PVDF in Waste Water Management: Enhancing System Capacity

PVDF Technology Evolution and Objectives

Polyvinylidene fluoride (PVDF) has emerged as a crucial material in waste water management systems, with its evolution closely tied to the growing demands for efficient and sustainable water treatment solutions. The technology's development can be traced back to the 1960s when PVDF was first synthesized, but its application in water treatment gained momentum in the late 1980s and early 1990s.

The primary objective of PVDF technology in waste water management is to enhance system capacity while maintaining or improving filtration efficiency. This goal has driven continuous innovation in membrane design, material properties, and manufacturing processes. Over the years, researchers and engineers have focused on improving PVDF's hydrophilicity, mechanical strength, and fouling resistance to meet the increasing challenges of water purification.

In the early stages of PVDF membrane development, the focus was on creating basic filtration membranes with adequate pore size and distribution. As the technology progressed, attention shifted towards enhancing membrane performance through surface modifications and the incorporation of additives. These advancements aimed to address issues such as membrane fouling and flux decline, which were limiting factors in early PVDF-based systems.

The evolution of PVDF technology has been marked by several key milestones. The introduction of hollow fiber PVDF membranes in the 1990s significantly increased the surface area available for filtration, thereby boosting system capacity. Subsequently, the development of nanocomposite PVDF membranes in the early 2000s further improved performance by incorporating nanomaterials to enhance properties such as antimicrobial activity and self-cleaning capabilities.

Recent technological trends in PVDF membrane development include the exploration of novel fabrication techniques such as electrospinning and 3D printing. These methods offer the potential for creating more complex and efficient membrane structures, further pushing the boundaries of system capacity and filtration effectiveness.

The ongoing objectives for PVDF technology in waste water management are multifaceted. Researchers are striving to develop membranes with higher flux rates and improved selectivity, capable of removing emerging contaminants such as microplastics and pharmaceutical residues. Additionally, there is a strong focus on creating more durable and long-lasting membranes to reduce operational costs and environmental impact.

Another critical objective is the development of PVDF membranes with enhanced antifouling properties. This involves innovative surface modifications and the integration of smart materials that can respond to environmental stimuli, potentially leading to self-cleaning membranes that maintain high performance over extended periods.

Market Demand Analysis for PVDF in Wastewater

The market demand for PVDF (Polyvinylidene Fluoride) in wastewater management has been experiencing significant growth in recent years. This surge is primarily driven by the increasing global focus on water scarcity and the need for efficient water treatment solutions. PVDF membranes have emerged as a crucial component in advanced wastewater treatment systems, offering superior performance in terms of filtration efficiency and durability.

The wastewater treatment industry has been rapidly expanding, with a particular emphasis on membrane-based technologies. PVDF membranes are widely used in various applications within this sector, including microfiltration, ultrafiltration, and membrane bioreactors. These membranes are valued for their excellent chemical resistance, thermal stability, and mechanical strength, making them ideal for handling diverse types of wastewater.

In the industrial sector, stringent environmental regulations have been a key driver for the adoption of PVDF membranes. Industries such as textiles, pharmaceuticals, and food processing are increasingly investing in advanced wastewater treatment systems to comply with discharge standards and reduce their environmental footprint. This regulatory pressure has created a substantial market for PVDF-based solutions.

Municipal wastewater treatment plants are another significant market for PVDF membranes. As urban populations continue to grow and water resources become scarcer, there is an increasing need for efficient and reliable wastewater treatment technologies. PVDF membranes offer a cost-effective solution for upgrading existing plants and constructing new facilities capable of meeting stringent water quality standards.

The market for PVDF in wastewater management is also benefiting from the growing trend towards water reuse and recycling. In water-stressed regions, there is a rising demand for technologies that can treat wastewater to a level suitable for non-potable reuse applications. PVDF membranes play a crucial role in these advanced treatment processes, enabling the production of high-quality reclaimed water.

Geographically, the Asia-Pacific region is expected to be a major growth market for PVDF in wastewater applications. Rapid industrialization, urbanization, and increasing water pollution in countries like China and India are driving the demand for advanced water treatment technologies. North America and Europe, with their established water treatment infrastructure, are also significant markets, particularly for upgrading and retrofitting existing systems.

The market potential for PVDF in wastewater management is further enhanced by ongoing research and development efforts. Innovations in membrane technology, such as the development of anti-fouling PVDF membranes and hybrid membrane systems, are expanding the application scope and improving the overall performance of PVDF-based solutions. These advancements are expected to fuel market growth and open up new opportunities in the wastewater treatment sector.

Current PVDF Challenges in Wastewater Management

Polyvinylidene fluoride (PVDF) membranes have become increasingly popular in wastewater management due to their excellent chemical resistance, thermal stability, and mechanical strength. However, as the demand for more efficient and sustainable water treatment systems grows, several challenges have emerged in the application of PVDF membranes.

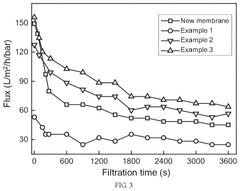

One of the primary challenges facing PVDF membranes in wastewater management is membrane fouling. This phenomenon occurs when contaminants accumulate on the membrane surface or within its pores, leading to reduced permeability and decreased system efficiency. Fouling can be particularly problematic in wastewater treatment, where the influent contains a complex mixture of organic and inorganic compounds, microorganisms, and suspended solids. The hydrophobic nature of PVDF membranes makes them more susceptible to organic fouling, which can significantly impact their long-term performance and lifespan.

Another significant challenge is the trade-off between membrane permeability and selectivity. While increasing the pore size of PVDF membranes can enhance water flux and system capacity, it often comes at the cost of reduced selectivity and contaminant rejection. Striking the right balance between these two factors remains a critical challenge in optimizing PVDF membrane performance for wastewater treatment applications.

The limited chemical compatibility of PVDF membranes with certain organic solvents and strong oxidizing agents poses another challenge in wastewater management. Although PVDF exhibits excellent resistance to many chemicals, it can be degraded by some organic solvents commonly found in industrial wastewater streams. This limitation restricts the use of PVDF membranes in certain industrial applications and necessitates careful consideration of the wastewater composition when designing treatment systems.

Thermal stability is another area where PVDF membranes face challenges in wastewater management. While PVDF has good thermal resistance compared to many other polymeric membranes, its performance can still be affected by high temperatures encountered in some industrial processes. Prolonged exposure to elevated temperatures can lead to membrane deformation, reduced mechanical strength, and altered pore structure, ultimately impacting the membrane's separation efficiency and lifespan.

The environmental impact of PVDF membrane production and disposal is an emerging challenge that needs to be addressed. As the demand for PVDF membranes in wastewater treatment grows, concerns about the sustainability of their production process and end-of-life management have come to the forefront. The use of fluorine-based chemicals in PVDF synthesis raises environmental and health concerns, while the disposal of used membranes presents challenges in terms of recyclability and potential environmental contamination.

Lastly, the cost-effectiveness of PVDF membranes in large-scale wastewater treatment systems remains a challenge. While PVDF membranes offer superior performance in many aspects, their higher cost compared to some alternative materials can limit their adoption in budget-constrained projects. Balancing the long-term benefits of PVDF membranes against their initial investment costs continues to be a consideration for many wastewater treatment facility operators and decision-makers.

Existing PVDF-based Wastewater Treatment Methods

01 PVDF membrane fabrication and modification

Various techniques for fabricating and modifying PVDF membranes to enhance their performance and capacity in filtration systems. This includes methods for improving pore structure, surface properties, and overall membrane efficiency.- PVDF membrane fabrication and modification: Various techniques for fabricating and modifying PVDF membranes to enhance their performance and capacity in filtration systems. This includes methods for improving pore structure, surface properties, and overall membrane efficiency.

- PVDF-based energy storage systems: Development of PVDF-based materials and structures for energy storage applications, such as batteries and capacitors. This includes innovations in electrode design, electrolyte composition, and overall system architecture to improve capacity and performance.

- PVDF in water treatment and purification: Applications of PVDF systems in water treatment and purification processes, focusing on enhancing filtration efficiency, fouling resistance, and overall system capacity for handling large volumes of water.

- PVDF composite materials for enhanced properties: Development of PVDF-based composite materials by incorporating various additives or nanoparticles to improve mechanical strength, thermal stability, and overall system capacity in different applications.

- PVDF in sensor and actuator technologies: Utilization of PVDF's piezoelectric properties in sensor and actuator technologies, focusing on improving sensitivity, response time, and overall system capacity for various sensing and actuation applications.

02 PVDF-based energy storage systems

Development of PVDF-based materials and structures for energy storage applications, such as batteries and capacitors. This includes innovations in electrode design, electrolyte composition, and overall system architecture to improve capacity and performance.Expand Specific Solutions03 PVDF in water treatment and purification

Applications of PVDF systems in water treatment and purification processes, focusing on enhancing filtration efficiency, fouling resistance, and overall system capacity for handling large volumes of water.Expand Specific Solutions04 PVDF composite materials for enhanced properties

Development of PVDF-based composite materials by incorporating various additives or nanoparticles to improve mechanical strength, thermal stability, and overall system capacity in different applications.Expand Specific Solutions05 PVDF in sensor and actuator systems

Utilization of PVDF's piezoelectric properties in sensor and actuator systems, focusing on improving sensitivity, response time, and overall system capacity for various sensing and actuation applications.Expand Specific Solutions

Key Players in PVDF Wastewater Solutions

The application of PVDF in waste water management is in a growth phase, with increasing market size due to rising environmental concerns and stringent regulations. The technology's maturity varies across different applications, but overall, it's advancing rapidly. Companies like Veolia Water Solutions & Technologies Support SAS, Repligen Corp., and Salsnes Filter AS are at the forefront, developing innovative PVDF-based solutions to enhance system capacity. Academic institutions such as Tongji University and Tiangong University are contributing to research and development. The market is competitive, with both established players and emerging companies like Tus Environmental Science & Technology Development Co., Ltd. and Guirun Environmental Technology Co., Ltd. entering the field, driving technological advancements and market expansion.

Repligen Corp.

Salsnes Filter AS

Innovative PVDF Membrane Technologies

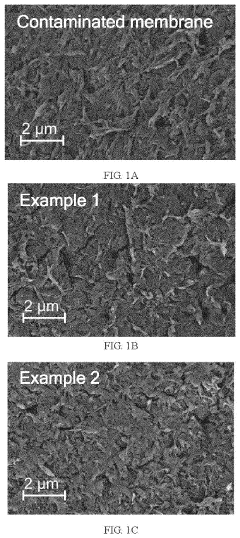

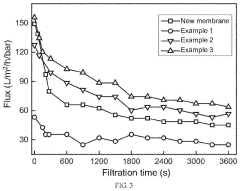

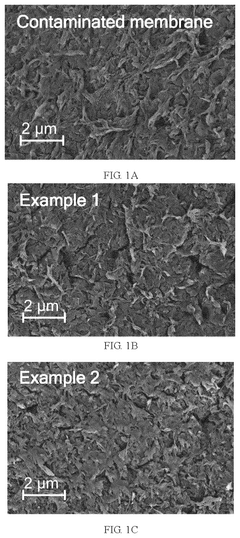

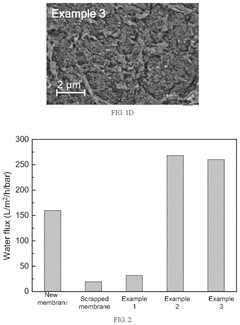

- A method involving chemical cleaning, structural transformation using a mixed solvent solution, and hydrophilicity repair with a dopamine solution to restore membrane flux and anti-contamination performance, allowing for the reuse of scrapped PVDF membranes.

- A method involving chemical cleaning, structural transformation using organic solvents, and hydrophilicity repair with dopamine to restore membrane flux and anti-contamination performance, allowing for the reuse of scrapped PVDF membranes.

Environmental Impact of PVDF in Wastewater

The environmental impact of PVDF (Polyvinylidene Fluoride) in wastewater management is a critical consideration as its usage in membrane filtration systems continues to grow. PVDF membranes have gained popularity due to their excellent chemical resistance, thermal stability, and mechanical strength, making them ideal for various wastewater treatment applications.

One of the primary environmental benefits of PVDF in wastewater treatment is its ability to effectively remove contaminants, including microplastics, suspended solids, and dissolved pollutants. This results in cleaner effluent discharge, reducing the overall environmental burden on receiving water bodies. The high filtration efficiency of PVDF membranes also contributes to water conservation efforts by enabling the reuse of treated wastewater in industrial processes or irrigation.

However, the production and disposal of PVDF membranes raise some environmental concerns. The manufacturing process of PVDF involves the use of fluorine-based chemicals, which can have potential environmental impacts if not properly managed. Additionally, the end-of-life disposal of PVDF membranes presents challenges due to their non-biodegradable nature and the presence of fluoropolymers.

To address these concerns, research is being conducted on developing more sustainable PVDF membrane production methods and exploring recycling options for used membranes. Some studies have shown promise in chemical recycling techniques that can recover valuable materials from spent PVDF membranes, potentially reducing their environmental footprint.

The long lifespan of PVDF membranes, typically ranging from 5 to 10 years, helps offset some of the environmental impacts associated with their production and disposal. This durability reduces the frequency of membrane replacement, thereby minimizing waste generation and resource consumption over time.

In terms of energy efficiency, PVDF membranes generally require less energy for operation compared to traditional wastewater treatment methods. This lower energy demand translates to reduced greenhouse gas emissions associated with the treatment process, contributing to the overall environmental sustainability of wastewater management systems.

As the use of PVDF in wastewater treatment continues to expand, ongoing research focuses on optimizing membrane performance while minimizing environmental impacts. This includes developing novel PVDF membrane formulations with enhanced fouling resistance, which can further extend membrane life and reduce the need for chemical cleaning agents. Such advancements promise to improve the environmental profile of PVDF-based wastewater treatment systems in the future.

Cost-Benefit Analysis of PVDF Systems

The cost-benefit analysis of PVDF systems in waste water management is a crucial aspect of evaluating their potential for enhancing system capacity. PVDF (Polyvinylidene fluoride) membranes have gained significant attention in recent years due to their superior performance characteristics and durability in water treatment applications.

Initial investment costs for PVDF systems are generally higher compared to traditional water treatment methods. The membrane modules, supporting infrastructure, and installation expenses contribute to the elevated upfront costs. However, these initial expenditures should be weighed against the long-term benefits and operational savings that PVDF systems offer.

One of the primary advantages of PVDF systems is their enhanced filtration efficiency. The membranes can effectively remove a wide range of contaminants, including suspended solids, bacteria, and even some dissolved substances. This improved water quality translates to reduced downstream treatment requirements and potentially lower chemical usage, resulting in operational cost savings over time.

PVDF membranes also demonstrate excellent chemical resistance and mechanical strength, leading to extended operational lifespans. This durability reduces the frequency of membrane replacement, thereby lowering long-term maintenance costs. Additionally, the robust nature of PVDF allows for more aggressive cleaning protocols, which can help maintain system performance and extend membrane life even further.

Energy consumption is another critical factor in the cost-benefit analysis. While PVDF systems may require initial energy inputs for pressure-driven filtration, their overall energy efficiency can be superior to conventional treatment methods. The ability to operate at lower pressures compared to some other membrane materials contributes to reduced energy costs over the system's lifetime.

The increased capacity of PVDF systems is a significant benefit that must be factored into the analysis. These systems can handle higher flux rates and maintain performance under challenging water conditions, potentially reducing the physical footprint required for treatment facilities. This aspect can lead to substantial savings in land acquisition and construction costs, especially in urban areas where space is at a premium.

Operational flexibility is another advantage of PVDF systems. They can be easily scaled to accommodate fluctuating demand or expanded to meet growing capacity needs. This adaptability can result in more efficient capital expenditure planning and reduced risks associated with over- or under-sizing treatment facilities.

When considering the environmental impact, PVDF systems often demonstrate favorable outcomes. The improved water quality and reduced chemical usage contribute to a smaller environmental footprint. Furthermore, the longevity of PVDF membranes means less frequent disposal and replacement, aligning with sustainability goals and potentially offering cost savings through reduced waste management expenses.

In conclusion, while the initial investment in PVDF systems for waste water management may be higher, the long-term benefits often outweigh the costs. Improved water quality, operational efficiency, durability, and environmental performance contribute to a compelling value proposition. A comprehensive cost-benefit analysis should consider these factors over the entire lifecycle of the system to accurately assess the financial and operational advantages of implementing PVDF technology in waste water management applications.