How do submersible pumps adapt to variable speed conditions?

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Submersible Pump Technology Evolution and Objectives

Submersible pumps have undergone significant technological advancements since their inception in the early 20th century. Initially designed for simple water extraction, these pumps have evolved to meet the complex demands of various industries, including oil and gas, mining, and wastewater management. The primary objective in the evolution of submersible pump technology has been to enhance efficiency, reliability, and adaptability to diverse operating conditions.

One of the key challenges in submersible pump technology has been adapting to variable speed conditions. This requirement arose from the need to optimize pump performance across a wide range of flow rates and pressures, as well as to improve energy efficiency. The development of variable frequency drives (VFDs) in the 1980s marked a significant milestone in addressing this challenge, allowing for precise control of pump speed and output.

The integration of smart sensors and advanced control systems has further revolutionized submersible pump technology. These innovations enable real-time monitoring of pump performance, fluid characteristics, and environmental conditions. By continuously adjusting pump speed based on this data, modern submersible pumps can maintain optimal efficiency across varying operational demands.

Material science has played a crucial role in the evolution of submersible pumps. The development of corrosion-resistant alloys and advanced polymers has extended pump lifespan and expanded their applicability in harsh environments. These materials have also contributed to improved heat dissipation, allowing pumps to operate more efficiently at variable speeds without overheating.

Hydraulic design improvements have been another focus area in adapting submersible pumps to variable speed conditions. Engineers have optimized impeller and diffuser designs to maintain high efficiency across a broader operating range. This has resulted in flatter pump curves, allowing for more stable operation and reduced energy consumption when operating at off-design points.

The miniaturization of electronic components has enabled the integration of sophisticated control systems directly within the pump assembly. This advancement has led to the development of "intelligent" submersible pumps capable of self-diagnosis, automatic speed adjustment, and even predictive maintenance. These features significantly enhance the pump's ability to adapt to changing conditions without external intervention.

Looking forward, the objectives for submersible pump technology continue to focus on increasing adaptability to variable speed conditions while improving overall system efficiency. Emerging technologies such as artificial intelligence and machine learning are expected to play a significant role in achieving these goals, enabling more precise prediction of optimal operating parameters and further enhancing the pump's ability to adapt to complex, dynamic environments.

One of the key challenges in submersible pump technology has been adapting to variable speed conditions. This requirement arose from the need to optimize pump performance across a wide range of flow rates and pressures, as well as to improve energy efficiency. The development of variable frequency drives (VFDs) in the 1980s marked a significant milestone in addressing this challenge, allowing for precise control of pump speed and output.

The integration of smart sensors and advanced control systems has further revolutionized submersible pump technology. These innovations enable real-time monitoring of pump performance, fluid characteristics, and environmental conditions. By continuously adjusting pump speed based on this data, modern submersible pumps can maintain optimal efficiency across varying operational demands.

Material science has played a crucial role in the evolution of submersible pumps. The development of corrosion-resistant alloys and advanced polymers has extended pump lifespan and expanded their applicability in harsh environments. These materials have also contributed to improved heat dissipation, allowing pumps to operate more efficiently at variable speeds without overheating.

Hydraulic design improvements have been another focus area in adapting submersible pumps to variable speed conditions. Engineers have optimized impeller and diffuser designs to maintain high efficiency across a broader operating range. This has resulted in flatter pump curves, allowing for more stable operation and reduced energy consumption when operating at off-design points.

The miniaturization of electronic components has enabled the integration of sophisticated control systems directly within the pump assembly. This advancement has led to the development of "intelligent" submersible pumps capable of self-diagnosis, automatic speed adjustment, and even predictive maintenance. These features significantly enhance the pump's ability to adapt to changing conditions without external intervention.

Looking forward, the objectives for submersible pump technology continue to focus on increasing adaptability to variable speed conditions while improving overall system efficiency. Emerging technologies such as artificial intelligence and machine learning are expected to play a significant role in achieving these goals, enabling more precise prediction of optimal operating parameters and further enhancing the pump's ability to adapt to complex, dynamic environments.

Market Demand for Variable Speed Submersible Pumps

The market demand for variable speed submersible pumps has been steadily increasing in recent years, driven by the growing need for energy efficiency and operational flexibility across various industries. These pumps are particularly sought after in sectors such as water and wastewater management, oil and gas extraction, and agriculture, where adaptability to changing flow requirements is crucial.

In the water and wastewater industry, municipalities and utilities are increasingly adopting variable speed submersible pumps to optimize their pumping systems. These pumps allow for precise control of water flow, reducing energy consumption and minimizing wear on equipment. The ability to adjust pump speed according to demand fluctuations results in significant cost savings and improved system reliability.

The oil and gas sector has also shown a strong interest in variable speed submersible pumps, especially for artificial lift applications in oil wells. As reservoir conditions change over time, these pumps can be adjusted to maintain optimal production rates, extending the economic life of wells and improving overall field productivity.

Agricultural applications represent another growing market for variable speed submersible pumps. Farmers are recognizing the benefits of these pumps in irrigation systems, where water requirements vary depending on crop type, growth stage, and weather conditions. The ability to fine-tune water delivery helps conserve resources and improve crop yields.

Market analysts project that the global variable speed submersible pump market will continue to expand at a compound annual growth rate of several percentage points over the next five years. This growth is attributed to increasing awareness of energy conservation, stricter environmental regulations, and the ongoing modernization of water infrastructure in developing countries.

The demand for these pumps is also being fueled by technological advancements in pump design and control systems. Manufacturers are developing more efficient motors, improved impeller designs, and sophisticated control algorithms that enhance the performance and reliability of variable speed submersible pumps. This innovation is making these pumps more attractive to a wider range of industries and applications.

As industries worldwide focus on sustainability and operational efficiency, the market for variable speed submersible pumps is expected to remain robust. End-users are increasingly recognizing the long-term cost benefits and operational advantages of these pumps, despite higher initial investment compared to fixed-speed alternatives. This shift in perspective is driving adoption across both new installations and retrofit projects, further expanding the market potential for variable speed submersible pump technologies.

In the water and wastewater industry, municipalities and utilities are increasingly adopting variable speed submersible pumps to optimize their pumping systems. These pumps allow for precise control of water flow, reducing energy consumption and minimizing wear on equipment. The ability to adjust pump speed according to demand fluctuations results in significant cost savings and improved system reliability.

The oil and gas sector has also shown a strong interest in variable speed submersible pumps, especially for artificial lift applications in oil wells. As reservoir conditions change over time, these pumps can be adjusted to maintain optimal production rates, extending the economic life of wells and improving overall field productivity.

Agricultural applications represent another growing market for variable speed submersible pumps. Farmers are recognizing the benefits of these pumps in irrigation systems, where water requirements vary depending on crop type, growth stage, and weather conditions. The ability to fine-tune water delivery helps conserve resources and improve crop yields.

Market analysts project that the global variable speed submersible pump market will continue to expand at a compound annual growth rate of several percentage points over the next five years. This growth is attributed to increasing awareness of energy conservation, stricter environmental regulations, and the ongoing modernization of water infrastructure in developing countries.

The demand for these pumps is also being fueled by technological advancements in pump design and control systems. Manufacturers are developing more efficient motors, improved impeller designs, and sophisticated control algorithms that enhance the performance and reliability of variable speed submersible pumps. This innovation is making these pumps more attractive to a wider range of industries and applications.

As industries worldwide focus on sustainability and operational efficiency, the market for variable speed submersible pumps is expected to remain robust. End-users are increasingly recognizing the long-term cost benefits and operational advantages of these pumps, despite higher initial investment compared to fixed-speed alternatives. This shift in perspective is driving adoption across both new installations and retrofit projects, further expanding the market potential for variable speed submersible pump technologies.

Current Challenges in Variable Speed Adaptation

Submersible pumps operating in variable speed conditions face several significant challenges that hinder their optimal performance and efficiency. One of the primary issues is the difficulty in maintaining proper cooling and lubrication at lower speeds. As the pump's speed decreases, the flow rate of the pumped fluid also reduces, potentially leading to inadequate cooling of the motor and insufficient lubrication of bearings and seals. This can result in overheating and premature wear of critical components, ultimately reducing the pump's lifespan and reliability.

Another challenge lies in the increased risk of cavitation at lower speeds. Cavitation occurs when the pressure in the pump falls below the vapor pressure of the fluid, causing the formation and collapse of vapor bubbles. This phenomenon can cause severe damage to the pump's impeller and other internal components. Variable speed operation exacerbates this issue, as the pump may frequently operate in conditions that are more prone to cavitation, especially during transitions between different speed settings.

The control and monitoring of submersible pumps in variable speed applications present additional complexities. Accurate speed control is crucial for maintaining optimal performance and efficiency across different operating conditions. However, the submerged nature of these pumps makes it challenging to implement sophisticated control systems and sensors. The harsh underwater environment can interfere with signal transmission and sensor accuracy, potentially leading to suboptimal control and reduced overall system efficiency.

Furthermore, the electrical and mechanical components of submersible pumps must be designed to withstand the stresses associated with variable speed operation. Frequent speed changes can lead to increased wear on bearings, seals, and motor windings due to thermal cycling and mechanical stress. The pump's materials and construction must be carefully selected to ensure durability and reliability under these demanding conditions.

Energy efficiency optimization across the entire speed range poses another significant challenge. While variable speed drives can improve overall system efficiency, achieving optimal performance at all operating points is complex. The pump's efficiency curve may not align perfectly with the system's requirements at all speeds, leading to energy losses and reduced overall efficiency in certain operating ranges.

Lastly, the integration of variable speed submersible pumps into existing systems and infrastructure can be problematic. Retrofitting older installations with variable speed capabilities may require significant modifications to power supply, control systems, and piping arrangements. This can result in high implementation costs and potential disruptions to ongoing operations, making the adoption of variable speed technology less attractive for some applications.

Another challenge lies in the increased risk of cavitation at lower speeds. Cavitation occurs when the pressure in the pump falls below the vapor pressure of the fluid, causing the formation and collapse of vapor bubbles. This phenomenon can cause severe damage to the pump's impeller and other internal components. Variable speed operation exacerbates this issue, as the pump may frequently operate in conditions that are more prone to cavitation, especially during transitions between different speed settings.

The control and monitoring of submersible pumps in variable speed applications present additional complexities. Accurate speed control is crucial for maintaining optimal performance and efficiency across different operating conditions. However, the submerged nature of these pumps makes it challenging to implement sophisticated control systems and sensors. The harsh underwater environment can interfere with signal transmission and sensor accuracy, potentially leading to suboptimal control and reduced overall system efficiency.

Furthermore, the electrical and mechanical components of submersible pumps must be designed to withstand the stresses associated with variable speed operation. Frequent speed changes can lead to increased wear on bearings, seals, and motor windings due to thermal cycling and mechanical stress. The pump's materials and construction must be carefully selected to ensure durability and reliability under these demanding conditions.

Energy efficiency optimization across the entire speed range poses another significant challenge. While variable speed drives can improve overall system efficiency, achieving optimal performance at all operating points is complex. The pump's efficiency curve may not align perfectly with the system's requirements at all speeds, leading to energy losses and reduced overall efficiency in certain operating ranges.

Lastly, the integration of variable speed submersible pumps into existing systems and infrastructure can be problematic. Retrofitting older installations with variable speed capabilities may require significant modifications to power supply, control systems, and piping arrangements. This can result in high implementation costs and potential disruptions to ongoing operations, making the adoption of variable speed technology less attractive for some applications.

Existing Variable Speed Adaptation Solutions

01 Variable speed control for submersible pumps

Submersible pumps can be equipped with variable speed control systems to adjust the pump's speed based on demand or operating conditions. This allows for improved efficiency, energy savings, and better control of fluid flow rates in various applications.- Variable speed control for submersible pumps: Submersible pumps can be equipped with variable speed control systems to adjust the pump's speed according to demand. This allows for improved efficiency, energy savings, and better control of fluid flow rates. The speed control can be achieved through various methods such as frequency inverters or advanced motor controllers.

- Optimizing pump performance in deep-sea applications: Specialized designs and materials are used to enhance submersible pump performance in deep-sea environments. These pumps are engineered to withstand high pressures, corrosive fluids, and extreme temperatures. Advanced sealing technologies and robust construction materials ensure reliable operation at great depths.

- Multi-stage submersible pump systems: Multi-stage submersible pumps are designed to achieve higher discharge pressures and flow rates. These pumps consist of multiple impellers and diffusers arranged in series, allowing for increased head and improved efficiency in applications requiring high lift or pressure.

- Intelligent monitoring and control systems: Advanced monitoring and control systems are integrated into submersible pumps to optimize performance and prevent failures. These systems can include sensors for temperature, vibration, and pressure, as well as remote monitoring capabilities and predictive maintenance algorithms to ensure optimal pump speed and operation.

- Energy-efficient submersible pump designs: Innovative designs focus on improving the energy efficiency of submersible pumps. This includes the use of high-efficiency motors, optimized impeller geometries, and advanced materials to reduce friction and power consumption while maintaining or improving pump speed and performance.

02 Optimizing pump performance through speed regulation

By regulating the speed of submersible pumps, operators can optimize performance for specific applications. This includes adjusting flow rates, pressure, and power consumption to match system requirements, resulting in improved overall efficiency and reduced wear on pump components.Expand Specific Solutions03 Innovative motor designs for submersible pump speed control

Advanced motor designs, such as permanent magnet motors or brushless DC motors, are being incorporated into submersible pumps to enable precise speed control. These motors offer improved efficiency, reduced maintenance, and better responsiveness to speed adjustments.Expand Specific Solutions04 Integration of sensors and control systems for speed management

Modern submersible pumps often incorporate sensors and advanced control systems to monitor operating conditions and automatically adjust pump speed. This integration allows for real-time optimization of pump performance based on factors such as flow rate, pressure, and power consumption.Expand Specific Solutions05 Energy-efficient operation through speed optimization

By implementing speed control strategies, submersible pumps can achieve significant energy savings. Adjusting pump speed to match system demands reduces power consumption during periods of low demand, leading to improved overall energy efficiency and reduced operating costs.Expand Specific Solutions

Key Players in Submersible Pump Industry

The market for submersible pumps adapting to variable speed conditions is in a growth phase, driven by increasing demand for energy-efficient and versatile pumping solutions across industries. The global submersible pumps market is expected to reach significant size in the coming years, with a compound annual growth rate reflecting steady expansion. Technologically, the field is advancing rapidly, with companies like Baker Hughes Co., Grundfos International As, and WILO SE leading innovation in variable speed adaptation. These firms are developing sophisticated control systems and motor designs to enhance pump performance under varying conditions. Other players such as Ebara Corp. and KSB SAS are also contributing to the technological maturity of the sector, focusing on improving efficiency and reliability in diverse applications.

Baker Hughes Co.

Technical Solution: Baker Hughes has developed Electric Submersible Pump (ESP) systems with variable speed drives to adapt to changing well conditions. Their Centrilift XP Enhanced ESP system uses advanced power and control technologies to adjust pump speed in real-time[4]. The system employs downhole sensors to monitor temperature, pressure, and vibration, allowing for precise speed control. Baker Hughes' ESPs can operate efficiently across a wide range of speeds, typically from 30 Hz to 120 Hz[5]. The company has also implemented machine learning algorithms to predict optimal pump speeds based on historical data and current well conditions, further enhancing adaptability[6]. Their ESPs feature specialized impeller and diffuser designs that maintain hydraulic efficiency across various speeds.

Strengths: Wide operating range, real-time adaptation, advanced monitoring. Weaknesses: High initial cost, complexity in installation and maintenance.

Ebara Corp.

Technical Solution: Ebara Corporation has developed submersible pumps with variable speed capabilities, focusing on energy efficiency and adaptability. Their e-VISION series incorporates inverter technology to adjust pump speed based on demand[7]. These pumps use advanced hydraulic designs optimized for variable speed operation, maintaining high efficiency across a wide range of flows. Ebara's submersible pumps feature built-in sensors that monitor operating conditions, allowing for automatic speed adjustments to maintain optimal performance. The company has also implemented a unique impeller design that reduces cavitation risks at lower speeds[8]. Ebara's pumps can typically operate efficiently between 30% to 100% of their rated speed, providing significant flexibility in various applications.

Strengths: Energy efficient, wide operating range, reduced cavitation risk. Weaknesses: May have limitations in extreme operating conditions, higher initial investment.

Core Innovations in Pump Speed Control

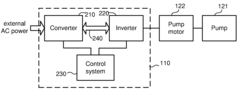

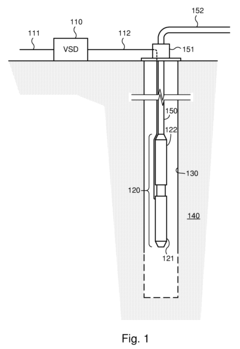

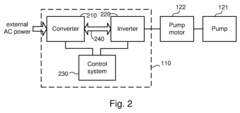

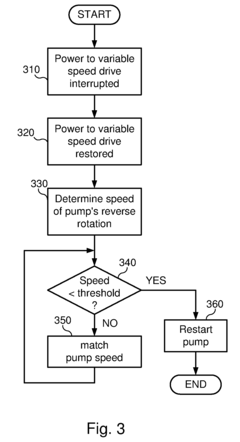

Systems and Methods for Reducing Pump Downtime by Determining Rotation Speed Using a Variable Speed Drive

PatentActiveUS20080247880A1

Innovation

- A variable speed drive system with a control system that detects interruptions, determines the reverse rotational speed of the pump motor, and restarts it when the speed is low enough to ensure sufficient torque, reducing the need for prolonged waiting periods by matching the motor frequency and voltage to optimize restart conditions.

Submersible pump

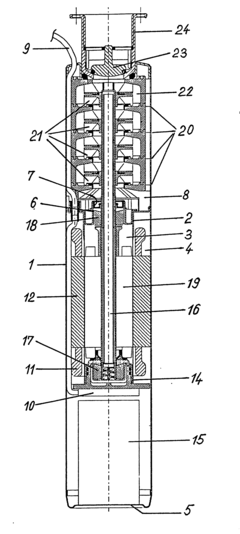

PatentInactiveEP0346731A2

Innovation

- A submersible pump unit design where the motor, pump body, and frequency converter are arranged in series within a tubular jacket, with a thermally conductive base and heat-dissipating materials, and an internal cable routing to simplify production and reduce thermal resistance, along with a self-adjusting axial bearing for easier installation.

Energy Efficiency Considerations

Energy efficiency is a critical consideration in the adaptation of submersible pumps to variable speed conditions. As pump systems account for a significant portion of industrial energy consumption, optimizing their performance across different operating speeds can lead to substantial energy savings and reduced operational costs.

Variable speed drives (VSDs) play a crucial role in enhancing the energy efficiency of submersible pumps. By allowing the pump to operate at different speeds, VSDs can match the pump's output to the system's demand, avoiding energy waste associated with throttling or bypass control methods. This ability to adjust speed results in a cubic reduction in power consumption, as per the affinity laws, where a small decrease in speed can lead to a significant reduction in energy use.

The design of submersible pumps for variable speed operation involves careful consideration of the pump's hydraulic characteristics. Manufacturers optimize impeller and diffuser designs to maintain high efficiency across a wide range of speeds. This often includes the use of computational fluid dynamics (CFD) to analyze and improve flow patterns within the pump at different operating points.

Material selection also plays a vital role in energy efficiency. Advanced materials with low friction coefficients and high wear resistance are employed to reduce mechanical losses and maintain efficiency over time. Coatings and surface treatments on pump components can further reduce friction and improve overall pump efficiency.

Proper motor selection is essential for energy-efficient variable speed operation. Submersible pump motors designed for VSD compatibility often feature enhanced insulation systems to withstand the voltage stresses associated with pulse width modulation. High-efficiency motor designs, such as those utilizing permanent magnet technology, can provide superior performance across the speed range.

Control strategies are implemented to maximize energy savings. These may include algorithms that continuously optimize the pump's speed based on system pressure, flow rate, or other process variables. Advanced control systems can also incorporate predictive maintenance features, ensuring that the pump operates at peak efficiency throughout its lifecycle.

Heat management is another crucial aspect of energy efficiency in variable speed submersible pumps. Efficient cooling systems are designed to dissipate heat effectively at different operating speeds, preventing efficiency losses due to overheating and extending the life of pump components.

By addressing these energy efficiency considerations, submersible pumps can adapt to variable speed conditions while minimizing energy consumption and maximizing operational efficiency. This not only reduces operational costs but also contributes to sustainability goals by lowering the overall environmental impact of pump systems.

Variable speed drives (VSDs) play a crucial role in enhancing the energy efficiency of submersible pumps. By allowing the pump to operate at different speeds, VSDs can match the pump's output to the system's demand, avoiding energy waste associated with throttling or bypass control methods. This ability to adjust speed results in a cubic reduction in power consumption, as per the affinity laws, where a small decrease in speed can lead to a significant reduction in energy use.

The design of submersible pumps for variable speed operation involves careful consideration of the pump's hydraulic characteristics. Manufacturers optimize impeller and diffuser designs to maintain high efficiency across a wide range of speeds. This often includes the use of computational fluid dynamics (CFD) to analyze and improve flow patterns within the pump at different operating points.

Material selection also plays a vital role in energy efficiency. Advanced materials with low friction coefficients and high wear resistance are employed to reduce mechanical losses and maintain efficiency over time. Coatings and surface treatments on pump components can further reduce friction and improve overall pump efficiency.

Proper motor selection is essential for energy-efficient variable speed operation. Submersible pump motors designed for VSD compatibility often feature enhanced insulation systems to withstand the voltage stresses associated with pulse width modulation. High-efficiency motor designs, such as those utilizing permanent magnet technology, can provide superior performance across the speed range.

Control strategies are implemented to maximize energy savings. These may include algorithms that continuously optimize the pump's speed based on system pressure, flow rate, or other process variables. Advanced control systems can also incorporate predictive maintenance features, ensuring that the pump operates at peak efficiency throughout its lifecycle.

Heat management is another crucial aspect of energy efficiency in variable speed submersible pumps. Efficient cooling systems are designed to dissipate heat effectively at different operating speeds, preventing efficiency losses due to overheating and extending the life of pump components.

By addressing these energy efficiency considerations, submersible pumps can adapt to variable speed conditions while minimizing energy consumption and maximizing operational efficiency. This not only reduces operational costs but also contributes to sustainability goals by lowering the overall environmental impact of pump systems.

Environmental Impact of Variable Speed Pumps

Variable speed submersible pumps have a significant impact on the environment, primarily through energy efficiency and resource conservation. These pumps can adjust their speed to match the required flow rate, resulting in substantial energy savings compared to fixed-speed pumps. By operating at lower speeds when demand is reduced, variable speed pumps consume less electricity, leading to decreased greenhouse gas emissions from power generation.

The environmental benefits extend beyond energy savings. Variable speed pumps reduce water waste by precisely controlling flow rates, preventing over-pumping and minimizing leaks. This conservation of water resources is particularly crucial in regions facing water scarcity or drought conditions. Additionally, the ability to operate at lower speeds reduces wear and tear on pump components, extending the lifespan of the equipment and decreasing the frequency of replacements, thereby reducing the environmental impact associated with manufacturing and disposing of pump parts.

Noise pollution is another environmental concern addressed by variable speed submersible pumps. By operating at lower speeds during periods of reduced demand, these pumps generate less noise, contributing to a quieter environment. This is especially beneficial in residential areas or sensitive ecosystems where noise disturbance can have negative impacts on wildlife and human well-being.

The use of variable speed pumps also contributes to the reduction of chemical usage in water treatment processes. By providing more precise control over flow rates, these pumps can optimize the dosing of chemicals, reducing the overall amount of chemicals required and minimizing the potential for harmful substances to enter the environment.

Furthermore, variable speed submersible pumps play a role in mitigating the environmental impact of wastewater treatment. By adjusting their speed to match influent flow rates, these pumps help prevent overflows and reduce the risk of untreated wastewater being released into the environment during peak flow periods. This adaptability contributes to more effective and environmentally friendly wastewater management.

In the context of irrigation systems, variable speed pumps enable more efficient water distribution, reducing water loss through evaporation and runoff. This not only conserves water resources but also minimizes soil erosion and the potential for nutrient leaching, which can have detrimental effects on local ecosystems and water quality.

Overall, the environmental impact of variable speed submersible pumps is largely positive, contributing to energy conservation, water resource management, and reduced pollution. As technology continues to advance, these pumps are likely to play an increasingly important role in sustainable water management and environmental protection strategies.

The environmental benefits extend beyond energy savings. Variable speed pumps reduce water waste by precisely controlling flow rates, preventing over-pumping and minimizing leaks. This conservation of water resources is particularly crucial in regions facing water scarcity or drought conditions. Additionally, the ability to operate at lower speeds reduces wear and tear on pump components, extending the lifespan of the equipment and decreasing the frequency of replacements, thereby reducing the environmental impact associated with manufacturing and disposing of pump parts.

Noise pollution is another environmental concern addressed by variable speed submersible pumps. By operating at lower speeds during periods of reduced demand, these pumps generate less noise, contributing to a quieter environment. This is especially beneficial in residential areas or sensitive ecosystems where noise disturbance can have negative impacts on wildlife and human well-being.

The use of variable speed pumps also contributes to the reduction of chemical usage in water treatment processes. By providing more precise control over flow rates, these pumps can optimize the dosing of chemicals, reducing the overall amount of chemicals required and minimizing the potential for harmful substances to enter the environment.

Furthermore, variable speed submersible pumps play a role in mitigating the environmental impact of wastewater treatment. By adjusting their speed to match influent flow rates, these pumps help prevent overflows and reduce the risk of untreated wastewater being released into the environment during peak flow periods. This adaptability contributes to more effective and environmentally friendly wastewater management.

In the context of irrigation systems, variable speed pumps enable more efficient water distribution, reducing water loss through evaporation and runoff. This not only conserves water resources but also minimizes soil erosion and the potential for nutrient leaching, which can have detrimental effects on local ecosystems and water quality.

Overall, the environmental impact of variable speed submersible pumps is largely positive, contributing to energy conservation, water resource management, and reduced pollution. As technology continues to advance, these pumps are likely to play an increasingly important role in sustainable water management and environmental protection strategies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!