How Dipropylene Glycol Enhances Skin Feel in Cosmetics?

JUL 7, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DPG in Cosmetics: Background and Objectives

Dipropylene glycol (DPG) has emerged as a pivotal ingredient in the cosmetics industry, revolutionizing the way products interact with the skin. This multifaceted compound has garnered significant attention due to its unique properties that enhance the overall sensory experience of cosmetic formulations. The evolution of DPG in cosmetics can be traced back to the mid-20th century when formulators began exploring alternatives to traditional solvents and emollients.

The primary objective of incorporating DPG into cosmetic products is to improve the skin feel, which is a crucial factor in consumer satisfaction and product efficacy. DPG's ability to act as a humectant, solvent, and viscosity modifier makes it an invaluable asset in a wide range of cosmetic applications, from moisturizers and serums to makeup and hair care products. Its low molecular weight allows for easy penetration into the skin, contributing to improved hydration and a smoother texture.

As the cosmetics industry has progressed, there has been a growing emphasis on developing products that not only deliver functional benefits but also provide a luxurious sensory experience. This shift in consumer expectations has driven the exploration of ingredients like DPG that can enhance the tactile properties of cosmetic formulations. The technology behind DPG's skin feel enhancement has evolved to address various aspects of sensory perception, including initial application, absorption, and long-term skin texture improvement.

Recent technological advancements have focused on optimizing the molecular structure and interactions of DPG to maximize its skin-enhancing properties. Researchers have been investigating the synergistic effects of DPG with other cosmetic ingredients to create innovative formulations that offer superior skin feel and performance. This has led to the development of next-generation cosmetic products that boast improved spreadability, reduced tackiness, and enhanced moisture retention.

The ongoing research in this field aims to further elucidate the mechanisms by which DPG interacts with the skin at a molecular level. Scientists are exploring how DPG influences the skin's lipid barrier, water content, and overall structure to provide a comprehensive understanding of its benefits. Additionally, there is a growing interest in developing sustainable and eco-friendly alternatives that can match or surpass the skin feel enhancement capabilities of DPG, aligning with the industry's shift towards more environmentally conscious practices.

The primary objective of incorporating DPG into cosmetic products is to improve the skin feel, which is a crucial factor in consumer satisfaction and product efficacy. DPG's ability to act as a humectant, solvent, and viscosity modifier makes it an invaluable asset in a wide range of cosmetic applications, from moisturizers and serums to makeup and hair care products. Its low molecular weight allows for easy penetration into the skin, contributing to improved hydration and a smoother texture.

As the cosmetics industry has progressed, there has been a growing emphasis on developing products that not only deliver functional benefits but also provide a luxurious sensory experience. This shift in consumer expectations has driven the exploration of ingredients like DPG that can enhance the tactile properties of cosmetic formulations. The technology behind DPG's skin feel enhancement has evolved to address various aspects of sensory perception, including initial application, absorption, and long-term skin texture improvement.

Recent technological advancements have focused on optimizing the molecular structure and interactions of DPG to maximize its skin-enhancing properties. Researchers have been investigating the synergistic effects of DPG with other cosmetic ingredients to create innovative formulations that offer superior skin feel and performance. This has led to the development of next-generation cosmetic products that boast improved spreadability, reduced tackiness, and enhanced moisture retention.

The ongoing research in this field aims to further elucidate the mechanisms by which DPG interacts with the skin at a molecular level. Scientists are exploring how DPG influences the skin's lipid barrier, water content, and overall structure to provide a comprehensive understanding of its benefits. Additionally, there is a growing interest in developing sustainable and eco-friendly alternatives that can match or surpass the skin feel enhancement capabilities of DPG, aligning with the industry's shift towards more environmentally conscious practices.

Market Demand Analysis for Enhanced Skin Feel

The market demand for enhanced skin feel in cosmetics has been steadily growing, driven by consumers' increasing focus on sensory experiences and product performance. This trend is particularly evident in the skincare and personal care sectors, where texture and application experience play crucial roles in product satisfaction and repurchase decisions.

Dipropylene glycol (DPG) has emerged as a key ingredient in meeting this demand due to its unique properties that contribute to improved skin feel. Its ability to act as a solvent, humectant, and emollient makes it versatile in various cosmetic formulations, from lotions and creams to serums and foundations.

Consumer surveys indicate a strong preference for products that offer a luxurious, silky texture and absorb quickly without leaving a greasy residue. DPG's low molecular weight allows it to penetrate the skin surface, providing hydration without heaviness. This characteristic aligns well with the current market trend towards lightweight, fast-absorbing formulations that cater to busy lifestyles and multi-step skincare routines.

The global cosmetics market has seen a shift towards "clean" and "natural" beauty products. While DPG is a synthetic ingredient, its safety profile and multifunctional nature make it an attractive option for formulators looking to create effective products with a simplified ingredient list. This aligns with consumer demands for transparency and minimalism in beauty products.

In the Asia-Pacific region, where skincare routines are often more elaborate, the demand for products with enhanced skin feel is particularly high. The market for cosmetics incorporating DPG and similar ingredients that improve texture and sensory attributes has shown significant growth in countries like South Korea, Japan, and China.

The rise of social media and beauty influencers has also contributed to the increased focus on product texture and application experience. Consumers are more informed and discerning, often seeking out products that not only deliver results but also provide a pleasurable sensory experience during application.

Market research indicates that products featuring enhanced skin feel command premium pricing, with consumers willing to pay more for formulations that offer superior texture and absorption. This has led to a proliferation of high-end skincare and cosmetic lines emphasizing their use of ingredients like DPG to improve product feel and performance.

As sustainability becomes a growing concern, there is also a market demand for ingredients that can enhance product efficacy and reduce the need for multiple products. DPG's multifunctional nature aligns with this trend, potentially reducing the overall environmental impact of cosmetic consumption.

Dipropylene glycol (DPG) has emerged as a key ingredient in meeting this demand due to its unique properties that contribute to improved skin feel. Its ability to act as a solvent, humectant, and emollient makes it versatile in various cosmetic formulations, from lotions and creams to serums and foundations.

Consumer surveys indicate a strong preference for products that offer a luxurious, silky texture and absorb quickly without leaving a greasy residue. DPG's low molecular weight allows it to penetrate the skin surface, providing hydration without heaviness. This characteristic aligns well with the current market trend towards lightweight, fast-absorbing formulations that cater to busy lifestyles and multi-step skincare routines.

The global cosmetics market has seen a shift towards "clean" and "natural" beauty products. While DPG is a synthetic ingredient, its safety profile and multifunctional nature make it an attractive option for formulators looking to create effective products with a simplified ingredient list. This aligns with consumer demands for transparency and minimalism in beauty products.

In the Asia-Pacific region, where skincare routines are often more elaborate, the demand for products with enhanced skin feel is particularly high. The market for cosmetics incorporating DPG and similar ingredients that improve texture and sensory attributes has shown significant growth in countries like South Korea, Japan, and China.

The rise of social media and beauty influencers has also contributed to the increased focus on product texture and application experience. Consumers are more informed and discerning, often seeking out products that not only deliver results but also provide a pleasurable sensory experience during application.

Market research indicates that products featuring enhanced skin feel command premium pricing, with consumers willing to pay more for formulations that offer superior texture and absorption. This has led to a proliferation of high-end skincare and cosmetic lines emphasizing their use of ingredients like DPG to improve product feel and performance.

As sustainability becomes a growing concern, there is also a market demand for ingredients that can enhance product efficacy and reduce the need for multiple products. DPG's multifunctional nature aligns with this trend, potentially reducing the overall environmental impact of cosmetic consumption.

Current Challenges in Cosmetic Formulations

The cosmetics industry faces several significant challenges in formulating products that meet consumer demands for both efficacy and sensory appeal. One of the primary hurdles is achieving the desired skin feel without compromising on product performance or safety. Consumers increasingly expect cosmetics to provide a luxurious, smooth, and non-greasy sensation upon application, while simultaneously delivering active ingredients effectively.

A major challenge lies in balancing the incorporation of functional ingredients with the need for an appealing texture. Many active ingredients, such as sunscreens, antioxidants, and moisturizing agents, can negatively impact the sensory properties of a formulation. For instance, high concentrations of sunscreen filters often result in a heavy, sticky feel that consumers find unpleasant.

Another significant issue is the stability of formulations. Cosmetic chemists must ensure that products maintain their desired texture, viscosity, and sensory attributes throughout their shelf life. This becomes particularly challenging when incorporating natural and organic ingredients, which are prone to oxidation and microbial contamination.

The demand for multifunctional products presents another formulation challenge. Consumers seek products that offer multiple benefits, such as moisturizing, sun protection, and anti-aging properties, all in a single formulation. Combining these diverse functionalities while maintaining an optimal skin feel requires sophisticated formulation techniques.

Environmental factors also play a role in formulation challenges. Products must perform consistently across various climates and humidity levels, maintaining their texture and skin feel in different conditions. This is particularly crucial for global brands that distribute products worldwide.

The push for "clean" and sustainable cosmetics adds another layer of complexity. Formulators must find alternatives to traditional synthetic ingredients that provide similar sensory benefits but meet clean beauty standards. This often involves working with a more limited palette of ingredients, making it harder to achieve the desired skin feel.

Regulatory compliance presents an ongoing challenge, with different regions having varying restrictions on ingredients that can affect product texture and skin feel. Formulators must navigate these regulations while still delivering products that meet consumer expectations for sensory appeal.

In addressing these challenges, the use of innovative ingredients like dipropylene glycol becomes crucial. Such multifunctional ingredients can help formulators overcome texture issues, enhance stability, and improve overall skin feel without compromising on product efficacy or safety profiles.

A major challenge lies in balancing the incorporation of functional ingredients with the need for an appealing texture. Many active ingredients, such as sunscreens, antioxidants, and moisturizing agents, can negatively impact the sensory properties of a formulation. For instance, high concentrations of sunscreen filters often result in a heavy, sticky feel that consumers find unpleasant.

Another significant issue is the stability of formulations. Cosmetic chemists must ensure that products maintain their desired texture, viscosity, and sensory attributes throughout their shelf life. This becomes particularly challenging when incorporating natural and organic ingredients, which are prone to oxidation and microbial contamination.

The demand for multifunctional products presents another formulation challenge. Consumers seek products that offer multiple benefits, such as moisturizing, sun protection, and anti-aging properties, all in a single formulation. Combining these diverse functionalities while maintaining an optimal skin feel requires sophisticated formulation techniques.

Environmental factors also play a role in formulation challenges. Products must perform consistently across various climates and humidity levels, maintaining their texture and skin feel in different conditions. This is particularly crucial for global brands that distribute products worldwide.

The push for "clean" and sustainable cosmetics adds another layer of complexity. Formulators must find alternatives to traditional synthetic ingredients that provide similar sensory benefits but meet clean beauty standards. This often involves working with a more limited palette of ingredients, making it harder to achieve the desired skin feel.

Regulatory compliance presents an ongoing challenge, with different regions having varying restrictions on ingredients that can affect product texture and skin feel. Formulators must navigate these regulations while still delivering products that meet consumer expectations for sensory appeal.

In addressing these challenges, the use of innovative ingredients like dipropylene glycol becomes crucial. Such multifunctional ingredients can help formulators overcome texture issues, enhance stability, and improve overall skin feel without compromising on product efficacy or safety profiles.

DPG-based Solutions for Improved Skin Feel

01 Moisturizing and skin feel enhancement

Dipropylene glycol is used in skincare formulations to improve skin feel and provide moisturizing effects. It acts as a humectant, helping to retain moisture in the skin, and contributes to a smooth, non-greasy texture in cosmetic products.- Moisturizing and skin feel enhancement: Dipropylene glycol is used in skincare formulations to improve skin feel and provide moisturizing effects. It acts as a humectant, helping to retain moisture in the skin, and contributes to a smooth, non-greasy texture in cosmetic products.

- Solvent and carrier properties: Dipropylene glycol serves as an effective solvent and carrier for active ingredients in skincare products. It helps to dissolve and disperse various components, ensuring uniform distribution and improved efficacy of the formulation.

- Emollient and skin conditioning: As an emollient, dipropylene glycol helps to soften and smooth the skin, improving its overall texture and appearance. It contributes to the skin conditioning properties of cosmetic formulations, leaving the skin feeling supple and comfortable.

- Viscosity modification and texture improvement: Dipropylene glycol can be used to adjust the viscosity of skincare products, helping to achieve the desired texture and flow properties. It contributes to the overall sensory experience of the product during application.

- Penetration enhancement and delivery system: Dipropylene glycol can act as a penetration enhancer, improving the absorption of active ingredients into the skin. It can be incorporated into delivery systems to optimize the efficacy of skincare formulations and enhance their overall performance.

02 Solvent and carrier properties

Dipropylene glycol serves as an effective solvent and carrier for active ingredients in skincare products. It helps to dissolve and disperse various components, ensuring uniform distribution and improved efficacy of the formulation.Expand Specific Solutions03 Emollient and skin conditioning

The compound acts as an emollient, softening and smoothing the skin. It helps to improve the overall skin feel by reducing roughness and providing a silky texture to cosmetic formulations.Expand Specific Solutions04 Viscosity modification

Dipropylene glycol can be used to adjust the viscosity of skincare products. It helps to achieve the desired consistency and flow properties, contributing to improved application and skin feel of the final product.Expand Specific Solutions05 Fragrance enhancement and fixation

In addition to its skin feel properties, dipropylene glycol is used in fragrance formulations to enhance and fix scents. It helps to stabilize volatile fragrance components and improve their longevity on the skin.Expand Specific Solutions

Key Players in Cosmetic Ingredients Industry

The market for dipropylene glycol in cosmetics is in a growth phase, driven by increasing demand for enhanced skin feel in personal care products. The global cosmetics market, valued at over $380 billion in 2019, is expected to grow significantly, with skin care as a key segment. Technologically, dipropylene glycol's use in cosmetics is well-established, but innovation continues in formulation and application. Major players like L'Oréal, Shiseido, and Beiersdorf are investing in research to optimize its use, while smaller companies like COSMAX and Guangdong Marubi Biotechnology are developing niche products. The technology's maturity allows for widespread adoption, but there's still room for differentiation through innovative formulations and combinations with other ingredients.

Shiseido Co., Ltd.

Technical Solution: Shiseido has leveraged Dipropylene Glycol in their cosmetic formulations to enhance skin feel and overall product performance. Their approach involves using DPG as a versatile ingredient that functions as a solvent, humectant, and texture enhancer. Shiseido's research has shown that DPG can improve the spreadability of products, leading to a more even application and a smoother skin feel[5]. They have also utilized DPG's ability to enhance the solubility of active ingredients, allowing for more effective delivery of beneficial compounds to the skin. Shiseido has developed innovative formulations that combine DPG with other skin-conditioning agents to create products with exceptional texture and long-lasting hydration[6].

Strengths: Strong focus on innovation, extensive R&D capabilities, and expertise in Asian skincare markets. Weaknesses: May face challenges in adapting formulations for diverse global skin types and preferences.

L'Oréal SA

Technical Solution: L'Oréal has developed advanced formulations incorporating Dipropylene Glycol (DPG) to enhance skin feel in cosmetics. Their approach involves using DPG as a solvent and humectant, which helps to improve the texture and spreadability of products while maintaining skin hydration. L'Oréal's research has shown that DPG can enhance the penetration of active ingredients, leading to more effective skincare formulations[1]. They have also found that DPG can help stabilize emulsions, resulting in smoother, more luxurious textures in creams and lotions. L'Oréal has optimized the concentration of DPG in their formulations to balance its moisturizing properties with its ability to enhance the overall sensory experience of their products[3].

Strengths: Extensive research capabilities, global market presence, and ability to optimize DPG concentrations for various product types. Weaknesses: Potential concerns about synthetic ingredients among natural beauty consumers.

Innovations in DPG Application Techniques

Oil-in Water type cosmetic composition comprising high level of Dipropylene glycol

PatentActiveKR1020230044827A

Innovation

- A cosmetic composition comprising an aqueous phase with 15% or more dipropylene glycol, combined with specific emulsifiers like glyceryl stearate SE, cetearyl olivate, sorbitan olivate, cetearyl alcohol, and cetearyl glucoside, and a thickener such as ammonium acryloyl dimethyl taurate/VP copolymer, along with optional silicone oil, to enhance moisturizing power and stability.

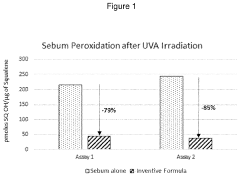

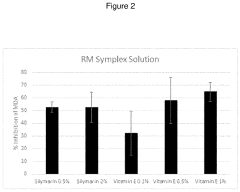

Serums for reducing lipid peroxidation

PatentPendingUS20230372231A1

Innovation

- A cosmetic composition comprising 0.1 to 1.8 wt.% Silybum Marianum Extract, 0.1 to 20 wt.% skin actives, 3 to 15 wt.% Propylene Glycol, 8 to 18 wt.% Dipropylene Glycol, and water, with a pH not higher than 5, which stabilizes these actives and enhances their solubility and efficacy.

Regulatory Compliance for Cosmetic Ingredients

Regulatory compliance is a critical aspect of cosmetic ingredient usage, including dipropylene glycol (DPG). In the United States, the Food and Drug Administration (FDA) regulates cosmetics under the Federal Food, Drug, and Cosmetic Act and the Fair Packaging and Labeling Act. DPG is generally recognized as safe (GRAS) by the FDA for use in cosmetics and personal care products.

The European Union's Cosmetic Regulation (EC) No. 1223/2009 governs the use of cosmetic ingredients in EU member states. DPG is listed in the EU Cosmetic Ingredient Database (CosIng) and is permitted for use in cosmetic formulations. However, manufacturers must ensure that their products containing DPG comply with the regulation's safety assessment requirements.

In Japan, the Ministry of Health, Labour and Welfare regulates cosmetics under the Pharmaceutical Affairs Law. DPG is approved for use in cosmetics and is listed in the Japanese Standards of Cosmetic Ingredients (JSCI).

The International Nomenclature of Cosmetic Ingredients (INCI) system, which is widely used for ingredient labeling, recognizes DPG under the name "Dipropylene Glycol." Manufacturers must adhere to proper labeling requirements in various markets to ensure compliance.

When using DPG in cosmetic formulations, manufacturers must consider concentration limits set by regulatory bodies. While specific limits may vary by region, general guidelines suggest that DPG is safe for use in leave-on products at concentrations up to 10% and in rinse-off products at higher concentrations.

Safety assessments are crucial for regulatory compliance. The Cosmetic Ingredient Review (CIR) Expert Panel has evaluated the safety of DPG and concluded that it is safe for use in cosmetics under current practices of use and concentration. This assessment supports the regulatory acceptance of DPG in many jurisdictions.

Manufacturers must also consider potential allergen regulations when using DPG. While DPG itself is not typically classified as an allergen, it may be subject to disclosure requirements in certain markets if used at specific concentrations.

To ensure global compliance, cosmetic companies often adopt a harmonized approach that meets the most stringent regulatory requirements across different markets. This strategy helps streamline product development and reduces the need for market-specific formulations.

The European Union's Cosmetic Regulation (EC) No. 1223/2009 governs the use of cosmetic ingredients in EU member states. DPG is listed in the EU Cosmetic Ingredient Database (CosIng) and is permitted for use in cosmetic formulations. However, manufacturers must ensure that their products containing DPG comply with the regulation's safety assessment requirements.

In Japan, the Ministry of Health, Labour and Welfare regulates cosmetics under the Pharmaceutical Affairs Law. DPG is approved for use in cosmetics and is listed in the Japanese Standards of Cosmetic Ingredients (JSCI).

The International Nomenclature of Cosmetic Ingredients (INCI) system, which is widely used for ingredient labeling, recognizes DPG under the name "Dipropylene Glycol." Manufacturers must adhere to proper labeling requirements in various markets to ensure compliance.

When using DPG in cosmetic formulations, manufacturers must consider concentration limits set by regulatory bodies. While specific limits may vary by region, general guidelines suggest that DPG is safe for use in leave-on products at concentrations up to 10% and in rinse-off products at higher concentrations.

Safety assessments are crucial for regulatory compliance. The Cosmetic Ingredient Review (CIR) Expert Panel has evaluated the safety of DPG and concluded that it is safe for use in cosmetics under current practices of use and concentration. This assessment supports the regulatory acceptance of DPG in many jurisdictions.

Manufacturers must also consider potential allergen regulations when using DPG. While DPG itself is not typically classified as an allergen, it may be subject to disclosure requirements in certain markets if used at specific concentrations.

To ensure global compliance, cosmetic companies often adopt a harmonized approach that meets the most stringent regulatory requirements across different markets. This strategy helps streamline product development and reduces the need for market-specific formulations.

Sustainability in DPG Production and Use

Sustainability in the production and use of Dipropylene Glycol (DPG) has become increasingly important as the cosmetics industry strives to meet consumer demands for environmentally friendly products. The manufacturing process of DPG traditionally involves the use of propylene oxide, which is derived from petroleum sources. However, recent advancements have led to more sustainable production methods.

One such method is the use of bio-based feedstocks to produce propylene glycol, which can then be converted to DPG. This approach significantly reduces the carbon footprint of DPG production by utilizing renewable resources instead of fossil fuels. Several companies have successfully implemented this technology, resulting in DPG with up to 100% bio-based content.

Another sustainable approach in DPG production is the implementation of closed-loop systems. These systems aim to minimize waste and maximize resource efficiency by recycling and reusing materials throughout the production process. This not only reduces environmental impact but also improves cost-effectiveness for manufacturers.

Water conservation is a crucial aspect of sustainable DPG production. Advanced water treatment and recycling technologies have been developed to reduce water consumption and minimize wastewater discharge. Some facilities have achieved near-zero liquid discharge, significantly reducing their environmental impact.

In terms of energy efficiency, many DPG producers have invested in renewable energy sources such as solar and wind power to reduce their reliance on fossil fuels. Additionally, heat recovery systems and process optimization techniques have been implemented to minimize energy consumption during production.

The use of DPG in cosmetics also contributes to sustainability efforts. Its multifunctional properties allow formulators to reduce the number of ingredients in a product, potentially simplifying supply chains and reducing overall environmental impact. Furthermore, DPG's ability to enhance the efficacy of preservatives can lead to the use of lower concentrations of these ingredients, aligning with the trend towards "clean" beauty products.

As the cosmetics industry continues to prioritize sustainability, ongoing research focuses on further improving the environmental profile of DPG. This includes exploring new bio-based production methods, enhancing recycling capabilities, and developing more efficient purification processes. These efforts aim to ensure that DPG remains a viable and sustainable ingredient in cosmetic formulations, meeting both performance requirements and environmental standards.

One such method is the use of bio-based feedstocks to produce propylene glycol, which can then be converted to DPG. This approach significantly reduces the carbon footprint of DPG production by utilizing renewable resources instead of fossil fuels. Several companies have successfully implemented this technology, resulting in DPG with up to 100% bio-based content.

Another sustainable approach in DPG production is the implementation of closed-loop systems. These systems aim to minimize waste and maximize resource efficiency by recycling and reusing materials throughout the production process. This not only reduces environmental impact but also improves cost-effectiveness for manufacturers.

Water conservation is a crucial aspect of sustainable DPG production. Advanced water treatment and recycling technologies have been developed to reduce water consumption and minimize wastewater discharge. Some facilities have achieved near-zero liquid discharge, significantly reducing their environmental impact.

In terms of energy efficiency, many DPG producers have invested in renewable energy sources such as solar and wind power to reduce their reliance on fossil fuels. Additionally, heat recovery systems and process optimization techniques have been implemented to minimize energy consumption during production.

The use of DPG in cosmetics also contributes to sustainability efforts. Its multifunctional properties allow formulators to reduce the number of ingredients in a product, potentially simplifying supply chains and reducing overall environmental impact. Furthermore, DPG's ability to enhance the efficacy of preservatives can lead to the use of lower concentrations of these ingredients, aligning with the trend towards "clean" beauty products.

As the cosmetics industry continues to prioritize sustainability, ongoing research focuses on further improving the environmental profile of DPG. This includes exploring new bio-based production methods, enhancing recycling capabilities, and developing more efficient purification processes. These efforts aim to ensure that DPG remains a viable and sustainable ingredient in cosmetic formulations, meeting both performance requirements and environmental standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!