How Dipropylene Glycol Affects Solvent Performance?

JUL 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DPG Solvent Background

Dipropylene glycol (DPG) is a versatile organic compound that has gained significant attention in the solvent industry due to its unique properties and wide range of applications. As a member of the glycol ether family, DPG is characterized by its high boiling point, low volatility, and excellent solvency power. These attributes make it an attractive choice for various industrial and consumer products, including paints, coatings, cleaning agents, and personal care items.

The development of DPG as a solvent can be traced back to the mid-20th century when the chemical industry was actively seeking alternatives to traditional petroleum-based solvents. The growing concern over environmental impact and worker safety led to the exploration of more sustainable and less toxic options. DPG emerged as a promising candidate due to its biodegradability and low toxicity profile compared to many conventional solvents.

In terms of chemical structure, DPG is a diether of propylene glycol, consisting of two propylene glycol units linked together. This unique structure contributes to its exceptional solvent properties, allowing it to dissolve a wide range of polar and non-polar substances. The presence of both hydrophilic and hydrophobic groups in its molecule enables DPG to form stable solutions with diverse compounds, making it a valuable ingredient in formulations that require compatibility with multiple components.

The evolution of DPG as a solvent has been driven by several factors, including regulatory pressures, technological advancements, and changing market demands. As environmental regulations became more stringent, particularly regarding volatile organic compound (VOC) emissions, DPG's low volatility made it an attractive alternative to traditional solvents in many applications. Its ability to reduce VOC content in formulations while maintaining or improving performance has been a key driver of its adoption across various industries.

Furthermore, the increasing focus on sustainability and green chemistry has bolstered the position of DPG in the solvent market. Its production from renewable resources, such as propylene derived from bio-based feedstocks, aligns with the growing trend towards more environmentally friendly chemical processes. This aspect has not only enhanced its appeal to environmentally conscious consumers but also positioned it favorably in light of potential future regulations on petrochemical-derived products.

The technological landscape surrounding DPG has also evolved significantly over the years. Advancements in production processes have led to improved purity and consistency of DPG, expanding its potential applications. Additionally, ongoing research into the synergistic effects of DPG with other solvents and additives has opened up new possibilities for formulation optimization across various industries, from coatings to personal care products.

The development of DPG as a solvent can be traced back to the mid-20th century when the chemical industry was actively seeking alternatives to traditional petroleum-based solvents. The growing concern over environmental impact and worker safety led to the exploration of more sustainable and less toxic options. DPG emerged as a promising candidate due to its biodegradability and low toxicity profile compared to many conventional solvents.

In terms of chemical structure, DPG is a diether of propylene glycol, consisting of two propylene glycol units linked together. This unique structure contributes to its exceptional solvent properties, allowing it to dissolve a wide range of polar and non-polar substances. The presence of both hydrophilic and hydrophobic groups in its molecule enables DPG to form stable solutions with diverse compounds, making it a valuable ingredient in formulations that require compatibility with multiple components.

The evolution of DPG as a solvent has been driven by several factors, including regulatory pressures, technological advancements, and changing market demands. As environmental regulations became more stringent, particularly regarding volatile organic compound (VOC) emissions, DPG's low volatility made it an attractive alternative to traditional solvents in many applications. Its ability to reduce VOC content in formulations while maintaining or improving performance has been a key driver of its adoption across various industries.

Furthermore, the increasing focus on sustainability and green chemistry has bolstered the position of DPG in the solvent market. Its production from renewable resources, such as propylene derived from bio-based feedstocks, aligns with the growing trend towards more environmentally friendly chemical processes. This aspect has not only enhanced its appeal to environmentally conscious consumers but also positioned it favorably in light of potential future regulations on petrochemical-derived products.

The technological landscape surrounding DPG has also evolved significantly over the years. Advancements in production processes have led to improved purity and consistency of DPG, expanding its potential applications. Additionally, ongoing research into the synergistic effects of DPG with other solvents and additives has opened up new possibilities for formulation optimization across various industries, from coatings to personal care products.

Market Analysis

The market for dipropylene glycol (DPG) as a solvent has shown significant growth in recent years, driven by its versatile applications across various industries. The global DPG market size was valued at approximately $1.5 billion in 2020 and is projected to expand at a compound annual growth rate (CAGR) of around 5% from 2021 to 2028. This growth is primarily attributed to the increasing demand for eco-friendly and high-performance solvents in industries such as paints and coatings, personal care products, and industrial cleaning.

In the paints and coatings industry, DPG has gained traction due to its excellent solvency properties and low volatility. These characteristics contribute to improved film formation, enhanced gloss, and better flow and leveling of coatings. The construction sector's growth, particularly in emerging economies, has further boosted the demand for DPG in this application.

The personal care and cosmetics industry has also witnessed a surge in DPG usage. Its ability to act as a humectant and solvent in various formulations, coupled with its low toxicity profile, has made it a preferred choice for manufacturers. The rising consumer awareness regarding product safety and the shift towards natural and organic ingredients have further propelled the adoption of DPG in this sector.

Industrial cleaning applications represent another significant market for DPG. Its excellent solvency power, low toxicity, and biodegradability make it an ideal component in cleaning formulations. The increasing focus on workplace safety and environmental regulations has driven the demand for safer and more effective cleaning solutions, benefiting DPG manufacturers.

Geographically, North America and Europe have been the leading consumers of DPG, owing to stringent environmental regulations and a well-established industrial base. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, urbanization, and increasing disposable incomes in countries like China and India.

The market landscape for DPG is characterized by the presence of several key players, including Dow Chemical Company, LyondellBasell Industries, and BASF SE. These companies are focusing on expanding their production capacities and developing innovative applications to maintain their market position. Additionally, strategic collaborations and mergers and acquisitions are becoming increasingly common as companies seek to strengthen their market presence and expand their product portfolios.

Looking ahead, the DPG market is poised for continued growth, driven by increasing environmental concerns, stringent regulations on volatile organic compounds (VOCs), and the ongoing search for high-performance, sustainable solvents across various industries. The development of bio-based DPG and its applications in emerging sectors such as electronics and pharmaceuticals are expected to create new growth opportunities in the market.

In the paints and coatings industry, DPG has gained traction due to its excellent solvency properties and low volatility. These characteristics contribute to improved film formation, enhanced gloss, and better flow and leveling of coatings. The construction sector's growth, particularly in emerging economies, has further boosted the demand for DPG in this application.

The personal care and cosmetics industry has also witnessed a surge in DPG usage. Its ability to act as a humectant and solvent in various formulations, coupled with its low toxicity profile, has made it a preferred choice for manufacturers. The rising consumer awareness regarding product safety and the shift towards natural and organic ingredients have further propelled the adoption of DPG in this sector.

Industrial cleaning applications represent another significant market for DPG. Its excellent solvency power, low toxicity, and biodegradability make it an ideal component in cleaning formulations. The increasing focus on workplace safety and environmental regulations has driven the demand for safer and more effective cleaning solutions, benefiting DPG manufacturers.

Geographically, North America and Europe have been the leading consumers of DPG, owing to stringent environmental regulations and a well-established industrial base. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, urbanization, and increasing disposable incomes in countries like China and India.

The market landscape for DPG is characterized by the presence of several key players, including Dow Chemical Company, LyondellBasell Industries, and BASF SE. These companies are focusing on expanding their production capacities and developing innovative applications to maintain their market position. Additionally, strategic collaborations and mergers and acquisitions are becoming increasingly common as companies seek to strengthen their market presence and expand their product portfolios.

Looking ahead, the DPG market is poised for continued growth, driven by increasing environmental concerns, stringent regulations on volatile organic compounds (VOCs), and the ongoing search for high-performance, sustainable solvents across various industries. The development of bio-based DPG and its applications in emerging sectors such as electronics and pharmaceuticals are expected to create new growth opportunities in the market.

Technical Challenges

The use of dipropylene glycol (DPG) as a solvent presents several technical challenges that researchers and industry professionals must address. One of the primary issues is the balance between solvency power and volatility. While DPG exhibits excellent solvency for a wide range of substances, its relatively low volatility can lead to slower drying times in applications where rapid evaporation is crucial. This characteristic can be particularly problematic in coatings and adhesives, where extended drying periods may impact production efficiency and product quality.

Another significant challenge lies in the hygroscopic nature of DPG. Its ability to absorb moisture from the environment can affect the stability and performance of formulations over time. This property necessitates careful consideration in product design and packaging to prevent unwanted water absorption, which could potentially alter the solvent's effectiveness or lead to changes in the overall composition of the product.

The viscosity of DPG also presents technical hurdles in certain applications. While its higher viscosity compared to some other glycol ethers can be advantageous in providing body to formulations, it may also limit its use in spray applications or in systems where low viscosity is required for proper flow and distribution. Formulators must carefully balance the benefits of DPG's solvency with its impact on the overall rheological properties of the final product.

Temperature sensitivity is another area of concern when working with DPG. Its performance as a solvent can vary significantly with temperature changes, which may affect the consistency and effectiveness of products across different environmental conditions. This variability requires extensive testing and validation to ensure that formulations remain stable and effective across the intended range of use temperatures.

Furthermore, the chemical compatibility of DPG with other ingredients in complex formulations poses ongoing challenges. While DPG is generally considered a versatile solvent, it may interact unfavorably with certain materials, potentially leading to unwanted reactions, separation, or degradation of active ingredients. Formulators must conduct thorough compatibility studies to avoid these issues and ensure long-term stability of their products.

Lastly, regulatory considerations and evolving environmental standards present ongoing challenges for the use of DPG as a solvent. As global regulations become more stringent regarding volatile organic compounds (VOCs) and environmental impact, formulators must continually assess and potentially reformulate products to meet new requirements while maintaining performance standards. This balancing act between regulatory compliance and solvent effectiveness remains a significant technical challenge in the industry.

Another significant challenge lies in the hygroscopic nature of DPG. Its ability to absorb moisture from the environment can affect the stability and performance of formulations over time. This property necessitates careful consideration in product design and packaging to prevent unwanted water absorption, which could potentially alter the solvent's effectiveness or lead to changes in the overall composition of the product.

The viscosity of DPG also presents technical hurdles in certain applications. While its higher viscosity compared to some other glycol ethers can be advantageous in providing body to formulations, it may also limit its use in spray applications or in systems where low viscosity is required for proper flow and distribution. Formulators must carefully balance the benefits of DPG's solvency with its impact on the overall rheological properties of the final product.

Temperature sensitivity is another area of concern when working with DPG. Its performance as a solvent can vary significantly with temperature changes, which may affect the consistency and effectiveness of products across different environmental conditions. This variability requires extensive testing and validation to ensure that formulations remain stable and effective across the intended range of use temperatures.

Furthermore, the chemical compatibility of DPG with other ingredients in complex formulations poses ongoing challenges. While DPG is generally considered a versatile solvent, it may interact unfavorably with certain materials, potentially leading to unwanted reactions, separation, or degradation of active ingredients. Formulators must conduct thorough compatibility studies to avoid these issues and ensure long-term stability of their products.

Lastly, regulatory considerations and evolving environmental standards present ongoing challenges for the use of DPG as a solvent. As global regulations become more stringent regarding volatile organic compounds (VOCs) and environmental impact, formulators must continually assess and potentially reformulate products to meet new requirements while maintaining performance standards. This balancing act between regulatory compliance and solvent effectiveness remains a significant technical challenge in the industry.

Current DPG Solutions

01 Solvent properties in cosmetic formulations

Dipropylene glycol exhibits excellent solvent properties in cosmetic formulations. It effectively dissolves various ingredients, enhancing the stability and homogeneity of products such as perfumes, skin care items, and hair care products. Its ability to solubilize both hydrophilic and lipophilic substances makes it versatile in formulation development.- Solvent properties in cosmetic formulations: Dipropylene glycol exhibits excellent solvent properties in cosmetic formulations. It effectively dissolves various ingredients, enhancing the stability and homogeneity of products such as perfumes, skin care items, and hair care products. Its ability to blend with both water and oil-based components makes it versatile in formulation development.

- Use in cleaning and degreasing applications: Dipropylene glycol demonstrates strong performance as a solvent in cleaning and degreasing applications. It effectively dissolves oils, greases, and other contaminants, making it suitable for industrial cleaning products, household cleaners, and automotive degreasers. Its low volatility and mild odor contribute to its effectiveness in these applications.

- Compatibility with other solvents and additives: Dipropylene glycol shows excellent compatibility with a wide range of other solvents and additives. This property allows for the creation of complex solvent systems with enhanced performance characteristics. It can be combined with various organic solvents, surfactants, and other functional ingredients to achieve desired product properties.

- Environmental and safety profile: Dipropylene glycol has a favorable environmental and safety profile compared to many other solvents. It is biodegradable, has low toxicity, and is not considered a volatile organic compound (VOC) in many regions. These characteristics make it an attractive choice for environmentally conscious formulations and applications where worker safety is a priority.

- Performance in polymer and resin applications: Dipropylene glycol demonstrates good performance as a solvent in polymer and resin applications. It can effectively dissolve various polymers and resins, making it useful in the production of coatings, adhesives, and plastics. Its high boiling point and low evaporation rate contribute to its effectiveness in these applications, allowing for better control of drying and curing processes.

02 Humectant and moisturizing effects

As a humectant, dipropylene glycol helps retain moisture in cosmetic and personal care products. It attracts and holds water, preventing products from drying out and improving their shelf life. In skincare formulations, it contributes to maintaining skin hydration and improving product feel.Expand Specific Solutions03 Application in cleaning compositions

Dipropylene glycol is utilized in various cleaning compositions due to its solvent properties. It helps in formulating effective cleaners for household and industrial use, aiding in the dissolution of dirt, grease, and other contaminants. Its low volatility contributes to the stability of cleaning product formulations.Expand Specific Solutions04 Use in paint and coating industries

In the paint and coating industries, dipropylene glycol serves as a coalescent and film-forming aid. It helps improve the flow and leveling of paints, enhances film formation, and contributes to the overall performance of coatings. Its low volatility allows for better control of drying times in paint formulations.Expand Specific Solutions05 Performance in industrial processes

Dipropylene glycol demonstrates versatility in various industrial processes. It is used as a processing aid in polymer production, as a coupling agent in formulations, and as a component in heat transfer fluids. Its thermal stability and low toxicity make it suitable for a wide range of industrial applications.Expand Specific Solutions

Key Industry Players

The market for dipropylene glycol and its impact on solvent performance is in a mature stage, with a global market size estimated to be over $1 billion. The technology is well-established, with major players like BASF, Dow Chemical, and LyondellBasell dominating production. These companies have extensive R&D capabilities and established manufacturing processes, indicating high technological maturity. Smaller specialty chemical firms like Stepan Co. and SK Chemicals are also active in developing niche applications. The competitive landscape is characterized by ongoing efforts to improve product purity and develop tailored formulations for specific industrial uses, driving incremental innovation in this mature market.

Henkel AG & Co. KGaA

Technical Solution: Henkel AG & Co. KGaA has conducted extensive research on the use of dipropylene glycol to enhance solvent performance in adhesives, sealants, and functional coatings. Their approach focuses on exploiting DPG's excellent solvency properties and low volatility to improve product performance and reduce environmental impact. Henkel's studies have shown that incorporating DPG into adhesive formulations can lead to improved bonding strength and durability, particularly in challenging environmental conditions[5]. They have also found that DPG's hygroscopic nature can be beneficial in maintaining the flexibility of sealants and coatings over time, leading to improved product longevity[6].

Strengths: Enhanced product performance, improved durability, and reduced environmental impact. Weaknesses: Potential increased production costs and the need for careful formulation to avoid excessive moisture absorption in some applications.

Procter & Gamble Co.

Technical Solution: Procter & Gamble Co. has integrated dipropylene glycol into their product formulations to enhance solvent performance across various consumer goods. Their research has focused on leveraging DPG's low toxicity and biodegradability to create safer and more sustainable products. P&G's studies have demonstrated that DPG can effectively replace more harmful solvents in cleaning products, personal care items, and fragrances without compromising performance[2]. They have also explored DPG's ability to act as a coupling agent, allowing for the combination of water-soluble and oil-soluble ingredients in a single formulation, thus improving product stability and efficacy[4].

Strengths: Safer and more sustainable product formulations, improved product stability, and versatility across multiple product categories. Weaknesses: Potential higher production costs and the need for reformulation of existing products.

DPG Innovations

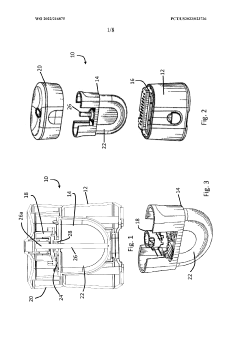

Solvent for insect repellent active ingredient and insert repellent system using same

PatentWO2022216875A1

Innovation

- A portable insect repellent system using a glycol solvent, such as a mixture of hexylene glycol and dipropylene glycol, with a heating element powered by a low voltage battery, allowing for higher active ingredient concentrations up to 27% and compatibility with device materials, enabling effective mosquito repellency in outdoor areas without aspiration hazards.

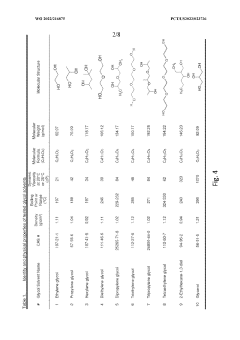

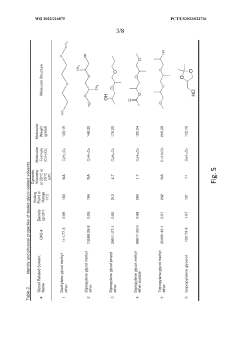

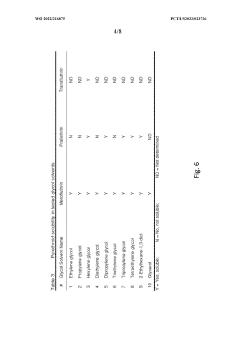

Soluble oligomers of propanediol as active ingredient for the regulation of sweat secretion

PatentInactiveGB2590797A

Innovation

- An aqueous cosmetic composition containing oligopropylene glycols based on 1,2-propanediol or 1,3-propanediol, which regulate sweat secretion by influencing sweat cell functions, reducing sweat production without the use of aluminium and zirconium salts, and combining these with deodorant active ingredients for enhanced efficacy.

Environmental Impact

Dipropylene glycol (DPG) is a widely used solvent in various industries, and its environmental impact is a crucial consideration in assessing its overall performance. The use of DPG as a solvent has both positive and negative implications for the environment, which must be carefully evaluated to ensure sustainable practices.

One of the primary environmental benefits of DPG is its low volatility compared to many other solvents. This characteristic reduces the amount of volatile organic compounds (VOCs) released into the atmosphere during use, contributing to improved air quality and reduced smog formation. Additionally, DPG's low evaporation rate helps minimize solvent losses and reduces the frequency of replenishment, leading to more efficient resource utilization.

DPG is also biodegradable, which is a significant advantage from an environmental perspective. When released into the environment, it can be broken down by natural processes, reducing its long-term impact on ecosystems. This biodegradability makes DPG a more environmentally friendly option compared to persistent organic solvents that can accumulate in the environment and cause long-lasting damage.

However, the production of DPG does have some environmental drawbacks. The manufacturing process typically involves the use of propylene oxide, which is derived from fossil fuels. This reliance on non-renewable resources contributes to carbon emissions and the depletion of finite resources. Furthermore, the production process may generate waste products and require significant energy inputs, adding to the overall environmental footprint of DPG.

In aquatic environments, DPG has relatively low toxicity to fish and other aquatic organisms compared to many other solvents. However, it can still have adverse effects if released in large quantities or if it accumulates in water bodies. Proper handling, storage, and disposal practices are essential to minimize the risk of environmental contamination.

The use of DPG in various applications can indirectly impact the environment through the products it helps create. For instance, in the production of paints and coatings, DPG can contribute to the development of more durable and long-lasting finishes. This increased durability can lead to reduced material consumption and waste generation over time, as products require less frequent replacement or reapplication.

When considering the environmental impact of DPG, it is also important to evaluate its performance in comparison to alternative solvents. In many cases, DPG may offer a more environmentally friendly option than traditional solvents with higher volatility, toxicity, or persistence in the environment. However, ongoing research into green solvents and bio-based alternatives may provide even more sustainable options in the future.

In conclusion, while DPG offers several environmental advantages as a solvent, including low volatility and biodegradability, its production and potential for aquatic contamination present some environmental challenges. Balancing these factors is crucial for industries using DPG, and continued efforts to improve production methods and develop more sustainable alternatives will be essential for minimizing its environmental impact in the long term.

One of the primary environmental benefits of DPG is its low volatility compared to many other solvents. This characteristic reduces the amount of volatile organic compounds (VOCs) released into the atmosphere during use, contributing to improved air quality and reduced smog formation. Additionally, DPG's low evaporation rate helps minimize solvent losses and reduces the frequency of replenishment, leading to more efficient resource utilization.

DPG is also biodegradable, which is a significant advantage from an environmental perspective. When released into the environment, it can be broken down by natural processes, reducing its long-term impact on ecosystems. This biodegradability makes DPG a more environmentally friendly option compared to persistent organic solvents that can accumulate in the environment and cause long-lasting damage.

However, the production of DPG does have some environmental drawbacks. The manufacturing process typically involves the use of propylene oxide, which is derived from fossil fuels. This reliance on non-renewable resources contributes to carbon emissions and the depletion of finite resources. Furthermore, the production process may generate waste products and require significant energy inputs, adding to the overall environmental footprint of DPG.

In aquatic environments, DPG has relatively low toxicity to fish and other aquatic organisms compared to many other solvents. However, it can still have adverse effects if released in large quantities or if it accumulates in water bodies. Proper handling, storage, and disposal practices are essential to minimize the risk of environmental contamination.

The use of DPG in various applications can indirectly impact the environment through the products it helps create. For instance, in the production of paints and coatings, DPG can contribute to the development of more durable and long-lasting finishes. This increased durability can lead to reduced material consumption and waste generation over time, as products require less frequent replacement or reapplication.

When considering the environmental impact of DPG, it is also important to evaluate its performance in comparison to alternative solvents. In many cases, DPG may offer a more environmentally friendly option than traditional solvents with higher volatility, toxicity, or persistence in the environment. However, ongoing research into green solvents and bio-based alternatives may provide even more sustainable options in the future.

In conclusion, while DPG offers several environmental advantages as a solvent, including low volatility and biodegradability, its production and potential for aquatic contamination present some environmental challenges. Balancing these factors is crucial for industries using DPG, and continued efforts to improve production methods and develop more sustainable alternatives will be essential for minimizing its environmental impact in the long term.

Regulatory Compliance

Regulatory compliance plays a crucial role in the use and application of dipropylene glycol (DPG) as a solvent. As industries increasingly adopt DPG for its versatile properties, adherence to regulatory standards becomes paramount to ensure safety, environmental protection, and product quality.

In the United States, the Environmental Protection Agency (EPA) regulates DPG under the Toxic Substances Control Act (TSCA). The agency has established guidelines for its manufacture, import, and use. Manufacturers and importers must comply with reporting requirements, including submitting premanufacture notices and maintaining detailed records of production and distribution.

The Food and Drug Administration (FDA) also oversees the use of DPG in food contact materials and cosmetics. While DPG is generally recognized as safe (GRAS) for certain applications, its use in food-related products must adhere to specific concentration limits and purity standards. In cosmetics, the Cosmetic Ingredient Review (CIR) has evaluated DPG and deemed it safe for use in current practices and concentrations.

Globally, the European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation governs the use of DPG. Manufacturers and importers must register DPG with the European Chemicals Agency (ECHA) and provide comprehensive safety data. The regulation also mandates the communication of safety information throughout the supply chain.

Occupational safety regulations, such as those set by the Occupational Safety and Health Administration (OSHA) in the US, require proper handling and storage of DPG in workplace settings. This includes providing appropriate personal protective equipment, implementing exposure controls, and maintaining safety data sheets (SDS) for workers.

Environmental regulations also impact the use of DPG as a solvent. Many countries have established limits on volatile organic compound (VOC) emissions, which can affect formulations containing DPG. Manufacturers must consider these regulations when developing products and may need to explore low-VOC alternatives or implement emission control technologies.

The transportation of DPG is subject to regulations set by various agencies, including the Department of Transportation (DOT) in the US and the International Maritime Dangerous Goods (IMDG) Code for sea transport. These regulations dictate proper packaging, labeling, and documentation requirements to ensure safe handling during transit.

As sustainability becomes increasingly important, regulations promoting circular economy principles are emerging. These may impact the lifecycle management of DPG, encouraging recycling, reuse, and responsible disposal practices. Manufacturers and users of DPG-based solvents should stay informed about evolving regulations in this area to maintain compliance and meet market expectations.

In the United States, the Environmental Protection Agency (EPA) regulates DPG under the Toxic Substances Control Act (TSCA). The agency has established guidelines for its manufacture, import, and use. Manufacturers and importers must comply with reporting requirements, including submitting premanufacture notices and maintaining detailed records of production and distribution.

The Food and Drug Administration (FDA) also oversees the use of DPG in food contact materials and cosmetics. While DPG is generally recognized as safe (GRAS) for certain applications, its use in food-related products must adhere to specific concentration limits and purity standards. In cosmetics, the Cosmetic Ingredient Review (CIR) has evaluated DPG and deemed it safe for use in current practices and concentrations.

Globally, the European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation governs the use of DPG. Manufacturers and importers must register DPG with the European Chemicals Agency (ECHA) and provide comprehensive safety data. The regulation also mandates the communication of safety information throughout the supply chain.

Occupational safety regulations, such as those set by the Occupational Safety and Health Administration (OSHA) in the US, require proper handling and storage of DPG in workplace settings. This includes providing appropriate personal protective equipment, implementing exposure controls, and maintaining safety data sheets (SDS) for workers.

Environmental regulations also impact the use of DPG as a solvent. Many countries have established limits on volatile organic compound (VOC) emissions, which can affect formulations containing DPG. Manufacturers must consider these regulations when developing products and may need to explore low-VOC alternatives or implement emission control technologies.

The transportation of DPG is subject to regulations set by various agencies, including the Department of Transportation (DOT) in the US and the International Maritime Dangerous Goods (IMDG) Code for sea transport. These regulations dictate proper packaging, labeling, and documentation requirements to ensure safe handling during transit.

As sustainability becomes increasingly important, regulations promoting circular economy principles are emerging. These may impact the lifecycle management of DPG, encouraging recycling, reuse, and responsible disposal practices. Manufacturers and users of DPG-based solvents should stay informed about evolving regulations in this area to maintain compliance and meet market expectations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!