How Dipropylene Glycol Helps Solvent Applications?

JUL 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DPG Solvent Background

Dipropylene glycol (DPG) has emerged as a versatile and widely used solvent in various industrial applications. Its unique chemical properties and favorable characteristics have made it an essential component in many solvent formulations. DPG is a clear, colorless, and low-volatility liquid with a mild odor, belonging to the family of glycol ethers.

The history of DPG can be traced back to the early 20th century when the demand for more efficient and environmentally friendly solvents began to rise. As industries sought alternatives to traditional petroleum-based solvents, DPG gained prominence due to its excellent solvency power and low toxicity. Its development was closely tied to the growth of the petrochemical industry and the increasing need for specialized solvents in various manufacturing processes.

DPG is primarily produced through the reaction of propylene oxide with water, resulting in a mixture of isomers. This production process has been refined over the years to improve yield and purity, making DPG more accessible and cost-effective for industrial use. The compound's molecular structure, consisting of two propylene glycol units linked by an ether bond, contributes to its unique solvent properties.

One of the key factors driving the adoption of DPG in solvent applications is its excellent solvency for a wide range of polar and non-polar substances. This versatility allows it to dissolve various organic compounds, making it suitable for use in paints, coatings, cleaners, and personal care products. Additionally, DPG's high boiling point and low evaporation rate contribute to its stability and longevity in formulations, enhancing the performance of end products.

The environmental and safety aspects of DPG have also played a significant role in its widespread adoption. Compared to many traditional solvents, DPG exhibits lower toxicity and reduced environmental impact. It is biodegradable and has a low potential for bioaccumulation, aligning with the growing emphasis on sustainable and eco-friendly industrial practices.

In recent years, the global demand for DPG has steadily increased, driven by its expanding applications in diverse industries. The compound's use has extended beyond traditional solvent applications to include roles as a coupling agent, viscosity modifier, and humectant in various formulations. This versatility has led to its incorporation in a wide array of products, from industrial coatings to cosmetics and pharmaceuticals.

As industries continue to evolve and face new challenges, the role of DPG in solvent applications is expected to grow further. Ongoing research and development efforts are focused on optimizing DPG-based formulations and exploring novel applications to meet emerging industry needs. The compound's balance of performance, safety, and environmental compatibility positions it as a key player in the future of solvent technology.

The history of DPG can be traced back to the early 20th century when the demand for more efficient and environmentally friendly solvents began to rise. As industries sought alternatives to traditional petroleum-based solvents, DPG gained prominence due to its excellent solvency power and low toxicity. Its development was closely tied to the growth of the petrochemical industry and the increasing need for specialized solvents in various manufacturing processes.

DPG is primarily produced through the reaction of propylene oxide with water, resulting in a mixture of isomers. This production process has been refined over the years to improve yield and purity, making DPG more accessible and cost-effective for industrial use. The compound's molecular structure, consisting of two propylene glycol units linked by an ether bond, contributes to its unique solvent properties.

One of the key factors driving the adoption of DPG in solvent applications is its excellent solvency for a wide range of polar and non-polar substances. This versatility allows it to dissolve various organic compounds, making it suitable for use in paints, coatings, cleaners, and personal care products. Additionally, DPG's high boiling point and low evaporation rate contribute to its stability and longevity in formulations, enhancing the performance of end products.

The environmental and safety aspects of DPG have also played a significant role in its widespread adoption. Compared to many traditional solvents, DPG exhibits lower toxicity and reduced environmental impact. It is biodegradable and has a low potential for bioaccumulation, aligning with the growing emphasis on sustainable and eco-friendly industrial practices.

In recent years, the global demand for DPG has steadily increased, driven by its expanding applications in diverse industries. The compound's use has extended beyond traditional solvent applications to include roles as a coupling agent, viscosity modifier, and humectant in various formulations. This versatility has led to its incorporation in a wide array of products, from industrial coatings to cosmetics and pharmaceuticals.

As industries continue to evolve and face new challenges, the role of DPG in solvent applications is expected to grow further. Ongoing research and development efforts are focused on optimizing DPG-based formulations and exploring novel applications to meet emerging industry needs. The compound's balance of performance, safety, and environmental compatibility positions it as a key player in the future of solvent technology.

Market Analysis

The market for dipropylene glycol (DPG) as a solvent has shown significant growth in recent years, driven by its versatile applications across various industries. The global DPG market size was valued at approximately $2.5 billion in 2020 and is projected to expand at a compound annual growth rate (CAGR) of 5.2% from 2021 to 2028. This growth is primarily attributed to the increasing demand for environmentally friendly and low-toxicity solvents in industrial processes.

The paint and coatings industry represents the largest end-use segment for DPG, accounting for over 30% of the total market share. DPG's excellent solvency properties, low volatility, and ability to improve flow and leveling characteristics make it an ideal choice for water-based paints and coatings. The construction sector's growth, particularly in emerging economies, is expected to further boost demand for DPG in this application.

Another significant market for DPG is the personal care and cosmetics industry. DPG's moisturizing properties and its ability to act as a carrier for fragrances and active ingredients have led to its increased use in skincare products, hair care formulations, and perfumes. The global personal care market is projected to grow at a CAGR of 5.9% from 2021 to 2026, which will likely drive the demand for DPG in this sector.

The cleaning and household products industry also represents a substantial market for DPG. Its effectiveness as a solvent in all-purpose cleaners, glass cleaners, and other household products has led to increased adoption. The COVID-19 pandemic has further accelerated the demand for cleaning products, indirectly benefiting the DPG market.

Geographically, Asia Pacific dominates the DPG market, accounting for over 40% of the global consumption. This is primarily due to the rapid industrialization in countries like China and India, coupled with the growth of end-use industries such as paints and coatings, personal care, and cleaning products. North America and Europe follow as the second and third-largest markets, respectively, driven by stringent environmental regulations favoring the use of low-VOC solvents.

The market for DPG faces some challenges, including price volatility of raw materials and competition from alternative solvents. However, the increasing focus on sustainable and bio-based solvents presents new opportunities for growth. Manufacturers are investing in research and development to improve production processes and develop new applications for DPG, which is expected to drive market growth in the coming years.

The paint and coatings industry represents the largest end-use segment for DPG, accounting for over 30% of the total market share. DPG's excellent solvency properties, low volatility, and ability to improve flow and leveling characteristics make it an ideal choice for water-based paints and coatings. The construction sector's growth, particularly in emerging economies, is expected to further boost demand for DPG in this application.

Another significant market for DPG is the personal care and cosmetics industry. DPG's moisturizing properties and its ability to act as a carrier for fragrances and active ingredients have led to its increased use in skincare products, hair care formulations, and perfumes. The global personal care market is projected to grow at a CAGR of 5.9% from 2021 to 2026, which will likely drive the demand for DPG in this sector.

The cleaning and household products industry also represents a substantial market for DPG. Its effectiveness as a solvent in all-purpose cleaners, glass cleaners, and other household products has led to increased adoption. The COVID-19 pandemic has further accelerated the demand for cleaning products, indirectly benefiting the DPG market.

Geographically, Asia Pacific dominates the DPG market, accounting for over 40% of the global consumption. This is primarily due to the rapid industrialization in countries like China and India, coupled with the growth of end-use industries such as paints and coatings, personal care, and cleaning products. North America and Europe follow as the second and third-largest markets, respectively, driven by stringent environmental regulations favoring the use of low-VOC solvents.

The market for DPG faces some challenges, including price volatility of raw materials and competition from alternative solvents. However, the increasing focus on sustainable and bio-based solvents presents new opportunities for growth. Manufacturers are investing in research and development to improve production processes and develop new applications for DPG, which is expected to drive market growth in the coming years.

Technical Challenges

Despite the widespread use of dipropylene glycol (DPG) in solvent applications, several technical challenges persist in its implementation and optimization. One of the primary issues is the variability in DPG's performance across different temperature ranges. While DPG exhibits excellent solvency at room temperature, its effectiveness can diminish significantly at extreme temperatures, particularly in cold environments. This temperature sensitivity can limit its applicability in certain industrial processes or outdoor applications where consistent performance is crucial.

Another challenge lies in the potential for DPG to absorb moisture from the atmosphere. This hygroscopic nature can lead to changes in the solvent's properties over time, affecting its stability and performance in long-term storage or use. Manufacturers must implement stringent moisture control measures to maintain the solvent's integrity, which can increase production costs and complexity.

The compatibility of DPG with various materials presents another technical hurdle. While DPG is generally considered a versatile solvent, it can react adversely with certain plastics, rubbers, and coatings. This reactivity necessitates careful material selection in equipment and packaging design, potentially limiting the range of applications or increasing development costs for DPG-based products.

Furthermore, the environmental impact of DPG usage remains a concern. Although it is considered less toxic than many other solvents, its biodegradability is not optimal. This characteristic poses challenges in waste management and environmental compliance, particularly in industries with strict ecological regulations. Developing more environmentally friendly formulations or finding effective recycling methods for DPG-containing waste streams is an ongoing challenge for researchers and manufacturers.

The purity of DPG in industrial applications is another critical issue. Impurities can significantly affect the solvent's performance and potentially introduce unwanted side reactions in chemical processes. Achieving and maintaining high purity levels of DPG at scale, while keeping production costs competitive, remains a technical challenge for manufacturers.

Lastly, the optimization of DPG's solvent properties for specific applications presents ongoing difficulties. While DPG offers a good balance of solvency and low volatility, fine-tuning these properties for niche applications often requires extensive research and development. This challenge is particularly evident in emerging fields such as advanced materials processing or in the formulation of high-performance coatings, where the demands on solvent performance are increasingly stringent.

Another challenge lies in the potential for DPG to absorb moisture from the atmosphere. This hygroscopic nature can lead to changes in the solvent's properties over time, affecting its stability and performance in long-term storage or use. Manufacturers must implement stringent moisture control measures to maintain the solvent's integrity, which can increase production costs and complexity.

The compatibility of DPG with various materials presents another technical hurdle. While DPG is generally considered a versatile solvent, it can react adversely with certain plastics, rubbers, and coatings. This reactivity necessitates careful material selection in equipment and packaging design, potentially limiting the range of applications or increasing development costs for DPG-based products.

Furthermore, the environmental impact of DPG usage remains a concern. Although it is considered less toxic than many other solvents, its biodegradability is not optimal. This characteristic poses challenges in waste management and environmental compliance, particularly in industries with strict ecological regulations. Developing more environmentally friendly formulations or finding effective recycling methods for DPG-containing waste streams is an ongoing challenge for researchers and manufacturers.

The purity of DPG in industrial applications is another critical issue. Impurities can significantly affect the solvent's performance and potentially introduce unwanted side reactions in chemical processes. Achieving and maintaining high purity levels of DPG at scale, while keeping production costs competitive, remains a technical challenge for manufacturers.

Lastly, the optimization of DPG's solvent properties for specific applications presents ongoing difficulties. While DPG offers a good balance of solvency and low volatility, fine-tuning these properties for niche applications often requires extensive research and development. This challenge is particularly evident in emerging fields such as advanced materials processing or in the formulation of high-performance coatings, where the demands on solvent performance are increasingly stringent.

Current DPG Solutions

01 Solvent and carrier in cosmetic formulations

Dipropylene glycol is widely used as a solvent and carrier in various cosmetic and personal care products. It helps to dissolve and disperse active ingredients, enhancing the overall effectiveness of the formulation. Its ability to mix with both water and oil makes it versatile in creating stable emulsions and improving the texture of products.- Use as a solvent in cosmetic formulations: Dipropylene glycol is commonly used as a solvent in various cosmetic and personal care products. It helps to dissolve and blend different ingredients, improving the overall stability and consistency of the formulation. This versatile compound can be found in a wide range of products, including skincare, haircare, and fragrances.

- Humectant and moisturizing properties: Dipropylene glycol acts as a humectant, attracting and retaining moisture in the skin and hair. It helps to keep products from drying out and provides a moisturizing effect when applied to the skin. This property makes it a valuable ingredient in lotions, creams, and hair care products.

- Application in fragrance and perfume industry: In the fragrance industry, dipropylene glycol is used as a diluent and fixative for perfumes and colognes. It helps to stabilize volatile fragrance compounds and can enhance the longevity of scents. This compound is also used in the production of air fresheners and other scented products.

- Use in industrial and household products: Dipropylene glycol finds applications in various industrial and household products. It is used as a component in antifreeze formulations, hydraulic fluids, and as a plasticizer in some polymer applications. In household products, it can be found in cleaning agents and detergents.

- Safety and regulatory considerations: Dipropylene glycol is generally recognized as safe for use in cosmetics and personal care products by regulatory agencies. However, its use is subject to certain concentration limits and guidelines in different countries. Manufacturers must adhere to these regulations when formulating products containing this ingredient.

02 Humectant and moisturizing agent

As a humectant, dipropylene glycol attracts and retains moisture, helping to keep the skin hydrated. It is often incorporated into skincare and haircare products to improve moisture retention and prevent dryness. This property makes it particularly useful in formulations designed for dry or sensitive skin.Expand Specific Solutions03 Viscosity modifier in liquid formulations

Dipropylene glycol can be used to adjust the viscosity of liquid formulations. It helps to create the desired consistency and flow properties in various products, including lotions, creams, and gels. This allows for better application and improved product performance.Expand Specific Solutions04 Fragrance fixative and stabilizer

In perfumes and fragranced products, dipropylene glycol acts as a fixative and stabilizer for volatile fragrance compounds. It helps to prolong the scent and improve its overall performance by slowing down the evaporation rate of fragrance molecules.Expand Specific Solutions05 Preservative enhancer and antimicrobial agent

Dipropylene glycol can enhance the effectiveness of preservatives in cosmetic formulations. It also exhibits some antimicrobial properties, helping to inhibit the growth of bacteria and fungi in products. This contributes to extending the shelf life and maintaining the safety of cosmetic and personal care items.Expand Specific Solutions

Key Industry Players

The market for dipropylene glycol in solvent applications is in a mature stage, with steady growth driven by diverse industrial uses. The global market size is estimated to be in the billions of dollars, reflecting its widespread adoption across sectors like cosmetics, personal care, and pharmaceuticals. Technologically, dipropylene glycol is well-established, with companies like Dow Global Technologies, LG H&H, and Stepan Co. leading in innovation and production. Major players such as L'Oréal, Johnson & Johnson, and Unilever utilize this versatile solvent in their product formulations, indicating its critical role in various consumer goods. The competitive landscape is characterized by a mix of chemical manufacturers and end-users, with ongoing research focused on enhancing efficiency and exploring new applications.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has made significant advancements in dipropylene glycol applications for solvents. Their approach focuses on large-scale production and integration of DPG into various industrial processes. Sinopec has developed DPG-based solvents for use in the petrochemical industry, particularly in gas sweetening processes where DPG acts as an efficient absorbent for acid gases[13]. In the field of polymers, they have created DPG-containing formulations that serve as plasticizers, improving the flexibility and durability of plastic products[15]. Sinopec has also explored the use of DPG in pharmaceutical applications, developing solvent systems that enhance drug solubility and stability[17].

Strengths: Massive production capacity, vertical integration from raw materials to end products, strong presence in Asian markets. Weaknesses: Potential environmental concerns associated with large-scale chemical production, regulatory challenges in international markets.

Dow Global Technologies LLC

Technical Solution: Dow Global Technologies LLC has developed advanced solvent applications utilizing dipropylene glycol (DPG). Their approach involves incorporating DPG into various formulations to enhance performance and sustainability. DPG acts as a coupling agent, improving the solubility and compatibility of different ingredients in complex mixtures[1]. In cleaning products, Dow's technology leverages DPG's excellent solvency and low volatility to create more effective and longer-lasting formulations[3]. For industrial coatings, they have engineered DPG-based solutions that provide better flow, leveling, and coalescence, resulting in improved finish quality and durability[5].

Strengths: Extensive expertise in chemical formulations, global reach for implementation, and strong R&D capabilities. Weaknesses: Potential higher costs compared to traditional solvents, and dependency on petrochemical feedstocks.

DPG Innovations

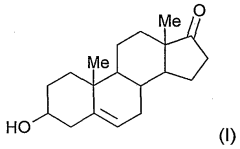

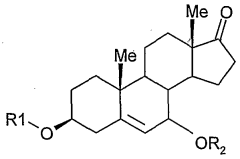

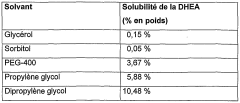

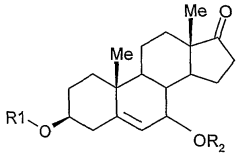

Composition containing a steroid and a glycol

PatentWO2003011244A1

Innovation

- Incorporating dipropylene glycol as a solubilizer for DHEA and its derivatives, which can be mixed at various temperatures to prevent recrystallization and enhance solubility, allowing for stable and effective topical formulations without compromising cosmetic properties.

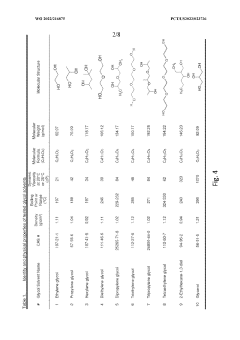

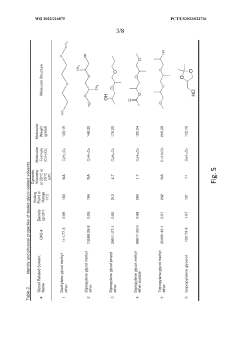

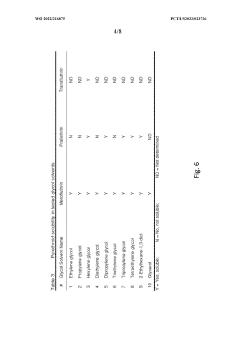

Solvent for insect repellent active ingredient and insert repellent system using same

PatentWO2022216875A1

Innovation

- A portable insect repellent system using a glycol solvent, such as a mixture of hexylene glycol and dipropylene glycol, with a heating element powered by a low voltage battery, allowing for higher active ingredient concentrations up to 27% and compatibility with device materials, enabling effective mosquito repellency in outdoor areas without aspiration hazards.

Environmental Impact

Dipropylene glycol (DPG) has gained significant attention in solvent applications due to its versatile properties and relatively low environmental impact compared to traditional solvents. As industries increasingly prioritize sustainability, understanding the environmental implications of DPG usage is crucial for informed decision-making and responsible product development.

One of the key environmental advantages of DPG is its low volatility, which results in reduced emissions of volatile organic compounds (VOCs) into the atmosphere. This characteristic makes DPG an attractive option for industries seeking to comply with stringent air quality regulations and reduce their carbon footprint. The lower evaporation rate of DPG also contributes to improved indoor air quality in various applications, such as paints, coatings, and cleaning products.

Furthermore, DPG exhibits good biodegradability properties, which mitigates concerns about its long-term persistence in the environment. Studies have shown that DPG can be effectively broken down by microorganisms in both aerobic and anaerobic conditions, reducing the risk of accumulation in soil and water ecosystems. This biodegradability feature aligns well with the principles of green chemistry and circular economy, promoting the development of more environmentally friendly products.

In terms of aquatic toxicity, DPG demonstrates relatively low impact compared to many conventional solvents. Its limited water solubility and low bioaccumulation potential contribute to reduced risks for aquatic organisms. However, it is important to note that proper handling and disposal practices are still necessary to prevent large-scale releases into water bodies, as concentrated amounts may still pose risks to sensitive aquatic ecosystems.

The production process of DPG also offers environmental benefits when compared to some alternative solvents. It can be synthesized from propylene oxide, which is derived from propylene, a byproduct of petroleum refining. This utilization of byproducts contributes to resource efficiency and helps reduce overall waste in industrial processes. Additionally, advancements in green chemistry have led to the exploration of bio-based routes for DPG production, further enhancing its environmental profile.

While DPG presents several environmental advantages, it is essential to consider the entire lifecycle of products containing this solvent. This includes assessing the energy consumption and emissions associated with its production, transportation, and end-of-life disposal. Comprehensive life cycle assessments (LCAs) can provide valuable insights into the overall environmental impact of DPG-based solutions compared to alternatives.

As regulations and consumer preferences continue to evolve, the demand for environmentally friendly solvents like DPG is expected to grow. This trend is likely to drive further research and development efforts aimed at optimizing the environmental performance of DPG and exploring new applications that leverage its unique properties while minimizing ecological footprints.

One of the key environmental advantages of DPG is its low volatility, which results in reduced emissions of volatile organic compounds (VOCs) into the atmosphere. This characteristic makes DPG an attractive option for industries seeking to comply with stringent air quality regulations and reduce their carbon footprint. The lower evaporation rate of DPG also contributes to improved indoor air quality in various applications, such as paints, coatings, and cleaning products.

Furthermore, DPG exhibits good biodegradability properties, which mitigates concerns about its long-term persistence in the environment. Studies have shown that DPG can be effectively broken down by microorganisms in both aerobic and anaerobic conditions, reducing the risk of accumulation in soil and water ecosystems. This biodegradability feature aligns well with the principles of green chemistry and circular economy, promoting the development of more environmentally friendly products.

In terms of aquatic toxicity, DPG demonstrates relatively low impact compared to many conventional solvents. Its limited water solubility and low bioaccumulation potential contribute to reduced risks for aquatic organisms. However, it is important to note that proper handling and disposal practices are still necessary to prevent large-scale releases into water bodies, as concentrated amounts may still pose risks to sensitive aquatic ecosystems.

The production process of DPG also offers environmental benefits when compared to some alternative solvents. It can be synthesized from propylene oxide, which is derived from propylene, a byproduct of petroleum refining. This utilization of byproducts contributes to resource efficiency and helps reduce overall waste in industrial processes. Additionally, advancements in green chemistry have led to the exploration of bio-based routes for DPG production, further enhancing its environmental profile.

While DPG presents several environmental advantages, it is essential to consider the entire lifecycle of products containing this solvent. This includes assessing the energy consumption and emissions associated with its production, transportation, and end-of-life disposal. Comprehensive life cycle assessments (LCAs) can provide valuable insights into the overall environmental impact of DPG-based solutions compared to alternatives.

As regulations and consumer preferences continue to evolve, the demand for environmentally friendly solvents like DPG is expected to grow. This trend is likely to drive further research and development efforts aimed at optimizing the environmental performance of DPG and exploring new applications that leverage its unique properties while minimizing ecological footprints.

Regulatory Compliance

Regulatory compliance plays a crucial role in the use of dipropylene glycol (DPG) as a solvent in various applications. As industries increasingly adopt DPG for its versatile properties, adherence to regulatory standards becomes paramount to ensure safety, environmental protection, and product quality.

In the United States, the Environmental Protection Agency (EPA) regulates DPG under the Toxic Substances Control Act (TSCA). The EPA has established guidelines for the manufacture, import, and use of DPG, including reporting requirements and risk assessment protocols. Manufacturers and importers must comply with these regulations to maintain market access and avoid potential penalties.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation also governs the use of DPG. Under REACH, companies must register DPG with the European Chemicals Agency (ECHA) and provide comprehensive safety data. This regulation ensures that potential risks associated with DPG are thoroughly assessed and managed throughout its lifecycle.

In the cosmetics industry, DPG is widely used as a solvent and fragrance ingredient. The FDA in the United States and the European Commission's Cosmetic Regulation set specific guidelines for its use in personal care products. These regulations typically include concentration limits and labeling requirements to protect consumer safety.

For industrial applications, such as paints and coatings, occupational safety regulations come into play. The Occupational Safety and Health Administration (OSHA) in the US and the European Agency for Safety and Health at Work (EU-OSHA) provide guidelines for safe handling, storage, and disposal of DPG in workplace settings. These regulations often mandate the use of personal protective equipment and proper ventilation systems.

Environmental regulations also impact the use of DPG as a solvent. Many countries have implemented volatile organic compound (VOC) emission standards that affect the formulation of products containing DPG. Manufacturers must ensure their products meet these standards to comply with air quality regulations and reduce environmental impact.

As global awareness of chemical safety increases, regulatory bodies continue to update and refine their guidelines. Companies using DPG in solvent applications must stay informed about these evolving regulations and adapt their practices accordingly. This may involve investing in research and development to find alternative formulations or implementing more stringent quality control measures.

Compliance with these regulations not only ensures legal operation but also builds consumer trust and enhances brand reputation. As such, regulatory compliance has become a key factor in the strategic planning and product development processes for companies utilizing DPG in their solvent applications.

In the United States, the Environmental Protection Agency (EPA) regulates DPG under the Toxic Substances Control Act (TSCA). The EPA has established guidelines for the manufacture, import, and use of DPG, including reporting requirements and risk assessment protocols. Manufacturers and importers must comply with these regulations to maintain market access and avoid potential penalties.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation also governs the use of DPG. Under REACH, companies must register DPG with the European Chemicals Agency (ECHA) and provide comprehensive safety data. This regulation ensures that potential risks associated with DPG are thoroughly assessed and managed throughout its lifecycle.

In the cosmetics industry, DPG is widely used as a solvent and fragrance ingredient. The FDA in the United States and the European Commission's Cosmetic Regulation set specific guidelines for its use in personal care products. These regulations typically include concentration limits and labeling requirements to protect consumer safety.

For industrial applications, such as paints and coatings, occupational safety regulations come into play. The Occupational Safety and Health Administration (OSHA) in the US and the European Agency for Safety and Health at Work (EU-OSHA) provide guidelines for safe handling, storage, and disposal of DPG in workplace settings. These regulations often mandate the use of personal protective equipment and proper ventilation systems.

Environmental regulations also impact the use of DPG as a solvent. Many countries have implemented volatile organic compound (VOC) emission standards that affect the formulation of products containing DPG. Manufacturers must ensure their products meet these standards to comply with air quality regulations and reduce environmental impact.

As global awareness of chemical safety increases, regulatory bodies continue to update and refine their guidelines. Companies using DPG in solvent applications must stay informed about these evolving regulations and adapt their practices accordingly. This may involve investing in research and development to find alternative formulations or implementing more stringent quality control measures.

Compliance with these regulations not only ensures legal operation but also builds consumer trust and enhances brand reputation. As such, regulatory compliance has become a key factor in the strategic planning and product development processes for companies utilizing DPG in their solvent applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!