How KERS contributes to electric aircraft feasibility

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

KERS in Electric Aircraft: Background and Objectives

Kinetic Energy Recovery Systems (KERS) have emerged as a promising technology in the pursuit of more efficient and sustainable electric aircraft. Originally developed for Formula One racing, KERS has found its way into various transportation sectors, including aviation. The primary objective of implementing KERS in electric aircraft is to enhance energy efficiency, extend flight range, and reduce overall power consumption.

The evolution of KERS technology in aviation has been driven by the growing demand for environmentally friendly transportation solutions and the need to overcome the limitations of current battery technologies. As the aviation industry faces increasing pressure to reduce carbon emissions, electric aircraft have gained significant attention. However, the weight and energy density constraints of batteries have posed challenges to the widespread adoption of fully electric aircraft.

KERS addresses these challenges by capturing and storing energy that would otherwise be lost during deceleration or descent phases of flight. This recovered energy can then be utilized during high-power demand situations, such as takeoff or climbing, effectively reducing the overall energy requirements of the aircraft. The integration of KERS into electric aircraft designs represents a significant step towards improving the feasibility and performance of these vehicles.

The development of KERS for electric aircraft has been influenced by advancements in materials science, power electronics, and energy storage technologies. Lightweight, high-strength materials have enabled the creation of more efficient and compact KERS components, while improvements in power electronics have enhanced the system's ability to rapidly capture, store, and deploy energy.

As the technology continues to mature, researchers and engineers are exploring various KERS configurations tailored specifically for electric aircraft applications. These include flywheel-based systems, which store energy mechanically, and electrical systems that utilize supercapacitors or advanced battery technologies. Each approach offers unique advantages and challenges, driving ongoing research and development efforts in the field.

The implementation of KERS in electric aircraft aligns with broader industry goals of achieving sustainable aviation and reducing dependence on fossil fuels. By improving energy efficiency and extending the range of electric aircraft, KERS technology contributes to making electric aviation more viable for a wider range of applications, from short-haul commercial flights to urban air mobility solutions.

Looking ahead, the continued development and refinement of KERS technology are expected to play a crucial role in overcoming the current limitations of electric aircraft. As the technology evolves, it has the potential to significantly impact the design and performance capabilities of future electric aircraft, paving the way for more sustainable and efficient air transportation systems.

The evolution of KERS technology in aviation has been driven by the growing demand for environmentally friendly transportation solutions and the need to overcome the limitations of current battery technologies. As the aviation industry faces increasing pressure to reduce carbon emissions, electric aircraft have gained significant attention. However, the weight and energy density constraints of batteries have posed challenges to the widespread adoption of fully electric aircraft.

KERS addresses these challenges by capturing and storing energy that would otherwise be lost during deceleration or descent phases of flight. This recovered energy can then be utilized during high-power demand situations, such as takeoff or climbing, effectively reducing the overall energy requirements of the aircraft. The integration of KERS into electric aircraft designs represents a significant step towards improving the feasibility and performance of these vehicles.

The development of KERS for electric aircraft has been influenced by advancements in materials science, power electronics, and energy storage technologies. Lightweight, high-strength materials have enabled the creation of more efficient and compact KERS components, while improvements in power electronics have enhanced the system's ability to rapidly capture, store, and deploy energy.

As the technology continues to mature, researchers and engineers are exploring various KERS configurations tailored specifically for electric aircraft applications. These include flywheel-based systems, which store energy mechanically, and electrical systems that utilize supercapacitors or advanced battery technologies. Each approach offers unique advantages and challenges, driving ongoing research and development efforts in the field.

The implementation of KERS in electric aircraft aligns with broader industry goals of achieving sustainable aviation and reducing dependence on fossil fuels. By improving energy efficiency and extending the range of electric aircraft, KERS technology contributes to making electric aviation more viable for a wider range of applications, from short-haul commercial flights to urban air mobility solutions.

Looking ahead, the continued development and refinement of KERS technology are expected to play a crucial role in overcoming the current limitations of electric aircraft. As the technology evolves, it has the potential to significantly impact the design and performance capabilities of future electric aircraft, paving the way for more sustainable and efficient air transportation systems.

Market Analysis for KERS in Aviation

The market for Kinetic Energy Recovery Systems (KERS) in aviation is experiencing significant growth potential as the industry shifts towards more sustainable and efficient aircraft designs. The global push for reduced carbon emissions and increased energy efficiency in air travel has created a fertile ground for innovative technologies like KERS. This system, which captures and stores kinetic energy during deceleration and converts it into electrical energy for later use, has already proven its worth in automotive applications and is now gaining traction in the aviation sector.

The aviation industry's increasing focus on electric and hybrid-electric propulsion systems has opened up new opportunities for KERS integration. As airlines and aircraft manufacturers seek ways to reduce fuel consumption and operational costs, KERS presents a compelling solution. The system's ability to capture energy that would otherwise be lost during landing and taxiing phases can significantly contribute to the overall efficiency of electric aircraft.

Market analysis indicates that the adoption of KERS in aviation is likely to follow a phased approach. Initially, the technology is expected to be implemented in smaller electric aircraft and urban air mobility vehicles, where weight and energy management are critical factors. As the technology matures and proves its reliability, larger commercial aircraft are anticipated to incorporate KERS into their designs.

The market size for KERS in aviation is projected to grow substantially over the next decade. This growth is driven by several factors, including stringent environmental regulations, rising fuel costs, and the increasing viability of electric aircraft. Additionally, government initiatives and investments in green aviation technologies are further propelling the market forward.

Key players in the aviation industry, including major aircraft manufacturers and tier-one suppliers, are actively exploring KERS technologies. This interest is manifested through increased R&D spending, strategic partnerships, and acquisitions of specialized KERS technology firms. The competitive landscape is expected to intensify as more companies recognize the potential of KERS in enhancing aircraft performance and sustainability.

Market segmentation reveals varying levels of KERS adoption across different aircraft types. Regional jets and short-haul aircraft are likely to be early adopters, given their frequent takeoff and landing cycles, which provide more opportunities for energy recovery. Long-haul aircraft, while presenting greater technical challenges for KERS integration, also offer significant potential for energy savings over extended flight durations.

The market analysis also highlights potential barriers to KERS adoption in aviation. These include the need for extensive testing and certification processes, integration challenges with existing aircraft systems, and the initial high costs associated with implementing new technologies. However, as the technology advances and economies of scale are achieved, these barriers are expected to diminish.

The aviation industry's increasing focus on electric and hybrid-electric propulsion systems has opened up new opportunities for KERS integration. As airlines and aircraft manufacturers seek ways to reduce fuel consumption and operational costs, KERS presents a compelling solution. The system's ability to capture energy that would otherwise be lost during landing and taxiing phases can significantly contribute to the overall efficiency of electric aircraft.

Market analysis indicates that the adoption of KERS in aviation is likely to follow a phased approach. Initially, the technology is expected to be implemented in smaller electric aircraft and urban air mobility vehicles, where weight and energy management are critical factors. As the technology matures and proves its reliability, larger commercial aircraft are anticipated to incorporate KERS into their designs.

The market size for KERS in aviation is projected to grow substantially over the next decade. This growth is driven by several factors, including stringent environmental regulations, rising fuel costs, and the increasing viability of electric aircraft. Additionally, government initiatives and investments in green aviation technologies are further propelling the market forward.

Key players in the aviation industry, including major aircraft manufacturers and tier-one suppliers, are actively exploring KERS technologies. This interest is manifested through increased R&D spending, strategic partnerships, and acquisitions of specialized KERS technology firms. The competitive landscape is expected to intensify as more companies recognize the potential of KERS in enhancing aircraft performance and sustainability.

Market segmentation reveals varying levels of KERS adoption across different aircraft types. Regional jets and short-haul aircraft are likely to be early adopters, given their frequent takeoff and landing cycles, which provide more opportunities for energy recovery. Long-haul aircraft, while presenting greater technical challenges for KERS integration, also offer significant potential for energy savings over extended flight durations.

The market analysis also highlights potential barriers to KERS adoption in aviation. These include the need for extensive testing and certification processes, integration challenges with existing aircraft systems, and the initial high costs associated with implementing new technologies. However, as the technology advances and economies of scale are achieved, these barriers are expected to diminish.

KERS Technology: Current State and Challenges

Kinetic Energy Recovery Systems (KERS) have gained significant attention in the aviation industry as a potential solution for enhancing electric aircraft feasibility. The current state of KERS technology in aviation is characterized by ongoing research and development, with several challenges yet to be overcome.

KERS technology, originally developed for automotive applications, has been adapted for use in aircraft to capture and store energy during deceleration or descent. This stored energy can then be utilized during takeoff, climb, or other high-power demand phases of flight. The primary advantage of KERS in electric aircraft is its potential to extend range and improve overall energy efficiency.

One of the main challenges facing KERS implementation in electric aircraft is weight optimization. While KERS can provide additional power, the system itself adds weight to the aircraft, which can offset some of the energy gains. Engineers are working to develop lightweight materials and compact designs to minimize this trade-off.

Another significant challenge is the integration of KERS with existing electric propulsion systems. Ensuring seamless coordination between the KERS and the primary electric motors is crucial for optimal performance. This requires sophisticated control systems and power management algorithms, which are still being refined.

The efficiency of energy conversion in KERS is another area of focus. Current systems typically achieve around 70-80% efficiency in converting kinetic energy to stored electrical energy and back. Improving this efficiency is a key goal for researchers, as even small gains can have a substantial impact on overall aircraft performance.

Thermal management presents another hurdle for KERS in aviation applications. The high-power transfer rates involved in capturing and releasing energy can generate significant heat. Developing effective cooling systems that don't add excessive weight or complexity to the aircraft is an ongoing challenge.

Reliability and safety considerations are paramount in aviation, and KERS technology must meet stringent standards. Ensuring the long-term durability of KERS components under the demanding conditions of flight operations is a critical area of development. Additionally, fail-safe mechanisms and redundancy systems are being designed to mitigate any potential risks associated with KERS malfunction.

The regulatory landscape for KERS in aviation is still evolving. Certification processes for these systems in electric aircraft are being developed, which presents both a challenge and an opportunity for standardization across the industry.

Despite these challenges, progress in KERS technology for electric aircraft has been promising. Several research institutions and aerospace companies are actively working on innovative solutions to address these issues. As the technology matures, it is expected to play an increasingly important role in enhancing the feasibility and performance of electric aircraft.

KERS technology, originally developed for automotive applications, has been adapted for use in aircraft to capture and store energy during deceleration or descent. This stored energy can then be utilized during takeoff, climb, or other high-power demand phases of flight. The primary advantage of KERS in electric aircraft is its potential to extend range and improve overall energy efficiency.

One of the main challenges facing KERS implementation in electric aircraft is weight optimization. While KERS can provide additional power, the system itself adds weight to the aircraft, which can offset some of the energy gains. Engineers are working to develop lightweight materials and compact designs to minimize this trade-off.

Another significant challenge is the integration of KERS with existing electric propulsion systems. Ensuring seamless coordination between the KERS and the primary electric motors is crucial for optimal performance. This requires sophisticated control systems and power management algorithms, which are still being refined.

The efficiency of energy conversion in KERS is another area of focus. Current systems typically achieve around 70-80% efficiency in converting kinetic energy to stored electrical energy and back. Improving this efficiency is a key goal for researchers, as even small gains can have a substantial impact on overall aircraft performance.

Thermal management presents another hurdle for KERS in aviation applications. The high-power transfer rates involved in capturing and releasing energy can generate significant heat. Developing effective cooling systems that don't add excessive weight or complexity to the aircraft is an ongoing challenge.

Reliability and safety considerations are paramount in aviation, and KERS technology must meet stringent standards. Ensuring the long-term durability of KERS components under the demanding conditions of flight operations is a critical area of development. Additionally, fail-safe mechanisms and redundancy systems are being designed to mitigate any potential risks associated with KERS malfunction.

The regulatory landscape for KERS in aviation is still evolving. Certification processes for these systems in electric aircraft are being developed, which presents both a challenge and an opportunity for standardization across the industry.

Despite these challenges, progress in KERS technology for electric aircraft has been promising. Several research institutions and aerospace companies are actively working on innovative solutions to address these issues. As the technology matures, it is expected to play an increasingly important role in enhancing the feasibility and performance of electric aircraft.

Existing KERS Solutions for Electric Aircraft

01 Energy storage and conversion systems

KERS feasibility is enhanced by efficient energy storage and conversion systems. These systems capture kinetic energy during braking and convert it into electrical or mechanical energy for later use. Advanced storage technologies like high-performance batteries or flywheels are crucial for maximizing energy recovery and utilization.- Energy storage and conversion systems: KERS feasibility is enhanced by efficient energy storage and conversion systems. These systems capture kinetic energy during braking and convert it into electrical or mechanical energy for later use. Advanced storage technologies like high-performance batteries or flywheels are crucial for maximizing energy recovery and utilization.

- Integration with vehicle systems: The feasibility of KERS depends on its seamless integration with existing vehicle systems. This includes compatibility with powertrains, braking systems, and electronic control units. Effective integration ensures optimal energy recovery without compromising vehicle performance or safety.

- Efficiency improvements and optimization: Enhancing KERS feasibility involves continuous improvements in system efficiency. This includes optimizing energy capture during deceleration, minimizing conversion losses, and developing advanced control algorithms for energy management. Innovations in materials and component design also contribute to overall system efficiency.

- Application in different vehicle types: KERS feasibility extends to various vehicle types, including passenger cars, commercial vehicles, and motorsports. Each application presents unique challenges and opportunities for energy recovery. Adapting KERS technology to specific vehicle requirements and use cases is crucial for widespread adoption.

- Cost-effectiveness and manufacturing considerations: The feasibility of KERS is closely tied to its cost-effectiveness and manufacturability. This involves developing cost-efficient production methods, sourcing affordable materials, and designing systems that can be easily integrated into existing manufacturing processes. Balancing performance improvements with economic viability is essential for widespread adoption.

02 Integration with vehicle systems

Successful KERS implementation requires seamless integration with existing vehicle systems. This includes compatibility with powertrains, braking systems, and electronic control units. Effective integration ensures optimal energy recovery without compromising vehicle performance or safety.Expand Specific Solutions03 Efficiency improvements and optimization

Enhancing KERS feasibility involves continuous improvements in system efficiency. This includes optimizing energy recovery rates, reducing energy losses during conversion and storage, and developing advanced control algorithms for energy management. These improvements contribute to increased overall system performance and fuel economy.Expand Specific Solutions04 Application in various vehicle types

KERS feasibility extends beyond traditional automobiles to various vehicle types. The technology can be adapted for use in heavy-duty vehicles, off-road equipment, and even non-automotive applications. Each application presents unique challenges and opportunities for energy recovery and utilization.Expand Specific Solutions05 Cost-effectiveness and manufacturing considerations

The feasibility of KERS is closely tied to its cost-effectiveness and manufacturability. This includes considerations such as material selection, production processes, and scalability. Developing cost-effective solutions and streamlining manufacturing processes are crucial for widespread adoption of KERS technology.Expand Specific Solutions

Key Players in KERS and Electric Aircraft Industry

The development of Kinetic Energy Recovery Systems (KERS) for electric aircraft is in its early stages, with the market still emerging and showing significant growth potential. The technology's maturity varies across companies, with established aerospace firms like Boeing, Rolls-Royce, and BAE Systems likely leading in research and development. Emerging players such as Ampaire and Lilium are also contributing to innovation in this field. The integration of KERS in electric aircraft is expected to enhance energy efficiency and range, potentially accelerating the adoption of electric aviation. As the technology progresses, collaborations between traditional aerospace companies and new entrants may drive further advancements, shaping the competitive landscape of the electric aircraft industry.

Ampaire, Inc.

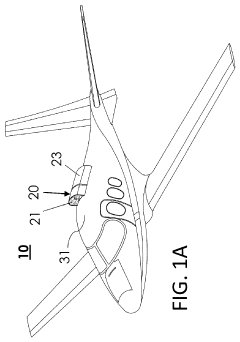

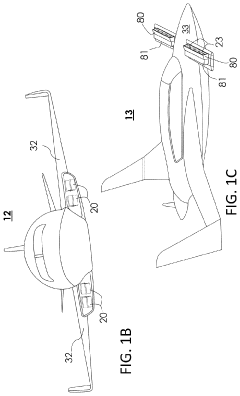

Technical Solution: Ampaire has developed a hybrid-electric powertrain for aircraft that integrates KERS (Kinetic Energy Recovery System) technology. Their system captures energy during descent and landing, storing it in lightweight batteries for use during takeoff and climb phases. This approach significantly reduces fuel consumption and emissions, with test flights showing up to 30% reduction in fuel usage [1]. The company's EEL (Electric EEL) aircraft, a modified Cessna 337 Skymaster, utilizes this technology to demonstrate the feasibility of hybrid-electric propulsion in existing airframes [3].

Strengths: Retrofitting existing aircraft reduces development costs; significant fuel savings. Weaknesses: Limited by current battery technology; regulatory challenges for certification.

Lilium eAircraft GmbH

Technical Solution: Lilium has developed an all-electric vertical take-off and landing (eVTOL) jet that incorporates KERS-like principles in its energy management system. While not traditional KERS, their aircraft uses regenerative braking in its electric motors during descent to recapture energy. The Lilium Jet features 36 electric engines mounted on tiltable wings, allowing for vertical take-off and efficient horizontal flight [2]. The company claims their aircraft can achieve a range of 300 km and a top speed of 300 km/h, demonstrating the feasibility of all-electric aircraft for regional transportation [4].

Strengths: Innovative eVTOL design eliminates need for runways; high-speed capability for an electric aircraft. Weaknesses: Limited range compared to conventional aircraft; high power requirements for vertical lift.

Core Innovations in KERS for Aviation

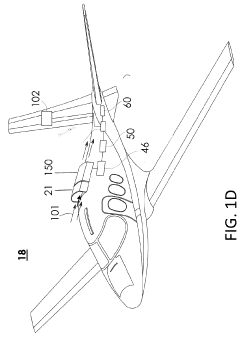

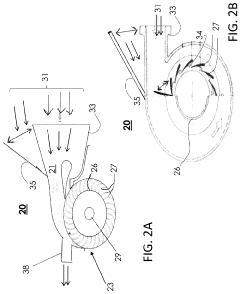

Advanced kinetic energy recovery system (AKERS) for electric aircraft

PatentWO2024254108A3

Innovation

- Multiple redundant independent charging systems including three advanced kinetic energy recovery systems for extended operation of electric aircraft.

- Incorporation of a fly-by-wire aircraft to aircraft midair recharging system for long-range flights.

- Smart charge combiner and high-voltage ultracapacitor storage system for efficient power management.

Advanced kinetic energy recovery system (AKERS) for electric aircraft

PatentInactiveUS20240063690A1

Innovation

- The Grayson Range Extender (GRE) system employs modular, scalable, high-efficiency, heat-resistant fluid turbine generators and redundant recharging systems, including Paddlewheel Air Brake, Grayson Air Turbine, and Air-to-Air recharging, to generate kinetic energy for extended range and rapid charging, reducing the need for battery upgrades and enhancing safety.

Environmental Impact of KERS in Aviation

The implementation of Kinetic Energy Recovery Systems (KERS) in aviation has significant potential to reduce the environmental impact of aircraft operations. By capturing and reusing energy that would otherwise be lost during deceleration or landing, KERS can contribute to improved fuel efficiency and reduced emissions in electric aircraft.

One of the primary environmental benefits of KERS in aviation is the reduction of greenhouse gas emissions. As electric aircraft become more prevalent, the integration of KERS can extend their range and efficiency, potentially decreasing the reliance on fossil fuels for longer flights. This shift towards more sustainable energy sources in aviation could lead to a substantial decrease in carbon dioxide emissions, a major contributor to climate change.

KERS also has the potential to mitigate noise pollution, a significant environmental concern in the aviation industry. Electric aircraft equipped with KERS can operate more quietly during takeoff and landing, as the system allows for smoother acceleration and deceleration. This reduction in noise levels can have positive impacts on communities near airports and wildlife in surrounding areas.

The implementation of KERS in aviation can contribute to the conservation of natural resources. By improving the overall energy efficiency of aircraft, KERS reduces the demand for raw materials used in traditional fuel production. This conservation extends to the manufacturing process of aircraft components, as the increased efficiency may lead to lighter and more compact designs, requiring fewer resources.

Furthermore, KERS can play a role in reducing the environmental impact of airport operations. The system's ability to capture and store energy during landing can potentially be utilized to power ground support equipment or contribute to the airport's energy grid. This integration of renewable energy sources within airport infrastructure aligns with global efforts to create more sustainable transportation hubs.

The adoption of KERS in aviation also has implications for air quality improvement. By reducing the reliance on conventional jet fuels, particularly during takeoff and landing phases, KERS-equipped electric aircraft can help decrease the emission of particulate matter and other air pollutants. This improvement in local air quality can have positive health impacts on both airport workers and nearby communities.

As the aviation industry continues to explore ways to reduce its environmental footprint, the integration of KERS in electric aircraft represents a promising avenue for sustainable development. The technology's potential to enhance energy efficiency, reduce emissions, and contribute to quieter operations aligns with global environmental goals and regulatory pressures facing the aviation sector.

One of the primary environmental benefits of KERS in aviation is the reduction of greenhouse gas emissions. As electric aircraft become more prevalent, the integration of KERS can extend their range and efficiency, potentially decreasing the reliance on fossil fuels for longer flights. This shift towards more sustainable energy sources in aviation could lead to a substantial decrease in carbon dioxide emissions, a major contributor to climate change.

KERS also has the potential to mitigate noise pollution, a significant environmental concern in the aviation industry. Electric aircraft equipped with KERS can operate more quietly during takeoff and landing, as the system allows for smoother acceleration and deceleration. This reduction in noise levels can have positive impacts on communities near airports and wildlife in surrounding areas.

The implementation of KERS in aviation can contribute to the conservation of natural resources. By improving the overall energy efficiency of aircraft, KERS reduces the demand for raw materials used in traditional fuel production. This conservation extends to the manufacturing process of aircraft components, as the increased efficiency may lead to lighter and more compact designs, requiring fewer resources.

Furthermore, KERS can play a role in reducing the environmental impact of airport operations. The system's ability to capture and store energy during landing can potentially be utilized to power ground support equipment or contribute to the airport's energy grid. This integration of renewable energy sources within airport infrastructure aligns with global efforts to create more sustainable transportation hubs.

The adoption of KERS in aviation also has implications for air quality improvement. By reducing the reliance on conventional jet fuels, particularly during takeoff and landing phases, KERS-equipped electric aircraft can help decrease the emission of particulate matter and other air pollutants. This improvement in local air quality can have positive health impacts on both airport workers and nearby communities.

As the aviation industry continues to explore ways to reduce its environmental footprint, the integration of KERS in electric aircraft represents a promising avenue for sustainable development. The technology's potential to enhance energy efficiency, reduce emissions, and contribute to quieter operations aligns with global environmental goals and regulatory pressures facing the aviation sector.

Regulatory Framework for KERS in Aircraft

The regulatory framework for Kinetic Energy Recovery Systems (KERS) in aircraft is a complex and evolving landscape that plays a crucial role in determining the feasibility and implementation of this technology in electric aircraft. As KERS technology advances and its potential for improving aircraft efficiency becomes more apparent, regulatory bodies are working to establish guidelines that ensure safety, reliability, and environmental compliance.

The Federal Aviation Administration (FAA) in the United States and the European Union Aviation Safety Agency (EASA) are at the forefront of developing regulations for KERS in aircraft. These agencies are focusing on several key areas, including system integration, safety standards, and performance requirements. One of the primary concerns is the integration of KERS with existing aircraft systems, ensuring that the energy recovery and storage mechanisms do not interfere with critical flight controls or power distribution systems.

Safety standards for KERS in aircraft are particularly stringent, given the potential risks associated with high-energy storage systems. Regulations are being developed to address thermal management, electrical isolation, and fail-safe mechanisms. These standards aim to prevent thermal runaway, electrical shorts, and ensure system redundancy in case of component failure.

Performance requirements for KERS in aircraft are another critical aspect of the regulatory framework. Agencies are establishing guidelines for energy recovery efficiency, power output capabilities, and system durability under various flight conditions. These regulations will help ensure that KERS systems meet the demanding requirements of aircraft operations while delivering tangible benefits in terms of fuel efficiency and reduced emissions.

Environmental considerations are also a significant factor in the regulatory landscape for KERS in aircraft. As part of broader initiatives to reduce the aviation industry's carbon footprint, regulators are incentivizing the adoption of energy-efficient technologies like KERS. This includes potential carbon credits or other regulatory benefits for aircraft equipped with certified KERS technology.

The certification process for KERS in aircraft is being developed to be rigorous and comprehensive. It will likely involve extensive testing, including ground tests, flight tests, and long-term reliability assessments. Manufacturers and operators will need to demonstrate compliance with all relevant regulations before KERS-equipped aircraft can be approved for commercial use.

As the technology continues to evolve, regulatory bodies are adopting a flexible approach to allow for innovation while maintaining strict safety standards. This includes provisions for regular reviews and updates to the regulatory framework, ensuring that it remains relevant and effective as KERS technology advances and new applications emerge in the field of electric aircraft.

The Federal Aviation Administration (FAA) in the United States and the European Union Aviation Safety Agency (EASA) are at the forefront of developing regulations for KERS in aircraft. These agencies are focusing on several key areas, including system integration, safety standards, and performance requirements. One of the primary concerns is the integration of KERS with existing aircraft systems, ensuring that the energy recovery and storage mechanisms do not interfere with critical flight controls or power distribution systems.

Safety standards for KERS in aircraft are particularly stringent, given the potential risks associated with high-energy storage systems. Regulations are being developed to address thermal management, electrical isolation, and fail-safe mechanisms. These standards aim to prevent thermal runaway, electrical shorts, and ensure system redundancy in case of component failure.

Performance requirements for KERS in aircraft are another critical aspect of the regulatory framework. Agencies are establishing guidelines for energy recovery efficiency, power output capabilities, and system durability under various flight conditions. These regulations will help ensure that KERS systems meet the demanding requirements of aircraft operations while delivering tangible benefits in terms of fuel efficiency and reduced emissions.

Environmental considerations are also a significant factor in the regulatory landscape for KERS in aircraft. As part of broader initiatives to reduce the aviation industry's carbon footprint, regulators are incentivizing the adoption of energy-efficient technologies like KERS. This includes potential carbon credits or other regulatory benefits for aircraft equipped with certified KERS technology.

The certification process for KERS in aircraft is being developed to be rigorous and comprehensive. It will likely involve extensive testing, including ground tests, flight tests, and long-term reliability assessments. Manufacturers and operators will need to demonstrate compliance with all relevant regulations before KERS-equipped aircraft can be approved for commercial use.

As the technology continues to evolve, regulatory bodies are adopting a flexible approach to allow for innovation while maintaining strict safety standards. This includes provisions for regular reviews and updates to the regulatory framework, ensuring that it remains relevant and effective as KERS technology advances and new applications emerge in the field of electric aircraft.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!