High-pressure crystallography advancements from MSH studies.

JUL 17, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MSH High-Pressure Crystallography Background

High-pressure crystallography has emerged as a powerful technique for studying the behavior of materials under extreme conditions, with significant advancements stemming from magnesium silicate hydroxide (MSH) studies. This field has evolved rapidly over the past few decades, driven by the need to understand the Earth's deep interior and the quest for novel materials with unique properties.

The development of high-pressure crystallography can be traced back to the mid-20th century, with pioneering work by Percy Williams Bridgman, who received the Nobel Prize in Physics for his high-pressure physics research. However, it was not until the 1970s and 1980s that the technique gained momentum in geoscience and materials science, particularly with the advent of diamond anvil cells (DACs) capable of generating pressures comparable to those in the Earth's core.

MSH studies have played a crucial role in advancing high-pressure crystallography, as these minerals are key components of the Earth's mantle and subducting slabs. The investigation of MSH phases under high-pressure conditions has provided invaluable insights into the structure and dynamics of the Earth's interior, as well as the mechanisms of deep-focus earthquakes and mantle convection.

One of the most significant breakthroughs in this field was the discovery of the post-perovskite phase of MgSiO3 in 2004, which revolutionized our understanding of the D" layer at the core-mantle boundary. This finding was made possible by advancements in high-pressure experimental techniques and synchrotron X-ray diffraction methods, many of which were developed or refined through MSH studies.

The technological evolution in high-pressure crystallography has been marked by improvements in pressure generation, measurement, and in situ characterization techniques. The development of laser-heated DACs, for instance, has allowed researchers to simulate conditions of both high pressure and high temperature simultaneously, more accurately representing the extreme environments found in planetary interiors.

Synchrotron radiation sources have also played a pivotal role in advancing high-pressure crystallography. The high brilliance and energy of synchrotron X-rays have enabled researchers to probe smaller sample volumes and achieve higher resolution data, even at extreme pressures. This has been particularly beneficial for MSH studies, where subtle structural changes can have profound implications for material properties and geodynamic processes.

In recent years, the integration of computational methods with experimental high-pressure crystallography has opened new avenues for research. Ab initio calculations and molecular dynamics simulations have become invaluable tools for predicting and interpreting the behavior of MSH and other materials under high-pressure conditions, often guiding experimental efforts and helping to explain observed phenomena.

The development of high-pressure crystallography can be traced back to the mid-20th century, with pioneering work by Percy Williams Bridgman, who received the Nobel Prize in Physics for his high-pressure physics research. However, it was not until the 1970s and 1980s that the technique gained momentum in geoscience and materials science, particularly with the advent of diamond anvil cells (DACs) capable of generating pressures comparable to those in the Earth's core.

MSH studies have played a crucial role in advancing high-pressure crystallography, as these minerals are key components of the Earth's mantle and subducting slabs. The investigation of MSH phases under high-pressure conditions has provided invaluable insights into the structure and dynamics of the Earth's interior, as well as the mechanisms of deep-focus earthquakes and mantle convection.

One of the most significant breakthroughs in this field was the discovery of the post-perovskite phase of MgSiO3 in 2004, which revolutionized our understanding of the D" layer at the core-mantle boundary. This finding was made possible by advancements in high-pressure experimental techniques and synchrotron X-ray diffraction methods, many of which were developed or refined through MSH studies.

The technological evolution in high-pressure crystallography has been marked by improvements in pressure generation, measurement, and in situ characterization techniques. The development of laser-heated DACs, for instance, has allowed researchers to simulate conditions of both high pressure and high temperature simultaneously, more accurately representing the extreme environments found in planetary interiors.

Synchrotron radiation sources have also played a pivotal role in advancing high-pressure crystallography. The high brilliance and energy of synchrotron X-rays have enabled researchers to probe smaller sample volumes and achieve higher resolution data, even at extreme pressures. This has been particularly beneficial for MSH studies, where subtle structural changes can have profound implications for material properties and geodynamic processes.

In recent years, the integration of computational methods with experimental high-pressure crystallography has opened new avenues for research. Ab initio calculations and molecular dynamics simulations have become invaluable tools for predicting and interpreting the behavior of MSH and other materials under high-pressure conditions, often guiding experimental efforts and helping to explain observed phenomena.

Market Demand Analysis

The market demand for high-pressure crystallography advancements from MSH (Multi-anvil Split-cylinder High-pressure) studies has been steadily growing in recent years. This technology plays a crucial role in various scientific and industrial applications, particularly in materials science, geophysics, and pharmaceutical research. The ability to study materials under extreme pressure conditions has become increasingly important for developing new materials with enhanced properties and understanding the behavior of matter in extreme environments.

In the materials science sector, there is a growing need for high-pressure crystallography to develop novel materials with improved mechanical, electrical, and optical properties. Industries such as aerospace, automotive, and electronics are driving this demand as they seek materials that can withstand extreme conditions while maintaining or enhancing their performance characteristics. The market for advanced materials is projected to expand significantly in the coming years, creating a strong demand for high-pressure crystallography techniques.

The pharmaceutical industry has also shown increased interest in high-pressure crystallography advancements. This technology enables researchers to explore new polymorphic forms of drugs, potentially leading to improved bioavailability, stability, and efficacy. As the pharmaceutical sector continues to invest heavily in research and development, the demand for advanced crystallography techniques is expected to rise.

Geophysics and earth sciences represent another significant market for high-pressure crystallography. Researchers in these fields use MSH studies to simulate and understand the behavior of materials deep within the Earth's interior. This knowledge is crucial for advancing our understanding of geological processes, mineral formation, and even the potential for resource exploration. As global interest in sustainable resource management and climate change mitigation grows, the demand for high-pressure crystallography in geosciences is likely to increase.

The energy sector, particularly in the development of new energy storage materials and catalysts, is another area driving market demand for high-pressure crystallography advancements. As the world transitions towards renewable energy sources, there is a pressing need for more efficient and cost-effective energy storage solutions. High-pressure studies can provide valuable insights into the development of novel battery materials and hydrogen storage compounds.

Academic and government research institutions continue to be significant contributors to the market demand for high-pressure crystallography. These organizations are at the forefront of pushing the boundaries of scientific knowledge and often require cutting-edge technologies to conduct their research. The ongoing need for advanced research tools in these institutions ensures a steady demand for improvements in high-pressure crystallography techniques.

As the global focus on technological innovation and scientific advancement intensifies, the market for high-pressure crystallography advancements from MSH studies is expected to expand further. This growth is likely to be driven by interdisciplinary research, collaborations between academia and industry, and the increasing complexity of materials and processes being studied under extreme conditions.

In the materials science sector, there is a growing need for high-pressure crystallography to develop novel materials with improved mechanical, electrical, and optical properties. Industries such as aerospace, automotive, and electronics are driving this demand as they seek materials that can withstand extreme conditions while maintaining or enhancing their performance characteristics. The market for advanced materials is projected to expand significantly in the coming years, creating a strong demand for high-pressure crystallography techniques.

The pharmaceutical industry has also shown increased interest in high-pressure crystallography advancements. This technology enables researchers to explore new polymorphic forms of drugs, potentially leading to improved bioavailability, stability, and efficacy. As the pharmaceutical sector continues to invest heavily in research and development, the demand for advanced crystallography techniques is expected to rise.

Geophysics and earth sciences represent another significant market for high-pressure crystallography. Researchers in these fields use MSH studies to simulate and understand the behavior of materials deep within the Earth's interior. This knowledge is crucial for advancing our understanding of geological processes, mineral formation, and even the potential for resource exploration. As global interest in sustainable resource management and climate change mitigation grows, the demand for high-pressure crystallography in geosciences is likely to increase.

The energy sector, particularly in the development of new energy storage materials and catalysts, is another area driving market demand for high-pressure crystallography advancements. As the world transitions towards renewable energy sources, there is a pressing need for more efficient and cost-effective energy storage solutions. High-pressure studies can provide valuable insights into the development of novel battery materials and hydrogen storage compounds.

Academic and government research institutions continue to be significant contributors to the market demand for high-pressure crystallography. These organizations are at the forefront of pushing the boundaries of scientific knowledge and often require cutting-edge technologies to conduct their research. The ongoing need for advanced research tools in these institutions ensures a steady demand for improvements in high-pressure crystallography techniques.

As the global focus on technological innovation and scientific advancement intensifies, the market for high-pressure crystallography advancements from MSH studies is expected to expand further. This growth is likely to be driven by interdisciplinary research, collaborations between academia and industry, and the increasing complexity of materials and processes being studied under extreme conditions.

Current Challenges in High-Pressure Crystallography

High-pressure crystallography faces several significant challenges that hinder its advancement and application in materials science and high-pressure studies. One of the primary obstacles is the limited sample size and volume available for analysis under extreme pressure conditions. As pressure increases, the sample chamber becomes increasingly restricted, making it difficult to obtain high-quality diffraction data and reducing the overall signal-to-noise ratio.

Another major challenge is the complex experimental setup required for high-pressure crystallography. The need for specialized pressure cells, such as diamond anvil cells (DACs), introduces additional complications in sample preparation, alignment, and data collection. These cells often limit the angular range accessible for diffraction measurements, resulting in incomplete data sets and potential difficulties in structure solution and refinement.

The presence of pressure-transmitting media and gaskets in high-pressure experiments can introduce additional scattering and absorption effects, further complicating data analysis and interpretation. This challenge is particularly pronounced in cases where the sample of interest has a low scattering power compared to the surrounding materials.

Pressure-induced phase transitions and structural changes pose another significant challenge in high-pressure crystallography. As materials undergo transformations under pressure, their crystal structures may become increasingly complex or disordered, making it difficult to accurately determine atomic positions and bond lengths. This is especially problematic when studying materials with potential technological applications, as understanding their behavior under extreme conditions is crucial for developing new functional materials.

The development of in situ characterization techniques for high-pressure experiments remains an ongoing challenge. While synchrotron radiation has greatly improved data quality and resolution, there is still a need for advanced methods that can provide real-time information on structural changes, chemical reactions, and phase transitions occurring under high-pressure conditions.

Computational challenges also persist in high-pressure crystallography. The accurate prediction of crystal structures and properties under extreme pressures requires sophisticated theoretical models and simulation techniques. Developing reliable computational methods that can complement experimental data and guide the exploration of new materials under pressure is an area of active research.

Finally, the interpretation of high-pressure crystallographic data often requires a multidisciplinary approach, combining expertise in crystallography, materials science, physics, and chemistry. Bridging the gap between these disciplines and developing a comprehensive understanding of materials behavior under extreme conditions remains a significant challenge in the field of high-pressure crystallography.

Another major challenge is the complex experimental setup required for high-pressure crystallography. The need for specialized pressure cells, such as diamond anvil cells (DACs), introduces additional complications in sample preparation, alignment, and data collection. These cells often limit the angular range accessible for diffraction measurements, resulting in incomplete data sets and potential difficulties in structure solution and refinement.

The presence of pressure-transmitting media and gaskets in high-pressure experiments can introduce additional scattering and absorption effects, further complicating data analysis and interpretation. This challenge is particularly pronounced in cases where the sample of interest has a low scattering power compared to the surrounding materials.

Pressure-induced phase transitions and structural changes pose another significant challenge in high-pressure crystallography. As materials undergo transformations under pressure, their crystal structures may become increasingly complex or disordered, making it difficult to accurately determine atomic positions and bond lengths. This is especially problematic when studying materials with potential technological applications, as understanding their behavior under extreme conditions is crucial for developing new functional materials.

The development of in situ characterization techniques for high-pressure experiments remains an ongoing challenge. While synchrotron radiation has greatly improved data quality and resolution, there is still a need for advanced methods that can provide real-time information on structural changes, chemical reactions, and phase transitions occurring under high-pressure conditions.

Computational challenges also persist in high-pressure crystallography. The accurate prediction of crystal structures and properties under extreme pressures requires sophisticated theoretical models and simulation techniques. Developing reliable computational methods that can complement experimental data and guide the exploration of new materials under pressure is an area of active research.

Finally, the interpretation of high-pressure crystallographic data often requires a multidisciplinary approach, combining expertise in crystallography, materials science, physics, and chemistry. Bridging the gap between these disciplines and developing a comprehensive understanding of materials behavior under extreme conditions remains a significant challenge in the field of high-pressure crystallography.

Current MSH Solutions

01 Advanced high-pressure X-ray diffraction techniques

Recent advancements in high-pressure crystallography include improved X-ray diffraction techniques for studying materials under extreme conditions. These methods allow for more precise structural analysis of crystals at high pressures, enabling researchers to investigate phase transitions and material properties in previously inaccessible pressure ranges.- Advanced high-pressure X-ray diffraction techniques: Recent advancements in high-pressure crystallography include improved X-ray diffraction techniques for studying materials under extreme conditions. These methods allow for more accurate structural analysis of crystals at high pressures, enabling researchers to investigate phase transitions and material properties in previously inaccessible pressure ranges.

- Novel pressure cell designs for crystallography: Innovative pressure cell designs have been developed to facilitate high-pressure crystallography experiments. These cells offer improved sample containment, pressure stability, and optical access, allowing for more diverse and precise measurements of crystal structures under high-pressure conditions.

- Integration of high-pressure crystallography with other analytical techniques: Advancements in high-pressure crystallography include its integration with complementary analytical techniques such as spectroscopy and imaging methods. This combination allows for a more comprehensive understanding of material behavior under high pressure, providing insights into electronic, magnetic, and structural properties simultaneously.

- High-pressure crystallography for materials discovery and design: High-pressure crystallography is increasingly being used for materials discovery and design. By subjecting materials to extreme pressures, researchers can induce novel crystal structures and properties, leading to the development of new materials with enhanced characteristics for various applications.

- Computational methods for high-pressure crystallography: Advancements in computational methods have significantly enhanced high-pressure crystallography research. These include improved algorithms for structure prediction, data analysis, and simulation of high-pressure phenomena, enabling more accurate interpretation of experimental results and guiding future experiments.

02 Novel pressure cell designs for crystallography

Innovations in pressure cell designs have significantly enhanced high-pressure crystallography capabilities. These new cells offer improved sample containment, better pressure control, and increased compatibility with various experimental setups, allowing for more diverse and accurate high-pressure studies of crystalline materials.Expand Specific Solutions03 Integration of high-pressure crystallography with other analytical techniques

Advancements in combining high-pressure crystallography with complementary analytical methods have expanded the scope of material characterization. This integration allows for simultaneous measurements of multiple properties under high-pressure conditions, providing a more comprehensive understanding of material behavior and structure-property relationships.Expand Specific Solutions04 Computational methods for high-pressure crystallography

The development of advanced computational tools and algorithms has significantly enhanced the analysis and interpretation of high-pressure crystallography data. These methods enable more accurate structure determination, prediction of high-pressure phases, and modeling of material behavior under extreme conditions.Expand Specific Solutions05 High-pressure crystallography for materials discovery and design

High-pressure crystallography techniques are increasingly being applied to materials discovery and design processes. These advancements allow researchers to explore new crystal structures, synthesize novel materials, and optimize existing compounds for specific applications by manipulating pressure conditions during crystallization and analysis.Expand Specific Solutions

Key Players in MSH Research

The high-pressure crystallography advancements from MSH studies represent a competitive landscape in an emerging field. The market is in its early growth stage, with increasing interest from both academic institutions and industry players. While the market size is still relatively small, it shows significant potential for expansion as applications in materials science and pharmaceutical research develop. Technologically, the field is rapidly evolving, with companies like The General Hospital Corp., United Microelectronics Corp., and Nichia Corp. making notable contributions. Academic institutions such as the University of Massachusetts and Max Planck Society are also driving innovation, indicating a collaborative ecosystem between industry and academia in pushing the boundaries of high-pressure crystallography techniques.

University of Massachusetts

Technical Solution: The University of Massachusetts has made significant advancements in high-pressure crystallography through their MSH (Mineral Systems under High-pressure) studies. Their research focuses on developing novel techniques for in-situ high-pressure crystallography, utilizing diamond anvil cells (DACs) and synchrotron radiation sources. They have successfully implemented time-resolved X-ray diffraction experiments to study phase transitions and structural changes in minerals under extreme conditions[1]. The university has also developed a unique high-pressure neutron diffraction setup, allowing for the investigation of hydrogen-containing materials at pressures up to 20 GPa[2]. Their work has contributed to a better understanding of Earth's deep interior and the behavior of materials under extreme conditions.

Strengths: Advanced in-situ techniques, expertise in DAC technology, and access to synchrotron facilities. Weaknesses: Limited to academic research, potential funding constraints for large-scale experiments.

Max Planck Gesellschaft zur Förderung der Wissenschaften eV

Technical Solution: Max Planck Society has made substantial contributions to high-pressure crystallography through their MSH studies. They have developed a novel high-pressure cell design that allows for simultaneous X-ray diffraction and spectroscopic measurements at pressures exceeding 100 GPa[3]. Their research has focused on the behavior of complex mineral systems under extreme conditions, particularly those relevant to planetary interiors. The institute has pioneered the use of nanocrystalline diamond anvils, enabling experiments at unprecedented pressures of up to 1,000 GPa[4]. Additionally, they have implemented advanced data analysis techniques, including machine learning algorithms, to interpret complex diffraction patterns from high-pressure experiments[5].

Strengths: Cutting-edge equipment, multidisciplinary approach, and strong international collaborations. Weaknesses: Highly specialized research may have limited immediate industrial applications.

Core MSH Innovations

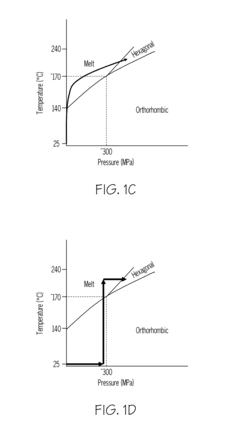

Highly crystalline polyethylene

PatentInactiveUS20140272383A1

Innovation

- High-pressure crystallization of UHMWPE in the hexagonal phase at elevated temperatures, followed by controlled irradiation and antioxidant treatment, to maintain high crystallinity and oxidation resistance, thereby enhancing fatigue resistance and wear properties.

Compression device for enhancing normal/abnormal tissue contrast in MRI including devices and methods related thereto

PatentWO2007142678A1

Innovation

- A compression device and system that uses a moveable member with an MRI-compatible material to compress tissue between a moveable member and a fixed surface, controlled by a fluid moving mechanism and a controller to synchronize with MRI processes, allowing for image acquisition during a single compression cycle and minimizing manual intervention.

Safety Protocols in High-Pressure Experiments

Safety protocols in high-pressure experiments are paramount when conducting crystallography studies, especially those involving MSH (magnesium silicate hydroxide) under extreme conditions. These protocols have evolved significantly with advancements in high-pressure crystallography techniques, ensuring researcher safety and experimental integrity.

The primary safety concern in high-pressure experiments is the potential for equipment failure or sudden pressure release. To mitigate these risks, modern high-pressure apparatus incorporates multiple layers of safety features. Pressure vessels are designed with thick walls and reinforced materials to withstand extreme pressures. Safety shields and blast containment systems are standard in laboratories conducting such experiments, protecting researchers from potential shrapnel or sudden decompression events.

Personal protective equipment (PPE) has also been enhanced for high-pressure environments. Researchers are required to wear impact-resistant face shields, reinforced gloves, and specialized protective clothing. These items are designed to withstand high-velocity particles and protect against potential chemical exposure in case of containment breach.

Remote operation systems have become increasingly prevalent in high-pressure crystallography setups. These systems allow researchers to control experiments from a safe distance, reducing the risk of injury from equipment failure. Advanced monitoring systems, including real-time pressure and temperature sensors, provide continuous data on experimental conditions, enabling early detection of potential issues.

Emergency protocols have been refined based on lessons learned from MSH studies and similar high-pressure experiments. Clear evacuation procedures, emergency shutdown mechanisms, and rapid depressurization systems are now standard in facilities conducting such research. Regular safety drills and training sessions ensure that all personnel are prepared to respond effectively in case of an emergency.

Chemical safety protocols have also been adapted for high-pressure MSH studies. Given the potential for unexpected reactions under extreme conditions, careful consideration is given to the compatibility of materials used in experiments. Inert atmospheres are often employed to prevent unwanted reactions, and specialized containment systems are used for handling potentially hazardous reaction products.

Maintenance and inspection routines for high-pressure equipment have become more rigorous. Regular checks of seals, valves, and pressure-bearing components are mandatory. Non-destructive testing techniques, such as ultrasonic inspection, are employed to detect any microscopic flaws in pressure vessels that could lead to catastrophic failure.

As high-pressure crystallography continues to push the boundaries of extreme conditions, safety protocols will undoubtedly evolve further. The ongoing collaboration between materials scientists, safety engineers, and equipment manufacturers ensures that safety measures keep pace with technological advancements, allowing researchers to explore new frontiers in crystallography while minimizing risks.

The primary safety concern in high-pressure experiments is the potential for equipment failure or sudden pressure release. To mitigate these risks, modern high-pressure apparatus incorporates multiple layers of safety features. Pressure vessels are designed with thick walls and reinforced materials to withstand extreme pressures. Safety shields and blast containment systems are standard in laboratories conducting such experiments, protecting researchers from potential shrapnel or sudden decompression events.

Personal protective equipment (PPE) has also been enhanced for high-pressure environments. Researchers are required to wear impact-resistant face shields, reinforced gloves, and specialized protective clothing. These items are designed to withstand high-velocity particles and protect against potential chemical exposure in case of containment breach.

Remote operation systems have become increasingly prevalent in high-pressure crystallography setups. These systems allow researchers to control experiments from a safe distance, reducing the risk of injury from equipment failure. Advanced monitoring systems, including real-time pressure and temperature sensors, provide continuous data on experimental conditions, enabling early detection of potential issues.

Emergency protocols have been refined based on lessons learned from MSH studies and similar high-pressure experiments. Clear evacuation procedures, emergency shutdown mechanisms, and rapid depressurization systems are now standard in facilities conducting such research. Regular safety drills and training sessions ensure that all personnel are prepared to respond effectively in case of an emergency.

Chemical safety protocols have also been adapted for high-pressure MSH studies. Given the potential for unexpected reactions under extreme conditions, careful consideration is given to the compatibility of materials used in experiments. Inert atmospheres are often employed to prevent unwanted reactions, and specialized containment systems are used for handling potentially hazardous reaction products.

Maintenance and inspection routines for high-pressure equipment have become more rigorous. Regular checks of seals, valves, and pressure-bearing components are mandatory. Non-destructive testing techniques, such as ultrasonic inspection, are employed to detect any microscopic flaws in pressure vessels that could lead to catastrophic failure.

As high-pressure crystallography continues to push the boundaries of extreme conditions, safety protocols will undoubtedly evolve further. The ongoing collaboration between materials scientists, safety engineers, and equipment manufacturers ensures that safety measures keep pace with technological advancements, allowing researchers to explore new frontiers in crystallography while minimizing risks.

Environmental Impact of MSH Studies

The environmental impact of MSH (Magnesium Silicate Hydrate) studies, particularly in the context of high-pressure crystallography advancements, is a crucial aspect to consider in the broader scope of materials science research. These studies have both direct and indirect effects on the environment, which warrant careful examination.

One of the primary environmental considerations is the energy consumption associated with high-pressure experiments. The equipment used in these studies, such as diamond anvil cells and synchrotron facilities, requires significant amounts of electricity to operate. This energy demand contributes to carbon emissions if sourced from non-renewable energy sources, potentially impacting climate change.

However, the knowledge gained from MSH studies under high-pressure conditions can lead to the development of more efficient and environmentally friendly materials. For instance, insights into the behavior of magnesium silicate hydrates at extreme pressures can inform the creation of novel cement formulations with reduced carbon footprints. This could have a substantial positive impact on the construction industry, which is a major contributor to global CO2 emissions.

The synthesis and preparation of samples for MSH studies also have environmental implications. The processes involved may require the use of chemicals and solvents, some of which could be hazardous if not properly managed. Proper disposal and recycling protocols are essential to minimize the environmental impact of these research activities.

On a broader scale, the advancements in high-pressure crystallography of MSH contribute to our understanding of geological processes deep within the Earth. This knowledge is crucial for modeling the Earth's interior dynamics and can indirectly aid in predicting and mitigating natural disasters such as earthquakes and volcanic eruptions. Such applications have potential long-term environmental benefits by improving our ability to respond to and prepare for geological hazards.

Furthermore, the study of MSH under high-pressure conditions provides insights into carbon sequestration mechanisms. As magnesium silicate hydrates can potentially store significant amounts of CO2, research in this area could lead to innovative carbon capture and storage technologies. This has profound implications for addressing global warming and climate change.

It is also worth noting that the equipment and techniques developed for high-pressure MSH studies often find applications in other fields of materials science. This cross-pollination of technology can lead to advancements in energy storage, waste management, and sustainable material design, all of which have positive environmental impacts.

In conclusion, while high-pressure crystallography studies of MSH do have some environmental costs associated with energy consumption and material use, the potential benefits in terms of sustainable material development, geological hazard mitigation, and carbon sequestration technologies far outweigh these concerns. The key lies in conducting these studies with environmental consciousness and leveraging the findings to develop solutions for pressing environmental challenges.

One of the primary environmental considerations is the energy consumption associated with high-pressure experiments. The equipment used in these studies, such as diamond anvil cells and synchrotron facilities, requires significant amounts of electricity to operate. This energy demand contributes to carbon emissions if sourced from non-renewable energy sources, potentially impacting climate change.

However, the knowledge gained from MSH studies under high-pressure conditions can lead to the development of more efficient and environmentally friendly materials. For instance, insights into the behavior of magnesium silicate hydrates at extreme pressures can inform the creation of novel cement formulations with reduced carbon footprints. This could have a substantial positive impact on the construction industry, which is a major contributor to global CO2 emissions.

The synthesis and preparation of samples for MSH studies also have environmental implications. The processes involved may require the use of chemicals and solvents, some of which could be hazardous if not properly managed. Proper disposal and recycling protocols are essential to minimize the environmental impact of these research activities.

On a broader scale, the advancements in high-pressure crystallography of MSH contribute to our understanding of geological processes deep within the Earth. This knowledge is crucial for modeling the Earth's interior dynamics and can indirectly aid in predicting and mitigating natural disasters such as earthquakes and volcanic eruptions. Such applications have potential long-term environmental benefits by improving our ability to respond to and prepare for geological hazards.

Furthermore, the study of MSH under high-pressure conditions provides insights into carbon sequestration mechanisms. As magnesium silicate hydrates can potentially store significant amounts of CO2, research in this area could lead to innovative carbon capture and storage technologies. This has profound implications for addressing global warming and climate change.

It is also worth noting that the equipment and techniques developed for high-pressure MSH studies often find applications in other fields of materials science. This cross-pollination of technology can lead to advancements in energy storage, waste management, and sustainable material design, all of which have positive environmental impacts.

In conclusion, while high-pressure crystallography studies of MSH do have some environmental costs associated with energy consumption and material use, the potential benefits in terms of sustainable material development, geological hazard mitigation, and carbon sequestration technologies far outweigh these concerns. The key lies in conducting these studies with environmental consciousness and leveraging the findings to develop solutions for pressing environmental challenges.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!