation schedules and conserve water resources. PVDF sensors are particularly effective due to their high sensitivity to pressure changes, which correlate with soil moisture levels. This technology has shown promise in improving water use efficiency and crop yields in various agricultural settings.

Another significant application is in crop health monitoring systems. PVDF-based sensors can detect subtle changes in plant physiology, such as leaf movement or stem vibrations, which may indicate stress factors like pest infestations or nutrient deficiencies. This early detection capability enables farmers to take prompt action, potentially reducing crop losses and minimizing the use of pesticides and fertilizers.

Despite these advancements, the implementation of PVDF technologies in farmland automation faces several challenges. One major hurdle is the durability of PVDF sensors in harsh agricultural environments. Exposure to extreme temperatures, humidity, and chemical compounds in fertilizers and pesticides can degrade sensor performance over time. Researchers are working on developing more robust PVDF formulations and protective coatings to enhance sensor longevity in field conditions.

Another challenge lies in the integration of PVDF sensors with existing farm management systems. Many farms already have established infrastructure for data collection and analysis, and incorporating new PVDF-based systems requires significant investment in hardware and software upgrades. This integration challenge is compounded by the need for standardized data formats and communication protocols to ensure seamless operation across different agricultural technologies.

The cost of implementing PVDF technologies on a large scale remains a significant barrier for many farmers, particularly in developing regions. While the long-term benefits of improved resource management and increased yields are clear, the initial investment can be prohibitive. Efforts are underway to develop more cost-effective PVDF sensor designs and to create scalable solutions that can be adapted to farms of various sizes and budgets.

Existing PVDF Implementation Strategies

01 PVDF membrane technology

PVDF membranes are widely used in various applications due to their excellent chemical resistance, thermal stability, and mechanical strength. These membranes are employed in water treatment, gas separation, and biomedical applications. The technology involves the development of different membrane structures and surface modifications to enhance performance and selectivity.- PVDF membrane technology: PVDF membranes are widely used in various applications due to their excellent chemical resistance, mechanical strength, and thermal stability. These membranes are employed in water treatment, gas separation, and biomedical applications. The technology involves the development of different membrane structures and surface modifications to enhance performance and selectivity.

- PVDF-based piezoelectric devices: PVDF and its copolymers exhibit piezoelectric properties, making them suitable for various sensing and energy harvesting applications. This technology focuses on developing PVDF-based piezoelectric devices for use in sensors, actuators, and energy generators. The manufacturing processes and device structures are optimized to enhance the piezoelectric response and overall performance.

- PVDF nanocomposites: PVDF nanocomposites combine the properties of PVDF with various nanofillers to enhance mechanical, thermal, and electrical properties. This technology involves the development of novel PVDF nanocomposites with improved characteristics for applications in electronics, energy storage, and structural materials. The focus is on optimizing the dispersion of nanofillers and their interaction with the PVDF matrix.

- PVDF coating technologies: PVDF coatings are used to provide corrosion resistance, weatherability, and chemical resistance to various substrates. This technology encompasses the development of PVDF-based coating formulations, application methods, and curing processes. The focus is on improving adhesion, durability, and performance of PVDF coatings in different environmental conditions.

- PVDF-based energy storage devices: PVDF and its derivatives are utilized in energy storage applications, particularly in lithium-ion batteries and supercapacitors. This technology focuses on developing PVDF-based separators, binders, and electrolytes to enhance the performance and safety of energy storage devices. The research includes optimizing the polymer structure and incorporating functional additives to improve ionic conductivity and electrochemical stability.

02 PVDF-based piezoelectric devices

PVDF and its copolymers exhibit piezoelectric properties, making them suitable for various sensing and energy harvesting applications. This technology focuses on developing PVDF-based piezoelectric devices for use in sensors, actuators, and energy generators. The fabrication process often involves stretching and poling of PVDF films to enhance their piezoelectric response.Expand Specific Solutions03 PVDF nanocomposites

PVDF nanocomposites combine the properties of PVDF with various nanofillers to enhance mechanical, thermal, and electrical properties. This technology involves the development of new nanocomposite materials for applications in electronics, energy storage, and structural components. The incorporation of nanofillers can significantly improve the performance of PVDF-based materials.Expand Specific Solutions04 PVDF coating technology

PVDF coatings are used to provide corrosion resistance, chemical resistance, and weatherability to various substrates. This technology focuses on developing PVDF-based coating formulations, application methods, and curing processes. PVDF coatings find applications in architectural, industrial, and automotive sectors.Expand Specific Solutions05 PVDF in energy storage devices

PVDF and its derivatives are used as binders and separators in lithium-ion batteries and other energy storage devices. This technology involves the development of PVDF-based materials with improved electrochemical stability, ionic conductivity, and mechanical properties for enhancing the performance and safety of energy storage systems.Expand Specific Solutions

Key Players in Agricultural PVDF Solutions

The implementation of PVDF technologies in farmlands automation is in its early stages, with the market showing significant growth potential. The global smart agriculture market, which includes PVDF applications, is projected to expand rapidly. Technologically, PVDF implementation in agriculture is still evolving, with varying levels of maturity across different applications. Companies like Siemens Corp., Deere & Co., and ABB Patent GmbH are leading in industrial automation, potentially adapting their expertise to agricultural settings. Startups such as OnePointOne, Inc. and Aigen, Inc. are focusing on innovative agricultural technologies, while established players like QUALCOMM, Inc. and BYD Co., Ltd. may contribute their technological prowess to advance PVDF applications in farmland automation.

Schneider Electric Industries SASU

DENSO Corp.

Innovative PVDF Sensor Designs for Farmlands

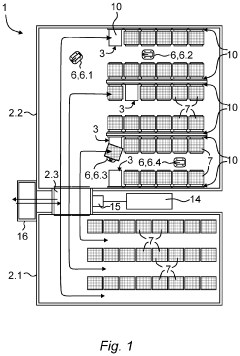

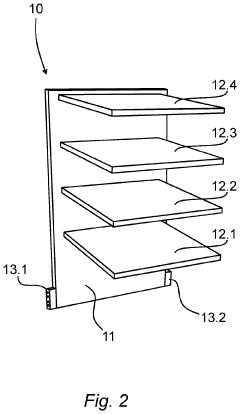

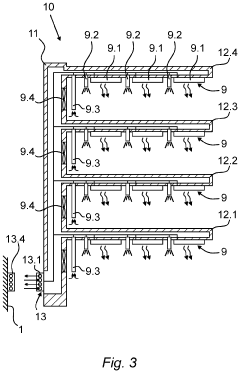

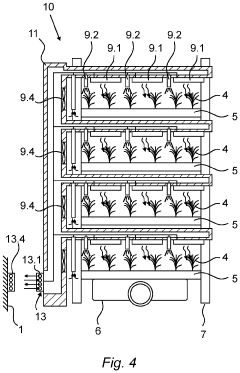

- An automated method for greenhouse operation involving a transport system that moves plant carriers between lighted and unlighted growth rooms, simulating day/night cycles with artificial lighting, and using a supply device to provide necessary resources, allowing for efficient energy use and reduced personnel requirements.

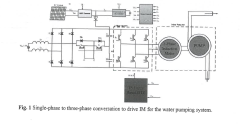

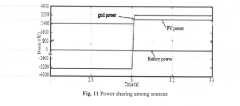

- A hybrid power supply system combining single-phase grid, PV source, and battery bank with active front-end converter, DC-DC converter, bi-directional power converter, and fuzzy logic control to manage energy efficiently and regulate motor speed, eliminating the need for three-phase supply and enhancing reliability.

Environmental Impact of PVDF in Agriculture

The implementation of PVDF (Polyvinylidene Fluoride) technologies in farmland automation brings both potential benefits and environmental concerns. As these technologies become more prevalent in agricultural practices, it is crucial to assess their environmental impact comprehensively.

PVDF-based sensors and actuators used in precision agriculture can significantly reduce the use of water, fertilizers, and pesticides. This optimization leads to decreased runoff of agrochemicals into nearby water bodies, potentially mitigating water pollution and eutrophication. The more efficient use of resources also contributes to reduced greenhouse gas emissions associated with the production and application of agricultural inputs.

However, the production and disposal of PVDF materials raise environmental concerns. The manufacturing process of PVDF involves fluorine-based chemicals, which can have a high global warming potential if released into the atmosphere. Proper containment and treatment of these chemicals during production are essential to minimize their environmental impact.

The durability of PVDF materials is a double-edged sword from an environmental perspective. While their long lifespan reduces the need for frequent replacements, it also means that PVDF products persist in the environment for extended periods when disposed of improperly. This persistence can lead to potential soil and water contamination if not managed correctly at the end of their life cycle.

Recycling PVDF materials presents challenges due to their chemical stability and resistance to degradation. Developing effective recycling methods for PVDF-based agricultural technologies is crucial to mitigate their long-term environmental impact and promote a circular economy in the agricultural sector.

The use of PVDF in agricultural automation may also have indirect environmental benefits. By enabling more precise and efficient farming practices, these technologies can potentially reduce the need for agricultural land expansion, thereby helping to preserve natural habitats and biodiversity.

As PVDF technologies become more widespread in farmland automation, it is essential to conduct comprehensive life cycle assessments to fully understand their environmental implications. These assessments should consider the entire lifecycle of PVDF products, from raw material extraction to end-of-life disposal or recycling.

In conclusion, while PVDF technologies offer significant potential for improving agricultural efficiency and reducing certain environmental impacts, their widespread adoption must be accompanied by responsible manufacturing practices, proper waste management, and ongoing research into sustainable alternatives and recycling methods to ensure a net positive environmental outcome in the long term.

Cost-Benefit Analysis of PVDF Farm Technologies

The implementation of PVDF (Polyvinylidene Fluoride) technologies in farmland automation presents a complex cost-benefit scenario that requires careful analysis. Initial investment costs for PVDF-based systems can be substantial, encompassing expenses for sensors, actuators, control systems, and installation. However, these upfront costs should be weighed against the long-term benefits and potential savings.

One of the primary advantages of PVDF technologies in agriculture is their ability to enhance water management and irrigation efficiency. By precisely monitoring soil moisture levels and controlling water distribution, PVDF sensors can significantly reduce water consumption, leading to lower utility costs and conservation of this vital resource. This is particularly valuable in regions facing water scarcity or drought conditions.

Energy savings represent another key benefit of PVDF farm technologies. Smart irrigation systems powered by PVDF sensors can optimize pump operation and reduce unnecessary energy expenditure. Over time, these energy savings can translate into substantial cost reductions for farm operations, especially in areas with high electricity rates.

The implementation of PVDF technologies can also lead to increased crop yields and quality. By providing real-time data on soil conditions and enabling precise control of irrigation and fertilization, these systems allow farmers to create optimal growing conditions for their crops. The resulting improvements in yield and crop quality can significantly boost farm revenues, offsetting the initial investment costs.

Maintenance costs for PVDF-based systems are generally low due to the durability and reliability of the technology. PVDF sensors are known for their resistance to harsh environmental conditions, chemicals, and UV radiation, which reduces the need for frequent replacements or repairs. This longevity contributes to a favorable long-term cost-benefit ratio.

Labor cost savings are another important factor to consider. Automation through PVDF technologies can reduce the need for manual monitoring and intervention in farm operations, allowing farmers to allocate their workforce more efficiently. This can lead to reduced labor costs and improved overall farm productivity.

While the benefits of PVDF farm technologies are significant, it's crucial to consider potential challenges that may impact the cost-benefit analysis. These include the need for technical expertise to operate and maintain the systems, potential integration issues with existing farm infrastructure, and the learning curve associated with adopting new technologies.

In conclusion, the cost-benefit analysis of PVDF farm technologies generally favors implementation, especially when considering long-term operational improvements and resource savings. However, the specific return on investment will vary based on factors such as farm size, crop types, local climate conditions, and existing infrastructure. A thorough assessment of these factors is essential for farmers to make informed decisions about adopting PVDF technologies in their operations.